Home > CNC Machining Materials > Metals > Titanium

CNC Machining Materials

ECOREPRAP Titanium CNC Machining Service

Precision Titanium 3 & 5-Axis Machining | Tight Tolerances | Grade 2 & Grade 5

All uploads are secure and confidential

CNC Machined Titanium Advantages

• Optimal Strength-to-Weight Ratio – CNC machining unlocks titanium’s full potential, delivering exceptional strength with minimal weight for critical high-performance applications.

• Superior Corrosion & Chemical Resistance – The process preserves titanium’s inherent durability, ensuring long-term reliability in the most demanding aerospace, marine, and industrial environments.

• Excellent Biocompatibility & Sterilizability – Machined to medical-grade standards, titanium is perfectly suited for implants and surgical instruments that require absolute safety and repeated sterilization.

• High Precision & Design Freedom – CNC technology enables the creation of complex, lightweight geometries with tight tolerances, transforming advanced designs into fully functional, reliable components.

Why Machining Titanium is Difficult

• Low Thermal Conductivity – Heat concentrates intensely at the cutting edge instead of dissipating, leading to rapid tool wear and potential thermal damage to the part’s microstructure.

• High Chemical Reactivity – Titanium readily alloys with and adheres to cutting tools during machining, causing galling, built-up edge, and accelerated tool failure.

• High Strength & Low Elastic Modulus – Its strength demands significant cutting forces, while its relative “softness” allows deflection and spring-back, challenging dimensional accuracy and surface finish.

• Specialized Process Demands – Successful machining requires rigid equipment, specialized tooling, high-pressure coolant, and deep expertise—making it a skill-intensive process far beyond standard metals.

