7 Types of Sheet Metal Bending You Should Know

Updated: December 06, 2023

Introduction

Are you searching for ways to improve your production flow of sheet metal manufacturing? Your company may greatly benefit from choosing an appropriate type of metal bending!

Shaping metal is a no-brainer, but you may be confused if a their-party provider offered you multiple options. That’s why you need a complete understanding of sheet metal bending first.

Read this post to learn about air bending, bending/bottoming, and coining. You will become an expert in no time!

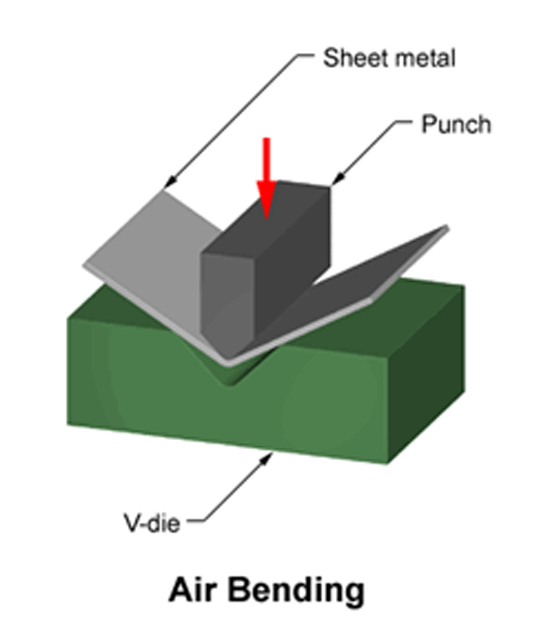

1. Air Bending

For starters, let’s define what sheet metal bending actually is. This process is basically shaping metal to a predefined design by applying force to it. Initial forms of workpieces may significantly vary. But they are mostly flat sheets of metal, typically.

Let’s get down to business. Air bending is probably the most widespread method of sheet metal bending. Its working principle is forcing a workpiece’s surface into a V, U, or any other shape. It is done simply by punching metal with a strong, working tool.

Such tools may vary in their tips and the die shoulders. These elements form the final shape of a sheet metal workpiece. But the principal point is that the workpiece does not touch the walls of the die while being bent.

You may familiarize yourself with the process of air bending from the image below.

It is worth mentioning that all the sheet metal bending processes differ in terms of angle accuracy. It does not have to do much with the precision of bending itself, i.e., with the dimensional error. It is rather the technically supported angle at which a workpiece can be bent.

For air bending, the angle accuracy is 45° or above. It means that you just cannot fabricate a metal part that will have an acute angle smaller than 45°. It is explained with an impossibility to punch most metals at low angles without them being cracked or cut through instead of being bent.

Air bending has the following significant strengths:

- It does not require initial investments in tooling.

- It is compatible with nearly any metal regardless of its thickness.

- A low-pressure bending method.

- Surface damage occurs rarely.

However, this method is not deprived of a few limitations:

- It does not suit shapes with acute angles smaller than 45° as bend accuracy is low.

- High production costs per part fabricated.

- Older equipment units tend to bend inaccurately unless laser measuring technology is incorporated.

- Bent workpieces show a spring-back effect, i.e., partially return their previous shape deteriorating the angle.

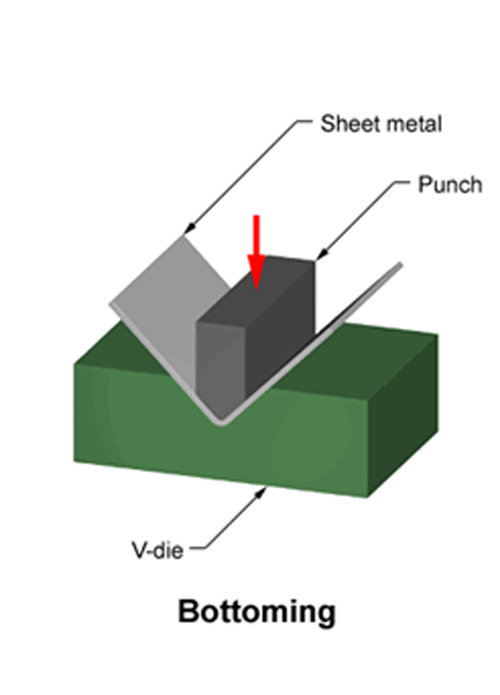

2. Bending/Bottoming

As for bottoming, this process is similar to the air bending one. It is also a press brake bending methodic based on punching a workpiece’s surface. In such a manner, sheet metal is forced into precise forms. In contrast with air bending, the principal point here is that the workpiece touches the walls of the die while being bent.

You may familiarize yourself with the process of bottoming from the image below.

Unlike coining, the pressure applied to workpieces is not that high to make an imprint on the material. Basically, there is no full contact of a punching tool and the die with a workpiece. But we’re jumping ahead.

Bending/bottoming has the following advantages over other methods:

- It suits shapes with any angle as bend accuracy can be adjusted.

- High precision of the method overall.

- Low production costs per part fabricated.

- Bent workpieces almost do not show a spring-back effect.

- Require high initial investments in tooling overall.

- Some shapes may require custom tooling.

- Tooling leaves marks on workpieces’ surfaces.

- Requires more pressure to be applied to metal than air-bending does.

3. Coining

Here’s the interesting process, which, as evident, is widely used to fabricate coins. Technically, coning is implemented in any case when a manufacturer needs a sheet metal to be stamped.

