Home > CNC Machining Materials > Metals > Alumimum

CNC Machining Materials

Aluminum CNC Machining Services

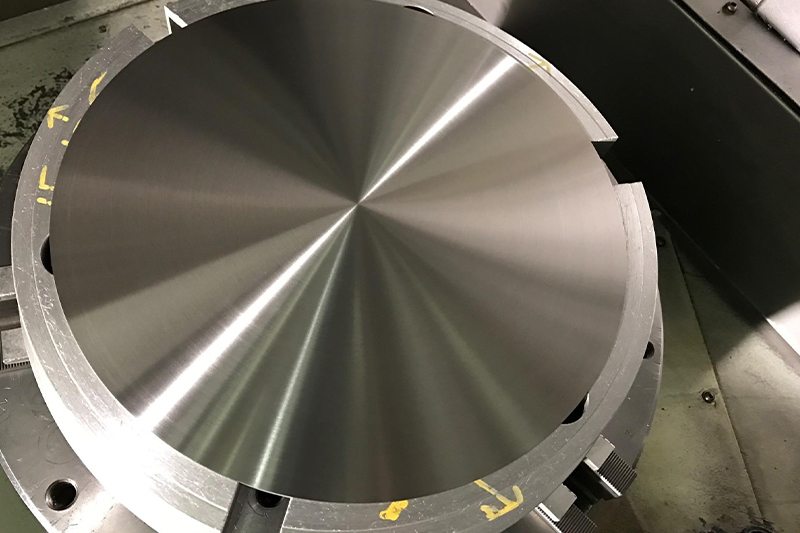

Aluminum CNC machining services provide high-precision production of aluminum components using advanced computer numerical control (CNC) equipment.

This process involves milling, turning, drilling, and tapping operations to achieve tight tolerances up to ±0.01 mm and smooth surface finishes suitable for aerospace, automotive, and electronic industries.

