Are you looking for 3d filament supplier for your 3d printing shop? EcoReprap is the best choise. We are the leading manufacturer for 3d printing materials, focus on wholesale 3d printer filament and 3d printing service.

At EcoReprap, we can offer large sections of 3d printing material, such as PLA, ABS, PETG, Wood, Nylon, Flex(TPU), Carbon Fiber PLA/PETG, ASA and more.

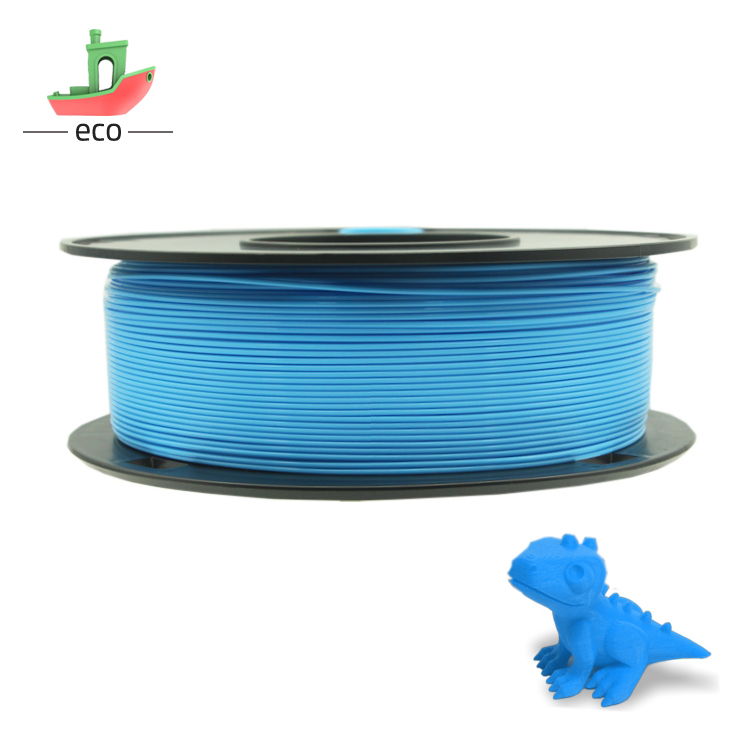

3D Printer Filament Collections

Low printing temperature and no odor in printing.

High strength and easy to work with.

High transparency and mechanical strength.

High elasticity and great surface.

The silk-like surface on the 3d prints, the base material is PLA.

Wood infill material has wood texture in the surface.

Similar to ABS material and have better UV resistance.

High transparent and heat resistance.

Good performance in impact strength and chemical resistance.

Flexible and high durability

Carbon fiber reinforced PLA with high flexibility.

Carbon Fiber reinforced PETG has better strength.

good fire retardant ability.

large spool for PLA filament, such as 2kg, 3kg, and 5kg.

High elasticity and impact strength.

3D Printer Filament FAQs

1. What is 3d printer filament made of ?

Most 3d printer filaments are made of thermoplastic. They can be soft when heating above the glass transition temperature. such as PLA, ABS, Petg and so on. The other is composite material which is designed to get more function. It includes wood PLA, PC/ABS, carbon fiber filament and so on.

2. How long does 3d printer filament last ?

It varies from materials and filament diameter. Due to the density being different, the length is also different, you can refer to 1kg PLA filament length here.

3. How to store 3D printer filament?

3D printing filament are highly hygroscopic, so it is vital to prevent water absorption. Also, particles of dust or metal contaminants deposited on the filaments deteriorate printing quality. So, places where you should store 3D printer filament and some corresponding tips are the following:

- Shelves for open filament storage in the room with a low relative humidity value.

- Use a drying agent – desiccant to prevent excessive moisture on your filament.

- Use the original package, kitchen zip bags, plastic cereal boxes, vacuum bags, or plastic tubs.

- Purchase a filament dryer.

- Use professional hermetically sealed boxes for storing filament.

