Due to advancements in technology, people are concerned whether to use CNC machines or laser cutters. Even though the machines are not the same, they use similar principles. Moreover, you can use any of the machines to achieve what you want.

Both CNC machines and laser cutters are used in the manufacturing industry to produce detailed and sophisticated components. Nevertheless, they operate differently and each has its benefits and drawbacks.

In this article, we will look at both machines and the advantages and disadvantages of the two.

The difference between CNC machine and the laser cutter is how they work, cost, experience, and speed. For example, a laser cutter uses a laser beam, thus it is contactless. On the other hand, CNC machine uses specialized machine tools to produce products.

Contents(show)

What is CNC Machining?

CNC or Computer Numeric Control is a cutting device. It is a machine that uses specific tools to efficiently and quickly produce products. It is a modern machine that is used by various manufacturing companies.

With CNC cutting, you can create a design based on what you need using programs such as AutoCAD or CorelDraw. When you are satisfied with the drawing, all you need is to place a piece of metal or another material on the cutting surface.

The computer will send a signal to the machine, it will interpret the design, and if the prototype meets all the requirements, it will produce what you want. It is even possible to produce multiple products.

For the CNC machine to cut, the tool moves back and forth, and side-to-side based on the shape of the design.

Types of CNC routing

CNC routing can be categorized into 5 types:

*Drilling – you can use a CNC router to create holes for the exact size you want.

*Male cuts – you can create an outside cut with the router. No matter the size, height, or dimension, it is possible with the machine.

*Female cuts – you can use the machine if you want to remove a piece. It is different from the male cut.

*Online cutting – it can follow simple line segments and mostly uses shapes.

*Cleanouts – the machine can be used to create grooves in various materials for 3D routing.

Advantages of CNC cutting

1. Material used

Even though some materials cannot work with CNC machines, it is a good one for people who want to work with carbon fiber, PVC, and softer metals such as aluminum.

Nevertheless, both CNC cutting and laser cutters have materials that work well with them. Therefore, you need to look for materials you need to work with to ensure you get the best one for your needs.

2. Thickness

CNC routers are considered by many because they can cut thick and thin materials. But, you need to go in multiple passes. With the laser cutter, it can only cut thin materials.

3. Depth of the cut

Apart from the thickness advantage, you can achieve 3D carvings with a CNC router. This is one of the main advantages of CNC cutting over the laser cutter.

A laser cutter is normally a 3D machine and it might not have some grade of depth cutting. But you can achieve all you want with CNC cutting.

4. Large working area

If you are looking for a machine that provides a larger working area, you need to go for a CNC router. Compared to the laser cutter, you can be certain the router will have the space you need.

5. Cost

With all the above benefits, a CNC machine is cheaper than a laser cutter. However, the price of the laser cutter goes up with bed size and wattage.

What is Laser cutter?

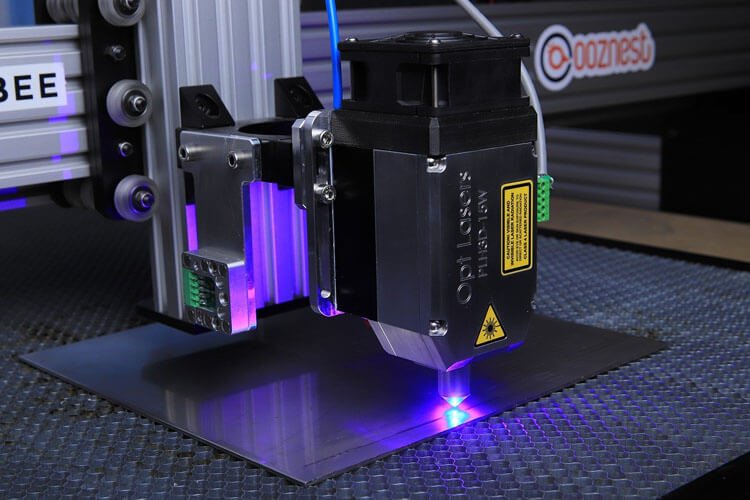

A laser cutter is a special machine that relies on the heart to make the chosen shape of an item. It relies on high light beam to burn through the metal. Even though it does not work for all applications, it comes with numerous benefits.

Advantages of a laser cutter

1. Ease of use

One of the advantages of a laser cutter is its ease of use. The machine is a plug-and-play. You do not need setups like other machines. Also, if you give two people a job on the two pieces of equipment, one using the laser cutter will be a lot faster. With the laser machine, all you need is to put it in its position and start working.

To design with a laser cutter is also easier. You do not need to keep adding tabs like someone using a CNC machine. What you view on your computer screen is the same thing you get on your item.

2. Accuracy

When it comes to accuracy, a laser cutter is the best. Whether they are small bits or larger ones, you can be sure to achieve what you want. The accuracy can be seen on sharp corners.

3. Less labor

The other advantage of using a laser machine is less labor. It is a machine that can be used by anyone. Since it is a contactless machine, you do not need to keep clamping the materials. Remove loose woodchips, or change bits.

4. Speed

Even though the speed depends on the materials used and specific equipment, the speed of a laser machine is excellent. Compared to a CNC cutter, you can be sure the job will be done faster with a laser cutter.

5. Noise

Another benefit of a laser machine is less noise. If you are looking for equipment that produces less noise, it is the laser machine. However, it depends on the model of the machine you are using.

Final word

From the above information, you can use a CNC router or Laser cutter in your manufacturing industry to produce reliable and precise components. Both are highly effective and reliable and can be used in a wide range of manufacturing sectors.

Even though most people may prefer lasers since they are easy to use, there are many other factors you need to consider. Consider the cost, speed, working area, and accuracy among other factors.