Best plastic for CNC milling: Materials, Machinability, and Key Considerations

Updated: Jan. 10, 2024

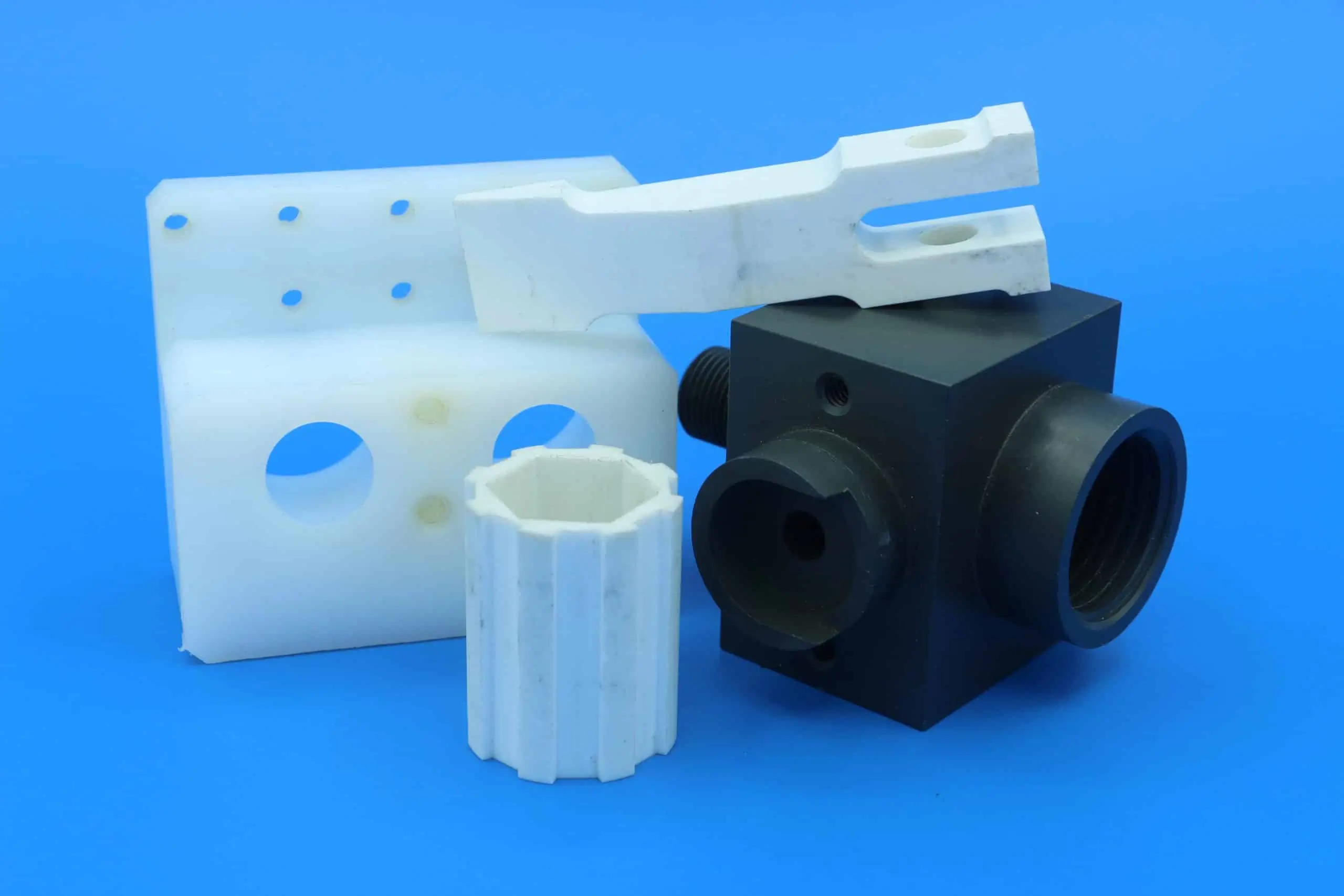

In the field of plastic processing, some plastics are more related to CNC machining.

