What is annealing peek for machining?

Updated: Mar. 23, 2024

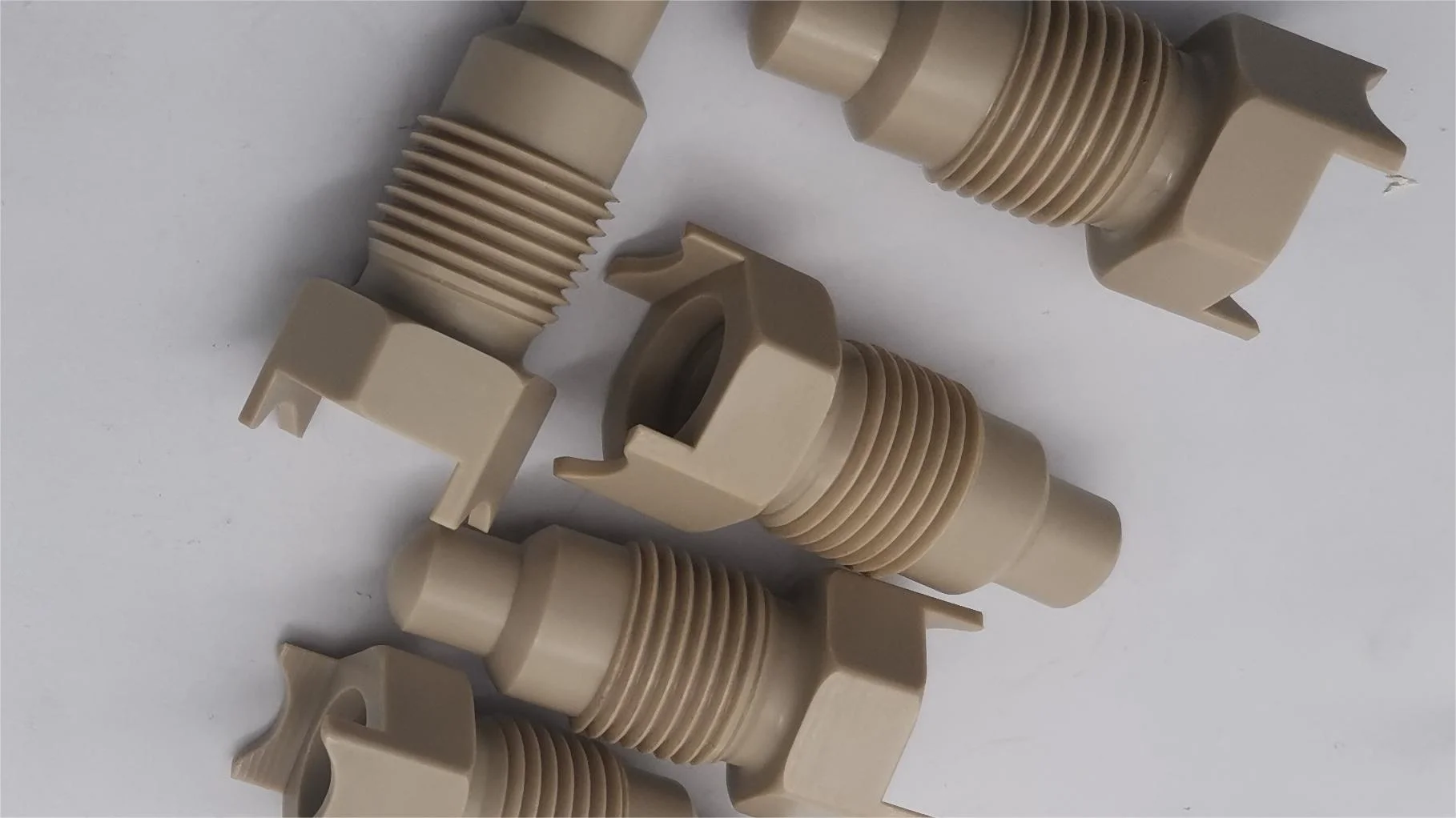

Annealing PEEK for machining means heating PEEK to a certain temperature to soften and relieve stress before CNC machining. It will make PEEK greater machinability, prevent cracks on the surface, and avoid other imperfections and weak points.

We will further explore the topic of PEEK annealing, why PEEK needs annealing, what the benefits of annealing are, and what the annealing process is.

Finally, we will also discuss whether there are any other ways to remove stresses from PEEK during CNC machining besides annealing.

1. Is it a must to anneal PEEK before CNC machining?

The answer is no. PEEK is a high-performance engineering plastic with good machinability. The general structure of the processing does not need its aging treatment, but the following concentration of circumstances, need to be before machining or rough machining, its aging treatment.

Situation 1: To process the PEEK zero not called longer, or the size is relatively large, easy to process excessive stress or deformation, so that, after the rough machining process, the need for annealing treatment, to eliminate its stress.

