- Capabilities

-

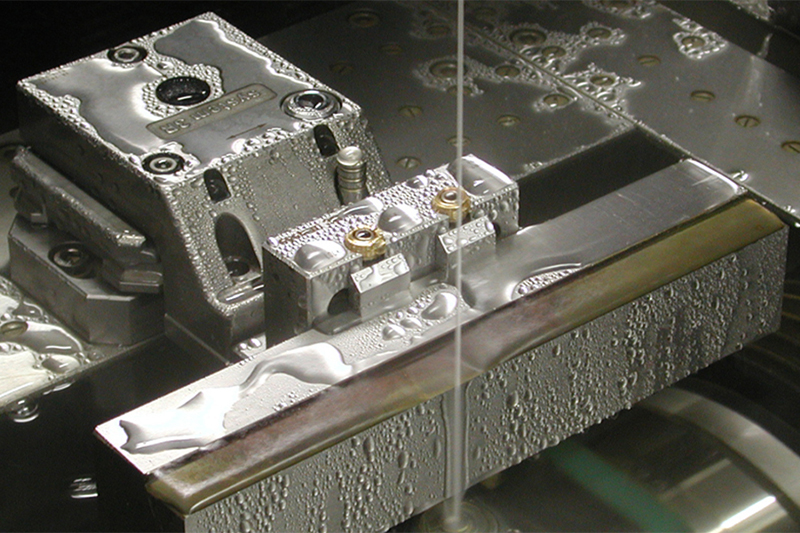

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

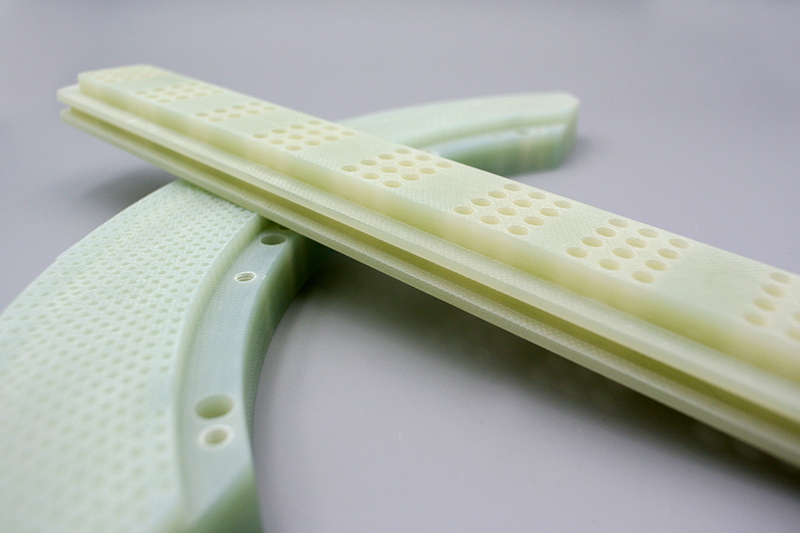

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

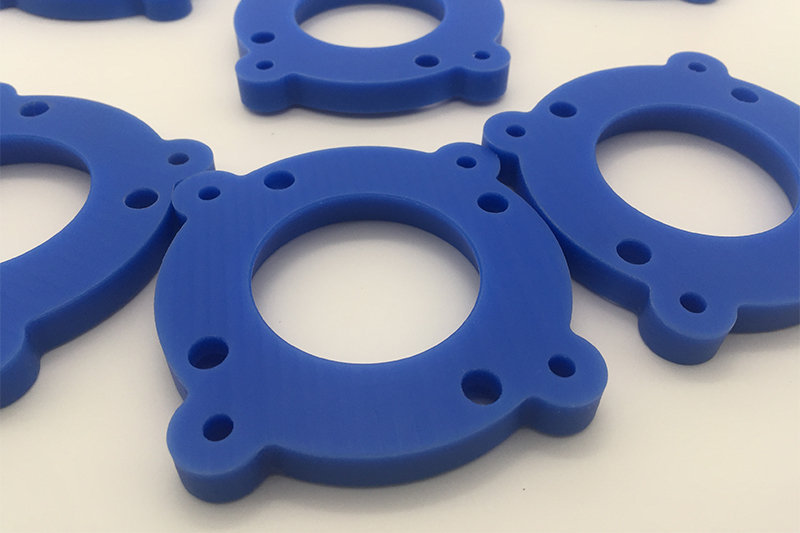

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Precision CNC Machining Services

Custom high precison CNC machining manufacturing services from prototypes to on-demand production.