Titanium Bar

CNC Machined Titanium Parts for Drone

ECOREPRAP Titanium CNC Machining Capabilities

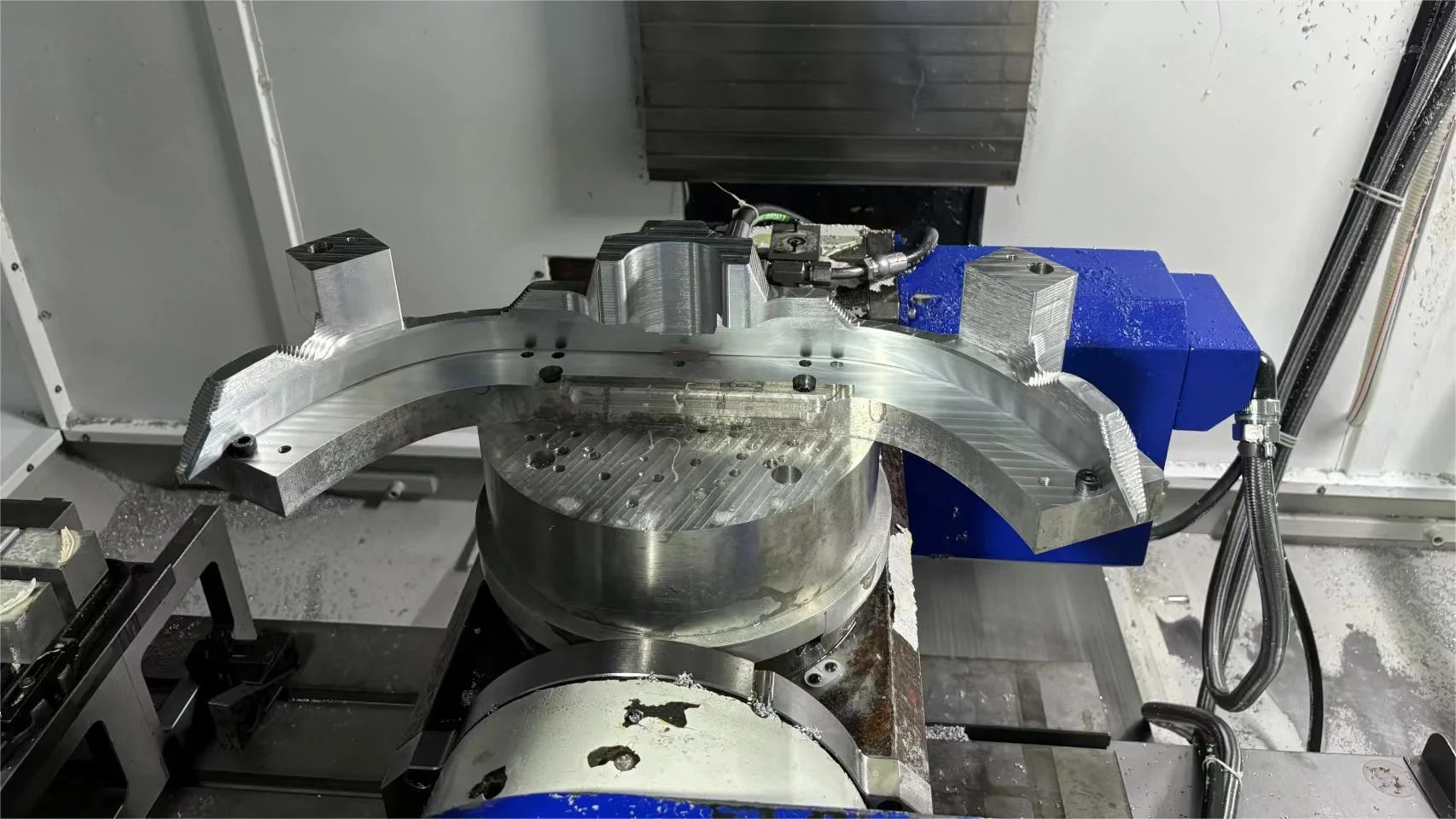

Advanced 3-Axis & True 5-Axis CNC Machining

We machine titanium parts using high-rigidity 3-axis mills, true 5-axis centers, and precision CNC lathes.

5-axis machining enables single-setup processing, reducing repositioning errors, improving accuracy, and protecting thin features from distortion.

CNC turning allows complex cylindrical, stepped, and threaded titanium parts to be produced efficiently.

Ideal for aerospace brackets, medical implants, housings, shafts, and structural titanium components.

Tight Tolerance Control on Titanium Parts

Typical titanium CNC machined parts are produced with standard tolerances of ±0.1 mm.

For geometry-dependent critical features, tolerances as tight as ±0.005 mm can be achieved.

Optimized cutting parameters and cooling methods are used to minimize heat buildup and thermal distortion.

Dedicated fixturing, rigid setups, and continuous tool wear monitoring ensure dimensional consistency and repeatability.

Titanium Surface Treatments

Anodizing: Creates durable oxide layers for color coding, corrosion resistance, and functional surface performance.

Sandblasting / Bead Blasting: Produces uniform matte finishes, removes machining marks, and improves surface consistency.

Polishing: Achieves smooth, low-roughness surfaces for medical, aesthetic, and precision components.

Application-driven surface selection: Titanium surface treatments are matched to functional, visual, and industry-specific requirements.

Thin-Wall & Complex Geometry Expertise

Proven capability in thin-wall titanium parts (≥0.5 mm, design-dependent)

Specialized cutting parameters to minimize:

Work hardening

Vibration & chatter

Warping after material removal

Optimized tool paths and step-down strategies for deep pockets and sharp internal corners

Titanium Subtypes Available

Titanium unique combination of physical and mechanical properties makes them almost unmatched among engineering materials.

There are different grades of Titanium for CNC machining.

| Ultimate tensile strength | Yield strength | Young’s modulus (modulus of elasticity) | Elongation at break | Hardness | Corrosion resistance | Magnetism | Weldability | Application | |||

| Titanium Grade 1 | 310 – 350 MPa | 220 – 240 MPa | 103 – 105 GPa | 28 -32 % | 120 HB | Excellent | Non-magnetic | High | Airframe components Cryogenic vessels Heat exchangers | Learn More | |

| Titanium Grade 2 | 420 – 470 MPa | 330 – 360 MPa | 105 – 110 GPa | 23 – 25 % | 80 – 82 HRB | Excellent | Non-magnetic | High | Aerospace Marine industry Medical industry | Learn More | |

| Titanium Grade 5 | 920 – 1000 MPa | 830 – 880 MPa | 113.8 GPa | 9 – 11 % | 334 HB | Very Hight | Non-magnetic | Low | Aerospace | Learn More |

