- Capabilities

-

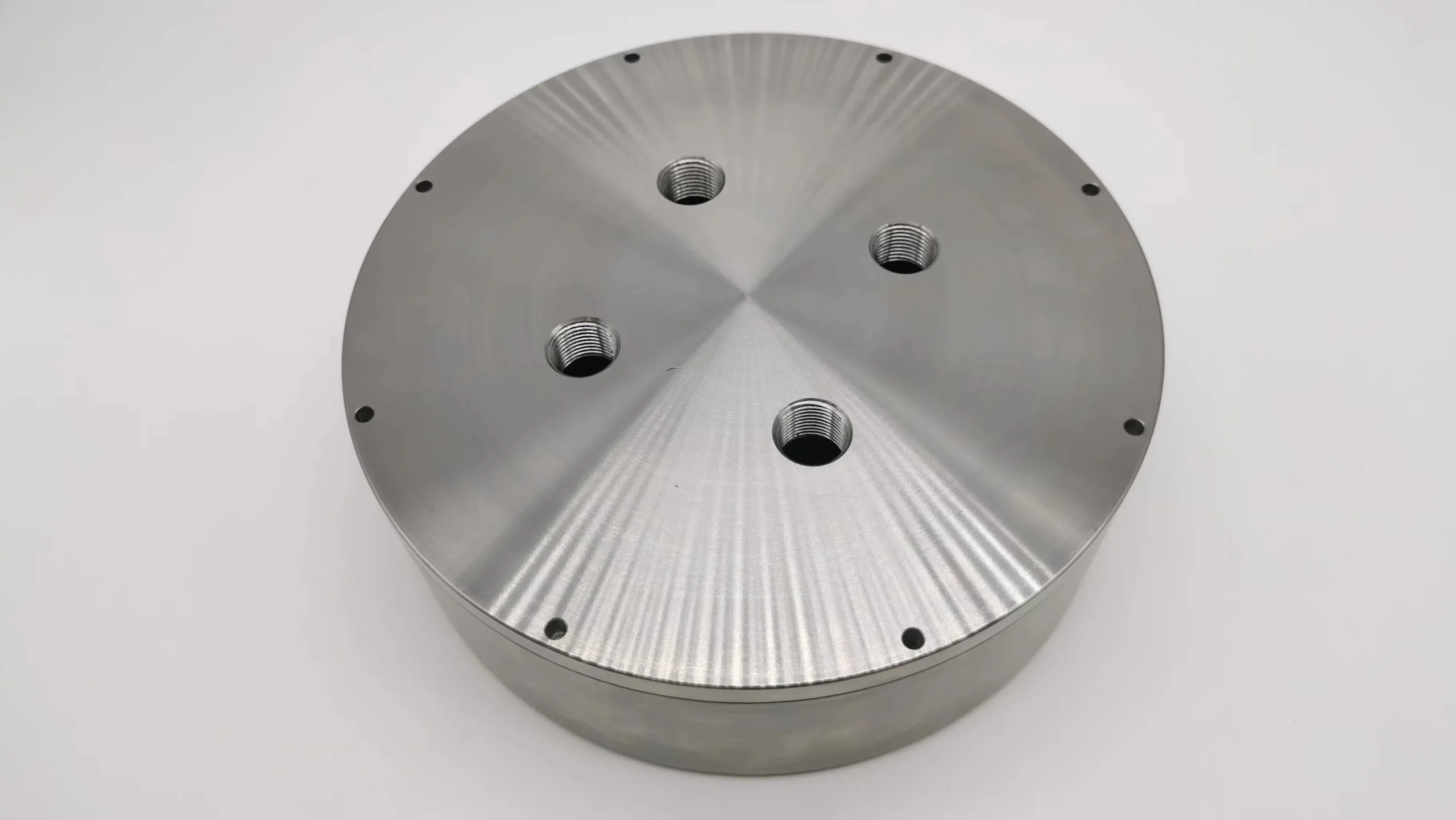

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

The Most Cost-Effective CNC Machining Metals

Updated: December 25, 2023

Which are the most cost-effective CNC machining metals? Aluminum are mid steel are considered to be the most cost-effective metal materials for metal CNC machining, because of their cheap raw material cost, strength-to-weight ration, and high performance. Among aluminum, there are some other metals which is cost-effective, like mild steel, and stainless steel. This article will give more information about factors influencing cost-effectiveness, and different metals in CNC machining.

1. Factors influencing CNC machining cost-effectiveness

Material properties and the machining processes are two main factors that influence the CNC machining cost-effectiveness.

