Choose the right material for your CNC machining project

Updated: December 06, 2023

Introduction

The widespread difficulty with handling a CNC machining project – choosing the right material. Failure to select a material that suits an intended component always results in poor manufacturing outcomes.

To avoid such mistakes, you should know more about choosing CNC machining materials. Also, it would be great if you compliment your knowledge of common CNC machining materials. For this purpose – read this post to the end.

1. Key Considerations for Choosing CNC Machining Materials

Basically, you can guide your decision regarding CNC machining materials choosing based on four factors. Here are our recommendations regarding them:

1.1. How will the part be used?

The first that you should pay attention to – the intended use of a part. You will see in the section below scopes of applications of each material.

It is already enough to rule out three-quarters of ones that will not do the work for you. The additional questions you may want to ask yourself on this stage of decision-making are the following:

- What is the industry? Well, it is expected that you already know the sphere you fabricate parts for. But, some components have a wide scope of applications. You should ensure that the material will sustain heavy-duty and be a design component, if necessary.

- Indoors or outdoors? In other words, what are the environmental conditions your part will be exposed to? It also significantly affects the decision regarding the material. Some plastics and metals are less or more moisture and wear-resistant.

- What are the stresses? Pay close attention to loads and stresses your parts are expected to sustain. They should perform well in all the intended operating conditions.

List all the factors that will impact your parts during their performance. Then, select the materials that meet the requirements the most. Such a procedure is your most devoted guide.

1.2. Does weight matter?

The short answer will be – yes. There are industries where the weight of components is crucial. It includes: automotive, medicine, electronics, transportation, aerospace, aircraft, military and defense, and many others.

Make sure that your parts are not heavier than expected. Otherwise, they will not be popular regardless of their superior properties. Manufacturing and industrial purposes can be met by parts made of any materials, irrespective of their weight.

This is because machines carry heavy loads on the production line. In other cases, look for something lightweight. As a bonus, we may recommend you stick to what your biggest competitors craft. Do not craft heavier components not to lose your potential buyers.

1.3. Does the part require high strength or heat resistance?

The cost-efficiency of your material is the last key consideration. It goes further than just the cost of a metal or plastic itself. While the material may fit your budget, it will result in extra expenses in the future. Pay attention to the following factors:

- Support and maintenance

In some cases, your fabrics may be responsible for the repair of the parts manufactured. If you save on expensive materials and compromise the quality – you may overpay for support and maintenance further. Also, it may negatively influence your brand reputation.

And it is something that is difficult to enhance. So regardless of the project budget, you are advised against saving on the quality of materials. In case you cannot afford a project – just do not start it or allocate more funds.

- Fancy materials

Sometimes you may want to choose a less cost-effective but attractive material / finished with the use of a colored coating. In most cases, it does not impact the performance of a part. Consider fancy materials redundant if they are not for decoration purposes.

In contrast, if your materials are for decorative parts – do not pick highly functional metals and plastics. They are usually more expensive, but you will not exploit their full potential this way.

- Added costs

It may include multiple additional expenses you may sustain because of a wrong choice of material. For example: you chose that cheaper material that requires finishing instead or an expensive one that does not post-processing. You lost money on an avoidable procedure.

