Types of Sheet Metal for Fabrication: The Ultimate Guide in 2023

Updated: May 05, 2024

Table of Contents

Have you ever wondered how many goods and tools for specific and how to choose material for meal sheet fabrication? That’s right, numerous. The physical properties of materials used to fabricate flat pieces of metals are beneficial for nearly any industry.

Let’s review the pros and cons of sheet metal materials and their types. We also detailed some recommendations useful for buying a sheet metal that perfectly meets your requirements.

1. What is Sheet Metal Material?

Sheet metal is basically any suitable metal material formed into a thin, flat piece. It is produced through a specific industrial process.

Such a procedure can be seen as an application of force onto the material. Due to the force, a metal is stressed to deform into a flat piece, typically having a square shape. It is also called “a cold working process” due to not heating material before machining it.

In its turn, sheet metal material is any type of metal suitable for cold machining. The physical property of a metal to be hammered to thin sheets is called “ductility.” All the materials that can be machined into sheet workpieces are detailed below.

You can purchase sheet metal in the form of cut pieces or in the form of coiled strips. Typically, the thicker metal is, the more convenient the coiled strip.

There are more materials often considered sheet metals. But I’m jumping ahead. You’ll know more by the end of this post.

2. What are the Advantages and Disadvantages of Sheet Metal Material?

So let’s get to it. Comparison of sheet metal material and formed sheet metal pieces is possible with other raw workpieces only. These may be metals that are not stressed into flat form.

Here is the list of all advantages and disadvantages of the sheet metal materials we determined for your review.

Advantages:

- Durability. Sheet metals are strong and durable overall. They are considered the ideal workpieces for the production of high-strength components suitable for numerous applications.

- Ease of transportation/fabrication. Flat pieces have a low weight to thickness ratio. It makes them more transportable and also contributes to the simplicity of use for fabrication.

- Good malleability. Metal materials used for the production of flat pieces are naturally malleable. They can be formed, bent, cut, and shaped into any custom design that meets absolutely any specification.

- Repairability. Sheet metals are easy to be fixed, replaced, or repaired with a piece of the same material. It is just the practical benefit of using components made from flat pieces.

- Sustainability. A comparatively wide range of materials for the fabrication of sheet metals may enhance a finished component in many ways. Sheet metals are sustainable and may be resistant to corrosion and physical deteriorations.

- Environment-friendliness. Metals are natural substances and are considered environmentally-friendly. The other pro is that sheet pieces can be recycled multiple times.

Disadvantages:

To be completely honest, there are not many cons of sheet metal itself. But some extra specificities make this form of material a bit challenging to use.

- A choice of metals. Not any metal can be machined into thin sheets. As previously mentioned, a material should have a certain degree of ductility. Overwise, it just cannot be hammered into a completely flat form. Thus, alternative options may offer a wider range of materials than sheet metals.

- The thickness of the material. Being considered the main pro of sheet metals, thickness significantly impacts a material’s physical properties. Sometimes, it is impossible to machine a sustainable flat piece of metal of required dimensions if sheet metal is too thin. You will find more explanations at the end of the post.

- Costs. Prices for sheet materials may significantly vary depending on the type of metal, the process of sheet metal forming, and other factors. The fact is: sheet metals are always more expensive than raw, unprocessed workpieces. But it does not make them less cost-effective from a practical perspective.

- Turnaround time. Sheet metal production is a labor-intensive and time-consuming manufacturing method. If you consider manufacturing flat pieces for your own needs, you should predict lengthier production timelines.