All uploads are secure and confidential

Key Features

- High accuracy machining for both prototype and volume production✅

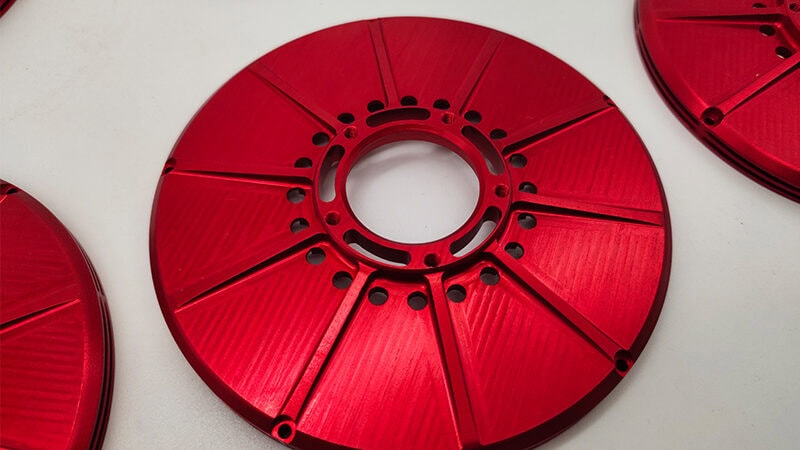

- Compatible with multiple aluminum grades: 6061, 7075, 2024, 5083, and 5052✅

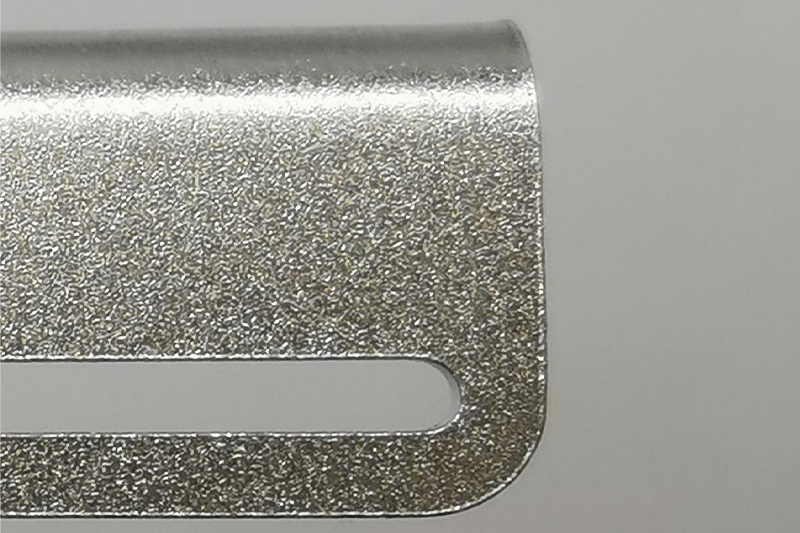

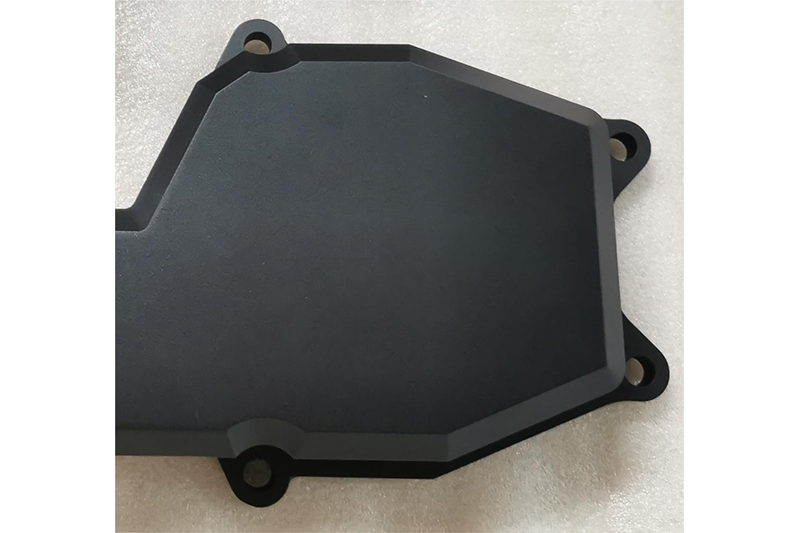

- Surface finishes including anodizing, sandblasting, and polishing✅

- Machining complexity supported: 3-axis, 4-axis, and 5-axis CNC milling✅

Ecoreprap Precision Manufacturing

At Ecoreprap, we specialize in high-precision aluminum CNC machining services backed by advanced technology and over a decade of manufacturing expertise.

- 45+ CNC Machining Centers – Equipped with high-performance HAAS and FANUC machines for consistent, high-accuracy production.

- Quality Certifications – Fully certified by ISO 9001:2015 and IATF 16949, ensuring strict quality management and traceability across every process.

- Monthly Output – Capable of producing 30,000+ aluminum parts per month, meeting both prototype and large-scale production needs.

- Experienced Engineering Team – Our engineers have 10+ years of CNC machining experience, providing optimized solutions from design review to final inspection.

At Ecoreprap, every aluminum component is manufactured to your exact specifications, with all dimensions verified before shipment to guarantee precision, reliability, and on-time delivery.

Why Choose Aluminum CNC Machining for Your Project?

Aluminum CNC machining is ideal for industries demanding lightweight, durable, and cost-effective solutions.

Ecoreprap’s process enhances precision, repeatability, and surface finish while maintaining short lead times.

Advantages of CNC Aluminum Machining:

- Lightweight & strong – reduces product weight without compromising strength✅

- High machinability – enables complex shapes and consistent results✅

- Corrosion-resistant – suitable for marine and outdoor uses✅

- Excellent heat dissipation – ideal for heat sinks and housings✅

- Cost-efficient – reduced cycle time and tool wear✅

Data Comparison

| Material | Density (g/cm³) | Machinability | Cost Index |

|---|---|---|---|

| Aluminum 6061 | 2.7 | Excellent | Low |

| Stainless Steel | 7.8 | Medium | High |

| Brass | 8.5 | Good | Medium |

| Titanium | 4.5 | Poor | Very High |

Ecoreprap’s machining optimization has achieved 18% faster cycle time and surface finish improvements up to Ra 0.8 μm, proving our process control and experience.

How to Select the Right Aluminum CNC Machining Service Provider?

Choosing the right machining partner determines the quality, accuracy, and reliability of your parts.

Ecoreprap helps you make informed decisions by offering transparent process control and certified capabilities.

Evaluate These Factors:

- Machining Equipment: Verify multi-axis CNC capacity for complex parts.

- Quality Certification: Check for ISO, RoHS, and REACH compliance.

- Delivery Record: Ecoreprap maintains 98% on-time delivery performance.

- Material Traceability: All aluminum is sourced from certified mills with traceable documents.

- Engineering Support: Free DFM analysis and prototype assistance for your design.

Ecoreprap’s Project Experience

- Delivered 5,000 precision housings for an EV battery project (2024)

- Achieved ±0.008 mm tolerance for aerospace brackets

- Reduced machining cost by 12% via toolpath optimization

- Provided 24-hour engineering support with full QC documentation

With Ecoreprap, you partner with a supplier who combines technical knowledge, production flexibility, and quality assurance.

Industries We Serve

Ecoreprap aluminum CNC machining services are trusted by global clients in industries that require precision, durability, and consistency.

Applications by Industry

- Aerospace: brackets, housings, and support frames

- Automotive: heat sinks, gearbox housings, and fixtures

- Electronics: connectors, cases, and heat exchangers

- Robotics: base plates, arms, and lightweight components

- Medical: fixtures, imaging brackets, and handles

Ecoreprap’s Global Credentials

- 120+ active clients from the USA, Germany, and Japan✅

- Annual export volume exceeding $8 million USD✅

- Compliance with REACH, RoHS, and DFARS standards✅

- In-house testing lab with CMM, hardness tester, and spectrometer✅

We ensure every aluminum part passes 100% visual and dimensional inspection before delivery.