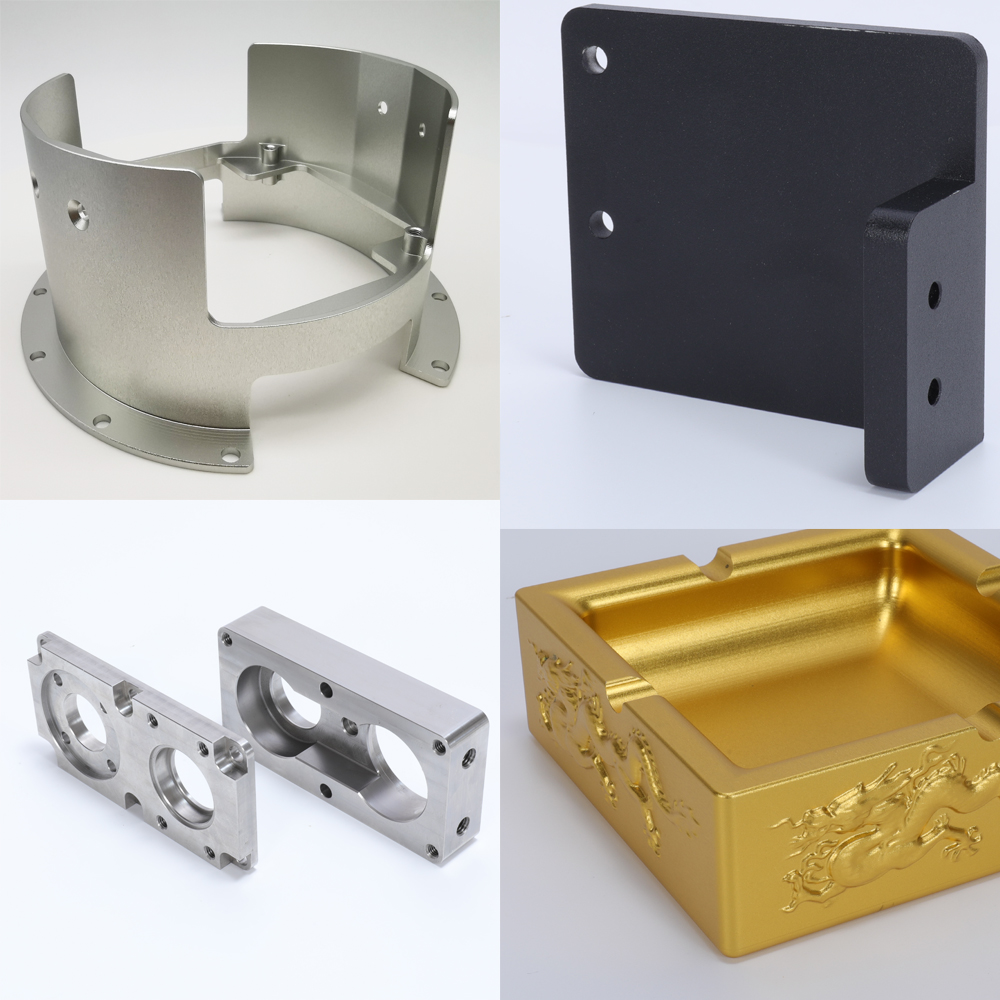

2. Common CNC Machining Materials Metals

2.1. Aluminum

It is the most common material to machine components from. This material does not occur in nature in the pure form. Neither is it used in production. But, Aluminum alloys are the very first consideration for a variety of manufacturing goods.

The popular aluminum alloys are: 6061-T6, 7075-T6, 2024-T4, MIC 6, and 6082 series. They are different in the methods of casting, and the content of components. Aluminum alloys are non-corrosive, lightweight, durable, non-magnetic, and have good electrical conductivity.

Aluminum is particularly important in the food-processing, electronics, and aircraft industries.

Related Post

2.2. Stainless Steel

Another key engineering material – stainless steel. All grades of stainless steel can be categorized into the following four types: austenitic, ferritic, duplex, and martensitic stainless steel.

They are different in the methods of casting and the content of components. Stainless steel is durable, corrosion-resistant, temperature-resistant, and has high tensile strength and an attractive appearance. As a bonus – it is non-toxic, environment-friendly, and recyclable.

Stainless steel is of particular importance in construction, oil & gas processing, chemical processing, and electric power industries. The most popular stainless steels are 304 and 316 grades.

2.3. Carbon Steel

Carbon steel is a metal alloy with an increased content of carbon. This steel is categorized into three types: low-carbon, medium-carbon, and high-carbon.

They differ in carbon and minor additive contents. Depending on the type, carbon steel has high hardness, toughness, and strength. They are wear and stress-resistant and rather affordable than expensive.

The drawback – is that medium and high-carbon steels are poorly malleable and hard to machine overall.

Carbon steel is particularly important in the construction, transportation, and automotive industries. It is worth emphasizing that this metal fabricates cutting tools and torsion springs.

2.4. Brass

Brass is a metal alloy that is widely known for its unique appearance. There are more than 60 brass alloys that differ in combinations of copper and zinc. Their mechanical properties vary as well as the color (from red to yellow).

This metal has excellent wear and corrosion-resistant properties. It is strong, durable, nonferromagnetic, and is easy to machine.