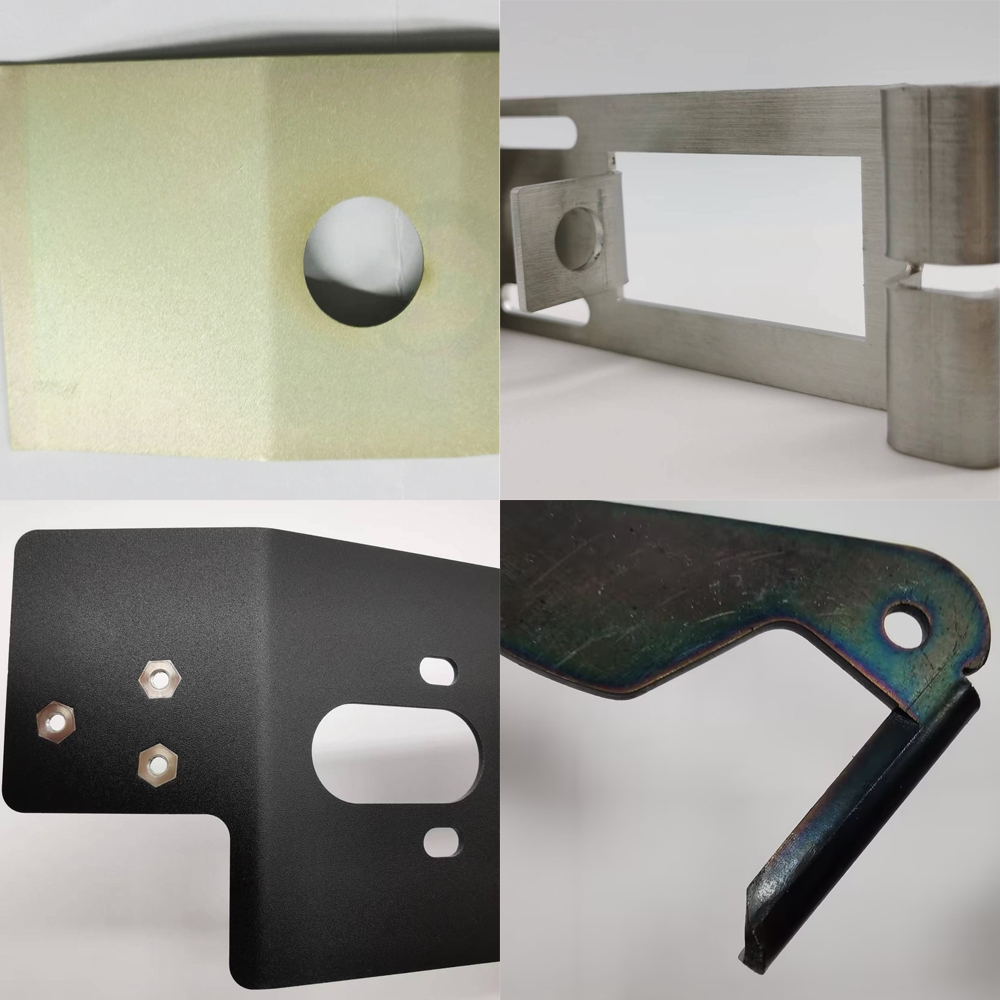

3. Applications of Sheet Metals

- Building materials. Sheet steel is frequently needed for structural parts, sustaining huge weights. A few other examples are ductwork and furnaces. Additionally, sheet metals can be machines into a roofing material such as rain gutters and flashing.

- Decorations. Such parts as spiral staircases, handrails, and gates are almost always manufactured from thin, flat pieces. One application you most likely have never thought of is equestrian purposes. It includes decorative horse tacks, an instance of which is breastplates.

- The automotive industry. Nearly half of the components of a vehicle’s body are made of sheet metals. Automated equipment units needed for automobile building are also partially formed from flat metals.

- Airplanes. The casing of all the planes is done with the use of sheet metal materials. A few examples are wings and fuselages fully covered in thin metal pieces.

- Medical instruments. Tolling for medical use is required to have specific mechanical and chemical properties. The purpose is to make metals withstand body fluids and chemical substances used in the process of healthcare delivery. Thus, many surgical tools are made of sheet metals.

The versatility of sheet metals makes them suitable for numerous applications. It is difficult to find an industry, the craft of items for which does not involve flat pieces of metal.

4. Types of Sheet Metal Materials

1. Stainless Steel

For starters, stainless steel is one of the most frequently used materials. It is not pure metal but an alloy. Its composition is 11% of chromium content and 1.2% or less of carbon content. The rest is iron and other alloying elements if necessary.

This material has superior corrosion-resistant properties. It is also heat-resistant and chemicals-resistant. From storage tanks to kitchen vessels, stainless steel offers reliability and great durability.

2. Brass

Brass is another popular alloy that contains about 84% of copper and 16% of zinc. This material has greater electrical and thermal conductivity and good corrosion-resistant properties. But the real kicker of this material is its appearance. From shiny gold to bloody red, brass with different contaminants can be of any color to your desire.

3. Aluminum

Aluminum is a metal with numerous minor and significant features. It is not costly and can undergo machining as laser cutting or milling. It is absolutely non-toxic. Aluminum also has great corrosion-resistant properties, even without a finish. As a bonus, this material can be recycled multiplied times.

