Surface Finishes

Mechanical Polishing Services

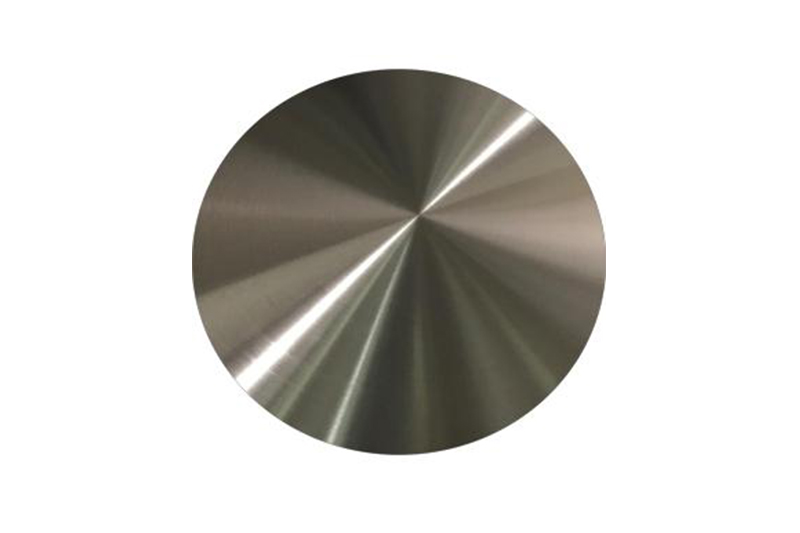

Improve the parts surface quality, giving them a smoother, shinier cosmetic appearance.

Mechanical Polishing

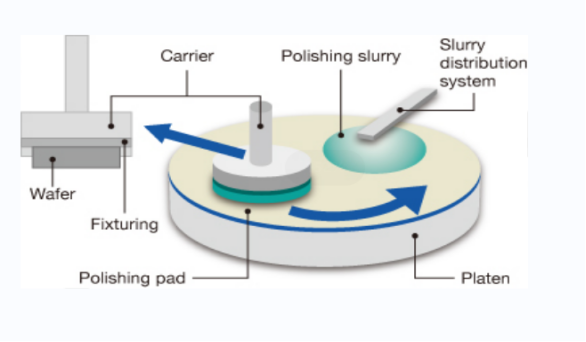

Mechanical Polishing is a manual process where the part is sanded, and then buffed on a set of abrasive wheels or rouges to achieve the desired surface finish. This is a subtractive process that removes defects from parts, including scratches, pits, and burrs. Polishing is suitable for seal performance, boosting the aesthetics of a part and other aesthetic applications.

| Applicable Materials | Cosmetic Availability | Visual Appearance | ||

| Metals, PMMA, PC | On request | Removed on primary surfaces |

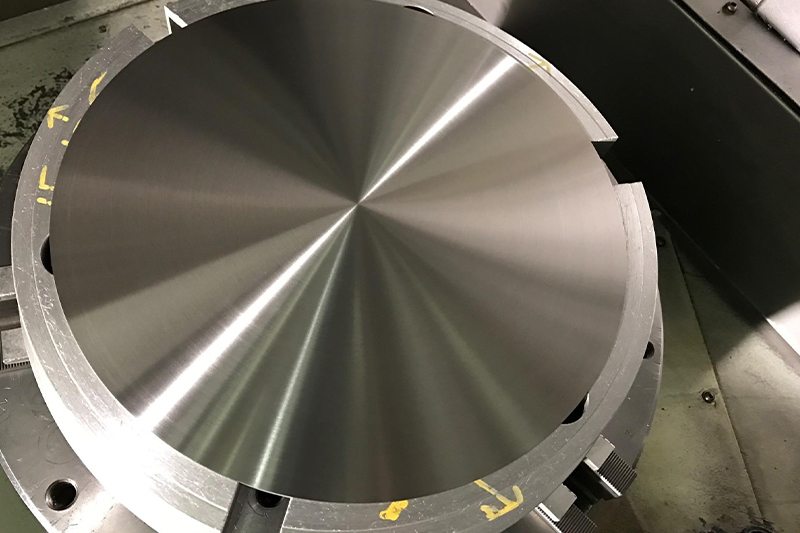

Mechanical Polishing Parts

Mechanical Polishing Process

Mechanical polishing entails the utilization of procedures such as grinding and rubbing in order to remove scrapes, cuts, and various other damage appearing on the surface of a material.

Mechanical Polishing Design Considerations

- Radiused corners and edges typically produce much better outcomes than sharp ones

- Wall surface thicknesses less than 1.5 mm do not hold up as well during polishing

- Inner or hard to get to functions (including threads) are difficult or impossible to gloss

- Really tight tolerances, reamed openings, and threads may require to be left out from brightening

FAQs

Mechanical polishing is a finishing process that uses abrasive materials to smooth and improve the surface quality of machined parts.

Mechanical polishing enhances the appearance and texture of parts, providing a smooth, reflective surface finish.

Mechanical polishing is suitable for various materials, including metals like stainless steel, aluminum, and plastics.

Yes, mechanical polishing is suitable for precision parts, offering tight dimensional control.

Mechanical polishing can achieve a very smooth surface finish with a low Ra (Roughness Average) value, often below 0.6 micrometers .

Yes, mechanical polishing effectively removes sharp edges, burrs, and surface imperfections.

Yes, mechanical polishing can be applied to parts with complex shapes and intricate features.

Yes, mechanical polishing can be combined with processes like electropolishing or passivation to achieve specific surface finish and performance requirements.