Today we will be looking at the differences between two common 3D printer materials, PETG and PLA. Though at first glance, these materials may seem similar, they are, in fact, surprisingly diverse. Let’s talk about it!

PLA:

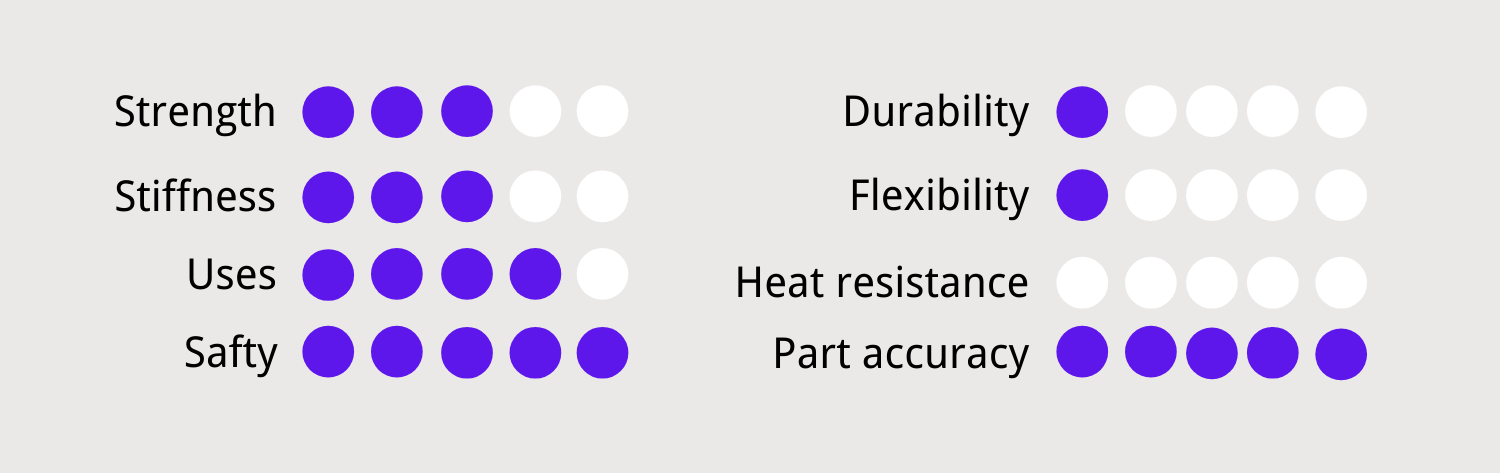

So firstly, let’s take a look at PLA. PLA stands for Polylactic Acid and is a naturally derived plastic made from cornstarch. PLA differs from most materials that are oil-based which leads to this material being more environmentally friendly.

One significant benefit of PLA as a material is that it is Biodegradable. Other oil-based plastics can take over 400 years to biodegrade also leave behind toxins in the ground. In the right conditions, PLA only takes 60 and leaves no toxins behind.

So you may be asking, is it an excellent material to print? Well, generally, yes. PLA is now the most common material people print. The main reason for this is that it is effortless to work. When printing other plastics, such as ABS, the warps will occur when cooled. It is not an issue with PLA. PLA can print with no heated bed.

Due to this, PLA uses widely in most FDM 3d printers. As the material is so easy to print, PLA can print faster than other types of materials.

PLA also has other benefits, such as it had little to no smell when being printed. The only smell released is a sweet scent. The material also offers a resistance to the environment around it. The filament does not soak up moisture and can be left open for large amounts of time; however, we recommended keeping it sealed in a bag. One other benefit to PLA is its high hardness, a feature that is useful when you want no flex in your prints.

Finally, PLA looks good. Prints come out crisp and well-formed, which is a massive pro for anyone looking to make beautiful models without artifacts.

There is also a more comprehensive range of filaments in PLA, such as Flame retardant filament or Conductive filament.

So let’s get onto some of the downsides to this magical material! We know that PLA is tough, but unfortunately, it is also very brittle. This feature causes prints under strain to snap relatively easily.

Another common problem with PLA is the temperature resistance. PLA Prints will deform if left in the heat. I have personally had this happen when going a print in direct sunlight on a hot summer’s day.

Apart from that, there are no other downsides to PLA as a filament.

PETG:

So now, let’s move to PETG! PETG stands for Polyethylene Terephthalate Glycol, quite a mouthful but let’s digest it. You may be used to seeing a very similar material to this called PET. this material is mainly used in water bottles and other recyclable single-use plastics. PETG is very similar to this but with the addition of the Glycol. Glycol is added to the material to make it printable. Without it, the filament would be cloudy and weak.

Pros:

What are the pros of PETG, thanks to the added Glycol, this material is reasonably durable. This material is capable of withstanding quite a bit of damage due to the added flexibility. Though not too flexible, this material does have a bit of giving. Along with the extra durability, these materials are also is relatively scratch resistant. This will be perfect if you are using it when your part is being used in a rough situation, and you do not want damage to show.

Another great feature when using PETG is its heat resistance. The glass transition temperature (the temperature where a material softens) is around 80 degrees Celsius. This is an enormous benefit if you plan to store your printed part somewhere warm, like a car or an attic. And that is about it for the positives for PETG.

Cons:

Now let’s get onto some of the cons about the material. Unfortunately, there are quite a few, but I am about to explain all of these issues are not significant, just slightly irritating.

Firstly PETG is hygroscopic – a fancy word for it being absorbent. This means that it can easily get damaged in damp situations. This causes the materials to pop when the water goes through the hotend and leaves prints with an unwanted texture. Luckily this is easy to prevent and fix. To dry your filament, stick your filament in the oven at 60 degrees Celsius for 4 hours. To store your filament correctly, it is always good practice to keep it in a sealable bag.

Another issue with PETG is stringing. Stringing is when small residues of parts of plastic are left on your prints. These look like tiny hairs. It is also not a massive issue as it is entirely possible to remove them with heat and some snippers. Unfortunately, this does affect the quality of the print. Surfaces are also not usually beautiful, Due to the PETG naturally being very translucent. This sometimes makes prints appear to have scars from the light.

Finally, the last issue I would like to talk about is post-processing. PETG is a very slippery filament, which means that it is tough to post-process. When painting PETG, the paint will not stick very well to the material. As we talked about earlier, PETG does not scratch very quickly. This is also a negative when you would like to sand your prints. Lastly, many glue and epoxy resins will not adhere to these materials, making it hard to stick parts together. The only way that I have managed to get parts to stick is by friction welding them, this used heat to merge two pieces to form one.

PLA vs PETG: Which is better for your project?

Let’s summarise what we have looked at today! Firstly let’s talk about heat resistance. When you want to print something that needs to withstand heat, I recommend that you use PETG. Suppose you are looking to print some excellent models and need detail, accuracy, and post-processed ability. In that case, I recommend that you use PLA as it can take paint and glue well, and the surface finish is generally much better than PETG.

If you want a material that is just easy to use, I recommend you use PLA, you don’t need to store it specially, and it prints at relatively low temperatures and has little to no stringing. If you are looking to print some rigid models that need to take a bit of wear and tear, I recommend using PETG due to its slight flexibility and scratch resistance.

If you are concerned about the waste of 3D printing, don’t be! Both of these materials will not harm the environment if disposed of safely.

So to conclude, it depends on what you print. I generally use PLA more than PETG just because it is easy to print, and it doesn’t require me to do any cleanup after the print finish. My prints don’t usually get beaten around or overheated, so for my prints, I use PLA.