Surface Finishes

Passivation Services

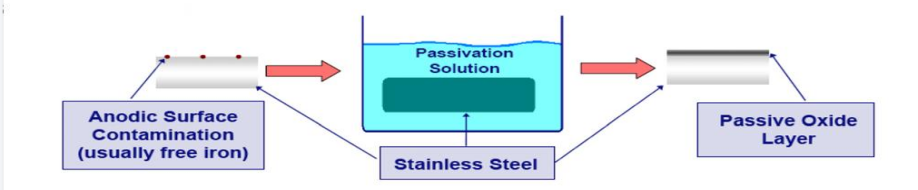

Passivation is a post-fabrication best practice for newly-machined parts, mostly for stainless steel, to have a chemical film barrier against rust, extend product life and remove contamination from product surface.

Passivation

Passivation is a chemical reaction that triggers a product to be much less affected by corrosion or other environmental aspects. Passivation creates a micro-coating to be applied on the surface of the product by allowing the material to oxidize, then converting the oxidation to a metalophosphate. This surface area is after that secured right into the component utilizing either a manganese or zinc compound.

| Applicable Materials | Cosmetic Availability | Visual Appearance |

| Stainless Steel, Copper, Brass | NA | Smooth glossy finish |

Passivation

Passivation

Passivation Detail

Passivation Process

Passivation includes the creation of an outer layer of guard product that is applied as a micro coating, developed by chemical reaction with the base product, or enabled to build by spontaneous oxidation in the air.

Passivation Design Considerations

- The success of passivation depends on the initial condition of the surface. Ensure that the metal surfaces are free from contaminants, scale, and oxides before initiating the passivation process.

FAQs

Passivation is primarily used for stainless steel and its alloys, though brass and copper can also have passivatio.

Passivation is a chemical process that removes contaminants from the surface of stainless steel to enhance corrosion resistance.

Passivation improves the corrosion resistance of stainless steel parts by creating a protective oxide layer.

Passivation typically has a minimal impact on part dimensions. It can be applied to parts with complex shapes and intricate features.

Yes, passivation can remove discoloration, scales, and contaminants on the surface of stainless steel.

No, passivation does not provide electrical insulation; it primarily enhances corrosion resistance.

Yes, rinsing the part after passivation is essential to remove any residual chemicals and ensure a clean surface.