PLA and ABS are the commonly used plastic for desktop 3d printers. While both types of filaments fall into the same thermoplastics classification, they have various properties to meet particular needs for different projects.

In this article, we’ll provide a complete breakdown of the features of PLA and ABS filaments. From its mechanical properties to 3d printing experience, we’ll compare, contrast and help assess which types of material work best for you to use.

Let’s get started.

What Are PLA and ABS

Commonly used in FDM 3D printers, PLA and ABS are both thermoplastic materials. This means that they turn into a soft and moldable state once heated and return to a solid form when cooled.

PLA(Polylactic Acid )is made of biodegradable thermoplastic. It makes from organic sources like sugarcane or corn starch. Its material is heat-sensitive, making it easy to manage for beginners. It is excellent for prototyping and detailed and complex prints such as architectural mockups.

ABS (Acrylonitrile Butadiene Styrene) is made of oil-based thermoplastic. Its material is a bit challenging to use for beginners since it requires more finesse and technicality. It’s stiff and more heat resistant, however much more durable. It works best for moving parts and tools.

| Comparison | PLA Filament | ABS Filament |

| Biodegradability | Yes, Plant Based | No, Petroleum Based |

| Natural Color | Clear | Off-white |

| Strength/Durability | Generally Less Durable | Generally More Durable |

| Flexibility | Lower Flexibility Tolerance | Some Flexibility |

| UV Resistance | May Not Withstand UV Contact | Generally More UV Resistant than PLA |

| Melting Temperature | Melt in Warmer Environments | Better thermal resistance |

| Chemical Resistance | Cannot Withstand Chemical Contact | More Chemical Resistant |

| Price | More expensive | Cheap |

| Variety | Much more options | Several |

| Storage | Airtight Storage Preferred | Airtight Storage Preferred |

| Fume in Printing | Slightly Sweet Scent | Burning Plastic |

| Print Temperature | Low printing temperature | Higher temperature |

| Heated Print Bed | Not need, May be Helpful | Always Required |

| Platform Adhesion | Hairspray, buildtalk or Blue Painter’s Tape Can Help | Hairspray, buildtalk or Blue Painter’s Tape Can Help |

| Wraping | Less Prone to Warping | More Prone to Warping |

| Support | PVA | Hips |

| Part Accuracy | Better than ABS | Good |

| Post Process | Sand, polish, paint | Sand, polish, paint |

PLA vs ABS Properties

1. Strength/Durability

Both PLA and ABS have adequate durability and strength. However, ABS is better than PLA in both areas, respectively.

As rigid as a material PLA is, it tends to be fragile. It’s not impact-resistant nor able to withstand high temperatures. It has a low solvent and water-resistance as well. However, it does have good tensile strength and is not susceptible to warping. It is excellent in molding complex details as prototypes but certainly not for thermal and functioning parts.

ABS, on the other hand, has better elasticity. Its flexural strength makes it an excellent material for end-use and technical applications. It’s both more heat and water-resistant compared to PLA.

