Sheet Metal Laser Cutting Services

- Wide range of capabilities: CNC bending, laser cutting, welding, press fitting, stamping and more

- Skilled engineers and technicians to provide expert design & DFM support

- In-house manufacturing for cost effectiveness and rapid turnaround

- Millions of precision metal components produced each year

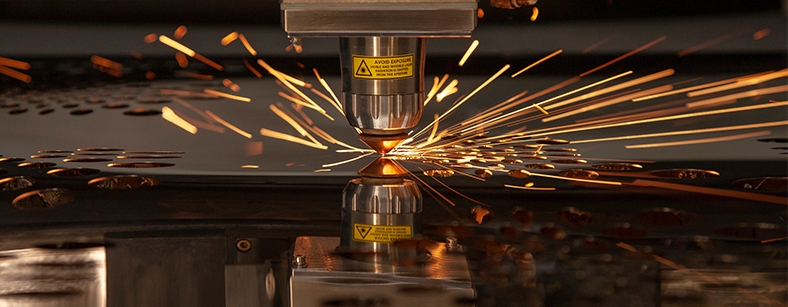

What is sheet metal laser cutting?

Sheet metal laser cutting is a highly precise manufacturing process that utilizes a focused laser beam to accurately cut through thin sheet metal materials, such as steel and aluminum. It employs computer control to follow design specifications, resulting in clean and intricate cuts with minimal heat-affected zones. It offers advantages like high precision, speed, design flexibility, and minimal material waste, making it ideal for various industries, from aerospace to automotive, for both prototyping and large-scale production of intricate metal parts.

Sheet Metal Laser Cutting Gallery

Sheet Metal Laser Cutting Materials

Sheet Metal Laser Cutting Finishes

Improve your part’s performance by selecting high-quality surface finishes that enhance the roughness, hardness, chemical resistance and cosmetic features of your finished component.

Sheet Metal Laser Cutting Tolerance

| Sheet Metal Laser Cutting | |

| Max Hole Diameter | Area = (π (diameter)2 ) / thickness |

| Corner Radius | Minimum R0.2 |

| Standard Sheet Size | 1.2 m × 2.4 m, or 1.5 m × 3.0 m |

| Sheet Metal Laser Cutting Tolerance | |

| Linear Tolerances: X.XX | +/- 0.20 mm |

| Hole Diameter Tolerances | +/- 0.08 mm |

| Material Thickness Nominal Value | |

| T<1.0mm | +/- 0.05 mm |

| 1.0 mm≤ T<2.0mm | +/- 0.05 mm |

| 2.0 mm≤ T <5.0mm | +/- 0.07 mm |

| 5.0 mm≤ T<20.0mm | +/- 0.20 mm |

Sheet Metal Laser Cutting Guidelines

We’ve put together top tips in our sheet metal fabrication guide to help you grasp sheet metal fabrication, covering laser cutting, bending, file preparation, and key design factors for efficient manufacturing.

Sheet Metal Laser Cutting FAQs

Laser cutting offers several benefits for many industries, ranging from precision, speed, repeatability, and flexibility.Some of the key benefits include:

– No need for tooling or dies – just program and produce

– Narrower kerf widths because of highly focused beam

– Less material distortion and a reduction in the heat affected zone as the machine is controlled using complex software to optimize part path, machine speed and sheet metal utilization

– Higher cutting precision and high levels of repeatability

– Less material contamination due to absence of cutting edge

– Little secondary finishing required as cuts and edges are of high quality

– Less material wastage thanks to superior sheet utilization

Our laser cutting machine with auto loading material tower among our other high-end machines makes the sheet metal laser cutting and laser cutting parts in general, more accurate and precise. Whether it’s stainless-steel laser cutting, laser cutting aluminum, or metal part fabrication as a whole, we deliver quality parts on time.

Laser cutting is commonly used for prototyping designs or testing product requirements. Common parts fabricated with laser cutting include flat patterns,face plates,washers,mounting plates,panels, which are widely use in industries such as energy storage, computer electronics, robotics, and aerospace.