Additionally, brass has great electrical and heat conductivity properties and even is biofouling resistant. Brass is particularly important in the plumbing, electronics, and furniture industries.

Additionally, it is used to fabricate jewelry and decorative elements because of its gold-like, shiny appearance.

Related Post

2.5. Titanium

Titanium is a silver-gray metal that is known for its attractiveness and the unique properties it possesses. It is available in a pure form or the form of titanium alloys. Five grades of pure titanium differ in the content of phases of crystal structures (α and β).

Titanium offers a superior weight-to-strength ratio and has a high melting point. It is a wear-resistant and non-reactive metal. Titanium is of particular importance in the construction, light, aircraft, and chemical processing industries.

It is used for multiple purposes. Mostly – when reduced weight combined with exceptional strength is crucial.

Related Post

Check the link to learn all the CNC machining metal materials and their surface finishes.

3. Common CNC Machining Materials Plastics

3.1 ABS

ABS is a highly widespread thermoplastic polymer. It is modified by the addition of monomers Acrylonitrile, Butadiene, and Styrene in varying proportions.

There are such types of ABS as general-purpose, high glow, high gross, high impact, plateable, and many others. This polymer is highly rigid (compared to other plastics), tough, impact-resistant, and wear-resistant. ABS sustains stresses and limited loads perfectly.

ABS is of particular importance in the electronics, construction, automotive, and furniture industries. ABS may be used in any case when heat resistance is not required. It is also a popular filament for 3D printing.

3.2. Nylon

Nylon is a silk-like polyamide polymer, or simply – thermoplastic. It can be categorized as a homopolymer, co-polymer, or reinforced plastic. There are 8 types of nylon available. Also, nylon may be used as an additive to other materials.

This lightweight, synthetic thermoplastic is highly elastic and strong. It is wear and chemicals-resistant, resilient, does not absorb water, and dries quickly. Nylon is particularly important in the textile, fashion, construction, and light industries.

This material does the work for a wide range of everyday goods. It includes wheels, toothbrushes, guitar strings, tennis racket strings, and others.

3.3. Polycarbonate

Polycarbonate is another thermoplastic polymer. It is naturally transparent and amorphous. Multiple grades of polycarbonate are available.

It includes clear, mirrored, bulletproof, abrasion-resistant, anti-static, and many others. This material has superior toughness, strength, stiffness, and impact resistance. It is wear-resistant overall, durable, and fire-retardant. It also has excellent dimensional stability and is easy to machine.

Polycarbonate is of particular importance in the electronics, automotive, defense, and medical industries. Polycarbonate replaces glass in every matter when high strength and durability are vital.

3.4. POM (Delrin)

Delrin is a high-performance acetal homopolymer/resin. It is available in such basic melt flow series as 100, 500, 900, and 1700. They differ in their viscosity; 1700 is the most fluid while 100 is the most viscous.

This material has high stiffness and dimensional stability. It is also chemical, fatigue, and wear-resistant. Delrin is of particular importance in the automotive, security, and construction industries.

Delrin can serve as a replacement of metal materials in any matter but when heat resistance is crucial. It is also a common material for 3D printing of injection molds.

3.5. Acrylic

Acrylic or plexiglass is another lightweight thermoplastic polymer intended to replace glass. It is available in multiple grades, including general-purpose, abrasion-resistant, impact-modified, light-diffusing, antimicrobial, and many others.

This thermoplastic has superior optical clarity. It resists temperature fluctuations, impact, stresses, and chemicals. As a bonus, it bonds well with adhesives and solvents. Acrylic plastic is essential in the medicine, construction, and electronics industries.

This material is a top choice when transparency and clarity are crucial. It also suits well for decorative purposes and precise machining.

Related Post

Check the link to learn all the CNC machining plastic materials and their surface finishes.

4. Summary

You can be recommended to choose optimal materials rather than ideal ones. Ones that fulfill entirely their intended purpose and are cost-effective simultaneously.

After reviewing the list of key considerations, you should have a set of factors written down. Use them to select one or two materials from our post. Then – do additional research on grades and types of a particular material.

Typically you will have up to 3 choices. Give all of them a try during rapid prototyping. And you are good to go.

Whether your project needs CNC machining metals or CNC machining plastics, ECOREPRAP can all provide you. Contact us now!