4. How to make a 3D printer filament?

To make DIY filament for 3D printing, you will need a filament extruder, heavy-duty scissors, a rubber mallet, and failed prints or bulk plastic pellets. The sequence of steps for making 3D printer filament is the following:

- Sort recycled prints by type and color.

- Put pieces into a bag and break them into smaller ones with a rubber mallet.

- Attach the nozzle to the extruder.

- Find out the right temperature (consult both extruder and plastic specifications).

- After the extruder is heated up, fill its hopper (but no more than half) with plastic.

- Gradually add more material.

- Guide the filament that is coming out of the extruder in a coil without touching it much.

- Turn off the extruder and cut the filament.

5. How to dry 3D printer filament?

In case you notice that your 3D printer filament’s surfaces are “fuzzy” and the printing quality is poor, you need to dry your material. You can do it in the following ways:

- Buy a specialized filament dryer and either push your wet printing material through it or make the dryer work alongside your 3D printer.

- Leave your filament in a regular oven for up to six hours till the material is completely dry. The appropriate temperatures are 40°C for PLA and 80°C for ABS and Nylon.

- Use a food dehydrator in exactly the same manner as you would use an oven.

6. Why does my 3D printer filament keep breaking?

In case your printing material snapped, it is likely because it has got brittle. The potential reasons are the following:

- The filament is stored for quite a while in inappropriate conditions (high relative air humidity).

- The filament is outdated (especially concerning PLA) or low-quality overall.

- The filament was exposed to high mechanical stresses that exceeded its tolerance and altered flexibility.

- In the case of DIY filament fabrication, some color additives may change the mechanical properties of printing material, making it deteriorate quickly and break.

7. How expensive is 3D printer filament?

Prices for printing material depend on the printing method, the type of filament, its quality, manufacturer, and other nuances.

For example, regular 3D printing filaments for fused filament fabrication (FFF) like PLA or PETG may cost somewhere between $20 and $50 per kilogram. Engineering or support filaments may be priced from $60 to as high as $120 per kilogram.

As for other printing materials, entry-level SLA resins are about $50 per liter, while more professional materials may be priced as high as $400 per liter. SLS powder’s typical cost may fall somewhere between $100 to $200 per kilogram.

8. Which is better, resin 3D printer or filament?

It is better to compare the printing quality of filament and resin 3D printers in order to clarify this question. In most cases, 3D printers that use filaments as the primary material can produce affordable, strong, large-sized pieces.

At the same time, ones that employ resins can fabricate well-detailed parts. It is because they are based on the more accurate printing method. So, there is no one answer, but it is likely that both printers have a chance to suit your particular purposes well.

9. How to take filament out of a 3D printer?

Perhaps you are struggling with a filament stuck in the hot end, or pulling out the filament requires excessive force. The steps you should follow to take your filament out accurately are:

- Preheat your hot end in accordance with the current filament’s temperate requirements.

- Manually extrude a small portion of the filament by unclamping it and pushing the material through the hot end to squeeze the melted part from the nozzle fully.

- Push down the coupling releasing your filament this way.

- Unplug the filament.

- Clip off the end of the filament.

- Unwind the filament back to the spool holder.

- Secure the loose end of the filament.

- Remove the current filament spool.

10. What 3D printer filament is food safe?

In case you need non-toxic printing materials for your children to play with or store food in, consider the following filaments:

- PLA.

- PP.

- PET and PET-G.

- HIPS.

- Nylon-6.

- Some brands of ABS, ASA, and PEI.

You should take precautionary measures while dishwashing your plastic parts. PET, nylon, and PLA soften and distort at temperatures above 60–70 °C. Also, none of the printed parts can sustain baking in the oven, while exposure to UV light (or sunlight), may release chemical compounds from the plastic.

[

11. How to put filament in a 3D printer?

The process of loading the replacement filament in your 3D printer is similar to taking it out, and you can do it by following these steps:

- Load the spool on the available filament slot.

