Surface Finishes

Silk Screen Services

Get your custom CNC machined parts marked with our screen printing service.

Silk Screening

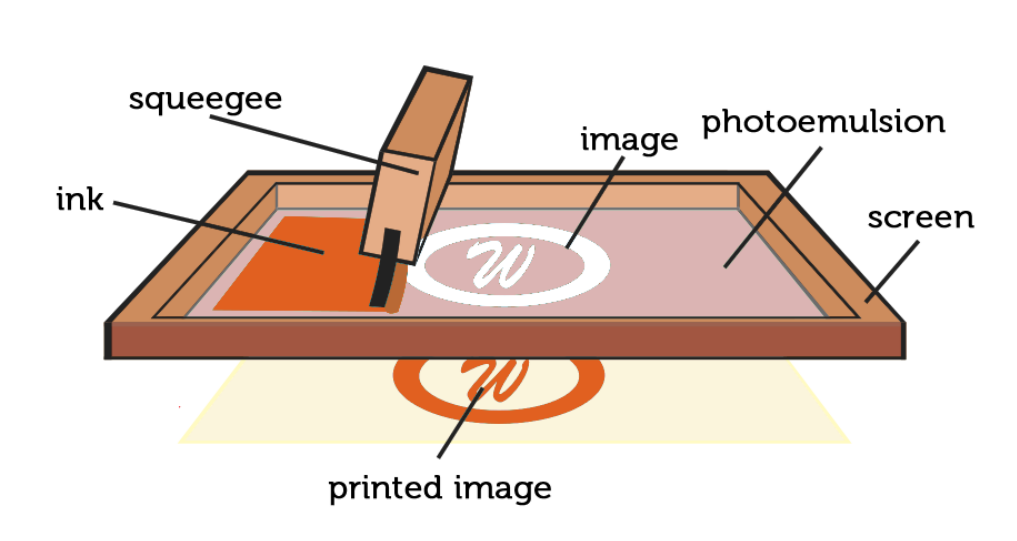

Silk screening, also known as screen printing, is a printing technique that involves using a mesh screen to transfer ink onto a substrate, such as fabric, paper, or other materials. The process gets its name from the historically used silk mesh, although today, synthetic materials like polyester are more commonly employed.

| Applicable Materials | Color Options |

| Metals,Plastics | White, Black, and Customized |

Laser Engraving Part

Silk Screening Process

1. Design creation ·

2. Preparing the screen

3. Exposing the emulsion

4. Creation of the stencil

5. Preparation for print

6. Printing

7. Quality check & finishing

Silk Screening Design Considerations

- Ensure that the CNC machined parts are thoroughly cleaned and free from any oils, debris, or contaminants that might affect ink adhesion.

- The surface finish of the CNC machined part can impact the adhesion of the ink. Smooth finishes generally provide better results.

FAQs

Turning often results in a smoother surface due to the continuous single-point cutting action and more controlled tool geometry. Milling, with its multi-point cutting tools and complex tool paths, can yield a rougher surface finish, but it is highly dependent on the specific machining parameters, tool quality, and setup. Proper tool selection and optimization of cutting parameters can help improve the surface finish in milling operations.

Specifying a surface finish “as machined” is important because it defines the quality and texture of the workpiece’s surface directly after CNC machining. This helps set expectations for the surface finish without any additional post-processing, which can be crucial for parts with strict functional or aesthetic requirements.

Several factors can influence the surface finish as machined, including the cutting tool’s sharpness, the material being machined, the CNC machine’s accuracy and rigidity, feed rates, and cutting speeds. Operator skill and the choice of machining parameters play a crucial role in achieving the desired surface finish.