What is 3d Printing? How Does it Work?

Updated: June 08, 2024

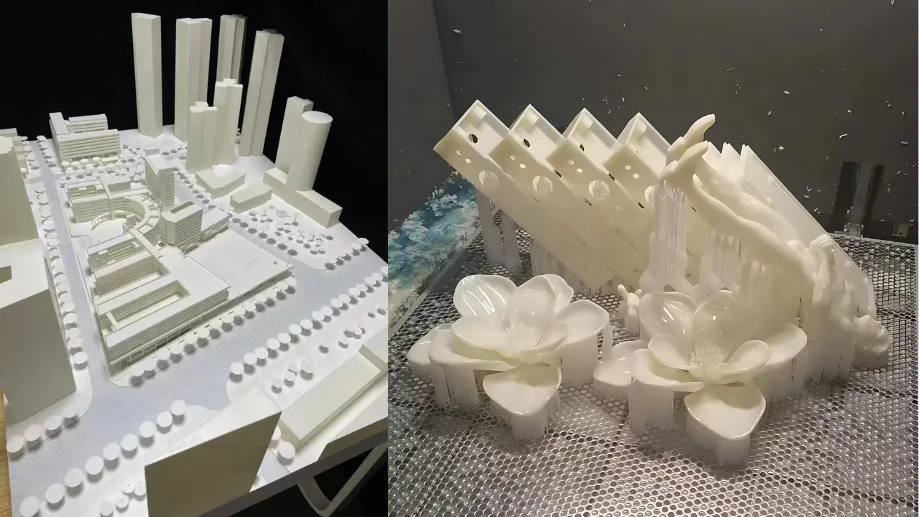

3D printing uses technologies such as FDM, SLA, and SLS to transform digital designs into physical objects by adding materials layer by layer. This post will go into detail about 3D printing in terms of what 3D is, what technologies it has, and what materials it can process.

What is 3d Printing?

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects layer by layer using computer-aided design (CAD). Unlike traditional subtractive manufacturing methods that remove material from a larger block, 3D printing adds material only where needed, minimizing waste.

It allows for the production of complex geometries and customized parts, making it a valuable tool in various industries such as engineering, healthcare, and aerospace. The technology involves converting digital models into physical objects by depositing materials like plastic, resin, or metal in precise layers.

What is 3D Printing Technology?

Three-dimensional (3D) printing works by laying down thin layers of materials, such as liquid or powdered plastics, metals, or cement, and then fusing these layers. Below are the key types of 3D printing technologies:

Stereolithography (SLA)

Stereolithography (SLA) uses a laser to turn liquid resin into hardened plastic through photopolymerization. SLA printers create precise, water-resistant prototypes and parts with fine details and smooth surfaces. This technology is perfect for making accurate prototypes, molds, patterns, and functional parts that need tight tolerances and smooth finishes.

Selective Laser Sintering (SLS)

SLS 3D printers use a high-power laser to sinter polymer powder particles into solid structures. The unmelted powder supports the part during printing, allowing for complex designs with internal features, recesses, thin walls, and negative spaces. SLS offers good mechanical properties. Common materials include nylon, which is lightweight, strong, flexible, and resistant to impact, chemicals, heat, UV, water, and dirt.

Multi-Jet Fusion (MJF)

MJF is a form of powder bed fusion that uses a robotic arm to deposit powder with selective use of binding and refining agents to ensure precision. Heat is then applied to induce a chemical reaction that solidifies the powder into the desired shape.MJF is commonly used to produce functional prototypes and end parts.

Fused Deposition Moulding (FDM)

Also known as Fused Filament Fabrication (FFF), FDM works by extruding thermoplastic filaments, such as ABS or PLA, layer by layer through a heated nozzle onto a build platform. fDM is well suited for basic conceptual models and rapid, low-cost prototyping of simple parts. However, it has the lowest resolution and accuracy compared to SLA or SLS and is not suitable for complex designs.

Selective Laser Melting (SLM)

Selective Laser Melting (SLM) uses lasers to fuse metal powders to create high-strength, high-density metal parts. This technology is used to produce fully functional metal parts and is commonly used in industries such as aerospace and automotive where high-performance parts are required.

What Material is Used in 3d Printing?

3D printing involves a variety of materials, including plastics, powders, resins, metals, and carbon fiber. Below is a brief description of these materials:

1. Plastics

Plastics are the most commonly used materials in 3D printing today. They are versatile, and durable and come in a variety of colors and finishes. Common types of plastics include

Polylactic Acid (PLA): PLA is an environmentally friendly material made from natural products such as corn starch and sugar cane, and is biodegradable. It is available in both soft and hard forms and is suitable for a wide range of products. Read: How to Get the Best Setting for PLA

Acrylonitrile Butadiene Styrene (ABS): Known for its strength and flexibility, ABS is popular in home 3D printers. It is used to make products such as toys and stickers and is often referred to as “Lego plastic”.