Ecoreprap Aluminum CNC Machining Capabilities

Ecoreprap specializes in precision CNC machining of aluminum parts with tight tolerances and refined finishes.

Capabilities Overview:

- CNC Milling: 3-axis, 4-axis, 5-axis

- CNC Turning: up to 300 mm diameter

- Surface Finish: Ra 0.8 μm achievable

- Tolerance: ±0.01 mm standard

- Rapid Prototyping: within 5–7 working days

- Production: small to large batch runs

Available Aluminum Subtypes For CNC Machining

| Subtype | Ultimate tensile strength | Yield strength | Young’s modulus (modulus of elasticity) | Elongation at break | Corrosion resistance | Magnetism | Weldability | Application | |

| Aluminum 6061-T6 | 260-310 MPa | 240-270 MPa | 68 – 74 GPa | 8-11 % | High | Non-magnetic | High | Automotive industry Marine industry Electrical fittings Couplings & valves | Learn More |

Aluminum 6063 | 110-210 MPa | 55-130 MPa | 68 – 69 GPa | 8-18 % | High | Non-magnetic | Good | Architectural products Door and windows frames Pipe and tubes for irrigation systems Electrical components | Learn More |

Aluminum 5052 | 170-210 MPa | 70-120 MPa | 68 – 71 GPa | 7-20 % | Good | Non-magnetic | High | Hydraulic tubes Kitchen appliances Cabinets Small boats Home freezers Aircraft tubes Fencing | Learn More |

| Aluminum 7075-T6 | 520-560 MPa | 460-470 MPa | 69 – 76 GPa | 6-9 % | Moderate | Non-magnetic | Poor | Aircraft and aerospace Marine Transportation | Learn More |

| Aluminum 2024-T351 | 395-470 MPa | 275-310 MPa | 71 – 73.1 GPa | 9-15 % | Poor | Non-magnetic | Good | Aircraft fuselage Commercial & military aircraft Wing tension members Critical Aircraft structures | Learn More |

| Aluminum 2014 | 190-245 MPa | 100-125 MPa | 72 – 73.3 GPa | 11 – 16 % | Poor | Non-magnetic | Fair | Aerospace & Defense industry Truck frames | Learn More |

Aluminum 7050 | 470-530 MPa | 390-460 MPa | 70 – 80 GPa | 5-12 % | Poor | Non-magnetic | Fair | Fuselage frames Bulkheads Wing skins Aerospace structures Commercial & military aircraft applications | Learn More |

Ecoreprap provides in-house anodizing, bead blasting, and powder coating, ensuring faster turnaround and consistent surface quality.

Quality Assurance & Certifications

At Ecoreprap, quality is not an option—it’s a system.

We follow strict inspection procedures for every aluminum CNC machining order.

Inspection Process

- First Article Inspection (FAI)

- In-process measurement and SPC monitoring

- Final CMM inspection

- 100% visual check and packaging control

Certifications

- ISO 9001:2015

- IATF 16949 (Automotive)

- RoHS / REACH Compliance

- Material Traceability Certification

Through lean manufacturing and 5S management, Ecoreprap maintains a defect rate below 0.2%, ensuring every product meets global standards.

Aluminum CNC Machining Surface Finishes

Cost-saving Design Tips

1.Design for manufacturing

The first tip to save cost when machining an aluminum alloy part is to follow design-for-manufacturing principles to limit difficult-to-machine features, such as setup numbers, inspection dimensions, tight tolerances, and deep pockets with small radii.

2.Choose the right alloy

Using the most innovative and pricey alloy might not be needed if the part is just a prototype. 6061 T6 aluminum is a good choice.

FAQs

Aluminum CNC machining is the process of using computer-controlled machines, such as a CNC mill and a CNC lathe, to shape, cut, and finish aluminum parts.

Aluminum is favored for its lightweight, corrosion resistance, and excellent machinability.

Common alloys include 6061, 7075, 5052, and 6063 for specific applications.

Yes, CNC machining can produce tight tolerances in aluminum parts for precision applications. Tight tolerance is up to 0.005mm.

Options include anodizing, powder coating, painting, and more, depending on the desired appearance and function.

Yes, aluminum’s strength-to-weight ratio makes it a common choice in aerospace and automotive applications.

Aluminum machining is cost-effective for high-volume production due to its efficiency and machinability.

Yes, CNC machining allows for the production of intricate and complex aluminum components.

Yes, with appropriate finishes, aluminum parts can endure challenging conditions.

Aluminum is a versatile choice for prototyping due to its ease of machining and availability.

Yes, when medical-grade or food-safe aluminum is used, it’s suitable for these applications.

Designers should consider material selection, tolerances, and the complexity of the part.

Yes, it’s a quick and cost-effective method for producing prototypes.