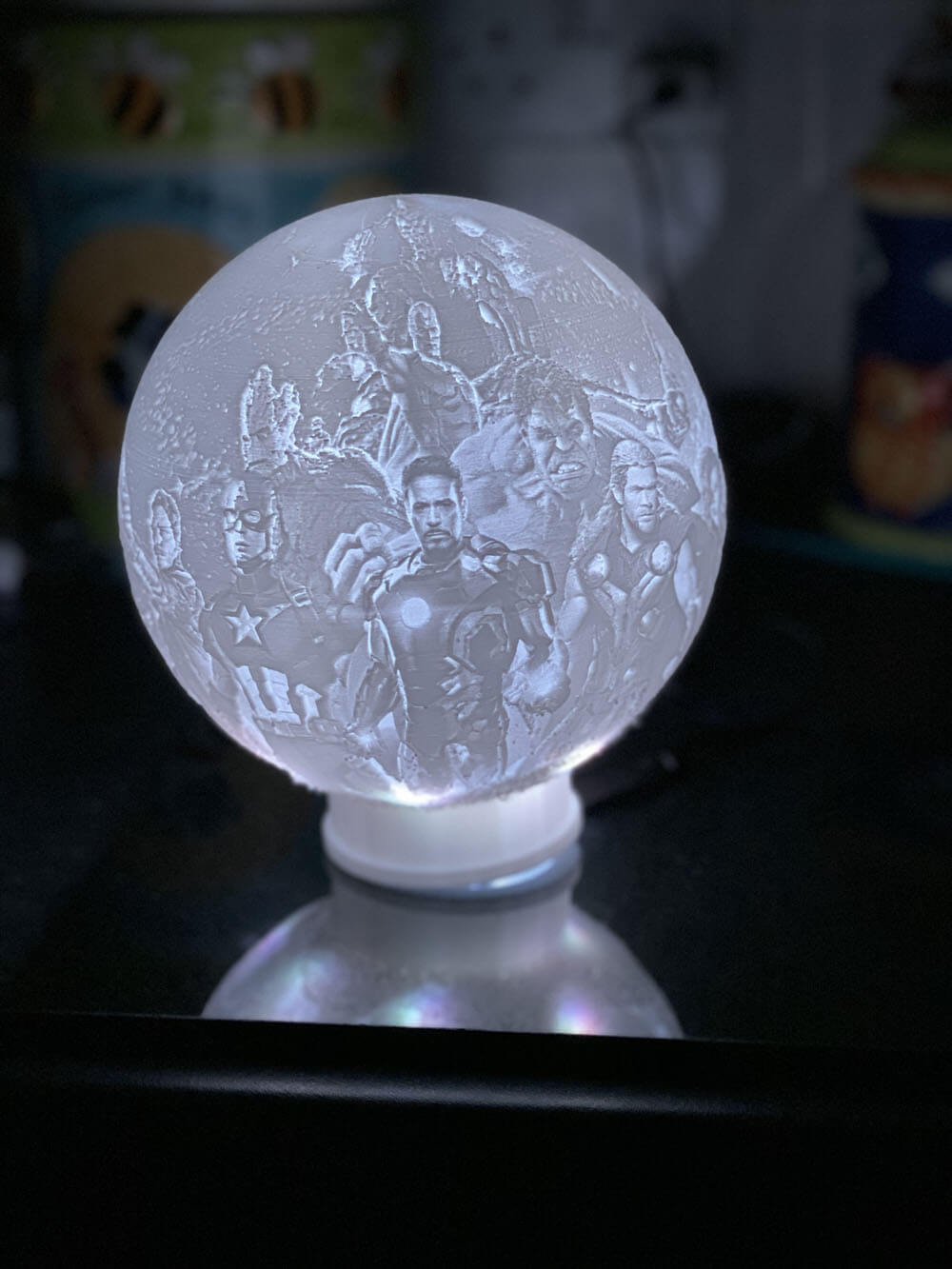

Avengers globe with pla print

2. UV Resistance

UV Rays and sunlight exposure to these materials aren’t ideal since they would negatively impact both of them. PLA is biodegradable. Meaning, its material certainly won’t respond well in the outdoors. It would break down to sunlight and high humidity after a long period of exposure.

As durable as the material ABS is, it’s also not built for extensive UV exposure. While it may stand a longer chance of withstanding UV than PLA, it would also degrade over time.

3. Flexibility

Both aren’t very flexible filaments compared to Nylon and TPU. However, ABS is more flexible than PLA. That’s why it is a preferred material for technical applications. Though, its flexibility makes it more prone to warping compared to PLA.

PLA materials have a more rigid foundation compared to ABS. While it is easier to print and more beginner-friendly than ABS, it’s certainly not suited for any technical use other than prototyping and mockups.

4. Heat Resistance

PLA is sensitive to heat and can’t withstand high temperatures. It is the lowest in heat resistance than other 3D filaments, including ABS, so it doesn’t require a heating bed to print.

ABS, on the other hand, has a high-temperature resistance. Its high resistance to heat makes it trickier to print, though, since it requires a heating bed and is more prone to warping. But other than that, its resistance to heat makes it more evident how durable a material ABS is.

5. Fumes

The fumes from 3D filaments have debated whether it may be a risky health hazard or not. Since PLA is made out of organic materials, it doesn’t emit a nasty odor. Some even claim that it smells like candy or completely odorless.

ABS, however, which is made out of oil-based plastic, emits a pretty toxic smell. Some research also suggests that the chemical odor of ABS harms respiratory health. While both materials aren’t dangerous in general, it’s best to proceed with caution during the manufacturing process and ensure that your area is well ventilated.

6. Biodegradability

It’s natural to consider how environmentally safe 3D filaments are. Even if PLA is biodegradable, they are making it very eco-friendly. It’s made out of organic materials such as starch plants like sugarcane or cornstarch.

On the other hand, ABS isn’t biodegradable. However, its material is entirely recyclable. ABS being durable, longer-lasting, makes it an ideal material to recycle more-so than other 3D filaments.

PLA vs ABS in 3D Printing

1. Nozzle Temp

When it comes to 3D printing, the quality of the models you produce depends on two factors: Heating & Cooling. PLA is very versatile and can work well, around 180°C to 230°C. Any higher than 230°C is not ideal for PLA’s material. However, it should print best at 210°C.

ABS requires a slightly higher temperature than PLA. 230°C to 250 °C is the ideal temperature to print successfully. It also requires more care since ABS is prone to warping.

2. Heated Bed

PLA doesn’t necessarily require a heated bed since it isn’t prone to warping. But if your printer has one, you can use it to make the first layers of adhesion easier. You can set the heated bed around 50°C to 60°C.