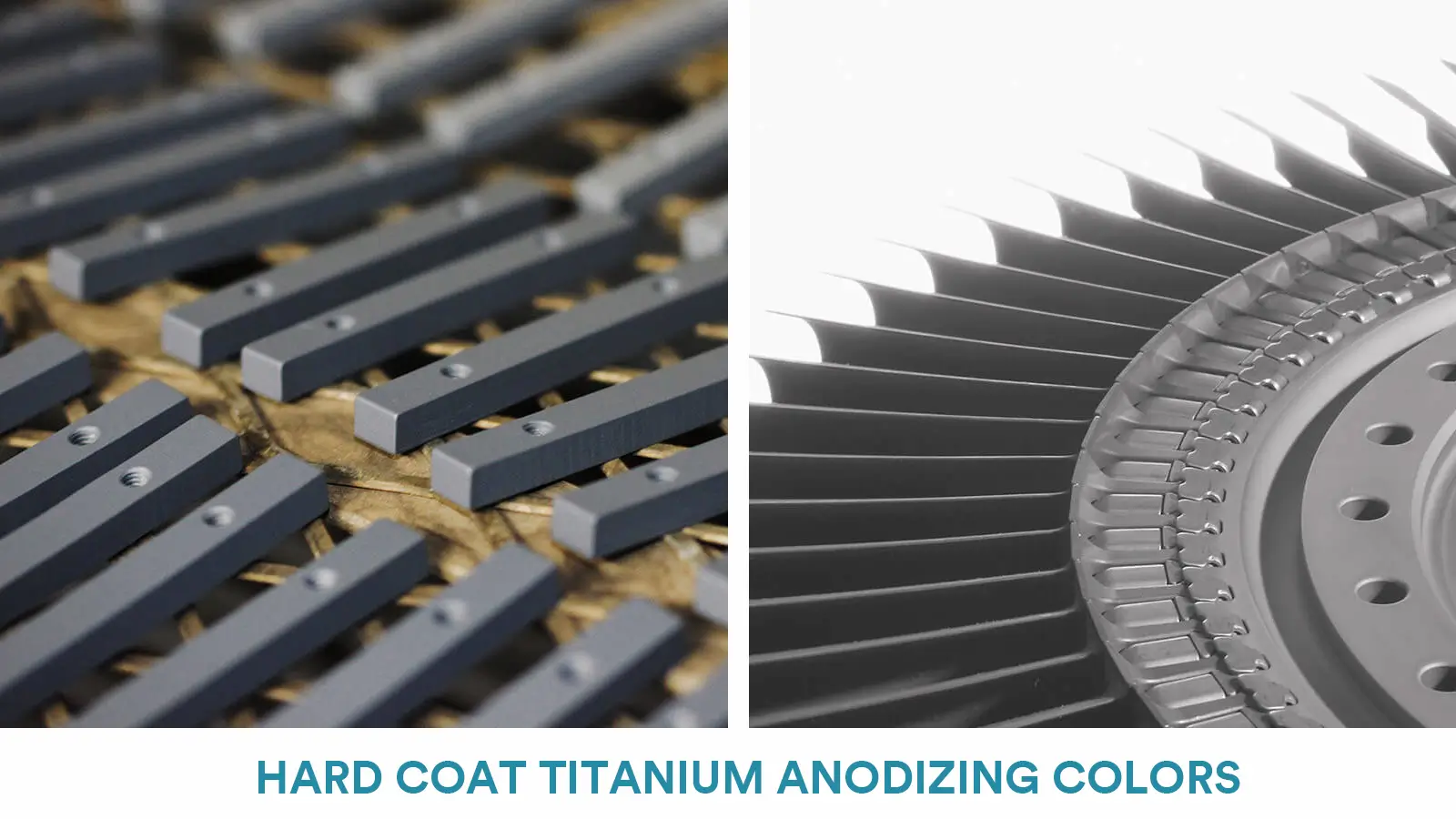

Titanium Surface Treatment Anodizing

Titanium Anodizing Types

• Titanium anodizing is commonly classified into three types: Type I (pretreatment/cleaning), Type II (functional or hard anodizing), and Type III (color or decorative anodizing).

• Type I anodizing is primarily used for surface cleaning or pretreatment and is rarely specified as a final customer-facing finish.

• Type II anodizing (AMS 2488) is the industry-standard functional process, delivering excellent anti-galling performance, enhanced wear resistance, and reliable corrosion protection.

• Type III color anodizing is applied mainly for visual identification and aesthetic differentiation, widely used in medical instruments and complex assemblies.

Titanium Anodizing Key Benefits

• Titanium anodizing forms a dense TiO₂ oxide layer that significantly improves part performance.

• Its primary benefit is anti-galling, preventing thread seizure and cold welding in titanium assemblies.

• The process enhances wear and corrosion resistance while maintaining dimensional stability for high-precision CNC-machined parts.

• Anodizing also improves biocompatibility and enables reliable color identification without paints or dyes.

Titanium Anodizing Features

• Titanium anodizing is a true electrochemical conversion process—the oxide layer grows from the base metal and will not peel or flake.

• Film thickness is precisely controlled by voltage, determining both surface performance and final color.

• Because the layer is transparent, surface preparation quality is critical.

