- Capabilities

-

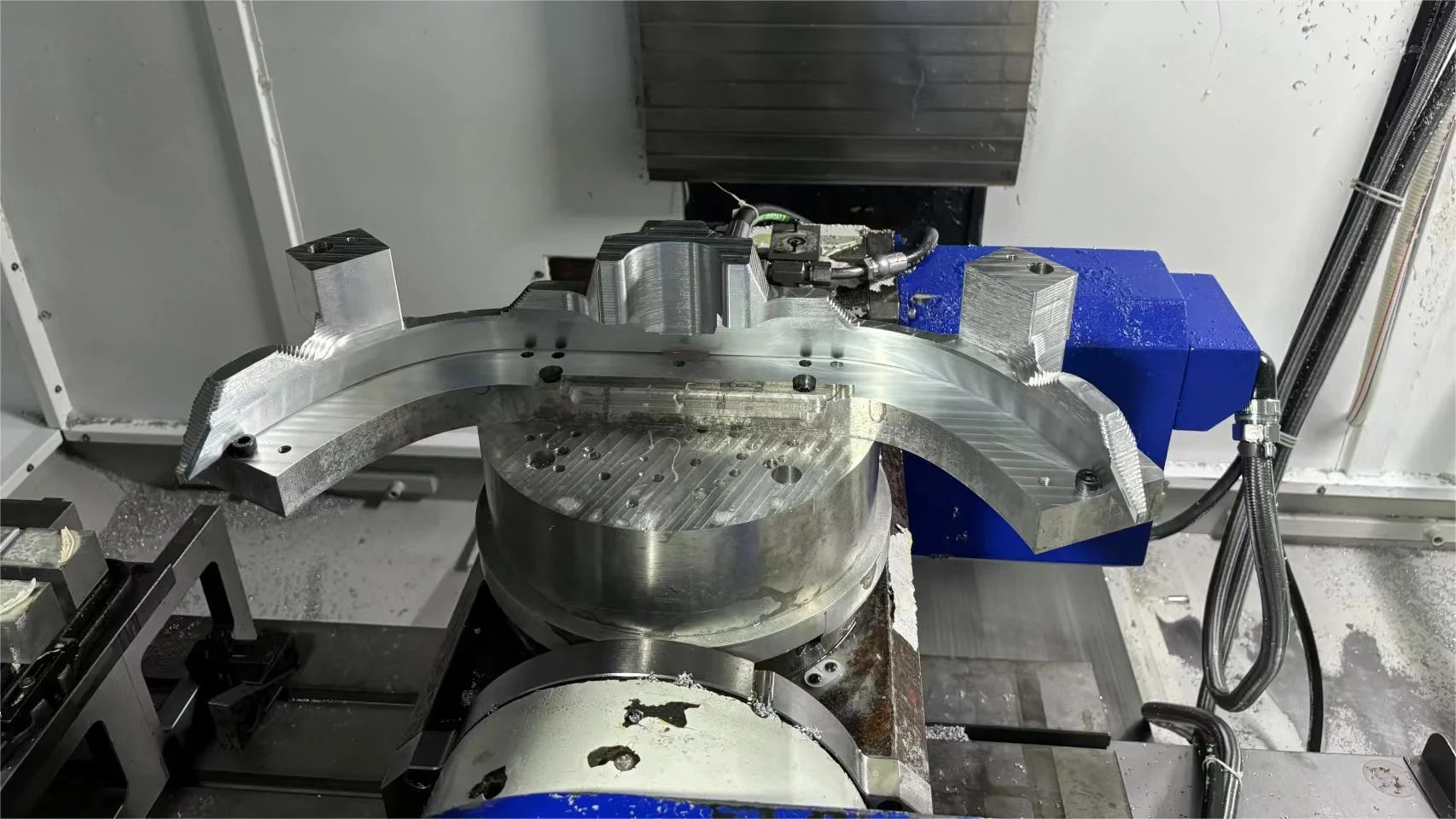

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

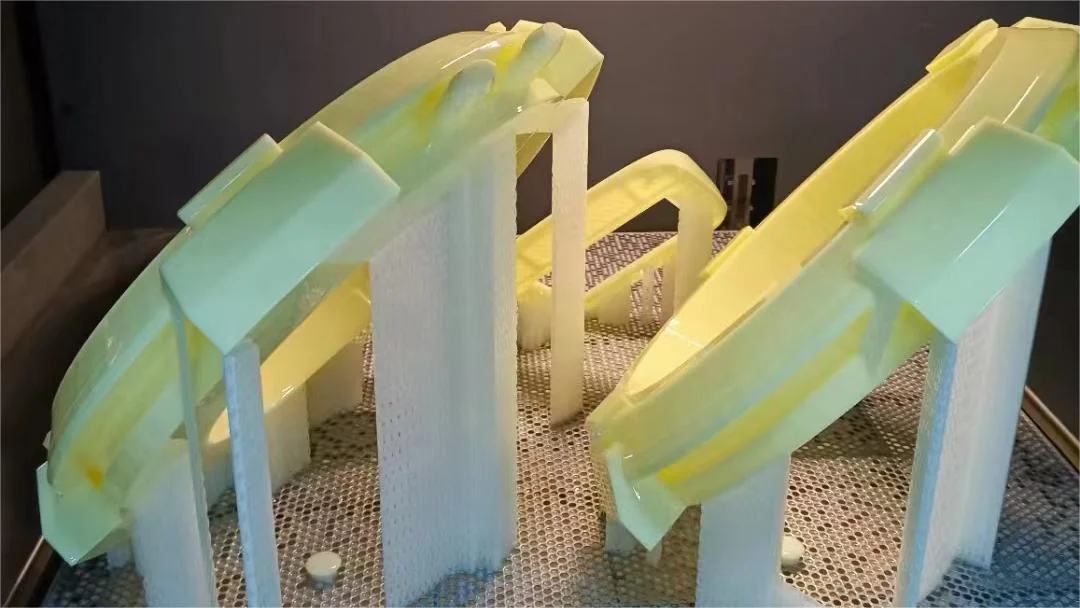