- Abudant materials and surface finishes

- Timely engineering experts support

- Super fast turnaround time

- Worldwide shipping

All your designs are secure and confidential

Menu

What is precision CNC machining?

CNC machining, short for computer numerical control machining, is a prevalent manufacturing method employing automated, high-speed cutting tools to shape metal or plastic stock into desired designs. CNC machines contain 3-axis, 4-axis, and 5-axis milling machines, lathes, milling-turning, and routers. They each have unique approach to cutting parts. In CNC milling, the cutting tool is mounted on a rotating spindle which moves across the material to cut away excess, shaping the workpiece into the desired form.Conversely, CNC turning involves the raw material or workpiece spinning on a spindle, while the cutting tool remains fixed in position.CNC milling and turning, also known as multi-axis machining or mill-turn machining, combines both milling and turning operations in a single machine.This process allows for the simultaneous use of multiple cutting tools to create complex parts with both rotational and prismatic features.

Precision CNC Machining Capabilities

CNC milling removes materials from the workpiece to create custom-designed parts with flat surfaces using cutting tools or multi-point milling cutters. With our 3-axis, 4-axis, and 5-axis CNC milling services, you can get milled parts with tight tolerance up to 0.001mm. Both continuous 5-axis machining and indexed 5-axis machining services are provided by us.

CNC turning is a precision machining process that efficiently removes material from the exterior of a cylindrical rod by utilizing a rapidly spinning cutting tool. CNC lathes are highly versatile machines known for their exceptional repeatability, making them exceptionally well-suited for wide applications, including rapid prototyping and both low and high-volume production.

Precision CNC Machining Gallery

Precision CNC Machining Metal Materials

ECOREPRAP offers 80+ popular CNC machining materials and can help source others if needed.

Aluminum

Light weight aluminum is a pure metal that is quickly alloyed with percentages of other materials like copper, manganese, silicone, or magnesium. It is not magnetic or combustible and has good electricity conductor. It offers good corrosion resistance and is easy to form and process. It is often used because of its weight.

Avialable: 6061, 5052, 7075, 6063

Carbon Steel

Carbon steels contain only trace amounts of other elements than carbon and iron. There are three subgroups based on the amount of carbon in the metal. Low Carbon Steels/Mild Steels contain up to 0.3%, Medium Carbon Steels (0.3-0.6%) and High Carbon Steels have more than 0.6%.

Avialable: 1018, 1045, A36, C45

Stainless Steel

Stainless steel is a wide range of sheet metals that contain at least 10% chromium. Standard or austenitic stainless steel is very common and does not require heat during the manufacturing process. These alloys are corrosion resistant, forming and welding friendly. Many different grades are available.

Avialable: 304, 316, 416, 420

Alloy Steel

Alloy steels can be created by adding alloying elements such as nickel, copper chromium and/or aluminum. Incorporating these elements enhances the steel's strength, ductility, corrosion resistance, and machinability.4140, 4130, 1215 are all widely used. Different alloy steel has different properties.

Avialable: 4140, 4130, 1215

Tool Steel

Cutting and drilling equipment is enhanced by tool steels. It's the combination of tungsten and molybdenum with cobalt and vanadium which increases heat resistance and durability. They are the preferred material for hand tools because they maintain their shape even under heavy use.

Avialable: D2, A2, O1, A3, S7

Brass

Brass is an alloy of zinc and copper. It has excellent electrical conductivity, and is easy to machine. With low friction properties and gold-like appearance, brass is commonly used in the architecture sector to manufacture gears, locks, pipe fittings.

Avialable: H65, H62

Copper

Copper can be shaped into many different shapes. Copper is a metal with good strength and hardness. It also has superior thermal and heating conductivity and corrosion resistance. It is therefore a material that is valued for both its aesthetic and functional properties.

Avialable: T2, C17200, TU2

Bronze

Bronze is an alloy typically composed of copper and tin as its main elements. It has good strength, electrical conductivity, and corrosion resistance. The copper content in bronze alloys usually ranges between 70% to 90%, while the tin content falls between 10% to 30%.

Avialable: 932,954,544

Titanium Alloy

Use in the aerospace, automotive, and clinical industries. Titanium has a high corrosion resistance, reduced thermal development, and is biocompatible and sterile.. Titanium Grade 5 and Titanium Grade 2 are two common used Titanium for CNC machining.

Avialable: Grade 5, Grade 2

Nickel Alloy

Nickel alloys exhibit various characteristics like corrosion resistance, high-temperature stability, excellent electromagnetic properties and oxidation resistance. Kovar and Invar are two common Nickel-iron alloys used in CNC machining, which have exceptional dimensional stability at a wide variety of temperature levels.