• Different titanium grades respond differently to identical anodizing parameters, making controlled anodizing a specialized capability.

Titanium Surface Treatment Sandblasting

What is Bead Blasting for CNC Titanium Parts?

• Bead blasting is a surface finishing process in which fine glass or ceramic beads are propelled at high speed using compressed air to clean and uniformly texture the titanium surface.

• The process removes machining residue, light oxide layers, and surface contaminants, producing a consistent, non-directional matte (satin) finish without affecting critical dimensions or tolerances.

Key Advantages

• Improves surface appearance by removing visible tool paths, delivering a clean, high-end industrial finish widely used in medical devices and consumer electronics.

• Enhances surface energy, significantly improving adhesion for secondary processes such as PVD coating, anodizing, or adhesive bonding.

• Induces mild compressive surface stress, similar to light shot peening, helping improve crack resistance and overall fatigue performance of titanium parts.

Key Features

• Uses glass beads for a smooth, uniform satin appearance, or ceramic beads for higher durability and consistency in long production runs.

• Creates a non-directional surface texture, effectively masking visible CNC tool marks.

• Increases surface roughness (Ra) in a controlled manner rather than polishing the surface.

• Requires dedicated, contamination-free media to prevent iron embedding and localized corrosion on titanium.

Titanium Surface Treatment Polishing

What is Polishing for CNC Titanium Parts?

• Polishing is a precision finishing process for CNC titanium parts that reduces surface roughness and improves surface uniformity.

• It can be performed mechanically, chemically, or via electropolishing, removing microscopic tool marks, machining residues, and blasting imperfections to achieve ultra-smooth, high-performance surfaces.

Key Advantages

• Reduces stress concentration by eliminating micro-scale machining marks, improving fatigue life.

• Enhances corrosion resistance through smoother, more uniform surfaces that support passive oxide layer formation.

• Lowers friction coefficient, helping prevent galling in sliding-contact components.

• Improves reliability and performance for medical, bio-contact, and precision assembly applications.

• Provides aesthetic and functional finishes ranging from satin/low-Ra textures to mirror-like optical surfaces.

Key Characteristics

• Achieves low surface roughness, typically Ra 0.8 μm after standard polishing, down to Ra 0.1 μm for medical, optical, or sealing applications.

• Can be applied to internal and complex geometries through electropolishing.

• Requires careful heat management to avoid smearing, work hardening, or distortion.

• Polishing removes material, so CNC parts need extra machining allowance (0.01–0.03 mm) for precise final tolerances.

• Special precautions prevent hydrogen embrittlement during chemical or electropolishing.

CNC-Machined Titanium Parts Gallery

Why Choose ECOREPRAP for CNC Machining Titanium Parts?

Cost-saving Design Tips for CNC Machining Titanium

Titanium is a costly material so remember cost considerations during the design phase. Below are some tips that can reduce the expenses of working with it.

1.Choosing the Right Titanium Grade

Select the correct material for your application so that its high price doesn’t become excessive. For example, if a lot of material is machined away, Grade 2 titanium may be the better option as it is more machinable. Grade 5, on the other hand, is applicable for high strength at extreme temperatures.

2.Increase Fillet Radii

Avoid sharp internal corners. Larger fillets allow the use of bigger, stiffer tools, enabling higher cutting speeds and reducing the risk of tool breakage.

3.Simplify Thin-Wall Features

Titanium has strong elasticity. Walls thinner than ~1 mm need very low feed rates to prevent vibration and chatter. Slightly thicker walls improve stability and machining efficiency.

4.Minimize Deep-Hole Features

Holes deeper than 4× their diameter are difficult to machine due to poor chip evacuation and heat buildup. Shorten hole depth or redesign as through-holes when possible.

5.Avoid Unnecessary Ultra-Tight Tolerances

Apply tight tolerances only where functionally required. Relaxing non-critical tolerances saves time, lowers cost, and improves overall efficiency.

FAQs

When CNC machining titanium, low cutting speeds are recommended. Tool tip temperatures can be easily increased by higher cutting speeds, which can compromise tools. Other related factors include sharp tools regularly replaced at the first sign of wear, feed rates high enough to prevent work hardening and the generous use of coolant.

High speed steel (HSS) drills are excellent for Titanium so long as it is sharp, but carbide tipped drills still provide the best results and deep hole drilling. Because titanium is not a great conductor of heat, much of the heat goes into cutting tools, highlighting the need for sharp and well-maintained tools.

Poor Thermal Conductivity – cutting tools end up taking the burden of heat generation.

“Sticky” or “Gummy” Properties – can lead to problems with long “stringy” chips as well as creating built-up edge.

