CNC Machining Services in China by Ecoreprap

For manufacturers seeking cost-effective, high-precision CNC machined parts, Ecoreprap provides reliable quality, fast turnaround, and scalable production.

Our services cover prototype, low-volume, and mass production for industries including automotive, industrial, electronics, and medical devices.

With ISO-compliant quality control and over 20 countries served, Ecoreprap ensures your parts meet global standards while staying budget-friendly.

Why Choose Ecoreprap CNC Machining Services in China?

Cost Efficiency vs Local Suppliers

Ecoreprap provides 20–50% cost savings versus US suppliers through optimized supply chains and labor advantages.

Example: a batch of 100 aluminum brackets costs $850 in China vs $1,400 in the US.

Engineering Communication & Export Experience

Our English-speaking engineering team works with US and European clients daily.

We review CAD files, provide technical feedback, and verify compliance with international standards.

Manufacturing Capacity & Scalability

From prototype to low-volume and mass production, Ecoreprap supports multi-shift CNC operations, ensuring on-time delivery without compromising precision.

Quality Standards for US & Global Markets

All parts inspected per ISO 9001 procedures. Tolerances down to ±0.01 mm, with full inspection reports included.

Ecoreprap CNC Machining Capabilities

CNC Milling (3/4/5-Axis)

- CNC Milling (3/4/5-Axis)

- Complex geometric parts

- Tolerance: ±0.01–0.05 mm

- Materials: Aluminum, Steel, Stainless Steel

CNC Turning

Cylindrical components, batch stability

High repeatability for precision shafts

Multi-Axis Machining

- Complex 3D surfaces, reduced setup error

Prototyping & Low-Volume Production

- Rapid prototypes from 1 piece

- Supports proof-of-concept testing

Materials, Tolerances & Surface Finishes

Aluminum

Light weight aluminum is a pure metal that is quickly alloyed with percentages of other materials like copper, manganese, silicone, or magnesium.

It is not magnetic or combustible and has good electricity conductor. It offers good corrosion resistance and is easy to form and process. It is often used because of its weight.

Avialable: 6061, 5052, 7075, 6063

Alloy Steel

Alloy steels can be created by adding alloying elements such as nickel, copper chromium and/or aluminum.

Incorporating these elements enhances the steel's strength, ductility, corrosion resistance, and machinability.

4140, 4130, 1215 are all widely used. Different alloy steel has different properties.

Avialable: 4140, 4130, 1215

Carbon Steel

Carbon steels contain only trace amounts of other elements than carbon and iron.

There are three subgroups based on the amount of carbon in the metal.

Low Carbon Steels/Mild Steels contain up to 0.3%, Medium Carbon Steels (0.3-0.6%) and High Carbon Steels have more than 0.6%.

Avialable: 1018, 1045, A36, C45

Stainless steel

Stainless steel is a wide range of sheet metals that contain at least 10% chromium.

Standard or austenitic stainless steel is very common and does not require heat during the manufacturing process.

These alloys are corrosion resistant, forming and welding friendly.

Many different grades are available.

Avialable: 304, 316, 416, 420

ABS

Common thermoplastic, impact resistant, easy to machine.

ABS is a common thermoplastic with all-around excellent mechanical residential or commercial properties, exceptional effect stamina, excellent warmth resistance and great machinability.

PMMA

Clear rigid plastic is often used as a substitute for glass.

PMMA is a clear inflexible plastic typically utilized as a substitute for glass.

PC

High toughness, excellent impact strength, and transparency.

Polycarbonate (PC) is a thermoplastic with high sturdiness, superb effect strength, and excellent machinability.

Can be optically transparent.

POM

High rigidity, high precision, reduced rubbing, simple to make.

POM is an engineering thermoplastic used in precision parts requiring high stiffness, low friction, and excellent dimensional stability.

Delrin and Acetal are two well-known POM brands.