Avialable: Kovar, Invar,Inconel 718

Magnesium Alloy

Magnesium alloys are versatile materials with several useful characteristics applicable across various industries. Due to their sensitivity to corrosion, particularly in high humidity environments, proper protection and maintenance are required to ensure Magnesium alloys performance and durability.

Avialable: AZ31B

Zinc Alloy

Zinc alloys are versatile materials with excellent corrosion resistance, low melting point, good formability, recyclability and good conductivity properties. Zamak 3 is the most widely used grade of Zinc available and provides excellent dimensional stability.

Avialable: Zamak 3

Precision CNC Machining Plastic Materials

ABS

Common thermoplastic, impact resistant, easy to machine. ABS is a common thermoplastic with all-around excellent mechanical residential or commercial properties, exceptional effect stamina, excellent warmth resistance and great machinability.

PMMA

Clear rigid plastic is often used as a substitute for glass. PMMA is a clear inflexible plastic typically utilized as a substitute for glass.

PC

High toughness, excellent impact strength, and transparency. Polycarbonate (PC) is a thermoplastic with high sturdiness, superb effect strength, and excellent machinability. Can be optically transparent.

POM

High rigidity, high precision, reduced rubbing, simple to make. POM is an engineering thermoplastic used in precision parts requiring high stiffness, low friction, and excellent dimensional stability. Delrin and Acetal are two well-known POM brands.

PE

Superb strength-to-weight proportion, influence, and climate resistance. Polyethylene (PE) is a polycarbonate with a high strength-to-weight proportion, good effect stamina, and exceptional weather condition resistance.

Nylon

Excellent mechanical properties, thermal, chemical, and abrasion resistant. Nylon-polyamide (PA) - is a design polycarbonate with exceptional mechanical residential or commercial properties and high chemical and abrasion resistance.

PEEK

High-performance polycarbonate, extremely high toughness, thermal and chemical immune. PEEK is a high-performance design polycarbonate with excellent mechanical properties and chemicals over a really large temperature array.

PTFE

Low friction, chemical, and thermal resistance. PTFE is a design thermoplastic with superb chemical and thermal resistance and the most affordable coefficient of rubbing of any kind of recognized solid.

PET

Challenging plastic that supplies excellent wear resistance and mechanical stamina. Family pet is a challenging plastic that uses superb wear resistance and mechanical strength.

PP

Polypropylene (PP) is an economical polycarbonate with variable effect resistance relying on the quality. PP is wear-resistant, flexible and can have high elongation, while it also has high chemical resistance.

PPS

Polyphenylene Sulfide (PPS) is a high-performance design plastic with excellent temperature level resistance, dimensional security, and electrical insulation in homes. PPS is generally discovered in heat applications such as automotive components, appliances, electronics, clinical devices, and commercial applications.

PVC

Excellent chemical and weather resistance and good toughness. PVC is the third most made use of plastic with all-around good mechanical buildings, exceptional chemical and weather condition resistance and great toughness.

PEI

As an amorphous material with exceptional strength and rigidity under long-term heat exposure, Polyetherimide (PEI) has made its place in high-performance applications like automotive, aerospace, industrial, and many more.

FR4

Flame retardant glass fiber epoxy laminate.FR4 is a class of glass fiber epoxy laminate that is fire resistant, with similar properties to G-10.

Garolite G-10

High toughness, low dampness absorption, and high level of electric insulation and chemical resistance. G-10 is a high-pressure fiberglass laminate flooring with high strength, reduced dampness absorption, and a high level of electric insulation and chemical resistance.

Carbon Fiber

Carbon fiber is typically appropriate for CNC (Computer Numerical Control) machining, but it requires particular strategies and factors to consider because carbon fiber differs significantly in framework and buildings from conventional metal products.

Bakelite

Bakelite is a thermosetting plastic with high heat resistance, excellent chemical resistance and solid mechanical residential or commercial properties. Bakelite has found substantial usage in electric and digital parts, such as switches and insulators, auto caps and manages, classic telephones and cookware, shutoff handles and tailors, and billiard balls.

PPSU

Polyphenylsulfone, PPSU for brief, is a high-performance thermoplastic recognized for its phenomenal warm resistance, outstanding chemical resistance, and solid mechanical buildings. PPSU is commonly utilized in medical and oral tools, aerospace parts, pipes fittings, and shutoffs.