In fabrication, several grades of aluminum can be used. Each of them has a unique set of properties. As an example, Grade 1100 metal has low strength but is weather-resistant. Grade 6061 is strong but not formable. The choice of metal is always a compromise between one or another property to find optimal ones for a specific manufacture needs.

4. Galvanized Steel

How to enhance already great material such as steel? To cover it with another metal, obviously. By integrating zinc into sheet steel’s surfaces through hot dipping, galvanized steel is obtained. It is even more corrosion-resistant and durable. Galvanized steel is a common material for automobile parts.

5. Mild Steel Sheet

Mild steel is another type of steel containing about 0.05-0.025% of carbon. It is also called “low carbon steel.” Basically, mild steel contains mostly iron with some other alloying elements in small proportions.

Mild steel sheets are highly ductile, machinable, and weldable than flat pieced made from other materials. This metal also has some magnetic properties, but its tensile strength is rather low.

6. Alloy Steel

Alloy steel is something that is difficult to characterize. And here is the reason why. The resulting properties may vary when many alloy elements such as vanadium, silicon, nickel, manganese, copper, chromium, and others are added to carbon steel.

Basically, the proportions of alloying elements define the features of these materials. Basically, there are two types of alloy steel: Low-alloy and high-alloy steel. The first category has the containment of all the alloying elements up to 8% of the weight in total. If the proportion of alloying elements exceeds this limit, a material obtained is considered high-alloy steel.

7. Corrugated Sheet Metal

And the last one is corrugated sheet metals. They are made of steel coils by forming thin layers into metal panels. This process is called “roll forming.” Corrugated sheet metals are perfect for roofing as they can withstand severe weather conditions. Typically, a few coils of different materials are used to form a sheet piece of metal with the properties required.

5. Things to Consider When Buying a Sheet Metal

Find below the list of physical properties of metals. We detailed them as comprehensively as possible so you could know how a metal with a given set of characteristics would perform.

Hardness

The material simply can resist physical stresses, such as hard pressing applied to a metal’s surface. Typically, it is defined by measuring the ratio of pressure load and area of indentation after keeping a steel ball onto a material under a specified load. See the infographics below.

Elongation Ratio/Ductility

Ductility is the ability of a material to deform permanently. Typically, there is some capacity of a material to withstand stress without failing. The percentage of a stretch from the original length of the steel to the point of failure is the measure of ductility. Greater ductility of metal implies that it is less likely to fail or deteriorate in properties if stretched.

Tensile Strength

It is one of many indexes of the strength of a material. It commonly means the ability of a metal to withstand stress without fracture.

If the strength applied is lower than the tensile strength, a piece of material will return its original shape and size afterward. Tensile strength is measured as force per unit area. The momentum when a metal breaks is called “the yield point.”

Maximum Temperature

It is referred to as a critical point at which a metal changes from solid to liquid form. Or when it starts melting. While some sustainable metals with the highest melting points can withstand more than 3000°C, most materials for flat pieces can be melted at 1500°C or lower.

As such, aluminum has one of the lowest melting points that equals 660°C. It is vital to know the maximum temperature of the metal to make sure that a manufacturer’s capacities can actually melt a material.

Malleability

It is the ability of a metal to be distorted below compression. In other words, it is how easily a metal can be hammered, shaped, and rolled into thin sheet pieces. It is measured by how much pressure a material can withstand without breaking.

The high value of this characteristic is essential for any material chosen for flat metals forming. Highly-malleable metals are mostly used for forming parts with intricate designs by bending, curving, etc.

Surface Finish

As mentioned above, metals can be coated by other materials and proceed in any way to enhance initial properties. There are numerous options to modify a sheet metal. You can learn more about sheet metal finishing here.

Basically, the more receptive to finishing a metal is, the more it is beneficial for a manufacturer. You would be surprised to know how significantly surface finish can impact a prepared component.

Cost

Finally, the cost is the determinant all manufacturers should pay attention to while choosing sheet metals. Apparently, material type plays a key role in determining the price of a piece of flat metal. The thickness of sheet metal can also contribute to the cost.

While higher thickness means that more material was spent, the lower thickness may cause difficulty forming a sheet metal piece.