Situation 2: The wall thickness of PEEK parts is relatively thin.

Situation 3: PEEK parts require not called high surface flatness, there are more strict tolerance requirements.

The heat generated during CNC machining, or too much reduce in a single pass, or a tool that is not sharp enough, will generate stress, especially under the above three cases. The generation of stress will affect the dimensional stability of the part meet dimensional or performance requirements.

2. What are the benefits of annealing PEEK?

We need to first understand the dangers of stress during processing.

- The material is prone to deformation or warpage.

- The material’s properties are reduced.

- Cracking of the material occurs.

- The dimensions of the final product cannot meet the tolerance requirements.

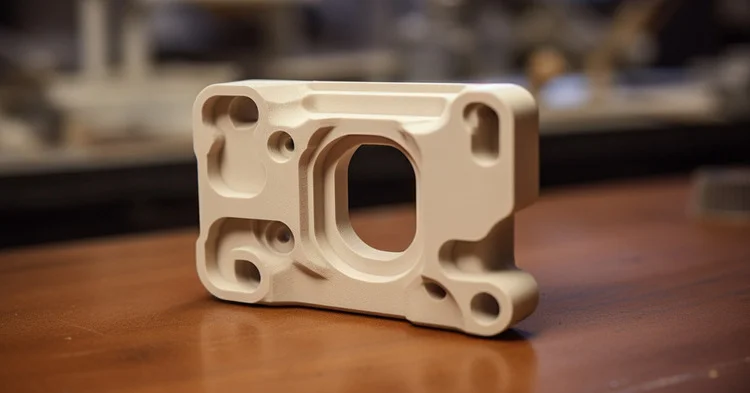

After stress is relieved, PEEK parts can achieve better flatness and tighter tolerances. Intermediate annealing is often required for parts requiring precision flatness and asymmetric contours. Flatness is improved by roughing, annealing and finishing with very low tool draft. Balanced machining on both sides of the shape centerline also helps prevent warpage.

3. How to anneal PEEK?

Here are brief steps for the annealing peek.

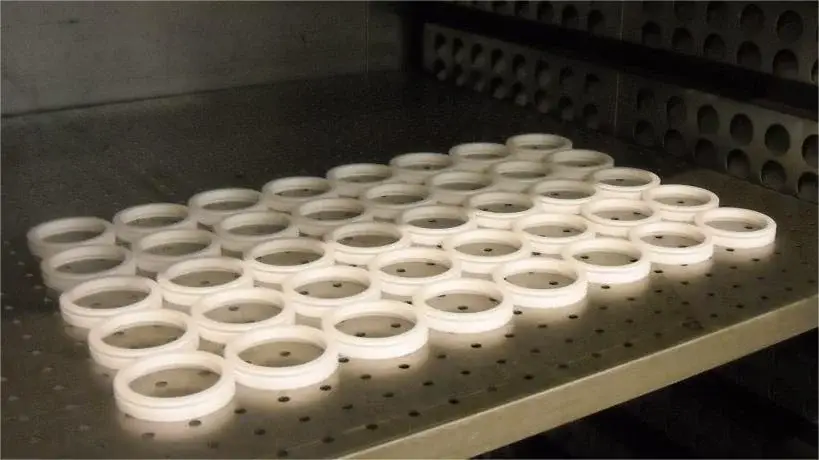

Step 1: Place PEEK material in air circulating oven such that air can circulate them.

Step 2: Heat the oven to 300 Fat a maximum heating rate of 20 F per hour.

Step 3: Hold oven temperature at 300F for 120 minutes plus 30 minutes for every 1/8″ of cross-section.

Step 4: Heat oven to 390°f at a maximum heating rate of 20°f per hour.

Step 5: Hold oven temperature at 390F for 2 hours plus 30 minutes for every 1/8″ of cross-section.

Step 6: Cool oven to 150° over 25 hours with a maximum cooling rate of 10’f per hour turn off oven and allow to cool to room temperature before removing PEEK.

4. Other methods to relieve stress

Besides annealing PEEK, what other methods are available for PEEK stress relief?

In addition to annealing PEEK, there are two other methods of removing stress from PEEK during CNC machining.

The first method is to take the roughly machined PEEK off the machine and leave it in the air for a few hours or a day or two before finishing it.

The second method is to hold the PEEK part at a stable temperature for a period of time to allow it to equilibrate at a certain temperature, which helps to reduce stress. Often the PEEK material is placed in warm water at a constant temperature for this operation.

This article details the specific steps that are extremely advantageous for annealing PEEK before machining or after rough machining, as well as two additional methods for removing stress from PEEK CNC machining. Through these three introductions, the stress can be effectively released to obtain dimensionally accurate PEEK machined parts.