Low Modulus of Elasticity – leads to spring back and chatter while machining.

High Work Hardening Tendency – further increases difficulty of machining.

Titanium has very high strength and a great strength-to-weight ratio. In fact it is only 5% less strong than steel but is 40% lighter making it great for high tech industries such as aerospace, automotive and energy.

Related Blogs About Titanium CNC Machining

Titanium Alloy Physical & Mechanical Properties

Titanium alloys offer exceptional specific strength, enabling CNC titanium parts to achieve steel-level strength at nearly half the weight—ideal for aerospace, motorsports, and high-performance applications.

Titanium Grades and Alloys Introduction

Titanium is not one material—grade selection matters. Titanium alloys vary significantly by microstructure (α, α+β, β). Ti-6Al-4V (Grade 5 / TC4) is the safest and most versatile choice for CNC machining.

Titanium and Titanium Alloy Anodizing Guide

Titanium anodizing is classified into Type I, Type II and Type III, each serving distinct purposes. The anodizing process grows a dense TiO₂ layer on titanium surfaces, with thickness controlled by voltage, determining both color and surface stability.

CNC Titanium Parts Surface Treatment Guide

The main surface treatment options for CNC titanium parts include bead blasting, anodizing, micro-arc oxidation (MAO), polishing, and physical vapor deposition (PVD).

Applications of CNC Machined Titanium

From aerospace and deep-sea applications to medical devices and advanced robotics, titanium continues to solve material challenges that conventional metals cannot.