ABS needs a heated bed to print correctly. Unlike PLA, ABS is prone to warping. The recommended temperature should be around 80°C to 110°C.

3. Cooling

Cooling is extremely crucial when it comes to the manufacturing process. The structural integrity of the model highly depends on it. When printing with PLA, keep the cooling fans. The material comes out best when it is adequately cooled.

ABS is no different. However, it requires cooling much slower than PLA since ABS tends to warp if cooled quickly. It’s best to use an enclosed printer for ABS to slow down the cooling process.

4. Support

Support materials help ensure that the material doesn’t deform and remain intact. For PLA, Hydrofill and PVA (Polyvinyl Alcohol) can be a good support material since it works well in the same temperature conditions.

ABS always is the partner with HIPS (High Impact Polystyrene). HIPS can be dissolved in d-Limonene to ensure that your print is free of any markings.

5. Warping

Since PLA Filaments print at lower temperatures, it doesn’t tend to warp. Warping can only be a problem in this material if it is in contact with a heated bed with a high temperature.

ABS, on the other hand, is prone to warping if you aren’t careful. The printing process of ABS does require avid temperature control to achieve the proper dimensions in its material.

Price

Price is another major factor when it comes to choosing 3D filaments. And filaments don’t come cheap either. While the cost of 3D filaments varies, PLA and ABS are two of the most inexpensive materials in the market. They both stem from the same price range, around $20-$30 per kilogram on average.

It’s easy to conclude why their cheaper price-compared to other 3D filaments-make them a popular choice in the market, specifically for prototyping and technical purposes.

Storage

Both PLA and ABS require airtight conditions to prevent moisture from gathering in the materials. PLA is especially sensitive to moisture and would most certainly degrade when left out.

While ABS isn’t as sensitive as PLA to moisture, properly storing them will help prevent the material from becoming brittle and prolong its quality. Airtight bags or vacuum-sealed containers are ideal storage spaces to keep your unused filaments.

Part Accuracy

Generally speaking, the accuracy of FDM printed components relies heavily on the printer’s model complexity and calibration. But both PLA and ABS can be used to produce dimensionally accurate parts.

After all, PLA is used for prototyping and architectural mock-ups due to its capability to produce complex prints. It’s also less prone to warping due to its lower printing temperature.

ABS filaments can also achieve the same dimensional accuracy. But may require a bit more technicality in the printing process since it is more susceptible to warping due to its higher printing temperature than PLA.

Surface Finish& Post-Processing

The surface of PLA is semi-transparent that makes its printed parts have an opaque and glossy finish. Some careful sanding by using multiple grit sandpaper can help smoothen out the surface. You also could use liquid polish to give the body a nice sheen.

On the other hand, ABS filaments often produce a more matte surface finish. Acetone is usually applied to help smoothen out ABS and give it a glossier finish. It can also be machined or drilled after printing.

Variety

Variety in materials helps fuel your creativity in creating 3D models. Luckily, both PLA and ABS have a wide variety of looks and colors. Exotic filaments of PLA or ABS combined with different materials are also available in the market.

Popular materials include Wood, Metal, Glow-in-the-dark, and even Translucent ones that can give an edge to your models and feed your creative mindset.

Application

PLA is perfect for beginners since it is the type of filament that is easiest to manage. While it may have some drawbacks, such as its all-around durability and temperature sensitivity, it’s a well-rounded material to use.

Keep in mind that it works best for complex models and prototyping. Moving parts or anything that requires durability and degradability isn’t ideal. To be specific, it is best to avoid using it for items that might be bent or twisted. It isn’t impact-proof nor heat resistant either.

PLA works best with:

- Low-wear toys

- Prototype parts

- Architectural mock-ups

- Non-food containers

ABS filaments are relatively durable, flexible, temperature-resistant, and ideal for mechanical parts. It’s also impact-proof and can withstand high temperatures. That’s why it is a material that is easy to take advantage of in terms of use. While it might require more skill and experience to print ABS filaments, it can provide a wide range of use.

It’s an ideal material to use for the following:

- Phone cases

- High-wear toys

- Automotive trim components

- Electrical enclosures

- Tool handles

Final word

It’s clear how both PLA and ABS filaments are two of the best materials to use for 3D printing, given their quality and affordable price range.

However, it’s important to note that the material’s overall value depends on what project you will use. How useful it is and how it successfully meets your needs should be your determining factors in choosing the best material.

If you’re a beginner and want to experience the world of 3D Modeling, then go for PLA. It’s affordable, easy to manage, and has enough color variety to engage your creativity.

ECOREPRAP’s main business has shifted from 3D printing filaments manufacturing to 3d printing services and CNC machining services since 2023. We will continue to share related blogs about filaments and CNC machining.