Table of Contents

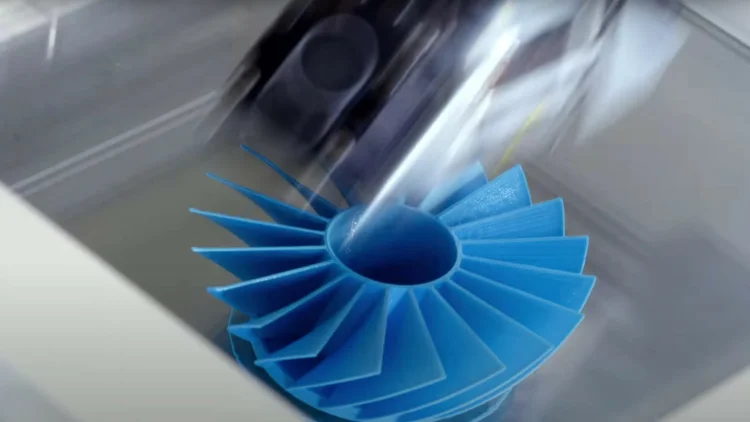

If you are new to 3d printing, maybe you note that it is hard to balance the printing speed and quality.

When you use a faster printing speed, the quality of 3d print will not so good. Either, slow speed means that you need to spend much more time. In this post, we will explain the details of 3d printing speed and how to get the best setting for PLA.

What is Speed Setting in 3d Printer?

When we talk about the 3d printing speed, most of us think that it is the moving speed of the extruder. They move around from one layer to another. The faster or slower decide the printing time for the part. Actually, it’s not.

To get good quality print, we need to set the best setting for speed. The speed contains so many parts; extruder speed is just one of the most speed types.

Print Speed

3D print speed is the primary speed setting that will take effects on 3d prints. As the name “print speed” implies, it determines the speed at which your printer motors move. And these motors comprise the extruder motors and the X and Y axis motors. Note that the outcome of your printing mainly depends on the selected print speed.

Now let’s break down the complexity of the print speed. The setting of the print speed has four sub-settings, which are;

- Infill speed: The print speed reduces the printing duration with quality printing strength.

- Outer wall shell speed: It reduces slightly to boost the quality of the surface of the print.

- Inner wall shell speed: It works to reduce the time spent on printing while sustaining the strength of the print.

- Top/Bottom speed: Generally, it is slightly reduced to boost the prints’ surface quality.

Travel Speed

Travel speed is the speed rate of the 3D printer’s print head when it is not extruding plastic. Increasing the travel speed can drastically reduce the duration used in printing. But too much increase of the travel speed can result in a misaligned layer of the model or print failure.

Retraction Speed

Travel speed is the speed rate of the 3D printer’s print head when it is not extruding plastic. Increasing the travel speed can drastically reduce the duration used in printing. But too much increase of the travel speed can result in a misaligned layer of the model or print failure.

Shell, Infill, and Layer Height

3d printer speed not only decides by “speed” alone and is also affected by the extruding thickness and plastic of each layer. So, let me briefly tell you some general information about how each of these concerns the speed rate of your print.

1. Shell thickness: In this setting, the extruded plastic use to forming the outlines of the 3D model. An increase in the shell thickness will not only result in increased consistency and strength. But also cause a notable increase in the print duration.

2. Infill: This describes the inner structure of the 3d model. The density of this internal structure has a remarkable effect on the print speed. Higher infill density will lead to higher strength and longer print time.

3. Layer Height: This influences how quickly your print will finish. The higher your layer height, the thicker each layer of your 3D prints and the shorter the print duration. Adjust your layer based on the required print resolution.

How Do I Get the Perfect Print Speed Settings?

The best way to get the perfect print speed of your 3D printer is by starting it at the default speed setting. That’s 60 mm/s and then increasing it by five mm/s. These are settings that you arrived at after consistent trial and error on the test prints. The perfect print speed setting entirely depends on the type of print you are settling to go for.