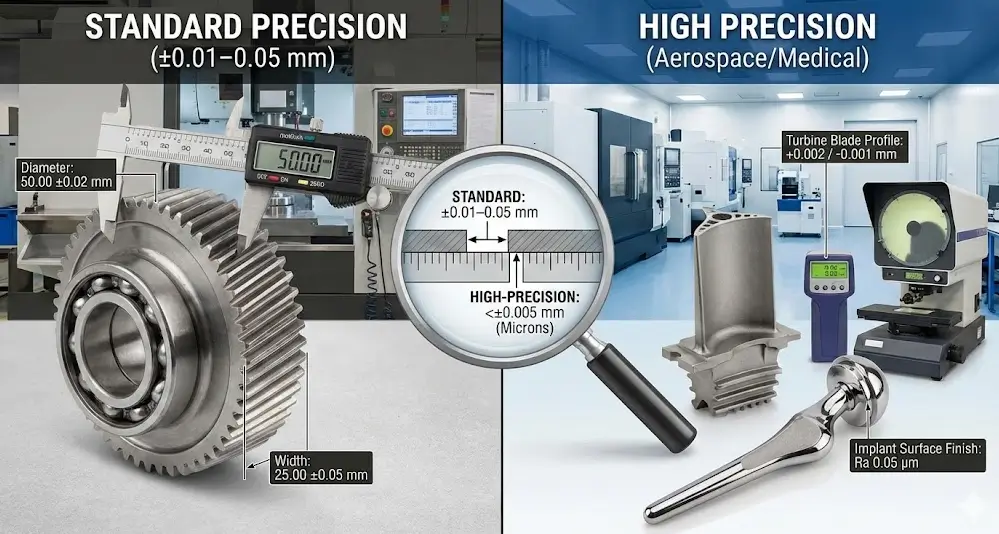

Tolerances

- Standard: ±0.01–0.05 mm

- High-precision available for aerospace/medical

Tolerances

Standard: ±0.01–0.05 mm

High-precision available for aerospace/medical

| Standards | CNC Milling | CNC Turning | |

| Maximum Part Size | 4000×1500×600 mm | 200×500 mm | |

| Minimum Part Size | 4×4 mm | 2×2 mm | |

| Minimum Feature Size | Φ 0.50 mm | Φ 0.50 mm | |

| Standard Tolerances | Metals: ISO 2768-m | Metals: ISO 2768-m | |

| Plastics: ISO 2768-m | Plastics: ISO 2768-m | ||

| Linear Dimension | +/- 0.025 mm | +/- 0.025 mm | |

| Hole Diameters(Not Reamed) | +/- 0.025 mm | +/- 0.025 mm | |

| Shaft Diameters | +/- 0.025 mm | +/- 0.025 mm | |

| Edge Condition | Sharp corner will be removed in the form of a chamfer or radius. The size of the chamfer, or resulting radii, must be indicated on the drawing. | ||

| Threads and Tapped Holes | Diameter: Φ 1.5-5 mm, depth: 3×diameter | Diameter: Φ 1.5-5 mm, depth: 3×diameter | |

| Diameter: Φ 5 mm or more, depth: 4-6×diameter | Diameter: Φ 5 mm or more, depth: 4-6×diameter | ||

| ECOREPRAP can produce threads of any specification and size required by our customers. | |||

| Text | Use CNC engraving or laser carving to create standard text based on customers’ requirements. Minimum width of 0.5mm, depth of 0.1mm. | Use laser marking to create standard text for CNC turned parts. | |

