- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Types of Brass Used in CNC Machining

Updated: May 11, 2024

Table of Contents

IBrass is known to be one of the most popular materials for manufacturing parts, using CNC milling and turning services. Brass is an alloy of two other metals which are zinc and copper and is highly adaptable due to varying the proportions of its components.

However, the versatility of this alloy often makes even specialists confuse some of the brass metal types’ properties. The potential implications are not choosing sufficient, for certain manufacture needs, alloy, and inappropriate conditions under which the workpieces from this metal are intended to be made.

Read below about brass crystal structures and types of brass metal, their composition, features, and pros and cons.

1. Brass crystal structures

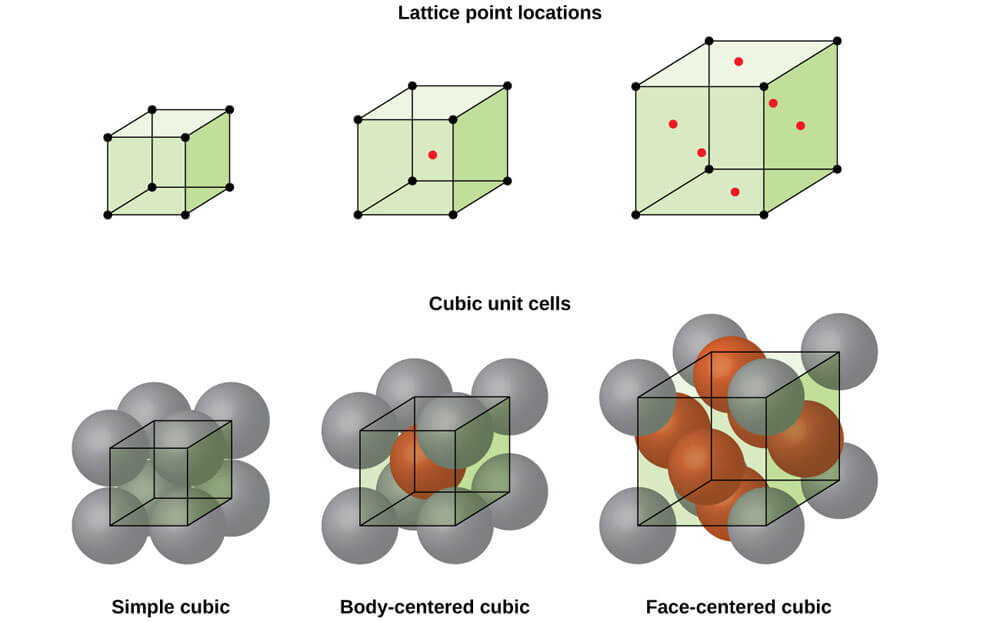

To begin with, it is necessary to define what crystal structure (of any crystalline material) is. It can be defined as an ordered arrangement of atoms, ions, or molecules in a crystal.

Constituent particles tend to form and maintain the principal three-dimensional cubic-like structure. Their other distinctive feature is a complete reflection of the symmetry and structure of the entire crystal regardless of what part of an entire unit they are. The length between principal edges and angles are known to be lattice constants or cell parameters.

Generally, there are three varieties of crystals, shown in the image below, to which brass belongs.

Depending on the alloy, brass metals may have only two types of phases in varying proportions. α-phase is the face-centered cubic crystal structure.

While forming a brass, it is known to be similar in its properties to copper. The presence of high proportions of β-phase, which has a body-centered cubic structure, makes brass alloy have more expressed zinc properties.

All the brass metals having different containment of zinc and copper also have varying amounts of α and β phases of crystal structures.

2. Types of brass metal

Red Brass

Red brass, also known as rose brass or “gunmetal” is an alloy composed of 14-16% of zinc, 0.05% of iron, 0.07% lead content, and the remainder copper.

Red brass can be recycled multiple times due to the high amount of copper. It is utilized in numerous mechanical parts, such as valves, sprinklers, siphons’ segments, and musical instruments. Before being replaced with steel gunmetal, it had been used mainly for gun making.

This alloy has the following pros and cons:

- The most durable among all the metals for the plumbing industry due to corrosion resistance.

- It can be easily machined.

- It is resistant to non-oxidizing acids.

- The high content of copper makes it more expensive than other types of brass.

- It is a soft metal.

Yellow Brass

Yellow or gold brass is often compared in its properties to red brass. It is composed of 57% of copper and 33% of zinc.

It is found mainly in decorative and industrial applications. It also has high corrosion resistance and can be used to manufacture kitchen spigots, screws, fasteners, musical instruments such as trombones and saxophones. Due to being lighted and clearer in color than the red brass, the yellow one can be used for producing plates, shelves, and costume jewelry.

Yellow brass is known to have the following pros and cons:

- Affordable price.

- Harder metal than the red brass.

- Can be used for decorative purposes.

- Can be easily machined.

- Tarnishes when exposed to water and soap.

- Lose form with time.

Oxygen-Free Copper

Oxygen-free copper is a metal composed of 99% copper and 1% or fewer impurities, which determines the grade of metal.

It has good corrosion resistance, high thermal and electrical properties, and excellent hot-working properties. The major applications of oxygen-free copper are conductors, wires, waveguides, grass-to-metal seals, cavity resonators, vacuum tubes, and others.

- It is resistant to shorts, durable, and long-lasting.

- It is resistant to oxidation and highly conductive.

- It can be recycled multiple times.

- It is a soft metal.

- Oxygen-free copper is comparatively expensive.

Tin Bronze

Tin bronze is composed of 89% copper and 11% tin. It is a hard metal having high ductility. It is wear-resistant and able to withstand the pounding.

Tin bronze finds its application in the forming industry. Parts made of this metal are expected to withstand high loads at low speeds. It is mainly used for producing springs, pump impellers, bushings, valve guides, piston rings, and bearings. It can be also utilized for manufacturing movable bridge components, and other similar structures.

- Tin bronze resists corrosion and metal fatigue.

- It conducts heat and electricity better than steel.

- It is a soft and weak metal compared to steel.

- It is an expensive metal.

Beryllium Copper

Beryllium copper is known to be a copper alloy with 0.5% to 3% of Beryllium. This type of brass combines high strength with non-magnetic and non-sparking qualities.

Beryllium copper is used in applications when it is vital to have good formability combined with high fatigue strength, creep resistance, and good hysteresis properties. Some of the parts that are typically made of this metal are screwdrivers, knives, hammers, cold chisels, wrenches, pliers, and others.

- It has the highest strength rating among copper-based alloys.

- Due to being non-sparkling, it can be used near flammable substances.

- It is resistant to non-oxidizing acids and can be heat-treated.

- It is expensive.

- Inhalation of beryllium dust may cause a serious lung condition.

3. Final Word

Brass is a highly prevalent type of material in CNC machining. Its alloys based on copper mixed with other elements such as tin, beryllium, or zinc enable the manufacture of versatile parts. Applications of brass alloys vary from decorative elements to parts of movable bridges.

Properties of types of brass alloys are significantly dependent not on the containment of different materials, but on the crystal structure.

Thus, based on the proportion of face-centered cubic or body-centered cubic phases, an alloy may express more copper or more zinc-like properties.

If you have some brass parts to be machined, ECOREPRAP is your go-to manufacturer with all brass types available. Contact us for a free quotation now!

Let's get your projects started, together!

Get custom parts machined in high quality, delivery on time.