Home > Sheet Metal Fabrication Materials >Stainless Steel

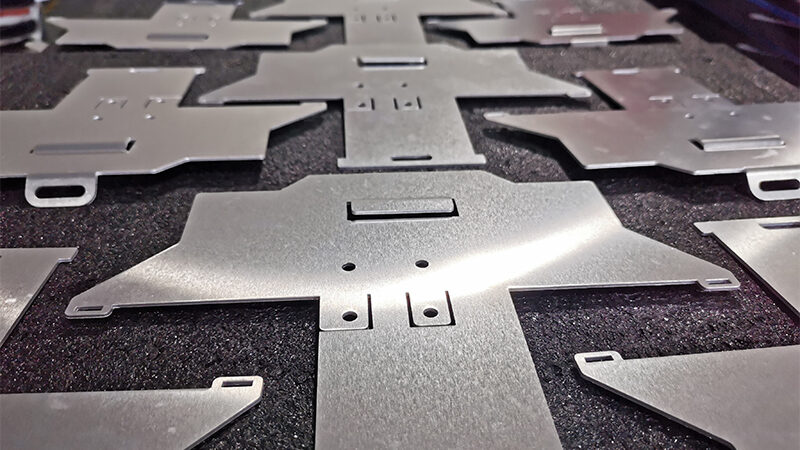

Stainless Steel Sheet Metal Fabrication

High toughness, ductility, wear, and corrosion resistance. Be easily bonded, machined, and polished.

All uploads are secure and confidential

Stainless Steel Sheet Metal Fabrication

Stainless steel includes a selection of sheet metals which include at the very least 10.5% chromium. There are various grades offered, using deterioration immune and a commercially familiar look. Conventional or austenitic stainless steel (300 series) is very typical and does not need warmth throughout the production process. They use great rust resistance, formability, and weldability. SS301 has high work solidifying and is generally made use of for trailer bodies and bolts. SS304 has low carbon and is an affordable quality however is not salt water immune. SS316 has a greater molybdenum material that improves its resistance to seawater corrosion. A lower carbon version (SS316L) is readily available for better rust resistance after welding.