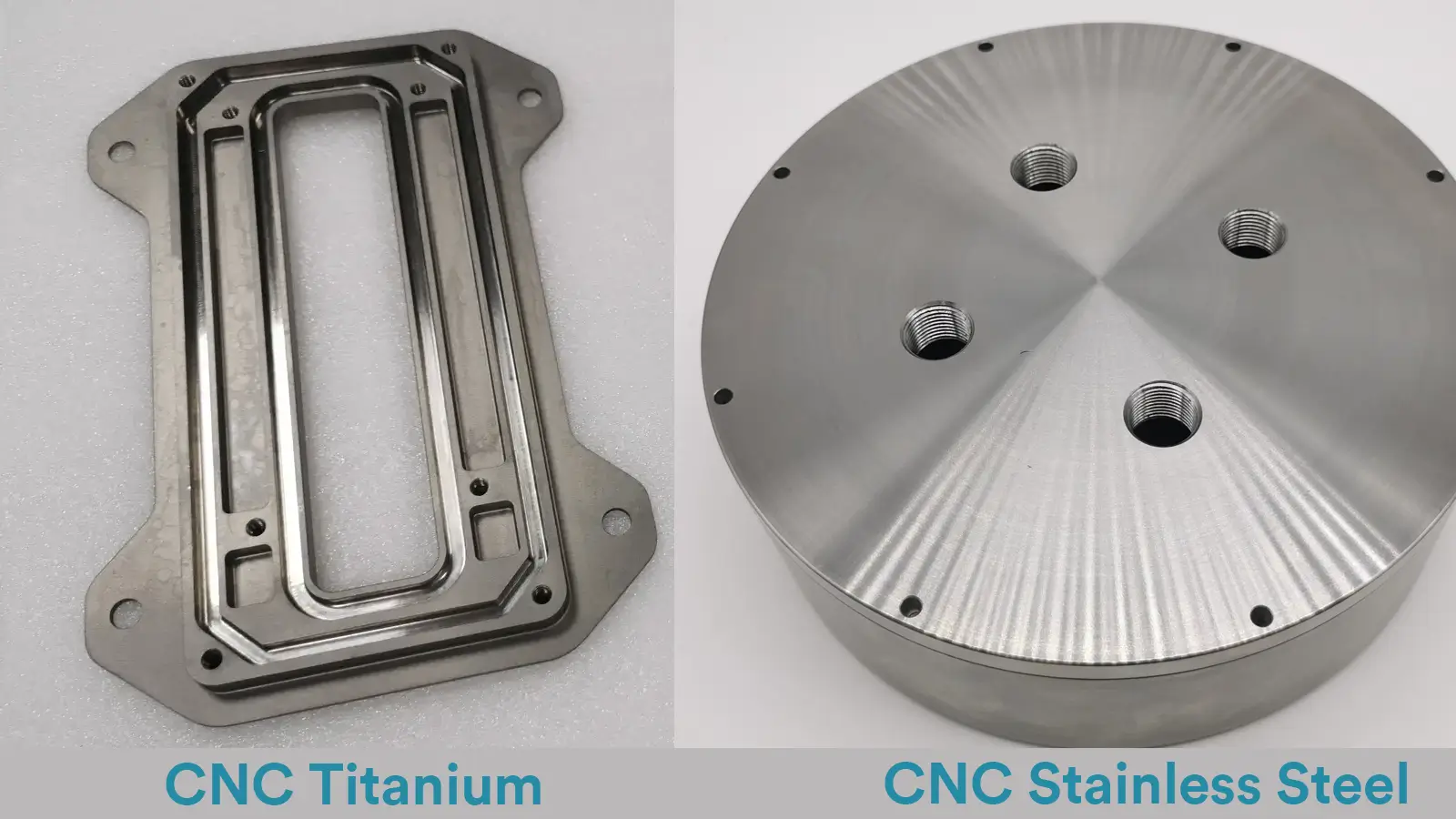

Titanium vs Stainless Steel: Key Differences in CNC Machining

Titanium is ideal for weight-critical, corrosive, and long-life applications, while stainless steel remains the most economical and robust choice.

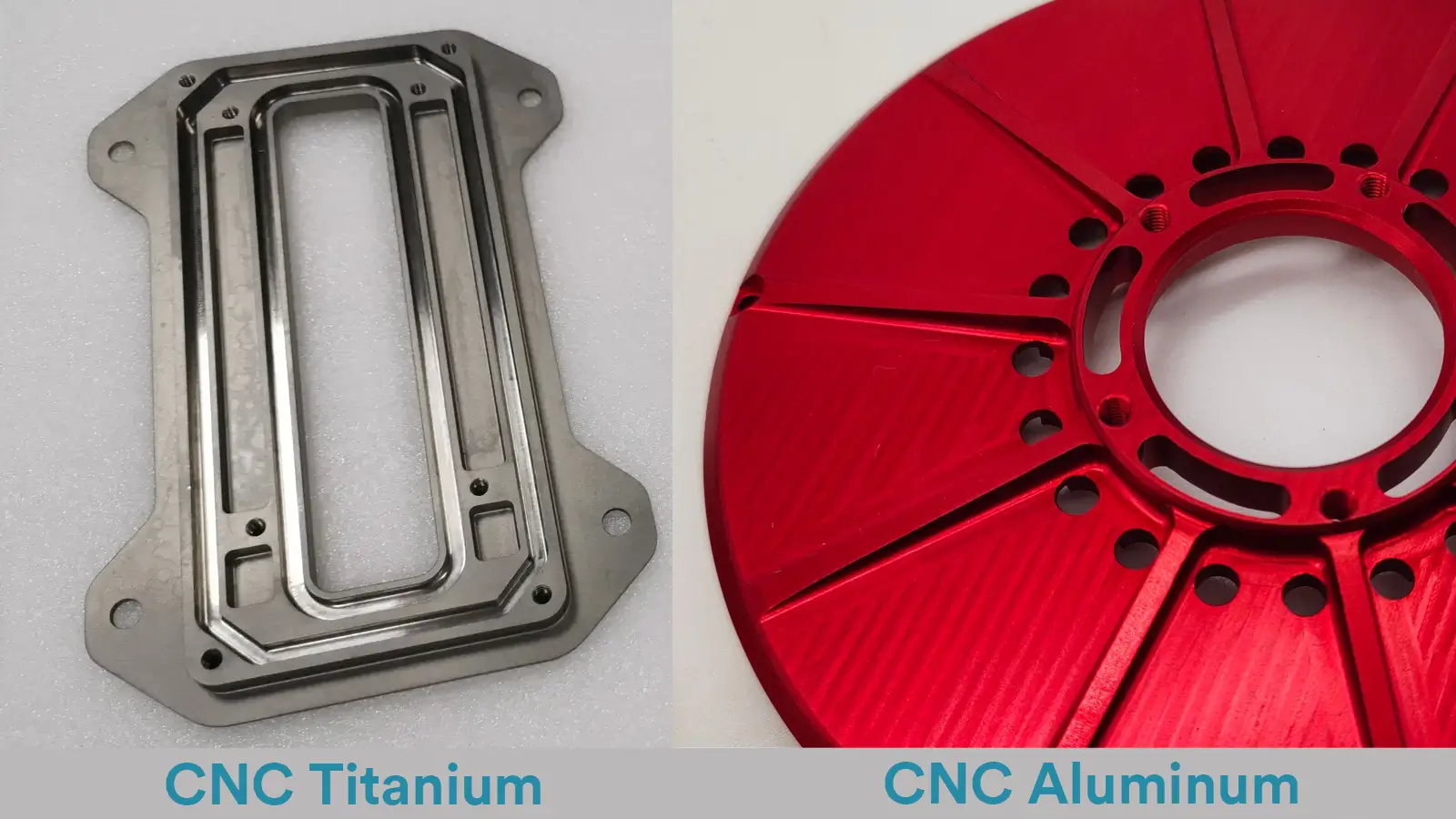

Titanium vs Aluminum CNC Machining

This guide compares titanium alloys (e.g., Ti-6Al-4V / TC4 / Grade 5) and aluminum alloys (e.g., 6061-T6 and 7075-T6) from an engineering perspective, providing insights to balance performance, weight, and budget.