Polyvinyl Alcohol (PVA): Used in low-end home printers, PVA is a dissolvable support material that can be used for complex prints.

Polycarbonate (PC): PC is used in 3D printers with high-temperature nozzles and can be used to make low-cost plastic fasteners and molded trays.

2. Powder

Advanced 3D printers use powder materials that are melted and layered to create the desired shape. Common powder materials include

Polyamide (nylon): Known for its strength and flexibility, nylon is ideal for printing fine models and interconnected parts.

Aluminum Compounds: Aluminium compounds are blends of polyamide and aluminum used to create robust 3D-printed models with a grainy appearance.

Resin

Resins are less commonly used because of their limited flexibility and strength compared to other materials. They are made from liquid polymers that solidify when exposed to UV light. Types of resins include

Highly Detailed Resins: Used for small models that require intricate detail, such as clothing and miniatures with detailed facial features.

Paintable Resins: Known for their smooth surface, they are often used for aesthetic parts.

Transparent Resin: The strongest type, used for items that require a smooth feel and transparent appearance.

4. Metal

Metals are the second most popular material for 3D printing and are mainly used for direct metal laser sintering (DMLS). This process is popular in aerospace and manufacturing due to its ability to produce complex parts quickly and efficiently. Commonly used metals include

Stainless Steel: For parts that come into contact with water.

Bronze: Used for decorative items such as vases.

Nickel: Suitable for printed coins.

Aluminum: For thin metal items.

Titanium: Suitable for strong and durable parts.

5. Other materials

Carbon Fiber: Used as a surface coating on plastic materials to increase strength. In some applications, it can be a quick and easy substitute for metal.

Graphite and Graphene: These materials are high-strength and electrically conductive, making them suitable for use in flexible device components and solar panels.

Nitinol: A nickel-titanium alloy is more flexible and is suitable for medical implants and products that require a high degree of flexibility.

Why 3d Printing is Important?

Because 3D printing does not require a mold, manufacturers can reduce the time it takes to produce parts, bypassing the time-consuming and costly step of producing a mold. Here are some of the benefits of 3D printing:

Reduced Production Time: 3D printing eliminates the need for molds, greatly reducing the time required to produce parts and speeding up the manufacturing process.

Cost-effectiveness: 3D printing is very economical in producing complex parts, reducing material waste, and minimizing production costs.

Design Flexibility: 3D printing enables rapid prototyping, which allows for quick design changes, often within a week.

On-demand Production: 3D printing supports on-demand production, allowing physical parts to be produced from digital files in a matter of hours, reducing inventory requirements.

Complex Geometry: 3D printing enables innovative designs by creating complex parts that cannot be produced by traditional methods.

How Does 3D Printing Work?

3D printing, also known as additive manufacturing, creates a physical object from a digital design by adding material layer by layer. Here’s a step-by-step explanation of how it works:

Step 1 Creating a Digital Model

- Design Software: Use CAD software like AutoCAD, Blender, or Tinkercad to create a 3D model.

- Download a Model: Alternatively, download pre-made models from repositories like Thingiverse or MyMiniFactory.

Step 2 Convert the Model to STL Format

- Exporting: Convert the 3D model to STL format, the standard for 3D printing.

- Checking the File: Use software like Meshmixer to repair any issues with the STL file.

Step 3 Slice the Model

- Slicing Software: Use software such as Cura, Slic3r, or PrusaSlicer to convert the STL file into G-code.

- Setting Parameters: Set parameters like layer height, print speed, temperature, and infill density.

Step 4 Prepare the Printer

- Loading Filament: Load the printer with filament (e.g., PLA, ABS, PETG).

- Leveling the Bed: Ensure the print bed is level to avoid printing issues.

Step 5 Start Printing

- Uploading G-code: Transfer the G-code file to the printer.

- Printing Process: The printer builds the object layer by layer, extruding melted filament.

Step 6 Post-Processing

- Removing the Print: Carefully remove the printed object from the print bed.

- Cleaning: Remove any support structures or excess material.

- Finishing Touches: Sand, paint, or polish the object as needed.

Conclusion

3D printing, or additive manufacturing, creates objects layer by layer from digital designs using materials like plastics, metals, and resins. It reduces production time and costs, enables complex designs, and supports on-demand manufacturing.

ECOREPREP offers services based on five different printing technologies (SLA, SLS, MJF, FDM, SLM). For all inquiries regarding 3D services, we will let our team of specialized application engineers help you choose the right material for your respective needs. To use and consult your project, please contact us.

Let's get your projects started, together!

Get custom parts machined in high quality, delivery on time.