6. What are the Minimum and Maximum Thickness of Sheet Metal?

We’ve decided to devote an entire section to such an important point as sheet metal thickness. You definitely should know all the pitfalls of choosing appropriate material. And minimum and maximum width or depth of sheet metal are some of such tricky points.

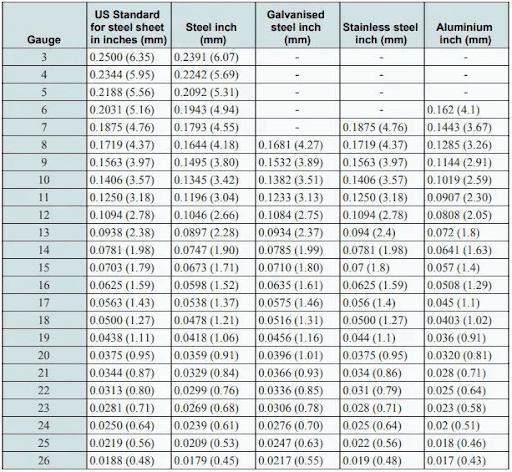

You may have heard the fancy word “gauge.” It is another way to measure sheet metal thickness, along with millimeters, mills, and inches. Gauge is the thickness of metal in relation to its weight per square foot. Thus, a higher gauge value equals a smaller thickness. One mil is a thousandth of an inch. Other measurement units are simple.

You can choose any measurement unit you like, just do not confuse regular mils with “mils” as a plural for millimeters. See the infographics below to learn how thicknesses of distinct metals are measured differently and split into gauges.

And here is the kicker. Actually, there are three groups of sheet metal materials determined by their thicknesses. Let’s review them.

Metal foil. Technically, it is not considered that very sheet metal we have been talking about throughout the entire post. Still, it is sheet metal material, the thickness of which is usually up to 0.2 mm.

Sheet metal. The major fabrication materials have commercial sizes ranging from 0.4 mm. to 12.0 mm. The typical thicknesses may be 1.0 mm., 3.0 mm., 6.0 mm., etc.

Metal plate. They are known for being way larger in width than standard sheet metals. Typical fabrication thicknesses are above 12.0 mm.

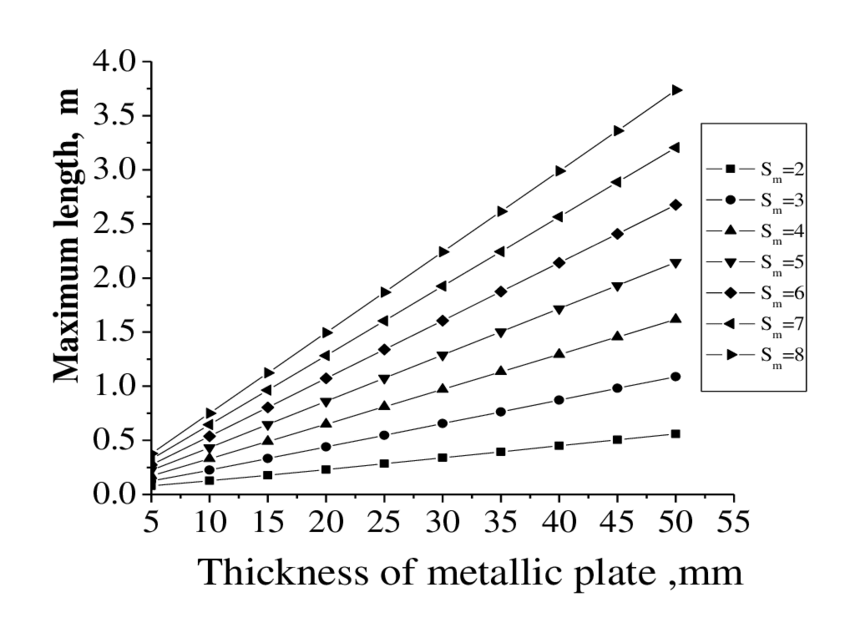

It is vital to know that thin sheet metal is easy to form, and it suits most engineering decisions greatly. However, Increased thickness enables them to produce sheet metals with higher lengths. You can see the dependency in the infographics below.

7. Final Word

In essence, sheet metals are such widespread workpieces for further fabrication of parts that any manufacturer has to stick to them. Luckily, there is a significant degree of versatility, thin and flat metal pieces offer. You can handpick a sheet metal with any properties that you like or require.

Choose the basic material, considering the points detailed above, select the appropriate thickness, and you’re good to go.