Some plastics, such as Polycarbonate, ABS, POM and HDPE, are actively used through the industry in consensus with plastics processing specialists.

This is because these high polymer materials are highly flexible, have superior processing properties.

The processing properties of these plastics are related to their physical and chemical properties.

First, Polycarbonate is a kind of strong thermoplastic, with excellent impact strength and stability of mechanics.

It also has a high degree of transparency, the production of a variety of high-precision optical components.

Moreover, it is easy to cut, drill, and also increases in the processing of strings of crayons are not easy to concentrate, while significantly avoiding the pressure of stress, so it is also very Processing is welcomed in the cnc machining.

Secondly, the material to wear is made of ABS, based on the needs of the country has excellent insulation properties, but can provide excellent thermal insulation, and easy to suffer long-term color effects.

Moreover, it has a low melting point, good fluidity and dissipation, and also has good thermal stability, even in the processing of cnc machining, it can also use its simple processing forming high-precision components.

Third, Polyoxymethylene, also known as Acetal or Polyacetal resin, has a very high musical strength and tenacity, as well as high hardness.

Especially in a state of high humidity and materiality, it has very stable dimensional efficiency.

Moreover, it is able to self-lubricate, and its friction coefficient is also very small, and it is very popular to manufacture various required mechanical parts, such as appropriate precision gears and bearings.

Finally, on a more special level, High-Density Polyethylene A special case of polyolefin The plastic is also a high percentage by toughness, high strength, and leading, chemical-soluble in water.

Its axon processing chemicals are highly stable, easy to cut and melt, Its pros and cons make it a priority in the processing of a wide range of industrial volume and durability for containers and end-use goods.

Selection of CNC plastic material

When choosing plastic materials for the purpose of CNC machining, one needs to consider a variety of factors, which include both the specifics of the materials used and the final products and certain properties of the equipment with which the products will be manufactured.| Material | Characteristics | Applications |

|---|---|---|

| ABS (Acrylonitrile Butadiene Styrene) | High strength, impact resistance, chemical resistance | 3D printing, prototyping, mechanical parts |

| PVC (Polyvinyl Chloride) | Good weather resistance, electrical insulation | Pipes, furniture, packaging |

| PP (Polypropylene) | Lightweight, high temperature resistance, chemical resistance | Containers, pipes, automotive parts |

| PS (Polystyrene) | High transparency, easy processing, low cost | Transparent packaging, toys, appliance casings |

| PC (Polycarbonate) | Good impact resistance, high transparency | Glass substitutes, automotive parts, electronic product casings |

| PA (Nylon) | Good wear resistance, good impact resistance, self-lubricating | Bearings, gears, engineering components |

| POM (Polyoxymethylene) | High hardness, good wear resistance, dimensional stability | Bearings, gears, mechanical parts |

ABS (Acrylonitrile Butadiene Styrene)

ABS is one of the most commonly used thermoplastics because it provides a combination of mechanical properties, impact resistance, and relative ease of machinability.

It is used in a variety of fields from functional prototypes to automotive components and consumer electronics;

It is especially useful for creating parts that need to be long-lasting and reliable.

One of the most notable features of ABS is the relatively high speed at which it can be machined without creating a large amount of wear on the cutting equipment.

This allows for a more efficient production process, which further facilitates its use in creating high-volume production runs.

Its cost in use is relatively low; combined with its good ability to keep its shape, it can be an economically advantageous choice for manufacturers.

When combined with its excellent surface finish capabilities, it can create parts that are not only functional and durable but also have high aesthetic qualities, without the need for the costly post-processing steps.

Polycarbonate (PC)

When compared to other types of plastics, polycarbonate is one of the strongest and most resistant to impact, which provides it with usability and weight advantages.

In addition, it is highly transparent, allowing the material to be used in covers for safety purposes, safety glasses, and all types of windows.

However, as the material is likely to melt and become deformed if exposed to high temperatures, certain specific issues must be considered during the machining process.