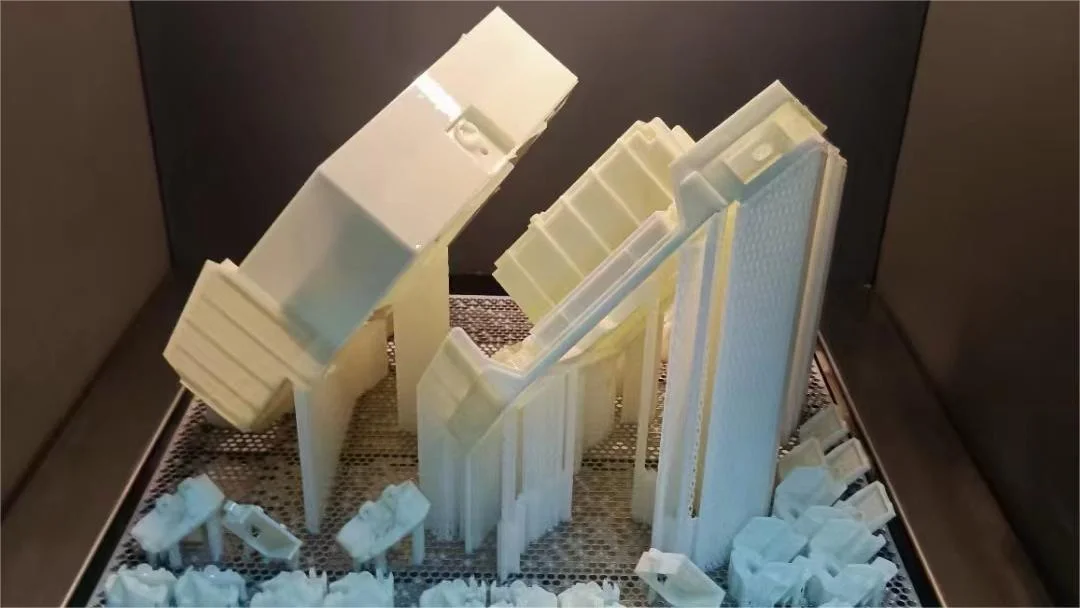

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

What is a rapid prototype in business?

