- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Chamfer vs Fillet: What’s the difference?

Updated: December 03, 2023

Introduction

There are plenty of edge finishing type used in CNC machining parts, like edge-honing, deburring, chamfering and filleting. Fillet and chamfer are the common design in part design. It affect the cost, operating condition of the finial parts.

In this post, we will explain the definition of chamfer and fillet, difference and tips when you choose to use them.

1. What is a fillet?

Loosely described, a fillet is a curved radius that is applied to an edge where two surfaces (usually flat) meet to eliminate the sharp edge. In most cases this is a square edge, i.e., the two surfaces meet at a 90﮿ angle however it is also possible to apply a fillet to materials that meet at irregular angles, although rare. The most common reasons for applying a fillet are to make the part look more aesthetically pleasing or to make the part safer for human interaction and handling.

2. What is a chamfer?

A chamfer on the other hand is the angle that is applied where two surfaces meet to eliminate the sharp edge. Unlike a fillet which feels smooth and continuous to the touch, one can feel and see exactly where the angle/s was applied with a chamfered workpiece. There are many sizes of chamfer tools however the 2 that are popular, the 45˚ (which is the more common one) and there is also the 60˚ chamfer. The latter is less common because it leads to a higher stress concentration, which will be described in more detail below.

3. When do you need a fillet or a chamfer?

Chamfers are generally preferred for assemblies that have mating parts because they are more forgiving to the slight irregularities that can be incurred during assembly because of tolerance issues, slight misalignments or other manufacturing irregularities. However, for precise assemblies, fillets work best because they leave very little room for unwanted movement. Do keep in mind though that tight tolerances come at a cost!

Chamfers are also usually applied to holes that will have a pin inserted. This is done in cases where the head of the pin must sit flush with the top of the hole.

4. Differences between a fillet and a chamfer

- Fillets have better stress concentration or stress flow. Stress concentration relates to how well an object disperses the force exerted on it. Fillets are better at handling stress concentration because the stress induced is distributed over a wider surface area as compared to chamfers. As such chamfers deform easier because the impact absorbed is not dispersed easily to surrounding material of the part. For a part that would be exposed to impact by secondary objects, fillets become the better option.

- Although fillets seem to be more advantageous to chamfers, they come at a cost! A fillet is a higher cost edge finishing technique compared to chamfering.

- With manual machining, the time taken to manufacture fillets is more than the time taken to produce a chamfer. The time to set up the tool is longer for filleting, the time taken to machine the actual fillet is longer compared to chamfering. Therefore, for commercially produced items, the time taken to finish an edge must be taken into consideration because machine time also has an impact on cost of production and hence on final cost of product. The longer the time on the machine, the more you pay.

- For chamfering, one tool can create many different chamfer sizes. With filleting, a specific size tool is needed to produce the specific radius for the particular job. While many different sized tools will be needed for filleting different radii, 1 tool will suffice for different chamfer sizes.

5. Factors to consider when choosing a fillet or a chamfer

- If edge-finishing (filleting or chamfering) is only being done for aesthetic reasons then it is important to take into account the cost involved for each process. Would the market be able to absorb the product at the higher cost induced by edge-finishing?

- While still on aesthetics, will the finished product need a coat of paint? The smooth radius of the fillet is easier to paint as compared to the chamfer. On a chamfered edge, the paint tends to sit or pool on some areas more than others resulting in an uneven distribution that will peel over time. This also means that chamfering is more prone to rust because some areas are not adequately protected from the elements.