| Lead Time | 3 to 10 business days | 3 to 10 business days | |

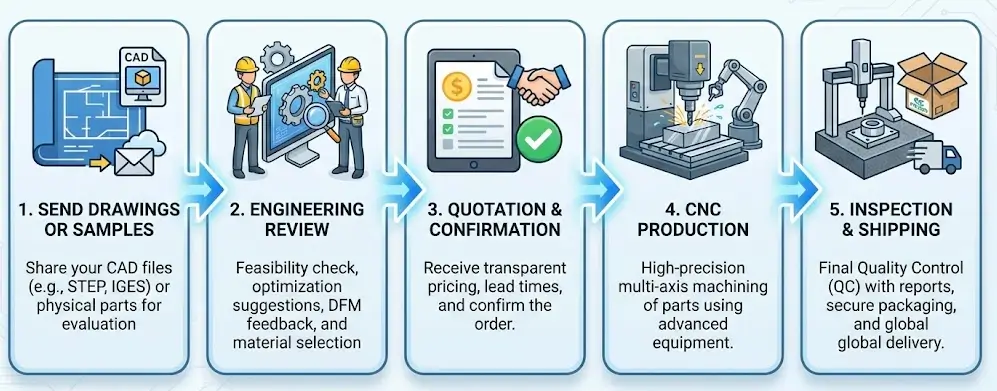

Ecoreprap CNC Machining Process

Step 1 | Send Drawings or Samples

Step 2 | Engineering Review – feasibility check, optimization suggestions

Step 3 | Quotation & Confirmation – transparent pricing

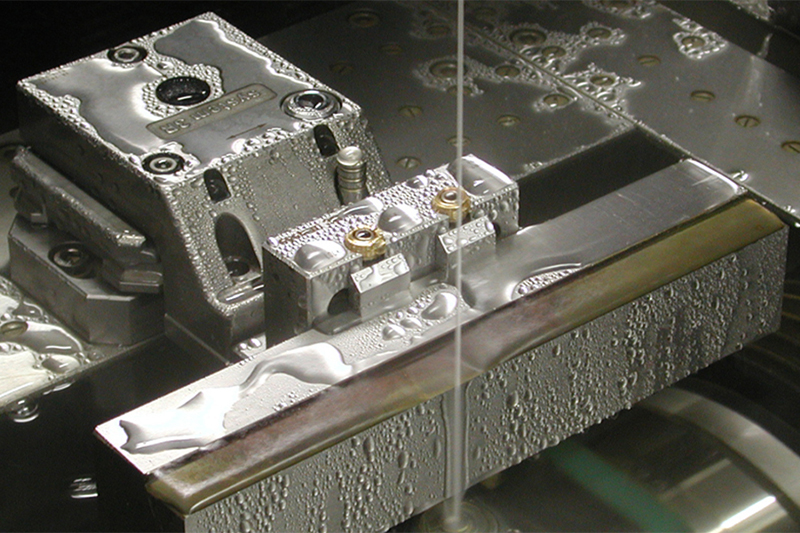

Step 4 | CNC Production – multi-axis machining

Step 5 | Inspection & Shipping – final QC, packaging

Quality Control & Compliance

- ISO 9001 compliant

- Dimensional & surface inspection

- Export experience ensures US & EU compliance

- Digital QC reports included

Precision CNC Machining Finishes

As Machined

Components as provided as cut, no additional therapy applied. Sharp edges are damaged and deburred for risk-free handling. For any type of crucial sides that need to be left sharp, please note and specify them in your drawings. For metals, as machined can be Ra 1.6 or Ra 3.2. For plastics, as machined usually refers to Ra 3.2.

Anodizing

Anodizing enhances aluminum parts' rust resistance, boosting wear resistance and firmness, and safeguarding the metal surface. Type II and Type III are both available. For Type II, it can be in different colors, clear, black, red, and gold are most usual. Type III layer is thicker and is better put on resistant and deteriorating immune.

Spray Coating

Spray coating normally includes the application of spray painting, powder coating, and Teflon coating for different covering materials and technologies. Spray painting and powder finish can have rich shades like black, white, red, and others. For powder coating, it can be glossy and matte. For spray painting, it can be shiny, matte, textured, metal.

Metal Plating

Electroplating is a surface treatment procedure that can enhance the deterioration resistance, hardness, conductivity, attachment, and decoration of sheet metal components. We offer vast layering options, gold plating, silver plating, zinc plating, copper plating, nickel plating, and chrome plating.

Mechanical Finishes

Mechanical finishing is a process that involves generation of different-looking surface textures on metal by brushing, tumbling, or bead blasting the surface. Its benefits lie in the aesthetic appeal and is also a great choice for covering and blending any imperfections or unwanted lines and marks that might appear as a result of the manufacturing process.

Part Marking

Part marking is an economical way to add logos or custom-made text to your layouts and is frequently used for custom components. Laser engraving and silk screening are 2 cost-effective techniques that permit better versatility with your design. They are an excellent alternative for logos and lettering that are tough to create with manufacturing alone.

Heat Treatment

Heat treatment is a material processing technique that involves heating and cooling materials to adjust their properties, including hardness, strength, toughness and more, to meet specific engineering or manufacturing requirements. Spring steel 65Mn must undergo heat treatment to acquire elasticity. S7 harnness can be increased by heat treatment.

Chemical Finishes

Chemical finishing includes chromate conversion gold, chromate conversion clear, passivation, black oxide, adodine, electropolishing. Chemical finishing can remove blemishes from a part, alter its conductivity levels, extend its lifespan, and even increase its resistance to wear and corrosion of the sheet metal fabrication parts.

Why ECOREPRAP Precision CNC Machining

Consistent Quality Every Time

We strictly implement a quality management system to ensure consistent, expected quality on the products. Full inspections also make sure you receive precision machined parts devoid of unwanted defects.

Professional Engineering Support

Work with our engineering experts that offer technical design guidance and inform you on manufacturability and cost-saving solutions. Free and accurate quotation with DFM review in 12 hours and lead time as fast as 3 days.

Strong Manufacturing Capacity

From prototyping to mass production, ECOREPRAP combines high-quality materials with state-of-the-art technologies to bring products to life. 100+ materials and 20+surface treatments are provided.

Worldwide Shipping Solution

Through international express DHL/ FEDEX, you will receive qualified parts within 3 to 7 days. For bulk orders, sea or rail transportation services are provided to reduce the shipping cost.

Other Machining Services

Electrical Discharge Machining

EDM is a auxiliary process to remove material from workpieces for CNC machining complex shapes or high-hardness materials.

Sheet Metal Fabrication Service

Get your sheet metal fabrication parts in 20+ metals. From one-off prototyping and on demand production, all your needs can be met here.

3D Printing Service

Get your parts 3D printed with SLA, SLS,MJF, SLM or FDM. Surface treatment like polishing, dyeing, and painting are all available.

Vacuum Casting Services

Vacuum casting is a custom manufacturing method used for the production of small series of functional plastic parts, materials including ABS-Like,PMMA-Like,PC-Like,PP-Like,Rubber-Like,Silicone.