Updated: Mar. 10, 2024

Rapid business models allow businesses to envision and test their ideas before pursuing full-blown manufacturing. Prototypes are vital to item growth processes. They confirm principles, discover design imperfections, gather individual comments, and perform any required adjustments or model procedures.

Rapid prototyping uses modern technologies such as 3D printing, computer-aided layout (CAD), and simulation to promptly and cost-efficiently generate physical or electronic models. Prototypes can vary from fundamental mockups to reasonable representations of end products.

1. Definition of Rapid Prototype in Business

Quick prototypes are substantial physical or digital depictions created to demonstrate and confirm a service or product concept before going into complete manufacturing.

It assists services in visualizing, testing, and refining their ideas, inevitably improving the end product design, minimizing risks, and improving customer experience.

Types of Rapid Prototypes

A fast prototype can take numerous types, depending on the nature of the services or product being developed.

It could be a physical model built utilizing additive manufacturing methods, where a 3D printer develops layer-by-layer structures based on an electronic design.

Additionally, it can be a digital prototype developed via CAD software application, enabling services to mimic and engage with the item in a digital environment.

Objectives of Rapid Prototyping

The primary goal of developing a rapid prototype in a business context is to gather responses, make necessary iterations, and verify the item idea before spending substantial resources in full-blown production.

By presenting a concrete depiction, services can involve prospective customers, stakeholders, and end-users, seeking their input and insights.

Benefits of Rapid Prototyping in Business

The advantages of quick prototyping in a business context are multi-fold.

It aids companies in identifying style problems, usability issues, and manufacturing difficulties at an early stage, minimizing dangers and costs related to alterations throughout later growth stages.

Fast prototyping also makes it possible for services to make educated choices on products, capability, and appearances, ensuring that the final product satisfies customer expectations and stands apart in the marketplace.

Role of Rapid Prototyping in Product Development

Fast prototyping plays a crucial duty in the item growth process by increasing time to market, minimizing threats, and boosting product top quality.

It assists in efficient interaction and cooperation within cross-functional groups, aligning purposes and simplifying the growth procedure.

By leveraging quick prototyping in the business context, organizations can iterate promptly, get critical feedback, and make data-driven choices that bring about successful product launches and consumer satisfaction are ta depictionsgible depictions, physical or electronic, produced to show and validate a product and complete ice ideas before entering into complete manin picturing.

It assists businesses picture, examining, and refining their ideas, inevitably boosting the final product design, decreasing dangers, and boosting individual experience. Relying on what you’re prototyping, quick prototyping takes different forms.

Using additive manufacturing strategies, 3D printers construct software programs that can create a CAD program to make a digital model, letting organizations mimic and communicate with the item practically.

Rapid prototyping objectives

Producing a quick model in the business context is all about obtaining comments, making models, and confirming the idea before engaging in production. Engaging potential clients, stakeholders, and individuals is easy by presenting a tangible depiction.

There are a lot of advantages to rapid prototyping in service.

By determining style flaws and usability concerns early, businesses can decrease prices and risks connected with adjustments during later advancement stages.

Prototyping also assists companies in deciding what products, functionality, and looks to utilize so the final product fulfills consumer expectations and attracts attention.

Rapid prototyping quickens the product development procedure, lowers dangers, and improves item top quality.

This assists cross-functional groups in communicating and collaborating, lining up purposes, and enhancing advancement.

Quick prototyping aids organizations to repeat quickly, get beneficial responses, and make data-driven decisions that cause successful item launches.

2. Prototyping vs. Traditional

There are numerous critical differences between quick prototyping and traditional prototyping:

Speed and Time

The creation and version of prototypes are faster with fast prototyping than with conventional techniques.

The company can develop prototypes faster with 3D printing and CAD modern technology, lowering style, building and construction, and assessment time.

Cost Efficiency

The creation and version of prototypes are faster with fast prototyping than with conventional techniques. The company can develop prototypes faster with 3D printing and modern CAD technology, lowering style, building and construction, and assessment time.

Iterative Design Process

Quick prototyping motivates a repetitive style process so that you can rapidly make changes and enhancements. Executing changes and alterations in standard prototyping is more complex and much more costly.