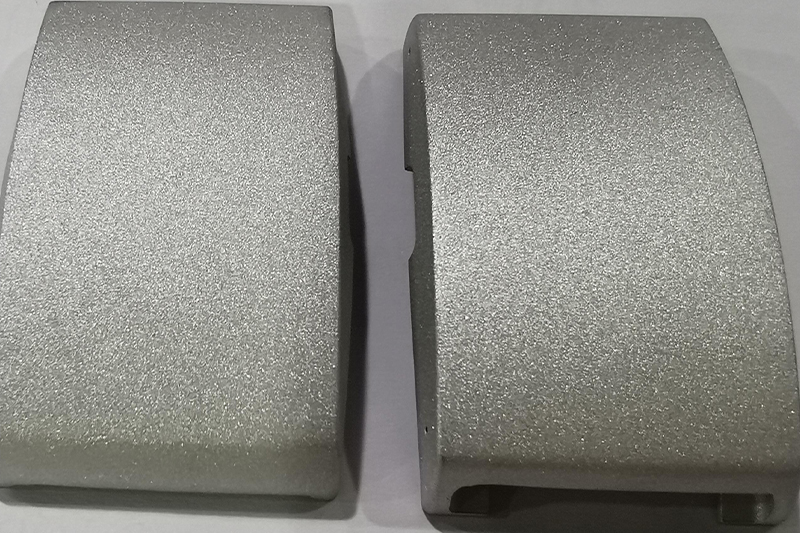

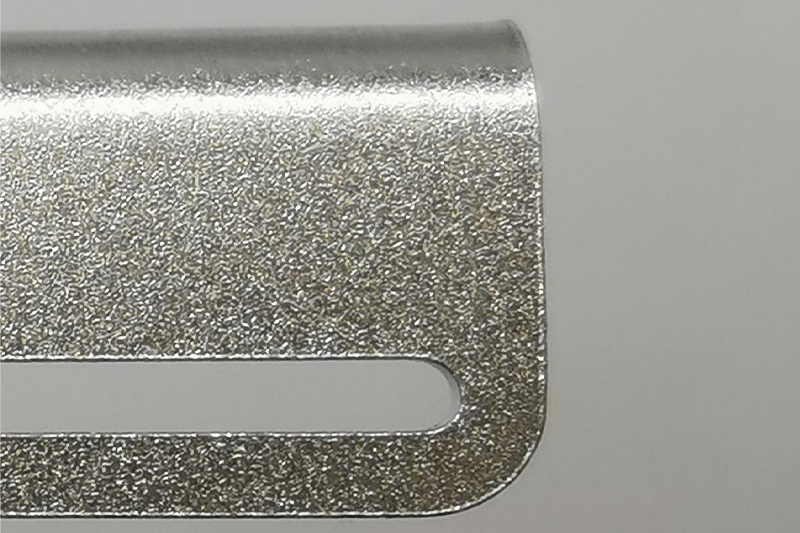

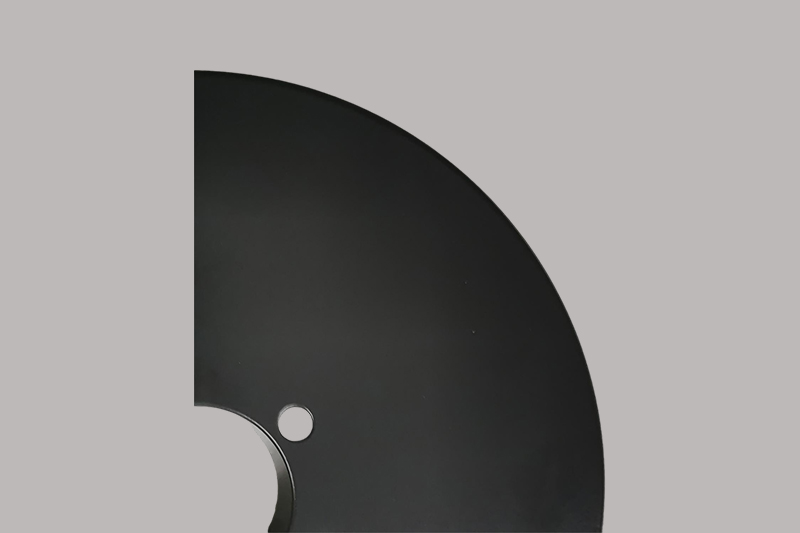

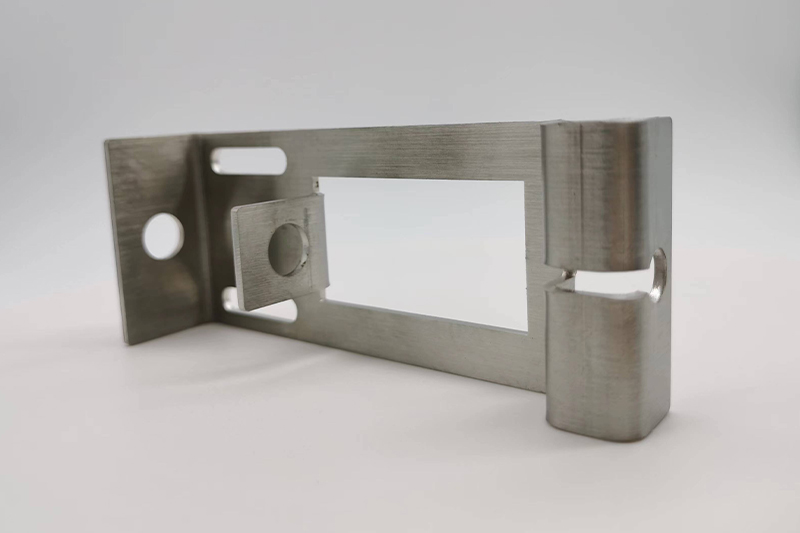

Stainless steel can be machined via sheet steel manufacture procedures consisting of reducing, flexing, forming, and welding. After machining, stainless steel elements might undertake completing procedures, such as sprucing up, grinding, or finishing, to enhance their appearance, corrosion resistance, or other functional properties.

It is located in broad application in a diverse series of items, including rooms, panels, brackets, and various other custom elements.

Stainless Steel Sheet Metal Fabrication Surface Finishes

Stainless Steel Sheet Metal Fabrication Advantages And Disadvantages

Advantages

- Chromium material creates a rust-resistant finish

- A great mix of strength and firmness

- Readily available in a variety of widths, density, and solidity degrees

- Can be used for warm or cold therapies/ procedures

- Appropriate for a selection of handling methods consisting of rotating, brazing, sprucing up, buffing

- Weldable and suitable for soldering or riveting processes

- Very machinable

- Recyclable

Disadvantages

- Can have corrosion at thick welding points

- Possible breaking during handling

- Tends to be extra expensive

- Shows dust and spots easily and often difficult to tidy

- May need sprucing up and completing

Stainless Steel Sheet Metal Fabrication Application

Construction

Construction products like roofing, cladding, building structures, doors and windows

Food Process

Food processing equipment, cookware, and appliances

Cooking

Cooking utensils, kitchen sinks

Vehicles

Vehicles including subways, cars airplanes

Containers

Fuel and chemical containers