In order to ensure that these considerations do not affect the quality, manufacturers must carefully choose the cutting parameters.

Specifically, the manufacturing require the adjustment of the cutting speed and feed rate, and with appropriate use of sharp tools, heat production can be minimized.

Proper cooling of the polycarbonate is also essential to prevent it from becoming warped or developing internal stresses.

While the material may technically be hard to machine, this way, it retains its advantageous features and does not decay in quality over time, which also improves the lifespan of the cutters and other tools.

Overall, with a few simple considerations appropriate and well-planned balance, the range of polycarbonate’s outstanding features can be used to their full utility effect.

Nylon (Polyamide)

Nylon is much appreciated for its high wear resistance, good tensile strength, and high elasticity.

Since it can create sturdy, mechanical parts like gears, bushings, and bearings, Nylon is an ideal construction material.

The usage of these parts will not encourage their rapid wear and help them function correctly.

However, the material has one important drawback – it tends to absorb water from the environment .

In this way, the dimensions of the machined part will shift, and it is not easy to say if it is safe to use the detail.

Before the process of machining, the plastic should be dried manually, and after it is done, the part must be conditioned.

In this way, Nylon will not undergo dimension changes, which makes the part stable in its size and shape.

PEEK (Polyether Ether Ketone)

PEEK is an excellent choice for demanding applications due to its remarkable thermal stability, chemical resistance, and mechanical qualities which make it suitable for use in the aerospace, automotive, and medical sectors.

These industries rely on PEEK for its resilience under punishing conditions like high heat and exposure to corrosive substances.

Components such as seals, bearings, and implants crafted from PEEK are engineered to withstand inhospitable operating environments without compromise.

However, machining PEEK demands adept skill.

The material necessitates specialized cutting tools and precise machining protocols to circumvent thermal deterioration and preserve its outstanding properties.

Deploying keen tools, suitable feed rates, and proper cooling is imperative to skillfully machining PEEK and achieving finished goods that satisfy rigorous qualifications.

Acetal (Polyoxymethylene, POM)

Acetal, also known as polyoxymethylene, possesses properties rendering it particularly suited for manufacturing intricate mechanical components requiring smooth sliding motion.

Its excellent machinability facilitates producing parts with a velvety surface finish and tight tolerances, vital for high-performance applications.

This renders Acetal a preferential material for crafting complex constituents including gears, pump assemblies, and various elements in electrical engineering wherein reliability and precision are paramount.

Additionally, Acetal’s resistance to creep as well as its dimensional stability under mechanical stress and fluctuating temperatures contribute to its widespread usage in these critical applications.

The ability to withstand prolonged frictional wear and environmental factors without deterioration renders Acetal an indispensable material in industries demanding durability and precision.

Also Read:

Best plastic for CNC milling

ABS

Moreover, owing to its somewhat peculiar sensitivity to high temperatures, ABS can easily melt or warp while being machined.

Hence, the cost of cooling arrangements like mist or flood cooling plays a crucial role in ensuring the maintenance of safe temperatures throughout the process.

Keeping the temperature at a stable level guarantees a perfect final product as it ensures that the ABS preserves its integrity and dimensions.

This, in turn, results in the production of high-quality and precise parts that can be subsequently used in a vast array of applications.

Polycarbonate

Polycarbonate is a versatile but delicate material.

It cannot be overheated, as it tends to melt.

Hence, to maintain the high quality of the final product, all machining processes must be carried out with precision and care.

It is necessary to use well-sharped tools that work quickly and generate as little friction and, consequently, heat as possible.

It is essential to work at low feed rates to avoid overheating and melting due to exposure to high temperatures.

In turn, a cooling system should be implemented.

It implies the use of compressed air or coolants that ensure that all heat generated is quickly dissipated .

Thus, the polycarbonate will not deform due to temperature and will retain its primary shape and properties.

Nylon

Nylon is a very strong material known for its mechanical properties, yet it is challenging for machining due to being hygroscopic, absorbing moisture.

