The main difference between anodizing and powder coating is that anodizing mainly serves the purpose of enhancing aluminum’s physical and electrochemical properties, while powder coating stands for superior resistance and visual attractiveness of any material.

Both metal finishing processes have their strengths and weaknesses, and scopes of application. We examine the major nuances regarding anodizing and powder coating in this post, so you can choose the process that best suits your product’s needs the best.

What is Anodizing

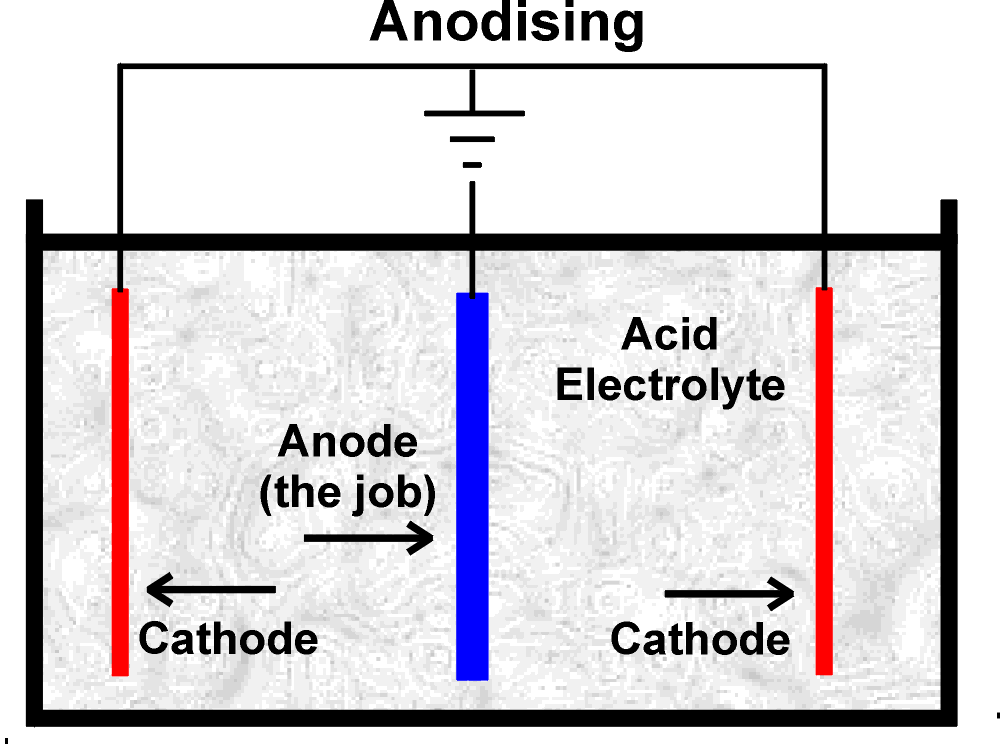

Anodizing is the advanced surface finish method that employs electrochemical reactions to change the surface chemistry of metals. Despite the potential possibility of applying anodizing to some other metals, only aluminum, and its alloys are typically anodized.

Let’s review the typical anodizing process that consists of five simple steps.

- The surface of an aluminum part is cleaned and rinsed.

- The part is placed into a bath with electrolytic liquid (such as sulfuric acid).

- A cathode is mounted to the inside of the bath with electrolyte (if it had not been previously).

- A positive electrical charge is applied to the part.

- Oxygen ions are released from the electrolyte and combined with aluminum atoms from the surface of the anodized part.

As a result, external layers of an aluminum component are turned into aluminum oxide and become a barrier layer. The surfaces of the anodized aluminum part have inner pores that can be filled with color pigments. Thus, it is possible to form a particular color of your choice, but from a limited range of pigments and with a certain shade variation between batches.

Pros

- High durability, long life span, great color stability.

- Exposure to heat, sunlight, and moisture does not deteriorate the color of components.

- Proceeded parts can be recycled without coating removal.

- Great corrosion resistance.

- Remove surface dirt, scars, wear from fabrication, and other defects.

- Environment-friendly and not harmful to human health.

Cons

- It is an expensive finishing process.

- Notable shade variation in color between batches of components.

- The barrier layer of anodized parts has low chemical resistance.

- Weld’s joints are left uncoated in anodizing.

- Anodized parts cannot be repaired or repainted.

- It can be applied to aluminum only for manufacturing purposes.

- Only clear and satin finishes are available

A photo of the aluminum CNC machining part with anodizing is shown below.

What is Powder Coating

Powder coating is a widespread and relatively simple method to finish a component from almost any material.. It offers a nearly unlimited range of colors and functional (protective) and decorative coatings. Powder coating is based on electrostatic spray deposition (ESD) to achieve a stable surface coating (especially metallic ones).

Let’s review the typical powder coating process that consists of several steps.

- Preparation of polymer resin system components (curatives, pigments, leveling agents, and flow modifiers).

- Mixing, melting, and cooling components.

- Grounding the polymer resin system to a uniform powder.

- With the use of a spray gun, which exploits the electrostatic charge to the powder, the coating is applied to a component’s surface.

- Baking a component in a cutting oven, where powder coating forms molecular chains with the substrate under heat.