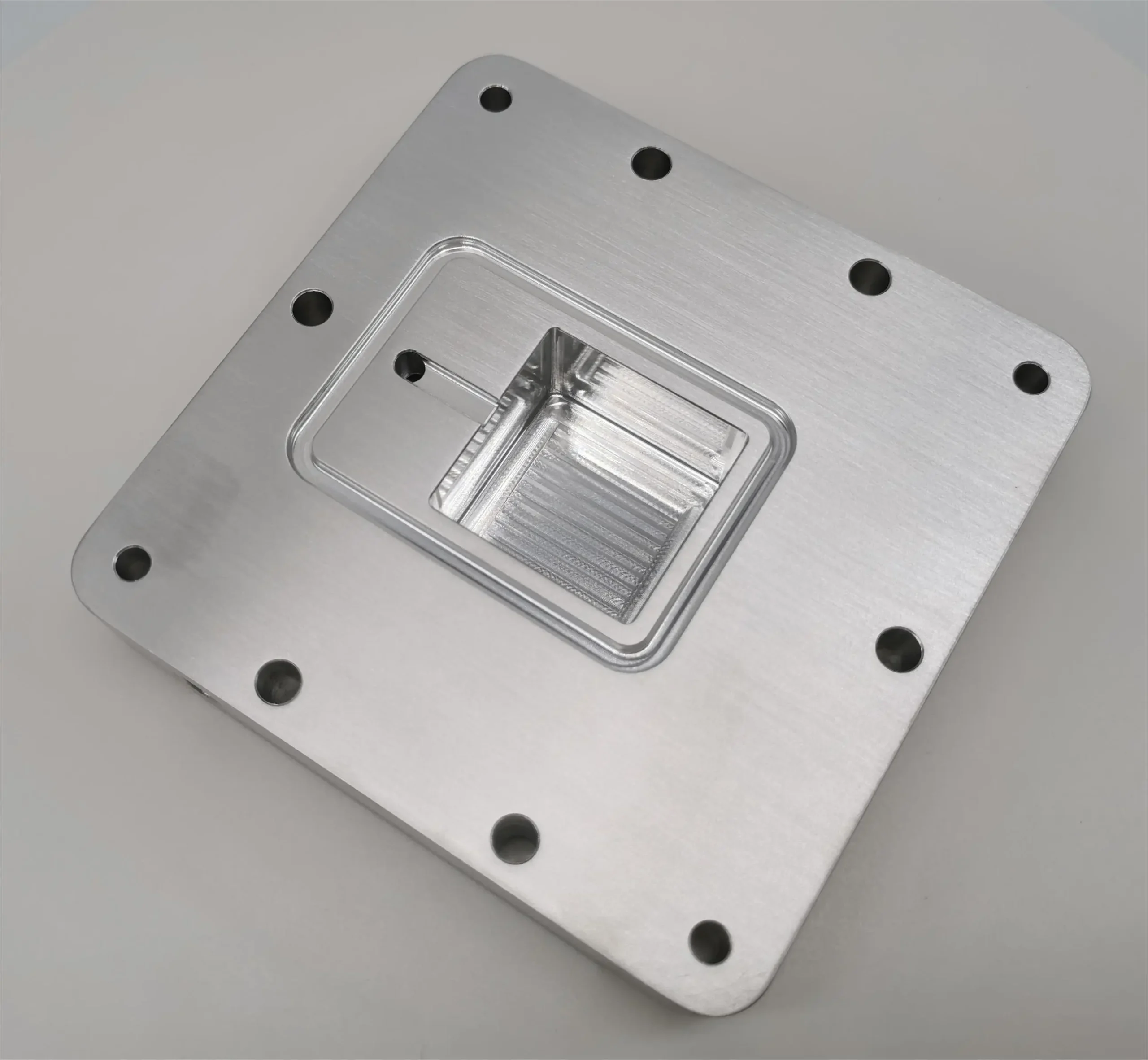

- The position of the edge in question matters. For external edges, either chamfers or fillets can be applied. However, for internal vertical edges (relative to the tool) fillets are automatically applied because of the round tool used to mill the surface. The tool makes a concave fillet as it turns the corner to begin milling a new surface hence with CNC machining, fillets are automatically applied to internal edges. See the picture below for reference.

- Regarding conditions of operation and use, fillets are the safer option for exterior edges that will come into contact with humans or with delicate products.

6. Summary

Whether chamfering or filleting, in both instances, using blunt or low-quality tools results in failure to produce the required result hence it is of utmost importance to always use high quality tooling to avoid wasting material.

You cannot pick either a chamfer or a fillet based on only a single parameter such as cost because there are a lot of other factors to consider as we have seen. If you have short lead time you cannot automatically opt for filleting because other parameters must be considered. Otherwise you would end up with a product delivered on time but failing to serve its primary purpose. The best way to approach a project is to iteratively match the specifications of the product to the different factors to consider beginning with the most important specifications first such as safety and functionality.

Contact ECOREPRAP for prototypes with a perfect chamfer and fillet.