PU

Polyurethane, PU for brief, is a flexible polymer with a wide range of applications, including foams, insulation in construction and refrigeration, and elastomers for making sturdy seals, gaskets, wheels, coverings, and adhesives.

HIPS

High-impact polystyrene, HIPS for brief, is a frequently used polycarbonate recognized for its impact resistance and versatility. It locates applications in electric and digital housings for simple, non-demanding applications and prototyping and model-making because of its convenience of machining and cost.

Precision CNC Machining Tolerance

| Standards | CNC Milling | CNC Turning | |

| Maximum Part Size | 4000×1500×600 mm | 200×500 mm | |

| Minimum Part Size | 4×4 mm | 2×2 mm | |

| Minimum Feature Size | Φ 0.50 mm | Φ 0.50 mm | |

| Standard Tolerances | Metals: ISO 2768-m | Metals: ISO 2768-m | |

| Plastics: ISO 2768-m | Plastics: ISO 2768-m | ||

| Linear Dimension | +/- 0.025 mm | +/- 0.025 mm | |

| Hole Diameters(Not Reamed) | +/- 0.025 mm | +/- 0.025 mm | |

| Shaft Diameters | +/- 0.025 mm | +/- 0.025 mm | |

| Edge Condition | Sharp corner will be removed in the form of a chamfer or radius. The size of the chamfer, or resulting radii, must be indicated on the drawing. | ||

| Threads and Tapped Holes | Diameter: Φ 1.5-5 mm, depth: 3×diameter | Diameter: Φ 1.5-5 mm, depth: 3×diameter | |

| Diameter: Φ 5 mm or more, depth: 4-6×diameter | Diameter: Φ 5 mm or more, depth: 4-6×diameter | ||

| ECOREPRAP can produce threads of any specification and size required by our customers. | |||

| Text | Use CNC engraving or laser carving to create standard text based on customers’ requirements. Minimum width of 0.5mm, depth of 0.1mm. | Use laser marking to create standard text for CNC turned parts. | |

| Lead Time | 3 to 10 business days | 3 to 10 business days | |

Precision CNC Machining Finishes

As Machined

Components as provided as cut, no additional therapy applied. Sharp edges are damaged and deburred for risk-free handling. For any type of crucial sides that need to be left sharp, please note and specify them in your drawings. For metals, as machined can be Ra 1.6 or Ra 3.2. For plastics, as machined usually refers to Ra 3.2.

Anodizing

Anodizing enhances aluminum parts' rust resistance, boosting wear resistance and firmness, and safeguarding the metal surface. Type II and Type III are both available. For Type II, it can be in different colors, clear, black, red, and gold are most usual. Type III layer is thicker and is better put on resistant and deteriorating immune.

Spray Coating

Spray coating normally includes the application of spray painting, powder coating, and Teflon coating for different covering materials and technologies. Spray painting and powder finish can have rich shades like black, white, red, and others. For powder coating, it can be glossy and matte. For spray painting, it can be shiny, matte, textured, metal.

Metal Plating

Electroplating is a surface treatment procedure that can enhance the deterioration resistance, hardness, conductivity, attachment, and decoration of sheet metal components. We offer vast layering options, gold plating, silver plating, zinc plating, copper plating, nickel plating, and chrome plating.

Mechanical Finishes

Mechanical finishing is a process that involves generation of different-looking surface textures on metal by brushing, tumbling, or bead blasting the surface. Its benefits lie in the aesthetic appeal and is also a great choice for covering and blending any imperfections or unwanted lines and marks that might appear as a result of the manufacturing process.

Part Marking

Part marking is an economical way to add logos or custom-made text to your layouts and is frequently used for custom components. Laser engraving and silk screening are 2 cost-effective techniques that permit better versatility with your design. They are an excellent alternative for logos and lettering that are tough to create with manufacturing alone.

Heat Treatment

Heat treatment is a material processing technique that involves heating and cooling materials to adjust their properties, including hardness, strength, toughness and more, to meet specific engineering or manufacturing requirements. Spring steel 65Mn must undergo heat treatment to acquire elasticity. S7 harnness can be increased by heat treatment.

Chemical Finishes

Chemical finishing includes chromate conversion gold, chromate conversion clear, passivation, black oxide, adodine, electropolishing. Chemical finishing can remove blemishes from a part, alter its conductivity levels, extend its lifespan, and even increase its resistance to wear and corrosion of the sheet metal fabrication parts.

Why ECOREPRAP Precision CNC Machining

Consistent Quality Every Time

We strictly implement a quality management system to ensure consistent, expected quality on the products. Full inspections also make sure you receive precision machined parts devoid of unwanted defects.