The process leads to high cross-link density that enables the powder to be well-integrated in a substrate. As a result, a stable protective or decorative coating is obtained.

On the stage of mixing components, you can add any color pigment and be sure that an obtained color will show no shadow variation between batches. As long as the proportions of the resin system’s components are not changed, of course.

Pros

- It is an affordable finishing process.

- Weld joints can be coated.

- Powder coatings ensured great chemical resistance.

- Scratched and damaged parts can be repaired and repainted.

- It can be applied to any material, not necessarily metal.

- Moderate corrosion resistance.

- A wide choice of finishes, such as satin, matt, gloss, textured, etc.

Cons

- Coating must be removed before recycling a component.

- The coating is less stable than the oxidized layer and has a lower lifespan.

- Parts are not that durable, and color may fade because of moisture, heat, and sunlight.

- It may be dangerous for labor during the process unless safety precautions are taken.

A CNC-machined steel with powder coating is shown below.

Differences Between Anodizing and Powder Coating

1. Process

Although we previously detailed the exact steps to anodize or powder coat an aluminum part, let’s summarize everything.

Anodizing employs tanks with electrolytes to sink components in and run a charge through. With the help of the current, electrochemical reaction – oxidation is driven. It changes a component’s surface itself instead of just covering it with an additional layer. Basically, the properties of aluminum are not changed but are greatly enhanced.

The scary part is the limitations of tanks’ volumes. There is a certain number of components, or, to be precise, squares of all the components’ surfaces, that can be processed in one run.

If fewer components are anodized simultaneously, cost-effectiveness is questioned. If more components proceeded at the same time, the quality of finishing might severely deteriorate. The current power should also be adjusted to a particular square of surfaces.

In contrast, powder coating is simply an application of previously prepared resin systems – powders, on a component’s surfaces. A specialized gun also applies static force to a powder’s particles so they can stick to a subtract. Then, powdered parts are heated in an oven, so colored particles can become dense and form a stable coating.

There are no limitations for a number of components manufactured in one run, as basically, the process is continual. It means that you can mix any amount of powder and apply it to components one by one without any restrictions.

Ovens have their volumes and can bake a restricted number of components simultaneously. But, compared to anodizing, powder coating has a short turnaround time. It is so because the process can be arranged in such a manner, so there is no ineffective period of time when labor or equipment units do not work.

2. Cost

As mentioned previously, anodizing is more expensive than powder coating in the matter of the price to process a certain number of components. Cost-efficiency can also be deteriorated by anodizing fewer components at one run.

In contrast, powder coating is more affordable overall. Additionally, there are no strict limitations that dictate an optimal number of components to be manufactured. It makes powder-coating a more budget-friendly option.

Reference: How Much Does Anodizing Cost?

3. Surface Finish

Both surface finishes that can be obtained with anodizing or powder coating are great. However, they are significantly different from each other.

The oxidized surface is less versatile in terms of finishes and offers mate and satin finishes only. The durability of anodized parts and lifespan are greater than powder-coated ones. There is no possibility of color fading, and corrosion resistance is superior.

On the other hand, powder-coated parts are chemically resistant and can be prepared using a wide range of finishes. Matte, satin, clear, or any other of your choice. Unfortunately, powder coating can be removed physically and can deteriorate over time.

4. Application

Applications of anodizing are the following:

- Architectural categories of all types.

- Commercial and residential building parts.

- Food preparation equipment.

- Equipment for medical use.

- Office furniture.

- Vehicle interior components.

- And many more.

Applications of powder coating are the following:

- Architectural steel parts and other metal products designed to be used outdoors.

- Industrial and outdoor machinery.

- Metallic roofs, curtain walls, other outdoor furniture.

- Metal cabinets for offices and other office furniture such as desk parts and chairs.

- Cart parts, such as door handles, bumpers, shock absorbers, etc.

- And many more.

5. Color Available

As mentioned in the above text, you have a limited choice of pigments to be applied to an anodized part. In case you require something out of the list, a supplier may make it work, but such a decision definitely will not be cost-effective.

In contrast, powder coating offers a wide range of colors to be applied. As a bonus, they are consistent from batch to batch.

6. Rework

It is nearly impossible to fix a damaged anodized component. Basically, to receive the same quality, you will be offered to remanufacture the part. The difficulty is that in the process of anodizing, small fabrication scratches are removed, while deep ones are just anodized as well.

At the same time, powder coating can be repainted as many times as needed. The scratched surface will be filled with powder particles, and no defects will be left visible eventually.

7. Layer Lifetime

Here is only one winner – anodizing. The oxidized surface is basically the integral part of the components themselves. It can be damaged only to that very extent, as unprocessed aluminum itself. It makes the anodized parts to be very long-lasting.

Unfortunately, powder coating can be easily removed under physical stress. Shortly, you will notice scratches on the surface and chipped pieces of powder. Depending on the conditions under which components are exploited, powder coating does not last long.

Summary

In general, Anodizing is an expensive but reliable method of improving your aluminum components with various features. In contrast, Powder coating offers a great choice of colors, sacrificing durability and enhancing a material’s properties just a little bit.

There is no sole winner in this comparison. Scopes of application are similar, with some areas in which only one of the finishes is appropriate. The manufacturing needs, budget, and requirements for particular components should guide you.