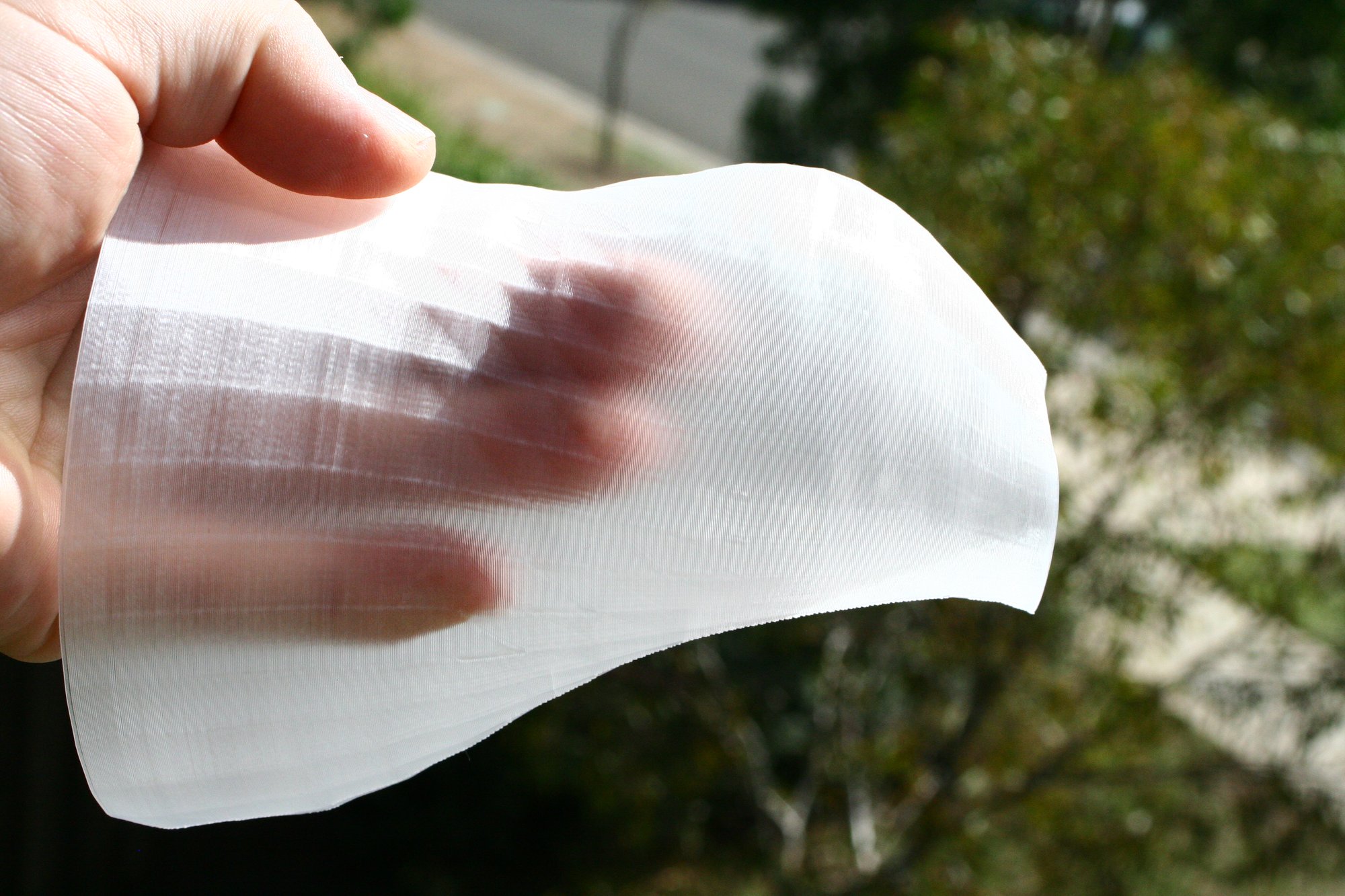

If your print speed is set to a very high speed, it may result in overheating due to insufficient cooling. If your print speed is set at a low rate, it may result in the deformation of the prints. This deformation is a result of the extended setting of the nozzle on the plastics. Hence, always consider the print’s temperature and the thickness of your filament.

The materials also play a critical role in the perfection of your print speed. Some materials enable you to in an instant and get incredible quality.

What is a Good Print Speed for PLA?

A good print speed for PLA is a spot that gives it a good balance of print quality and speed. And this falls between 40-60 mm/s range. Based on your 3D printer setup, type, and stability. Your PLA speed rate can reach 100 mm/s and above easily. When compared to Cartesian, Delta 3D printers are going to permit higher speeds.