Under the influence of moisture from the environment, nylon swells, which results in the inaccuracies of the dimensions and geometry of the machined product .

Thus, it is critical to pre-dry nylon in order to remove the excessive amount of water.

Another necessary step includes using a coolant during machining.

It provides a steady thermal condition and ceases further moisture absorption.

In turn, it leads to better dimension accuracy.

Such measures are preconditioned for precise and accurate machining of nylon.

PEEK

PEEK is also difficult to machine due to its excellent high-performance properties, such as high melting temperature.

Nevertheless, quality machining can be done with proper methodical assembly is possible via the next procedure, high-quality, and sharp assemblies must be selectively used since they can slice through the PEEK also create no more burn me from overheating.

Machine spindles must operate at very reduced rates to effectively dissipate the heat stress produced through machining.

Such temperatures must be insufficient to annihilate the operations or purposes integrity of temperature resistance, which is produced in high-precision parts without substance damage.

Acetal

Acetal , also known as Polyoxymethylene , is generally easy to machine, and the process may prove to be quite smooth.

However, it is also quite prone to chipping, capable of significantly damaging the finish and ultimately ruining the entire part.

In order to avoid that, the whole machining setup must be stable – the part should be well-clamped and the machinery should not exhibit any vibrations.

Frequently replaced sharp tools with properly set clamps and fixtures will ensure even and clean cuts, minimizing the presence of chips and achieving an excellent finish.

These characteristics allow the use of acetal components in a variety of precision applications with high demands for aesthetics.

What are the factors influencing selection of CNC?

When selecting the right CNC machine for your specific manufacturing task, there are numerous key factors that need to be taken into account to ensure that the machine you choose is capable of meeting the requirements of your project effectively and efficiently:Task and Material

Understanding the specific responsibilities assigned to the computerized machine is paramount.

Each manufacturing undertaking, be it milling, turning, or perforating, necessitates specific machine abilities.

For example, multifaceted errands combining various processes might necessitate a multi-useful CNC machine with the proficiency to perform numerous tasks in a solitary setup, drastically diminishing creation time and expanding productivity.

The decision of material is similarly critical.

Distinctive substances have unusual properties that can influence the machining process.

For instance, machining more flexible materials like plastics or aluminum may not require a similar level of intensity and inflexibility in a machine as harder materials like titanium or stainless steel, which introduce significantly more resistance to cutting devices.

The material decision affects not just the type of machine yet in addition the particulars of the parts, for example, the sort of cutting instrument and the machine’s yield limit.

Material Characteristics

The substances one will utilize (including but not limited to aluminum alloys, carbon steels, engineered plastics, composite laminates) impact the choice due to variances in hardness, tenacity, combustibility and thermal expansion properties.

Machining refractory materials mandates a machine incorporating more robust drives and stiffer construction to withstand elevated cutting pressures and temperatures without succumbing to premature component wear.

Workpiece Size and Complexity

Size and intricacy both merit scrutiny when selecting a CNC system. Larger components demand more expansive work envelopes and sturdier builds to guarantee dimensional fidelity, whereas intricate geometries may necessitate multi-axis dexterity for a one-shot setup accessing each surface.

The parts’ physical dimensions straightforwardly dictate the machine size required, while complex shapes could compel multi-dimensional mobility across articulating planes to fully form multifaceted forms without repositioning.

Dimensional complexity must also feature in decisions, as elaborate configurations or multiple faces potentially pull for progressive machines permitting maneuvering to reach all aspects comprehensively in a solo setup.

| Factor | Description |

|---|---|

| Processing Requirements | Material type, geometric shape, size accuracy, etc. |

| Material to be Processed | Metal, plastic, wood, etc. |

| Complexity of Processing | Requirements for complex parts |

| Production Batch | Single-piece processing or large-scale production |

| Budget | Machine cost and operating expenses |

| Technical Requirements | CNC system functions, accuracy, and reliability |

| Space Constraints | Interior space of the factory and equipment installation requirements |

| Maintenance and Service | Equipment maintenance and after-sales service support |

| Automation Requirements | Degree of automation and features such as automatic tool changing systems |

| Available Workforce | Operator skills and training costs |

Tips on Working with Plastics in CNC Milling

CNC machining of plastics requires precise control of various technical parameters. This ensures the quality of the machined parts and prevents material damage. Here’s a detailed exploration of these parameters:Speed (Spindle Speed)

Machining plastics requires a higher spindle speed to reduce the force on the material.