1.1 Material properties

Material properties including strength, machinability, and thermal conductivity play an important role in the suitability of CNC machining. Some metals with good machinability are easier to be milled or turned than others.

If the metal is easier to be machined, the cost will be cheaper, because the machining speed is much faster. The machining cost is reduced by shorter machining time.

1.2 Machining Processes

For CNC milling, improved techniques and high-speed machining are crucial to cost-effectiveness, which can minimize cycle time, thus reducing the machining cost.

For CNC turning, the choice of cutting tools and optimization of turning parameters is the success of reducing production times and enhancing the cost efficiency. CNC turning is highly rely on the precision tooling and strategic feed rates.

2. CNC machining metal types

Metals are widely used in CNC machining with their properties of precision, strength, and machinability. CNC machining metals are applied in different industries, for example, automotive parts, marine parts, aerospace parts, medical parts, and others.

Whether it is prototypes or engineering models, CNC metals are always a top choice. Some are general use metals like aluminum with a low cost. Some metals can withstand extremely harsh environments and are durable, like titanium.

Below are types of introduction of CNC machining metal.

2.1 Aluminum

Aluminum is a lightweight alloy with excellent strength-to-weight ratio, high thermal and electric conductivity, low density, and natural deterioration resistance. It has superb machinability, welding, and electroplating residential or commercial properties as well as great corrosion resistance.

Lightweight aluminum is a material that is easy to cut and machine, and aluminum alloys can be quickly, properly grated, pierced, and machined using CNC machining. After machining, lightweight aluminum has a low threat of contortion or issues and is very easy to polish and color.

Aluminum is among the most common materials used in the aerospace, medical, auto and motorcycle industries.

Popular aluminum types include 6061T6, 7075T6. Check all the cnc machining aluminum types offered by ECOREPRAP here.

2.2 Stainless steel

Stainless steel is one of the favorite cnc machining metals for its rust resistance. There is at least 10.5% chromium inside which makes stainless corrosion resistant.

Stainless steel is classified into austenitic, ferritic, martensitic, and duplex by crystal structure.

Stainless steel parts have a lot of advantages, including corrosion resistance, high tensile strength, durability, temperature resistance, easy fabrication, and form-ability. They are widely used in a broad industry, including building and construction, automobile, aerospace, and more.

Popular stainless steel types include 304, 316. Check all the cnc machining stainless steel types offered by ECOREPRAP here.

Read the blog Stainless Steel CNC machining to get a full comprehension of how to machine stainless steel.

2.3 Carbon steel

As an alloyed steel, carbon steel is the term normally made use of for alloys of steel that are not stainless. Carbon steel can consist of light steels which are usually cost-effective and very easy to device. Higher-end carbon steels are likewise fairly easy to machine and offer high-wear resistance and tensile toughness.

Popular carbon steel types include A36, 1018. Check all the cnc machining carbon steel types offered by ECOREPRAP here.

2.4 Tool steel

Tool steel is one type of carbon alloy steel which are especially suitable for making tools, including cutting devices, dies, hand tools, blades, and others. They have unique hardness and are abrasion resistant, not easy to deform.

For CNC machining tool steels, heat treatment is always used to increase the hardness after CNC machining.

Popular tool steel types include A2, D2 and S7. Check all the cnc machining tool steel types offered by ECOREPRAP here.

2.5 Brass

Brass is a functional copper-zinc alloy. It is mechanically stronger and has better deterioration than copper. Brass has excellent wear resistance and machinability.

Brass is widely used in electrical goods, consumer goods, architecture, automotive, and others.

2.6 Copper

Copper is commonly 99% pure even more. The remaining 1% is impurities such as lead, oxygen, or silver.

Copper is known for its electric and thermal conductivity, which finds wide application in the power, automotive, clinical, and aerospace industries.

Popular copper types include C101, and C110. Check all the cnc machining copper types offered by ECOREPRAP here.

2.7 Titanium

As mentioned above, Titanium can withstand very harsh environments. It is an advanced material with excellent corrosion resistance, strength-to-weight ratio, and biocompatibility.

Titanium is an ideal choice for engineering parts challenged by medical, energy, chemical processing, defense and aerospace industries.

Due to Titanium’s high hardness, the cnc machining of titanium requires a lot of expertise and experience. Titanium CNC machining also has a high requirement on the cutting tools. Sandblasting and Passivation is two common surface finishes for CNC machined titanium.