Material Options

A typical prototyping method limits material options to what’s conveniently available for manual construction. Fast prototyping, the user’s hand, enables you to use ics, metals, composites, and bio-compatible materials.

Visualization and Testing

Fast prototyping lets you visualize and test principles a lot more properly. Organizations can imitate and examine electronic prototypes with computer-aided design software. It aids in identifying prospective issues early on when you can imagine and examine principles electronically.

User Engagement

Getting responses from individuals is easier when you use rapid prototyping.

Customers’ stakeholders examine and refine the item by making physical or electronic prototypes.

3. Benefits of Rapid Prototyping in Business

These are a few other benefits and worth rapid prototyping brings:

Faster time to market

Fast prototyping speeds up the process of bringing products and services to market. By rapidly repeating and improving models, services can address layout problems, usability problems, and obstacles. Adjustments and renovations can be made quicker, lowering overall development time and getting items to market faster.

Save money

There are several ways fast prototyping conserves businesses’ cash. First, it minimizes the risk of investing much money in a poorly received service or product.

With prototyping, companies can collect comments and validate concepts before making pricey mistakes.

In addition, quick prototyping methods like 3D printing are cheaper than standard prototyping because they require less manual work.

Design and functionality improvements

A physical or electronic prototype can help companies examine and refine their products. Using quick prototyping, companies can imagine and test different style options, recognizing and addressing style defects, ergonomic problems, and use troubles.

Additionally, it advertises a repetitive design procedure so that you can quickly adjust and improve based on comments.

Engaged and satisfied users

Quick prototyping makes it easy to involve individuals in the item advancement process. Businesses can collect responses and insights early by offering tangible models to users, stakeholders, and clients. By doing this, they can line up the product layout with customer needs and choices, resulting in higher customer satisfaction and a higher chance of success.

Quick development procedures and quick prototyping promote interaction and partnership between cross-functional groups in the product development procedure.

With a prototype, stakeholders from different divisions, like layout, design, production, and marketing, can align their goals. As a result, product growth is much more effective, with far better synchronization, faster decision-making, and streamlined processes.

Advantages

Companies can acquire one-upmanship by using fast prototyping. By quickly repeating and refining prototypes, they can react faster to market changes and demands. In addition, quick prototyping lets services introduce and bring disruptive products to market more quickly, helping them complete and capture market share.

4. How Rapid Prototyping Works?

Rapid prototyping involves these steps:

Step 1: Create a concept

Prototyping starts with an idea or principle for a product. It can originate from customer responses, marketing research, or internal thinking.

Step 2: 3D design

The following action is to produce a 3D model. You use a computer-a to do this idea design (CAD to do this) software program. For accurate sizing, measurements, and requirements, the 3D version is the basis for producing the physical prototype. We’ll make a physical prototype as soon as possible.

Step 3: Make a prototype. We’ll make a physical prototype.

Rapid prototyping technologies like 3D printing, CNC machining, or laser selection are typically utilized.

Based on the material chemotype, we select an innovation.

Step 4: Testing the Model

After that, the model is tested and examined.

This step tests the prototype against style specs, and customer needs for capability, sturdiness, use, and performance. Whether the screening and assessment are done internally or by an outdoor company depends on you.

Step 5: Modifications and iterations

Throughout screening, the model style is customized and fine-tuned based on comments.

During this version, there’s a particular order that not only enhances and ensures the item’s future success the item’s future successful product. The last prototypes are p to make the toughly to make the item. Fast prototyping improves time to market, lowers advancement costs, and boosts top quality.

5. Rapid Prototyping Iteration

Here’s why iteration and feedback are essential in rapid prototyping:

Optimizing Design

Version and responses are crucial to enhancing product layout. Developers can identify locations that require improvement by making multiple models and obtaining comments from individuals.

This iterative process improves the style used and repairs visual or functional troubles.With comments integrated into succeeding iterations, the layout can get better and far better.

Reducing Risks

Rapid prototyping involves creating and testing multiple product iterations before going to mass production. Identifying and mitigating potential risks early on is possible by gathering feedback at every stage. Before resources are committed to full-scale production, this approach helps identify flaws or shortcomings in design. You’ll avoid costly issues by addressing these issues early on in redesigns or market rejection.