When the force is lower, then the plastic is less likely to crack and overall it will be machined easier.

However, it is necessary to tweak the speed of the spindles based on the specific properties of each plastic type.

Softer plastics can be more sensitive to the need of immediate action which cannot be done with high-speeds and you should take into account that polyethylene is a relatively weak plastic and if you go too fast then it will melt.

This means that your piece will be ruined and your machine will be significantly overloaded.

It is necessary to tweak the speed of your spindles to the properties of the specific plastic, and keep testing them before making your first cut.

This will eliminate the issues of human error during the cutting process and will save you a lot of money on wasted materials.

Feed Rate

Feed rate is how fast plastic moves toward the cutting tool. It’s a critical variable in CNC machining.

Choosing the right feed rate is vital. If the feed rate is too quick, the plastic gets dragged along cal matte and poor-quality cuts results.

These poor cuts have ragged edges and heat which causes excessive melting.

However, if the feed rate is too slow, the cutting tool remains in contact with the plastic longer than it should.

This extended contact generates enough heat to melt some plastics.

The ideal feed rate varies by plastic type.

Soft plastics, which melt easily, benefit from faster feed rates, while harder plastics can be cut at a slower pace, which allows for a cleaner cut.

Thickness also matters.

Thicker pieces of plastic might need changes in the feed rate to allow for clean cutting without excessive heat production.

Regular adjustments and testing are vital.

Manufacturers’ recommendations can be used as a benchmark, but other settings might work for you.

Use small batches of plastics to tinker with different feed rates and settings for optimal CNC cutting without meltage.

Depth of Cut

The depth of engagement significantly impacts machining results. Specifically, it refers to how deeply the tool cuts into the plastic with each pass. Understanding this parameter can facilitate achieving intended outcomes efficiently.Processing plastics prone to fracturing demands careful consideration.

Opting for shallower cuts per pass drastically lessens the chances of damage.

Such delicate materials often break or crack when confronted with aggressive machining, compromising not only the stock but potentially stalling production.

Conversely, softer plastics allow for a modified approach.

Here, employing deeper cuts for every pass proves advantageous.

This strategy aids in reducing the total number of passes required, lightening the workload.

Not only does this quicken the process, but it also serves to prolong tool lifespan.

Ultimately, adjusting the depth of cut largely relies on material properties and desired project results.

More precise work involving fragile stocks is best served by shallower cuts, while deeper cuts with compliant plastics enhances efficiency.

Each method serves its purpose contingent on task specifics.

This optimized technique preserves assets and lengthens equipment life, cultivating a more sustainable plastic machining process.

By tailoring the depth according to characteristics, machinists can ensure high quality outcomes and standards in their work.

Tool Geometry

Tool styles are an important part of manufacturing, particularly when working with plastics.

The tools employed are uniquely crafted with the material’s traits in mind.

Their design notably differs from those ideal for metals.

Why? Because plastics react differently under pressure.

Tools engineered for plastics often feature sharper edges.

This determination isn’t random. Keener edges pierce through plastic more smoothly, yielding sleeker surfaces.

Precision and avoiding unnecessary strain on the substance are key.

Moreover, these tools regularly have fewer grooves. Grooves route removed material.

Fewer grooves lessen the risk of clogging.

Clogging can lead to poor finishes and even, in severe cases, damage tools and products. Preventing clogs is paramount.

The specialized makeup of these tools serves a twofold role. Firstly, it cuts friction.

Less friction means less heat, and heat management is important when handling plastics.

