Surface Finishes

Beadblasting Services

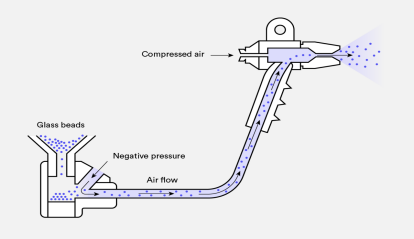

Bead blasting cleans up and evens out the surface of your customized components, improving the performance and aesthetic quality. It leaves a consistent matte or satin structure on machined components by administering high-pressure glass beads on the components. An entirely cosmetic choice is readily available on demand.

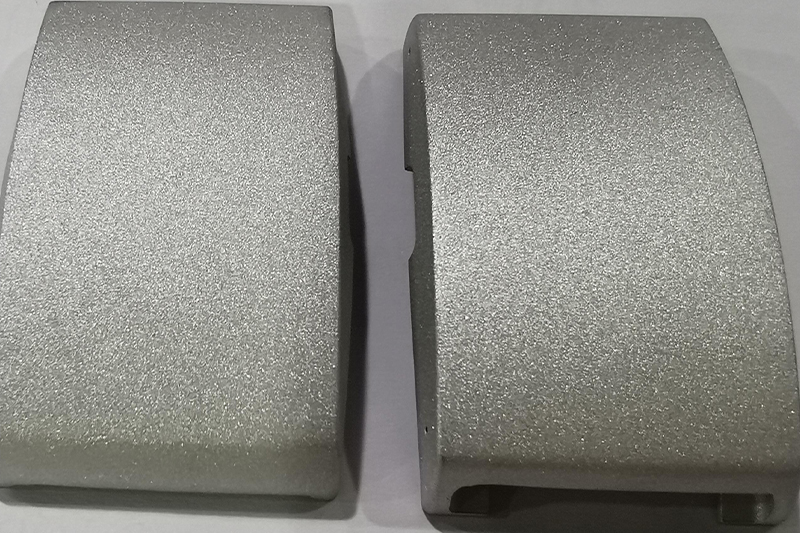

Beadblasting

Beadblasting utilizes a pressurized jet of unpleasant media to apply a matte, uniform coating to the surface area of parts. The most usual media used are differing sizes of glass beads or sand, though, for other levels of abrasion, points like plastic grains have also been made use of.

| Applicable Materials | Media | Cosmetic Availability | Visual Appearance | |

| Aluminum, Copper, Steel | Glass beads with grit options #120 #150 #200 | On request | Grainy, slightly matte texture. Machining marks are reduced for “non-cosmetic” options and entirely removed on primary surfaces for “cosmetic” options. |

Beadblasting Parts

Beadblasting SS 304

Beadblasting Detail

Beadblasting Process

Sandblasting makes use of a pressurized jet of unpleasant media to use a matte, uniform finish to the surface of components. One of the most typical media utilized are varying dimensions of glass grains or sand, though for other degrees of abrasion, points like plastic grains have likewise been used.

Sandblasting process is used to create a uniform, matte coating on components, however, can additionally be used to hide tooling marks or remove small defects partially before anodizing or other plating processes.

Beadblasting Design Considerations

- As thickness change is minimal, plugging threaded/reamed holes masking are not required unless tolerances are very tight,

- Avoid blowing up slim walls, as they are prone to contortion.

- Parts with intricate geometries may be hard or impossible to uniformly finish.

FAQs

CNC machining beadblasting is a surface finishing process that uses fine abrasive beads to create a uniform, matte texture on the surface of machined parts.

Beadblasting can improve aesthetics, remove sharp edges, and enhance the part’s feel, making it a popular choice for cosmetic and functional purposes.

Beadblasting is suitable for various materials, including metals, plastics, and ceramics.

Beadblasting typically achieves a matte finish with an Ra (Roughness Average) of around 1.5 to 2.5 micrometers (μm).

Beadblasting is suitable for various materials, including metals, plastics, and ceramics.

Beadblasting typically has minimal impact on part dimensions, making it suitable for precision components. For highly precise dimensions, especially with Type III anodizing, it’s important to note that it may cause size changes.

Yes, you can select the bead size to achieve different surface textures and finishes. ECOREPRAP provides grit 120, 150 and 200. Standard is 120 mesh.

While beadblasting can remove surface contaminants, it doesn’t offer significant corrosion resistance. Additional coatings or treatments may be required for this purpose.