Home > CNC Machining Materials > Metals > Copper

CNC Machining Materials

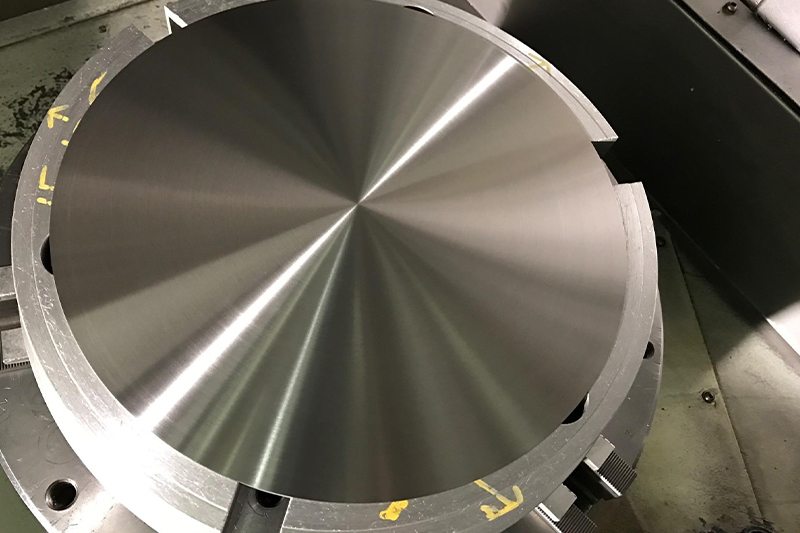

Copper CNC Machining

With a glossy reddish-orange appearance, Copper has superb thermal and electrical conductivity, commonly used for busbars, wire ports, and various other electrical applications.

All uploads are secure and confidential

Copper CNC Machining

Copper is listed as Cu (atomic number 29) on the table of elements and is an exceptional conductor of electrical power and warmth, 2nd just to silver. Commercially offered copper is commonly more than 99% pure. The remaining 1% is normally impurities such as oxygen, lead, or silver.

Copper is well known for its electric and thermal conductivity. It is really resistant to deterioration and is likewise inherently antimicrobial. The power, automotive, clinical, and aerospace sectors make use of copper, particularly for these buildings.

C101 Brass (Oxygen-Free Electronic, OFE): Oxygen-free copper with higher purity, containing about 99.99% copper. It has superior electrical conductivity and ductility, and excellent resistance to oxidation.

C110 (Electrolytic Tough Pitch, ETP): High-purity electrolytic copper, typically containing 99.9% copper. It offers excellent electrical and thermal conductivity.

Copper Subtypes

| Ultimate tensile strength | Yield strength | Young’s modulus (modulus of elasticity) | Elongation at break | Corrosion resistance | Magnetism | Weldability | Application | ||

| Copper C101 | 220 – 280 MPa | 60 – 240 MPa | 125 – 135 GPa | 9 – 30 % | Semi-magnetic | Poor | Electronics Automotive Domestic Appliances Cold formed components | Learn More | |

| Copper C110 | 220 – 280 MPa | 60 – 240 MPa | 115 – 120 GPa | 9 – 30 % | Moderate to Poor | Circuit breakers Electrical instruments Vacuum capacitors Magnetrons | Learn More |

Copper CNC Machining Surface Finishes

Cost-saving Design Tips

Copper is an extremely expensive material, so component design optimization is recommended.

1. Only use where required

Only using copper components where essential. Manufacturing an entire part out of copper is excessively expensive if only a small portion requires its one-of-a-kind properties.

2. Choose the right grade

Trying to utilize ultra-pure copper, such as 99.99% pure C101, for a simple mechanical component is not economical. However, if remarkable conductivity is not called for and a great deal of material is machined, C110 is likely a far better selection.

FAQs

Pure copper CNC machining is very difficult to and requires specialized knowledge. Alloying the copper with elements such as tin, silicon, zinc, aluminum, and nickel can drastically improve machinability because it changes the material composition.

Copper alloys have great electrical and thermal conductivity, which make them natural choices for many electrical applications, such as bus bars and wire connectors.

101 copper offers higher conductivity due to its purity.

110 copper is generally easier to CNC machine making it more cost effective.

Copper beryllium (CuBe) combines high strength with non-magnetic and non-sparking qualities. It is excellent for CNC machining, forming and general metalworking.

Copper’s unique benefits and properties make it a valuable material for a wide variety of applications and is easy to machine.

Copper has good corrosion resistance and is especially malleable and ductile. It is a good heat and electricity conductor and can be hard and soft soldered easily.

With copper CNC machining, precise copper parts can be produced quickly and with a high level of repeatability, ensuring each part meets strict requirements and specifications.

Copper is suitable for a wide array of applications such as pipes, electric cabling, circuit boards, electronics, wiring, radiators and cooling systems.