Excess warmth can warp or melt the material, ruining the workpiece.

Secondly, it fosters efficient chip removal.

Thorough chip evacuation is essential for maintaining cut quality and preventing potential harm to tools or products from accumulated chips.

Simply put, tooling tailored for plastics achieves balance.

It diminishes friction, regulates warmth, and ensures smooth chip removal.

This adjusted approach yields better finishes and more efficient processes, proving the right tools not only enable jobs but significantly better final results.

| Material | α Clearance Angle (°) | ϒ Rake Angle (°) | V Cutting Speed (ft/min) |

|---|---|---|---|

| ABS | 5 – 10 | 0 – 10 | 980 – 1640 |

| Acetal (copolymer) | 5 – 15 | 5 – 15 | 920 – 1640 |

| Acetal (homopolymer) | 5 – 15 | 5 – 15 | 920 – 1640 |

| Noryl | 10 – 20 | 5 – 15 | 980 |

| Nylon 6 | 10 – 20 | 5 – 15 | 920 – 1640 |

Comparing Plastics for Specific CNC Milling Applications

When manufacturing precision parts, the thermoplastic utilized can significantly influence the exactness and surface finish quality of the last item.

High-performance polymers that offer remarkable dimensional consistency, minimum dampness retention, and opposition to warm twisting are pivotal for accomplishing high precision and appealing visuals.

Materials, for example, Polyoxymethylene (POM), otherwise called Acetal, and Polymethyl Methacrylate (PMMA), generally known as Acrylic, stand apart in this class.

POM is globally recognized for its incredible exactness, superb machining capabilities, and great dimensional steadiness.

It is an ideal decision for making complex parts that require tight tolerances, like gears, bearings, and fasteners.

POM’s smooth surface permits a high-quality finish, making it a laudable choice for both utilitarian and tasteful segments.

PMMA, then again, offers extraordinary clarity and light transmission, very similar to glass, making it outstanding for precision parts that require both stylish interest and capacity, like focal points and shows.

Its capacity to be smoothed to a reflection like finish is an additional advantage for applications where surface quality is most extreme.

Structural Components

For structural parts, the mechanical quality, strength, and sturdiness of the thermoplastic material are essential.

Materials, for example, Polycarbonate (PC) and Polyamide (PA), generally known as Nylon, are notable for their remarkable strength-to-weight proportions and effect resistance, which make them fitting decisions for structural applications that demand solidness.

PC is characterized by its brilliant effect resistance and mechanical quality, making it proper for an extensive variety of structural applications, including bulletproof glass, auto parts, and headgear.

Its ability to withstand huge power without twisting or separating is a fundamental attribute when choosing a material for wellbeing basic parts.

While PA presents as an able polymer, possessing resilience, sturdiness, and compliance, its real strength emerges in repetition.

Mechanisms subjected to unending wear and grinding stress find solace in PA, as seen with gears, bracings, and automotive internals.

Its perseverance and impact absorption without breakage solidify its role as a dependable pick for load-bearing structures.

Cost-Calibrated Ventures

Massive projects require cost awareness, so selecting affordable plastics meeting needs is key.

Polyethylene and Polypropylene stand out for expense, multifariousness, and functionality.

Polyethylene proliferates, offering chemical resistance and toughness.

Densities vary, such as High-Density Polyethylene with a proficient power-to-weight ratio.

Polyethylene’s minimal price and benefits make it fit for packaging, holders, and piping.

Comparable in cost to Polyethylene, Polypropylene boosts temperature resistance, attributes, and lightness.

This suits automotive, consumer, and packaging uses where performance outweighs expense.

By strategically opting for materials coordinating with precision demands, solidity, or cost-efficiency, engineers and manufacturers maximize benefit versus cost in plastic parts and products.

Such choices prove pivotal amidst competition where trait, durability, and affordability all impact success.

Best plastic for CNC milling FAQs

Can you cut plastic with CNC?

Yes, employing Computer Numerical Control machines to cut plastics is entirely achievable and genuinely pretty widespread.