Professional Engineering Support

Work with our engineering experts that offer technical design guidance and inform you on manufacturability and cost-saving solutions. Free and accurate quotation with DFM review in 12 hours and lead time as fast as 3 days.

Strong Manufacturing Capacity

From prototyping to mass production, ECOREPRAP combines high-quality materials with state-of-the-art technologies to bring products to life. 100+ materials and 20+surface treatments are provided.

Worldwide Shipping Solution

Through international express DHL/ FEDEX, you will receive qualified parts within 3 to 7 days. For bulk orders, sea or rail transportation services are provided to reduce the shipping cost.

Other Machining Services

Electrical Discharge Machining

EDM is a auxiliary process to remove material from workpieces for CNC machining complex shapes or high-hardness materials.

Sheet Metal Fabrication Service

Get your sheet metal fabrication parts in 20+ metals. From one-off prototyping and on demand production, all your needs can be met here.

3D Printing Service

Get your parts 3D printed with SLA, SLS,MJF, SLM or FDM. Surface treatment like polishing, dyeing, and painting are all available.

Vacuum Casting Services

Vacuum casting is a custom manufacturing method used for the production of small series of functional plastic parts, materials including ABS-Like,PMMA-Like,PC-Like,PP-Like,Rubber-Like,Silicone.

Precision CNC Machining FAQs

The two primary CNC machining processes are CNC turning and CNC milling. Other machining processes include drilling, gear hobbing and electrical discharge machining,grinding among others.

Parts machined with metal will follow ISO 2768-m (medium) or ISO 2768-f (fine). Parts machined with plastics will follow 2768-m (medium). Geometric tolerances down to ± 0.001mm are possible but must be clearly indicated in technical drawings. We can achieve tighter tolerances on shafts with up to H7 fits with manual quoting and on occasion tighter.

We offer CNC milling (3-axis, 3+2-axis and 5-axis) and turning. Milled parts can be machined up to 2000 x 1500 x 300 mm for 3, 3+2 axis CNC milling. For 5-axis milling, the maximum part size is 650 x 650 x 300 mm. The maximum diameter for CNC turning is 431mm, length 990 mm. Minimum part dimensions recommended are around 2 x 2 x 2mm.The minimum for feature dimensions is 0.5 mm.

Deburing and edge breaking are standard procedures for all CNC machined parts. lf there are any critical edges that should be left sharp, they must be clearly indicated in technical drawings. Surfaces will be free of defects such as scratches, dents, stains, blemishes, hanging marks, minor defects. Surfaces indicated ascritical (primary (a) side, as indicated on the technical drawing) will be free of mill steps and other marks. For the secondary (b) side, minor hanging marks and up to 2 minor defects are acceptable. A number of post-processing and finishing methods can be applied to improve the surface roug hness, visual properties andwear resistance of machined parts.

We offer UNF, UNC, and metric threads for machining along with coil and key inserts. These are available on both milled or turned CNC parts.

ECOREPRAP caters to both one-off prototype and large-scale production runs. Thus, there is typically no strict MOQ. Whether you need a single part or thousands, ECOREPRAP aims to provide a solution.

Lead times can vary based on the complexity of the design, the chosen material, and the current workload. However, one of the advantages of CNC machining is its speed, especially for simpler parts. Once the setup is complete, machining times can be relatively quick. Parts machined as fast as 1 day! But for an accurate estimate, it’s best to request for quotes directly.

The main costs associated with CNC machining can be grouped into machining time, start-up costs,material costs, and feature costs. To reduce costs you need to understand the impact of these factors on cost.

The best way to reduce machining time is to design features that can be machined quickly, for example by choosing the correct radii for internal corners, reducing cavity depth, increasing wall thicknesses, limiting thread length and designing holes with standard sizes.

Material costs can be reduced by considering the size of the blank required, and the cost and machinability of the bulk material (softer alloys are faster to machine).

Start-up costs can be reduced by reducing the number part rotations or repositioning required to finish thepart, for example by separating geometries into multiple parts that can be assembled later.

Feature costs can be reduced by only usina tolerances when strictly necessary, removing all text & lettering and avoiding multiple surface finishes.

Product designers and engineers choose CNC machining to rapidly produce prototypes and production parts. The manufacturing technology offers a high level of precision, engineering-grade materials, quick-turn lead times.

Industries that use CNC machining include aerospace, automotive parts manufacturing, medical machine manufacturing, transportation, defense, and marine industries, along with oil and gas industries and electronics. CNC machining has allowed these industries to become more efficient at mass-producing custom CNC parts.