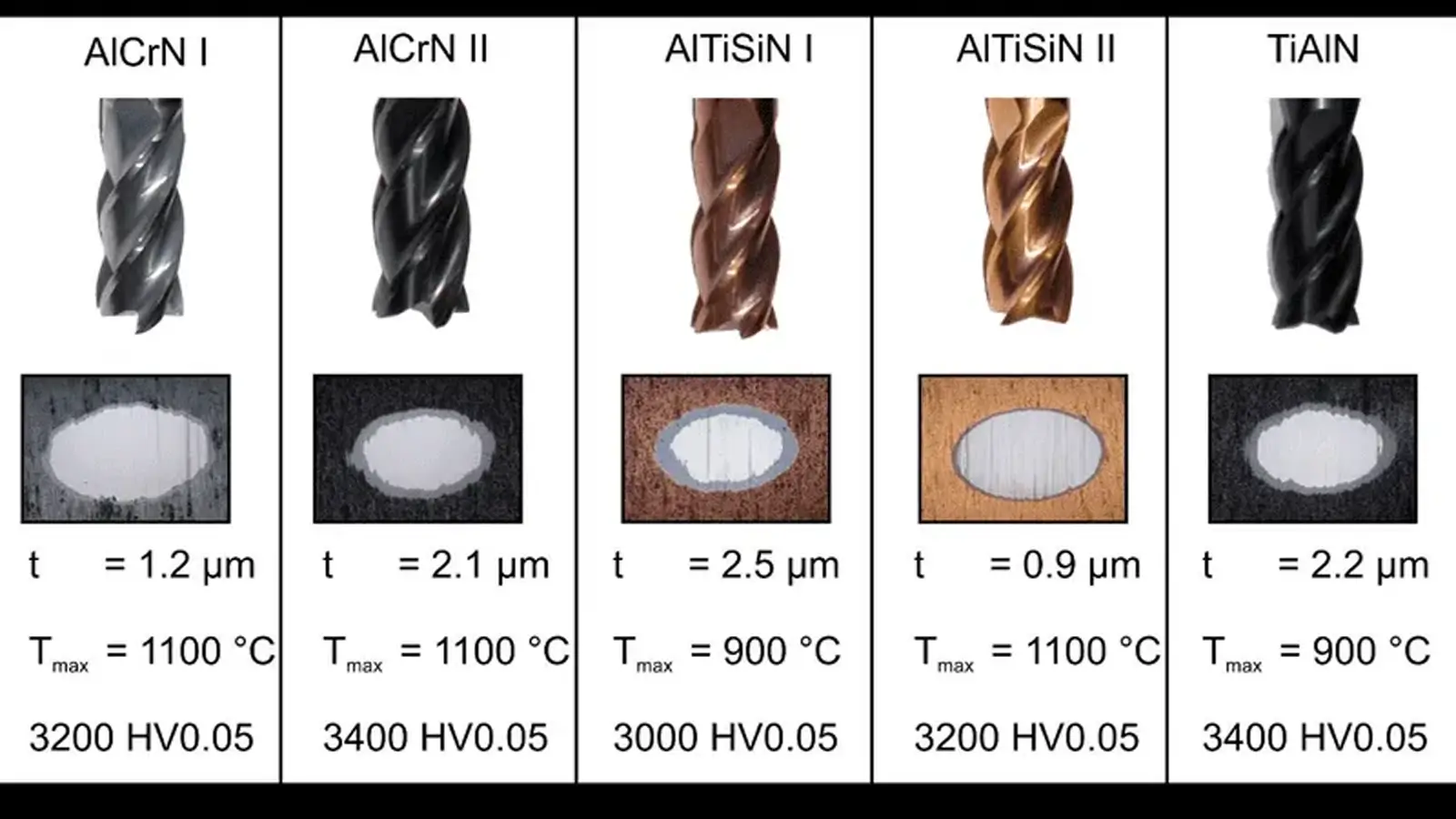

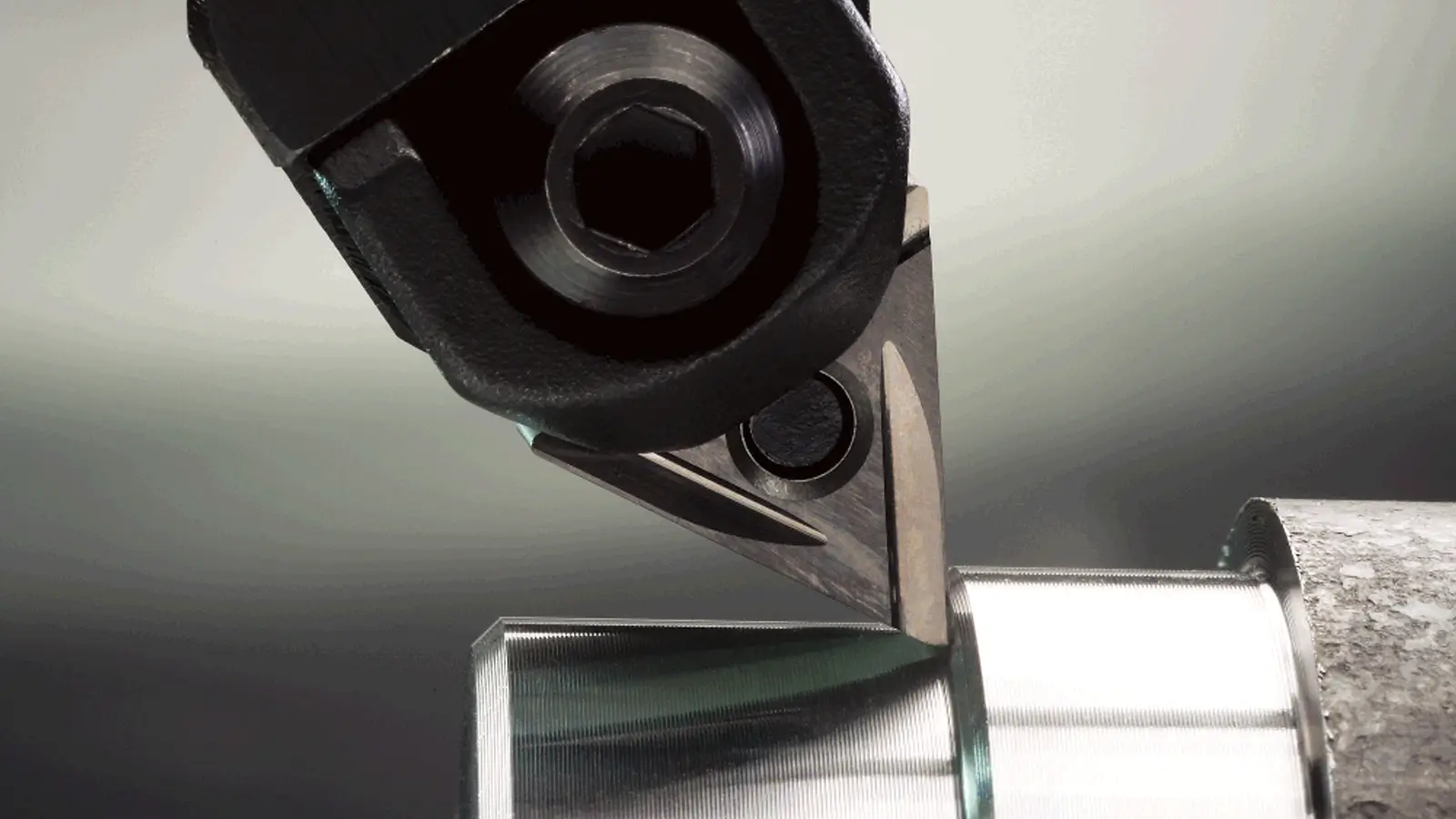

Cutting Tools for CNC Machining Titanium Alloy

A successful tool strategy for taming titanium is the precise integration of materials science (substrate & coating), geometric engineering (edge design), and manufacturing process (parameters, cooling, strategy).

Titanium CNC Machining Challenges and Cost Reduction Strategies

Titanium is difficult to machine because heat builds up at the cutting edge, tools wear rapidly, and the material deflects and work-hardens under load.

Top 5 Titanium CNC Machining Factories in China

Top Chinese titanium CNC factories leverage supply chain integration, engineering efficiency, and scaled experience to deliver stable quality at a predictable total cost.