Home > CNC Machining Materials > Metals > Nickel

CNC Machining Materials

CNC machining of nickel

Nickel alloys encompass a spectrum of materials derived from combining nickel with elements like chromium, iron, and molybdenum. Each variant boasts unique traits rendering it indispensable. Their unparalleled resilience against corrosion has made these alloys essential in punishing industrial settings involving noxious chemicals and extremes in temperature. This corrosion resistance is paramount in the chemical sector, where nickel alloys are fundamental components of reactors, heat exchangers, and piping networks transporting corrosive payloads.

In addition to corrosion resistance, nickel alloys exhibit stellar fortitude at scorching temperatures, a property vital for aerospace. Materials in jet engines and gas turbines endure infernos, demanding resilience millennia beyond ordinary metals. Nickel alloys uphold durability under thermal duress, critical to airborne safety and performance.

The mechanical characteristics of nickel alloys are as diverse as impressive.

Engineering optimizes traits like tensile strength, ductility, and resilience mandatory for tasks shouldering heavy burdens or fluctuating stresses.

Batteries, connectors, and electronics rely on nickel alloys to achieve objectives where functionality and reliability are non-negotiable.

In medicine, nickel alloys are chosen for biocompatibility and immunity to fluids within the body, qualifying uses from surgical tools to implants to prosthetics.

Ability to survive sterilization intact ensures devices serve patients for longer while threatening no harm.

All uploads are secure and confidential

Understanding CNC Machining Processes for Nickel

CNC machining of nickel is a process of employing automated, precise tools to cut, form, and finish nickel-based materials.

Nickel is known for its high strength, resistance to corrosion, and thermal properties and may be frequently used in industries such as aerospace, medical, and energy.

CNC machining it may involve specific operations of turning, milling, or drilling, and each of these is designed to fashion precise components with a high level of detail.

However, machining nickel is a process that brings certain difficulties, as the characteristics of the material are defined by its hardness and toughness.

The hardness of nickel usually implies that tools made to fashion it are susceptible to wear quickly and that both the cutter and the cut surface may generate heat quickly.

Thus, it is essential to choose the right cutting tool, which may be made of carbide or coatings of ceramic. Similarly, developers are urged to determine cutting speed range and feed rate. Remove overheating and floor fouling;

In some cases, such as high-speed machining and using of coated tools, these values can be increased.

In other cases, it is common to cool the tools and the machined surfaces using coolants and lubricants.

Copper Subtypes

| Ultimate tensile strength | Yield strength | Young’s modulus (modulus of elasticity) | Elongation at break | Corrosion resistance | Magnetism | Weldability | Application | ||

| Invar | 450 – 480 MPa | 260 – 280 MPa | 137 – 148 GPa | 30 – 35 % | Poor to Medium | Magnetic | Moderate to Good | Aircraft control Optical & laser systems Electronic devices | Learn More |

| Inconel 718 | 900 – 930 MPa | 490 – 510 MPa | 190 – 200 GPa | 40 – 45 % | Excellent | Non-magnetic | Excellent | Jet engines Rocket motors Spacecraft Space shuttles Nuclear reactors Pumps & turbo pumps Tooling | Learn More |

