Surface Finishes

Electroless Nickel Plating Services

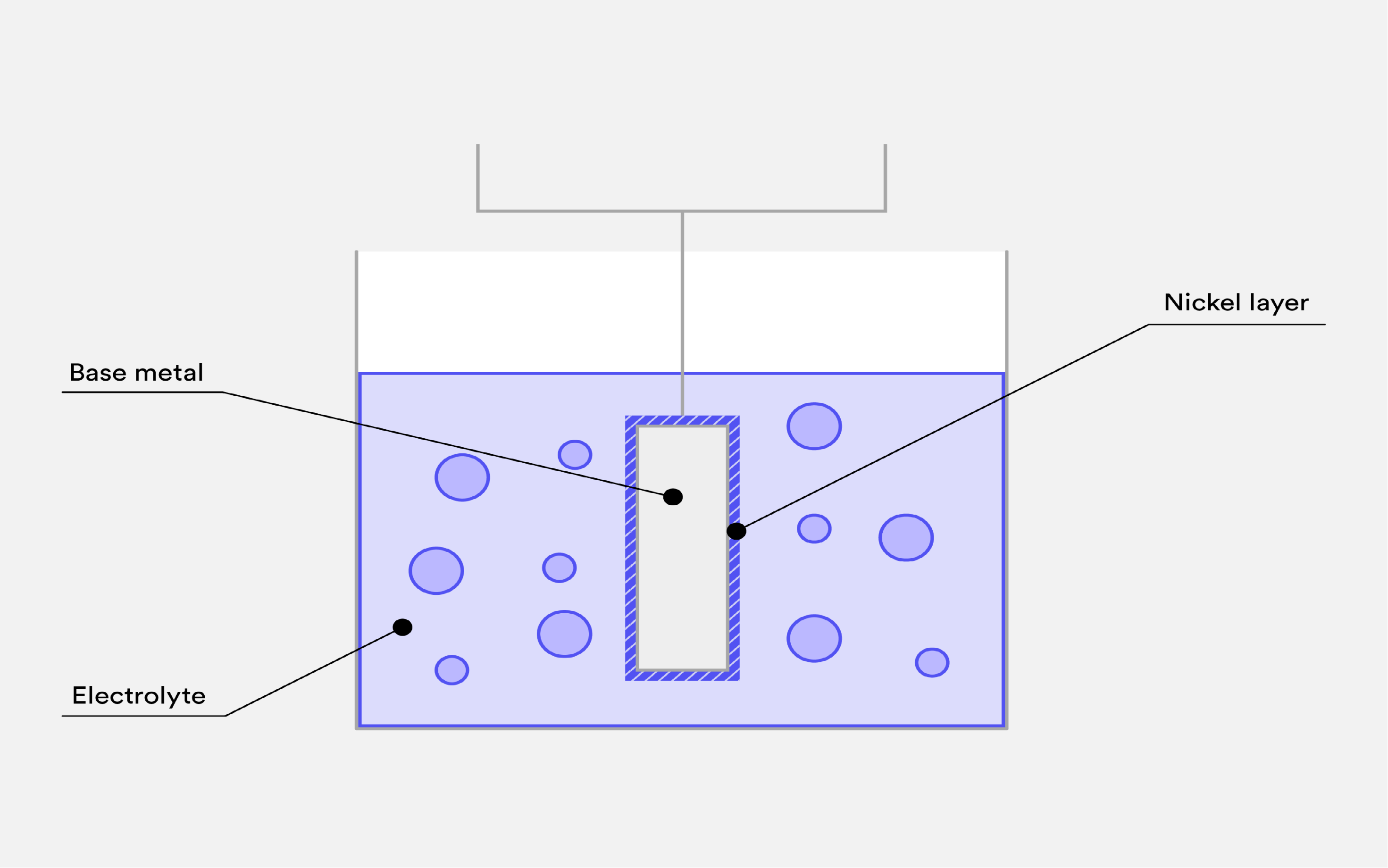

Electroless nickel plating is a procedure that deposits an alloy of nickel-phosphorus onto the surface of a metal. This is chemical just, so does not entail the use of power.

Electroless Nickel Plating

Electroless nickel plating (ENP of NiP) is a response that deposits a nickel-phosphorus alloy onto the surface of a metal. It utilizes a totally chemical reaction to generate plating and does not take advantage of electrical power. Though this process takes much longer than electroplating, benefits are a more consistent thickness over even one of the most complicated surface areas (because of not having to rely upon differing electrical areas), in addition to remarkable wear and deterioration resistance.

| Surface Preparation | Applicable materials | Cosmetic availability | Thickness | Visual appearance |

| Smooth machined (Ra 1.6μm) | Steel, Aluminum | No | 3μm to 40μm | Electroless nickel plated parts will have a smooth, semi-bright appearance. |

Electroless Nickel Plating Parts

Electroless Nickel Plating Part

Electroless Nickel Plating Part Detail

Electroless Nickel Plating Process

Electroless nickel plating is a wear, abrasion, and rust-resistant coating that is compatible with aluminum, stainless steel, and light steel.

Here’s how to apply electroless nickel plating:

- Components are first washed and degreased to eliminate any kind of impurities, cleansing away any oil or oil.

- After cleansing is finished, the substratum is turned on with another chemical, an acid, to eliminate oxides and trigger the surface area.

- Components are dipped in the plating chemical service, transferring the nickel-phosphorus alloy on the components till the desired density is reached

Electroless Nickel Plating Design Considerations

Masking: Electroless nickel plating does not have a significant dimensional impact, therefore masking parts is not necessary.

FAQs

Electroless nickel plating is an auto-catalytic chemical process used to deposit a layer of nickel onto metal surfaces for corrosion resistance and improved wear properties.

Electroless nickel plating provides excellent corrosion protection, wear resistance, and an even, uniform coating on complex part geometries.

Electroless nickel plating is suitable for a wide range of materials, including steel, aluminum, and some non-metallic substrates.

Electroless nickel plating adds a very thin layer, resulting in minimal dimensional changes and making it suitable for precision components.

Yes, electroless nickel plating can be applied to parts with intricate shapes and complex features, ensuring uniform coating thickness.

Electroless nickel plating can provide electrical conductivity, making it useful for electronic and electrical components.

Electroless nickel plating can produce a range of finishes, from matte to semi-bright and bright, depending on the specific process used.

Let's get your projects started, together.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.