CNC engineering is greatly liked for plastic machining because of its exactness and adaptability.

An assortment of cutting instruments can be used in the CNC process, like milling cutters, drills, and lasers.

The choice of apparatus relies upon the specific plastic you’re working with and the finish you aim to accomplish.

Precision and repeatability are advantages of CNC.

When utilizing CNC devices to cut plastics, it’s pivotal to take into account elements like the material’s hardness, melting point, and sensitivity to heat.

Specific plastics are prone to melting or warping if an excessive amount of heat is created amid the cutting operation.

Using coolants and keeping a steady feed pace can help mitigate overheating dangers.

Quality requires attention to the properties of the material.

Furthermore, the cutting of some plastics can bring about static electricity, which may appeal dust and other contaminants to the workpiece.

This can be overseen by utilizing an ionizing air blast to neutralize the static build-up, helping to keep the workpiece free of debris. Cleanliness is important for some applications.

In summation, CNC cutting is an important and powerful system for shaping plastic, capable of conveying precise, consistent, and high-quality outcomes.

Nevertheless, it’s principal to be aware of the material-particular qualities of the plastic you’re machining and to execute suitable strategies to assure a smooth and proficient cutting experience. Careful process design leads to quality.

What is the best clear plastic for machining?

| Material | Characteristics | Advantages |

|---|---|---|

| Acrylic (PMMA) | Acrylic has unrivaled clarity and light transmittance akin to glass, rendering it ideal for applications requiring transparency. Its rigidity and impact endurance are laudable, and it machines smoothly with little danger of melting or fracturing. | A go-to material for both aesthetic and useful clear plastic elements. |

| Polycarbonate (PC) | Renowned for defending against bullets, Polycarbonate boasts the most formidable impact resistance of transparent plastics, guaranteeing durability under demanding conditions. While its machining may generate increased heat relative to Acrylic, using suitable coolants can mitigate this, allowing for smooth machining using high-speed steel or carbide tools. | Suitable for applications where impact resistance is crucial. |

| Cyclic Olefin Copolymer (COC) | Gaining traction for machining uses, COC presents a notable fusion of excellent dimensional stability, low moisture absorption, and strong chemical resistance. Its transparency and ease of machining, with minimal prospect of chipping or cracking, render it a compelling pick for precision parts necessitating clear plastics. | Compelling choice for precision parts requiring clear plastics. Exhibits transparency and ease of machining. |

| Polyethylene Terephthalate (PETG) | PETG is distinguished by its high chemical and temperature fortitude, rendering it suitable for environments where such factors are a matter. Like Acrylic and COC, PETG machines well, exhibiting slight inclinations to chip or fracture, which helps maintain clarity and structural integrity after machining. | Suitable for environments with demanding chemical and temperature factors. Maintains clarity and structural integrity after machining. |

Is HDPE good for machining?

| Topic | Description |

|---|---|

| High-Density Polyethylene (HDPE) | Exhibits renowned chemical resistance and impact strength. Machining requires nuanced navigation due to potential impediments. Low friction and melting point ease operations but necessitate vigilance against cracking or deformation. Resilient against impacts and corrosives, making it suitable for demanding situations. Improper techniques may affect dimensional accuracy and finish. |

| Tool Selection and Machining Techniques | Cognizance of HDPE’s propensities necessitates careful selection of tools, speeds, feeds, and cooling methods aligned with its attributes and application needs. Low friction minimizes galling or cutter adherence, enhancing longevity and efficiency during machining. However, pushing boundaries risks compromising material integrity, particularly along its grain. Achieving flawless, smooth edges requires paramount precision. |

| Customized Methodology | Adopting a customized methodology tailored to HDPE’s characteristics and intended use optimizes machining outcomes. Despite the hurdles, judicious techniques leverage HDPE’s strengths for various components. Meticulous calibration allows HDPE to excel in exacting environments requiring resilience against impacts and chemicals. The right approach unlocks HDPE’s capabilities for assorted applications demanding durability and machinability. |