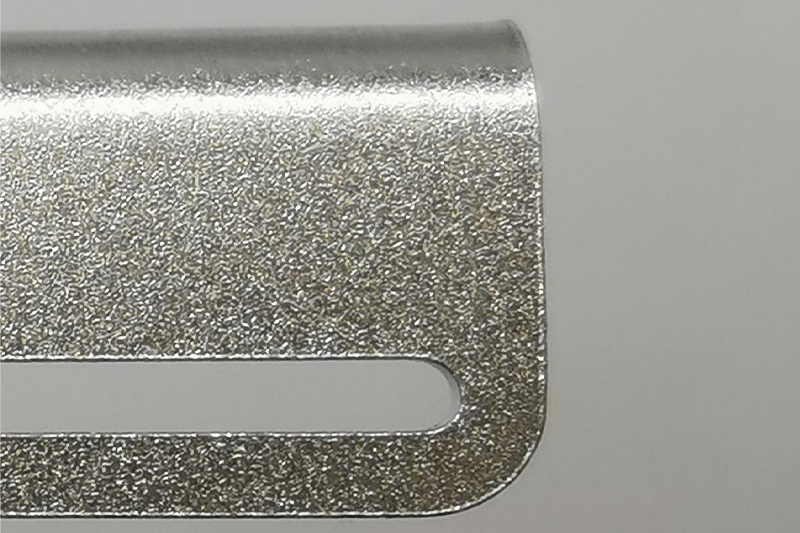

Nickel CNC Machining Surface Finishes

Nickel CNC machining surface finishes are imperative for guaranteeing the functionality and visual quality of the final product. Achieving the preferred surface finish involves prudent selection of machining parameters and techniques to oversee the peculiar properties of nickel, such as its hardness and propensity to work-harden.

Principal factors influencing surface finishes include cutting velocity, feed rate, and the kind of cutting instrument applied. Employing sharp, premier quality carbide or ceramic tools can reduce surface coarseness. Coolants and lubricants play a vital role in maintaining the temperature during machining, preventing thermal damage and improving the finish.

Procedures like high-speed machining (HSM) and exact grinding are regularly utilized to accomplish smoother surfaces.

Post-machining processes, for instance polishing and electroplating, can further enhance the surface finish, offering extra protection against corrosion and wear.

Sustaining optimal surface finishes is distinctly significant in industries like aerospace and medical, where surface integrity affects execution and longevity.

By judiciously controlling machining conditions and employing suitable finishing techniques, manufacturers can yield nickel components with superior surface quality that meet stringent industry standards.

Cost-saving Design Tips

Cost-saving design in CNC machining of nickel involves employing an assortment of tactics aimed at decreasing outlays while upholding elevated standards of excellence.

Principal techniques embrace material option, simplification of geometry, optimized machining processes, tooling perspectives, operational proficiency, post-machining actions, mechanization, and style for manufactureability (DFM).

Minimization

Selecting nickel alloys engineered for machining, resembling Nickel 200 or Hastelloy, can mitigate productive tribulations and utensil degeneration.

Optimizing layouts to minimize materials waste is essential, accomplished by means of competent nesting of articles and thoughtful geometric scheming.

Geometric Form Simplification

Streamlining configurations by dodging needless complex highlights can significantly cut machining time and costs.

Utilizing standardized components and measurements aids eliminate the necessity for tailored utensils and personalized configurations, additional decreasing outlays.

Optimized Machining Processes

Tool way optimization aided by forward CAM software program can streamline manufacturing strategies, decreasing non-cutting time and bettering efficiency.

High-pace machining (HSM) can extend material removal rates and slice cycle instances, although it necessitates cautious heat administration.

Utensil Considerations

Investing in high-quality, wear-resistant cutting instruments, such as carbide or ceramic, can decrease instrument modifications and servicing costs.

Implementing instrument existence monitoring structures helps predict and prevent instrument failures, minimizing downtime and portion rework.

Process Proficiency

Designing parts for fewer configurations and utilizing multi-axis CNC machines can reduce repositioning and clamping wants.

Batch production of comparable parts can streamline machining processes and cut machine reconfiguration time.

Post-Machining Actions

Reducing or eliminating secondary operations like polishing by attaining desired surface finishes straight throughout CNC machining saves time and costs.

Productive finishing techniques, such as tumbling or vibratory finishing, deal with numerous parts simultaneously, lowering labor costs.

Automation and Smart Manufacture

Incorporating automation, such as computerized tool changers and robotic handling structures, enhances production proficiency and cuts labor costs.

Real-time tracking and adaptive control structures optimize machining circumstances dynamically, decreasing waste.

Design for Manufactureability (DFM)

Collaborating with CNC machinists in the course of the design section guarantees parts are designed for ease of manufacture.

Developing prototypes for testing machining strategies can uncover potential issues early, saving time and money in full-scale manufacturing.

By employing these cost-saving style tactics, manufacturers can accomplish efficient, high-quality CNC machining of nickel while minimizing expenses.

FAQs

Nickel CNC machining is the process of using computer-controlled machines to shape, cut, and finish parts made from nickel-based alloys.

Nickel alloys offer high corrosion resistance, excellent strength, and exceptional heat resistance.

Invar and Inconel .