I’d recommend sticking to this range. But there are instances where using higher print speed and the results were fantastic. The low maintenance nature of PLA allows increased speed without risking the quality as well. But don’t over increase the speed.

Does Print Speed Reduce Print Quality?

There have been several numbers of controversies on the effects of speed on the quality of a print. Generally, when you are yet to optimize your printer, lower rates make 3d printers better quality. But a high speed has a more negligible effect when you have fully optimized your 3D printer. This optimization is a result of knowing how to set the printer’s settings. That will directly affect 3D printing speed without compromising the print’s quality.

If you use lower infill settings, will your print strength be reduced? The less infill you use, the less strength of your prints. Like I have said earlier in this post. When the print speed is too high, it will result in print failure and most likely render the print useless.

When you have, using the recommended 5mm/s increment for adjusting it. It will be much easier for you to detect the best speed rate for your printer with excellent quality.

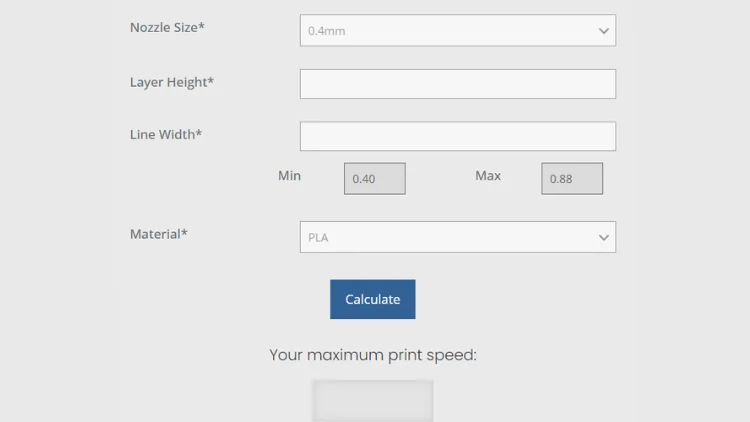

3d Printing Speed Calculator

The printing speed calculator is a digital calculator available on the Internet. It is designed to solve 3D printing speed settings and related challenges, which are printer configuration or finding the best parameters for their desired speed.

This calculator helps you find the maximum printing speed that you can reach with the current structure of your 3d printer. Enter your layer height, nozzle size, and line width, and choose the material you will be printing.

Factors Influencing 3D Printing Speed

- Layer Height: Smaller layer heights provide finer prints but take longer.

- Print Speed: Measured in millimeters per second (mm/s), this is the speed at which the printer head moves while extruding filament.

- Infill Percentage: More infill means more material, increasing the print time.

- Model Complexity: Complex models with many overhangs or supports require slower speeds to ensure quality.

- Printer Capabilities: Different printers have varying speeds and capabilities that can affect output times.

Average 3d Printing Speed

The average speed of a 3D printer depends on the type of printer and the material being used.

3D printing material | Typical print speed | Upper limit |

PLA | 60 mm/s | 150 mm/s |

ABS | 60 mm/s | 60 mm/s |

PETG | 50 mm/s | 60 mm/s |

TPU / flexible filament | 20 mm/s | 20 mm/s |

Nylon | 40 mm/s | 50 mm/s |

How Fast Does a 3D Printer Print?

It depends on the material you are printing. Like how large the part is, what orientation it is in, the alignment of your print object, and the internal support style. Materials-wise, the weaker and cheaper materials you use, the faster it will get the print done. PLA is usually quicker to print but is not as heat resistant or tough as ABS.

Although some things are so small that the printer can get it done in a couple of minutes, some other prints can take a couple of days to print. So one of the most significant factors is time. More material = more time.

Orientation can also have a significant effect on it. The more vertical layers you have, the longer the print will take. How fast your printers print also depends on the internal support. What you are making matters, but for you to decide. It highly depends on what you need or wants in terms of speed versus strength.

And if it sometimes has to go fast, the quality can easily compromise. You can get better results in 3D printing at lower speeds. But you will get the best result when it is optimized.

Summary

Suppose you use the correct printing speed and suitable materials. 3D printing can be efficient and effective. There are no specific settings to get the best result. It differs from different types of material and printers.

You should print test prints inconsistently. It is the only method to get the best setting.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He also spent three years in CNC engineering, quoting, design, and project management. Lucas holds an associate degree in mold design and has self-taught knowledge in materials science. He’s a lifelong learner who loves sharing his expertise.