Popular copper types include Grade 1, and Grade 2. Check all the cnc machining copper types offered by ECOREPRAP here.

2.8 Nickel Alloy

With excellent corrosion resistance and high-temperature stability, nickel alloy CNC machined parts are widely used in the chemical, aerospace, electronics and medical industries.

Invar, Kovar, and Inconel are well-known nickel alloys for CNC machining.

2.9 Magnesium Alloy

Magnesium, a usual material for die casting, is increasingly popular for CNC machining because it is lightweight and extremely machinable in regards to feed prices. Machined magnesium also generates exceptional surface area finishes due to shorter chips being produced throughout the machining process.

Magnesium is commonly used for die casting. But it has become more popular in CNC machining because of its lightweight and machinable properties.

Magnesium has a low ignition temperature, which makes it susceptible to combustion during CNC machining. To avoid combustion, we shall use special cooling, purposeful tools and controlled machining parameters.

AZ31B Magnesium is usually used for CNC machining.

2.10 Zinc Alloy

Zinc alloy metal is an inexpensive material, yet with good mechanical toughness. Zinc parts can be die cast first and then have important functions machined by CNC, reducing general CNC machining time and cost. The automotive industry makes substantial use CNC machined zinc alloys.

Zamak 3 is one of the most widely use of the quality of Zinc, offering exceptional dimensional security, together with other physical and mechanical buildings.

3. Most cost-effective metals for CNC machining

The article above introduced 10 commonly used metal materials in CNC machining. Selecting the most cost-effective metals for CNC machining depends on various factors such as application purpose, metal properties, and budget constraints.

Generally speaking, aluminum and mild steel are considered to be the most cost-effective metals in CNC machining processes.

4. Factors to consider when choosing CNC machining metals

There are many factors to be considered before choosing the right materials for your CNC projects. Keeping the manufacturing cost low without compromising the cnc machined parts quality is always preferred. Consider the following factors for choosing the most cost-effective metal for your machined part.

4.1 CNC machining metals properties

Consider the metal properties like hardness, tensile strength,and thermal conductivity first, whether it can meet your CNC machining project requirements.

4.2 CNC machining metals machinability

Learn about whether the metal is easy to be machined or not. Some metals, like aluminum, brass, low carbon steel are known for their excellent machinability, which can reduce production time and cost.

4.3 CNC machining metals use an environment

Some applications may require metals with specific environmental resistance, such as resistance to corrosion or high temperatures, for example, marine industry applications. Under this circumstance, stainless steel and titanium is a better choice.

4.4 CNC machining metals post-treatment

Do your CNC machined parts need special surface finish treatment after machining? Surface finish treatment can increase the cost and must be taken into consideration. The right CNC metal with as machined surface finish can save the surface finish cost.

5. Conclusion

This article discussed factors influencing CNC machining cost-effectiveness, the common CNC machining metals, the most cost-effective cnc machining metals, and factors to consider when choosing CNC machining metals.

There are a lot CNC machining materials including plastics, metals, and others. It is important to choose an experienced manufacturer for your CNC machined parts.

6. FAQs

6.1 What is the most cost-effective metal?

Aluminum and mild steel are considered to be the most cost-effective metals because of low raw material and excellent machinability.

6.2 What is the cheapest manufacturing metal?

Low-carbon steel is the cheapest manufacturing metal. Q235, A3 steel has a very low material price.

6.3 What is the best metal for machining?

Aluminum is one of the best metal materials for metal CNC machining. Asides from its inexpensive nature, this metal also has an ideal strength-to-weight ratio and high performance, making it ideal for lightweight machining parts.

6.4 What is the best low-carbon steel for machining?

Q235 is the best low-carbon steel for cnc machining for its inexpensive cost and good machinability.

6.5 What is the most machinable tool steel?

A2, O2, S7 are all commonly used tool steel in CNC machining.

6.6 Is Aluminum or stainless steel better for machining?

Aluminum CNC machining is easier than stainless steel cnc machining because the later has higher strength and hardness.

6.7 Which aluminum is best for machining?

AL6061-T6 is the most widely used aluminum grade in CNC machining.

6.8 What metals are cheaper than aluminum?

Low and mild carbon steel is cheaper than aluminum.

6.9 Why does titanium have poor machinability?Can titanium be CNC machined?

Titanium can be cnc machined but with poor machinability because titanium has super high strength and hardness. Titanium cnc machining requires special cutting tools and expertise.

Let's get your projects started, together!

Get custom parts machined in high quality, delivery on time.