- Preheat your hot end in accordance with the current filament’s temperature requirements.

- Unclamp the filament and feed it through the hot end.

- Prepare about 10cm of filament to be fed into the hot end.

- Heat up the filament to the required temperature.

- Feed the filament into the hot end until its melted parts begin to squeeze out of the nozzle.

- Secure the coupling.

- Push about 4cm of filament through the hot end to flush out the old printing material completely.

- Cut off excess filament using a pair of tweezers.

- Cool the hot end down.

12. What 3D printer filament should I use?

The choice of an appropriate printing material will depend on your purposes mostly. Let’s review several categories of 3D printer filaments for different applications:

- PLA and PET-G are both affordable materials that most beginners love to use. They are easy to use, but they can still produce parts of acceptable quality and intricate designs.

- PP, ABS, PA, and TPU are mid-level filaments for professional users, as they may need configuration adjustments but support more complicated designs. Other filaments like carbon fiber and require advanced printers and a well-thought-out approach.

- PA, Carbon fiber reinforced, or TPU also suit commercial purposes.

- PP, PA, Carbon fiber reinforced are considered ideal for high-stress applications.

13. What 3D printer filament is flexible?

Flexible printing materials are ones that have good elasticity. Commonly, such filaments are made of Thermoplastic Elastomers (TPE) – a blend of hard plastic and rubber.

The most widespread type of TPE is Thermoplastic Polyurethane (TPU). Thermoplastic co-polyester (TPC) and Thermoplastic Polyamide (TPA) are two other elastomers. Polypropylene (PP) and soft PLA types may also be considered flexible to a certain extent.

14. How to recycle 3D printer filament?

The best way for your plastic scrap and filament leftover disposal – is recycling. You may want to hand it over to a recycling facility. Alternatively, you can handle it yourself.

The latter will require you to purchase a 3D filament recycler. Then, you simply need to sort your scrap by type and color and break it into smaller pieces (unless your recycling unit has a shredder). Then, you can simply melt filament and plastic leftovers and force them through a recycler’s opening. Then, printing materials are automatically extruded, cooled down, and coiled onto a reel.

15. What filament should I use to print 3D printer parts?

The answer to this question will depend on the parts’ desired properties. Some of the different filaments’ characteristics are the following:

- Engineering PLA filament ensures good visual attractiveness of parts, while their resistance will be a bit far from satisfactory.

- ABS filament, on the other hand, enhances parts with good heat and wear resistance properties and makes them flexible to a certain extent.

- PETG filament-based parts are completely water-resistant and comparatively durable. They are also the only ones that do not degrade if exposed to UV light or direct sunlight.

- PP filament makes parts extremely fatigue resistant and chemical resistant. However, it cannot be combined with other materials.

- Nylon filament does not have multiple advantages over other materials. But, parts made from it are exceptionally good as components of movable elements because of the low friction.

- HIPS filament-based parts are impact-resistant and withstand forces easily. However, they are not chemical resistant and naturally dissolve in citric-based acids.

16. How to check 3D printer filament properties?

The most simple way to quickly check a particular filament’s properties is to examine its package. Manufacturers typically indicate vital info right on the wrapping, which may include resistance, melting point, tips for printing, etc. Alternatively, you may call and consult a manufacturer’s support team for detailed info. Even the same materials produced by different brands may have differences in their properties.

Also, you may be advised to take a look at tables of different filaments’ characteristics, like the one below.

17. What is PLA filament for a 3D printer?

Polylactic Acid (PLA) filament is one of the most popular materials for fused deposition modeling (FDM) printing. It is a thermoplastic polymer that is produced from renewable resources only. As such, polylactic acid is generated from cornstarch, potato starch, tapioca roots, sugarcane, and other biomaterials.

PLA filament is an environment-friendly, low-toxic printing material. It is easy to use, but it still offers competitive properties, including a low melting point, good durability, and moderate flexibility. It can be post-processed using simple methods and is offered in a variety of colors.