Laser Engrave Services

Laser Engraving (Laser Etching)

Laser engraving in CNC machining serves a multifaceted role, contributing to product branding and identification by adding logos and serial numbers, ensuring traceability and fostering brand recognition. Additionally, it facilitates personalization and customization of CNC machined products through the incorporation of personalized text, graphics, or designs, commonly observed in consumer electronics and personalized gifts. Furthermore, laser engraving enhances the aesthetic appeal of CNC machined parts by introducing intricate patterns and artistic designs, particularly applied to decorative elements in automotive parts, jewelry, and consumer goods.

| Applicable Materials | Color Options |

| Metals,Plastics | Natural, White,Black, Gray |

Laser Engraving Part

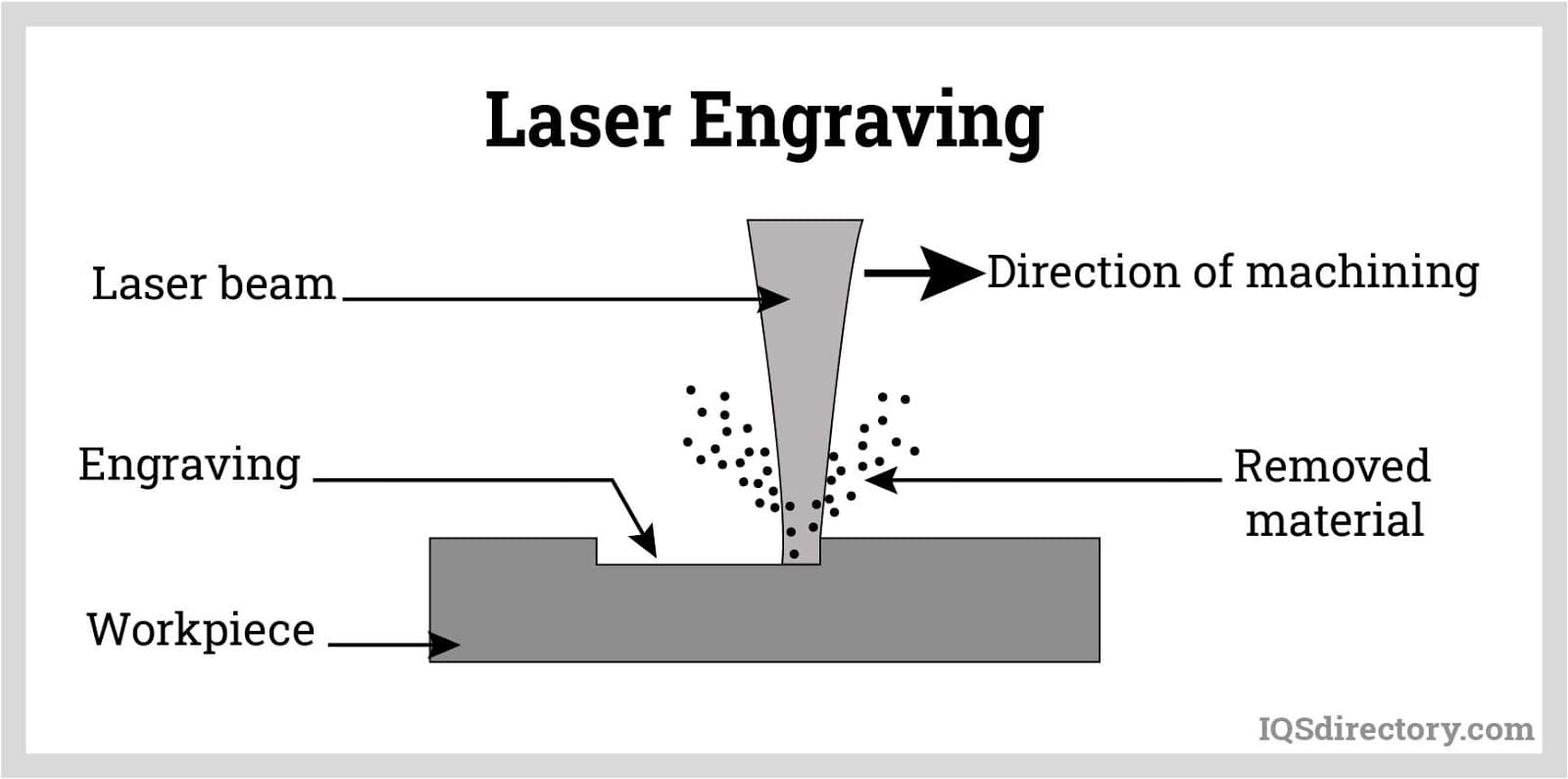

Laser Engraving Process

1 .Design Preparation: Create or obtain the design or artwork you want to engrave using graphic design or computer-aided design (CAD) software.

2 .Machine Setup: Prepare the laser engraving machine, ensuring it’s correctly calibrated and the laser is focused.

3 .Material Fixturing: Secure the material to be engraved in place on the engraving machine’s worktable or fixture to prevent movement during the process.

4 .Laser Parameters: Configure the laser settings, including power, speed, and frequency, based on the material and design requirements.

5 .Laser Engraving: Start the engraving process, during which the laser beam traces the design onto the material with precision.

6 .Quality Inspection: After engraving, inspect the finished product to ensure it meets the desired quality standards.

7 .Cleaning: Remove any debris or residue generated during the engraving process, leaving the engraved area clean.

8 .Optional Post-Processing: Depending on the material and design, you may choose to perform additional post-processing steps like paint filling, coating, or other enhancements.

Laser Engraving Design Consideration

- 3D model of the part

- Vector file (typically in AI format) of the font or geometry required for the marking

- Technical drawing (PDF format) indicating the exact location for the marking