Enhancing User Satisfaction

Models and responses aid companies in making items that match consumer choices and needs. During prototyping, you can get responses from customers to understand what they want. With this info, you can make iterative renovations to the product, leading to more satisfied users. The more user comments services take into account, the more user-centric layouts they can create.

Validation and Proof of Concept

Iterations and responses help validate and improve the concept. Making models and asking users and stakeholders for responses can assist businesses in identifying if their ideas are sensible and appealing.

Comments on functionality, features, and value recommendations aid in evaluating market needs. As a result of this recognition process, the end product aligns with market requirements and is most likely to do well.

Continuous Improvement

Quick prototyping enables constant renovation and development. As the product improves, feedback is this continuous improvement mindset that fosters innovation and creativity through every iteration. Motivating new ideas and f thinking fosters innovation and creative thinking.

Doing this ensures the end item isn’t stationary but regularly developing to fulfill your customers’ needs. In the product advancement procedure, iteration and responses contribute to time and cost performance. Determining style flaws and using troubles early can save organizations from revamping and manufacturing delays later.

Fast prototyping allows you to make changes and changes promptly, reducing redesigns and corrections. The product advancement process can be optimized by gathering responses and iterating, saving resources and accelerating the procedure.

Business Advantage

Fast prototyping includes version and feedback. They can remain ahead of rivals by constantly refining and improving their products. Gathering feedback and iterating responses and promptly permitting vers, and responsive iteration is required to choose a rapid prototyping company.

6. How to Select a Prototyping Company

Here are a few things to look for when selecting a fast prototyping company:

Experience and expertise

Find a fast prototyping company with experience in the sector. Look at the company’s portfolio and client testimonials, and study to see if they can provide premium prototypes. You’re more likely to get outcomes you enjoy if you collaborate with an experienced firm.

Capabilities in technology

Please look at the prototyping business’s technological capacities, including their prototyping strategies and materials. Inspect if they have 3D printers, CNC machines, or shot molding. Companies with diverse technological capabilities can offer different prototyping solutions. Prototyping solution companies with various technical capabilities can offer other prototyping solutions and quick prototyping businesses that supply modification choices.

See to it you can collaborate with different materials, develop models of various sizes and intricacy, and accommodate any one-of-a-kind layout demands. With customized prototyping solutions, you can accomplish the preferred result.

Speed and turnaround

When it comes to rapid prototyping, it’s all about speed, so think about the business’s turnaround time. Ensure they can satisfy your tight target dates and inquire about a prototyping company that has efficient processes to about prototyping company should have efficient processes. The prototyping company should have efficient processes and capability.

To ensure quick service, a prototyping company should have efficient processes that are top quality; a prototyping business needs to be on course and quicken product development.

QA & Testing

Choose a business that highlights quality assurance and screening throughout the prototyping process. Ensure the models meet industry standards and your specifications by asking about their quality control steps, examination treatments, and testing protocols. Prioritizing quality control can aid businesses in determining prospective issues early, leading to higher-quality models and a smoother production process.

Budget & Costs

Ensure the quick prototyping business’s price and framework fit your budget plan. Get quotes, compare prices and versions, and find out if there are any extra fees. Remember that quality and service are just as crucial as expense. Make sure your chosen company has affordable prices without endangering top quality.

Communication and support

Look at how the prototyping firm deals with customer assistance and interaction.

Prototyping companies ought to be responsive; you need good communication with parents and going to work. It would be best if you had good communication to close. It would be best if you had good communication with yourself. To clarify task demands, you need good communication, too. Choose a business communication that values consumer connections.

Reviews and Reputation

Ensure the quick prototyping company has an excellent track record by checking online testimonials, endorsements, and referrals.

QA company with favorable credibility will most likely provide quality solutions and reliable prototypes. Seek reviews highlighting the firm’s professional know-how, and confidently choose a prototyping partner, a prototyping partner, or a prototyping partner with self-confidence if they have an excellent track record. You can choose a prototyping partner with self-confidence if they have an excellent track record.

Let's get your projects started, together!

Get custom parts machined in high quality, delivery on time.