The working principle of the method is forcing a sheet metal into the bottom dies with up to 30 times more pressure than during air-bending. It causes permanent deformation of the workpiece into the shape required. At the same time, it makes a workpiece to take the form engraved on the surface of the bottom die, if necessary.

You may familiarize yourself with the process of coining from the image below.

The angle accuracy of this method may vary in the broad range. Basically, the method is intended to produce superior outcomes regardless of the shape needed. But it causes the necessity to choose tooling wisely.

Coining may benefit your production with the following pros.

- The spring-back effect is completely nihilated.

- Great precision of the method overall.

- It supports any bend accuracy.

- Can produce parts with imprinted designs.

Unfortunately, the process has a few essential cons.

- It is an expensive method requiring high initial investments.

- Moderate to high production costs per part fabricated.

- Most shapes require custom tooling.

- Tooling leaves marks on workpieces’ surfaces.

- High-pressure bending method.

4. Folding

If you ever make paper airplanes, the folding of sheet metals is pretty much the same. As evident from its name, folding is bending workpieces at a precise angle.

The working principle of the method is positioning and holding a metal sheet with a clamping beam tool. Then, this tooling swings a workpiece around a pivot point, making the material fold.

Depending on the material choice and the thickness of a workpiece, the maximal fold/bend angle is either 45° or 90°. Of course, you may fold a thicker workpiece again and again. But as a rule of thumb – folding is performed on thinner sheet metals compared to bending.

Actually, folding comprises a number of processes that meet the criteria of the manufacturing techniques.

- V-die bending.

- U-die bending.

- Forming.

- Free bending with one-sided clamping.

- Three-point bending.

- Free round bending.

The example of V-die bending is shown in the image below.

Folding has the following advantages over other methods:

- It is a relatively simple technique.

- Low to moderate production costs per part fabricated.

- Low initial investments in equipment units.

- The high accuracy of the method overall.

The method is not deprived of a few weaknesses to consider:

- Tooling leaves marks on workpieces’ surfaces.

- Bent workpieces show a moderate spring-back effect.

- The folding angles available are strictly limited.

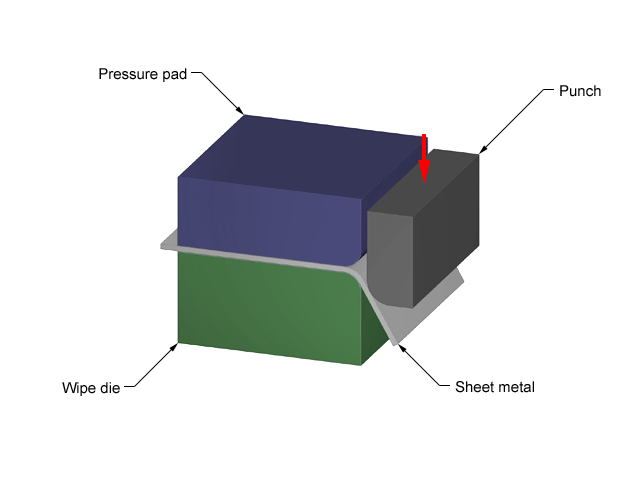

5. Wiping

Wiping die bending or edge bending is a modification of the folding manufacturing technique. It is simply another plastic deformation of sheet material.

The working principle of the method is holding a workpiece between a pad and a die and sliding the wiping flange/punch down. As a result, an applied force bends a workpiece giving it an angular shape.

You may familiarize yourself with the process of wiping from the image below.

Needless to say, the method does not support bending angles over 90°. It is so because of the geometry of the wiping flange.

But the good thing is that you may round the workpiece being bent. It is done by simply adding angle tangents from the radius to both the die and the flange. Take a look at the way it works on the image below.

The process of wiping has several significant strengths:

- Little to no surface damage compared to other methods.

- The applied force is spread evenly across the workpiece’s surface.

- Great precision of the method overall.

- May bend a workpiece multiple times in one run.

Limitations of the process to consider are the following:

- Bent workpieces show a moderate spring-back effect.

- It is an expensive method requiring high initial investments.

- Moderate to high production costs per part fabricated.

- Curved shapes require custom tooling.

6. Rotary Bending

Believe it or not, bending metal tubes is not that different from wiping or folding flat, sheet pieces of metal. Rotary bending is a complex process that may produce pipes with a vast range of central line radiuses.

The working principle of the method is bending a tube with a mandrel inserted inside so it fits the exact outside diameter. The inner, solid support prevents a tube’s collapse while a rotary die pushes it forward and rotates at the same time.

The method is highly versatile. It can rotate a tube to a maximum of 180° or bend multiple times the same tube in one rune. But only if an equipment unit supports such an option, of course.

You may familiarize yourself with the process of rotary bending from the image below.

The process of rotary bending you to benefit from the following advantages.

- May bend a workpiece multiple times in one run at different angles.

- Bent workpieces show a minor spring-back effect.

- It supports intricate tube and pipe designs.

- Potentially can process most materials of varying thicknesses.

The weaknesses of rotary bending are the following.

- It is an expensive method requiring moderate to high initial investments.

- Moderate to high production costs per part fabricated.

- Some shapes require custom tooling.

- High-pressure bending method.

- May cause deterioration of a workpiece’s surface or even a collapse if performed incorrectly.

- It is a complex method overall.

7. Joggle Bending

Joggling or segmented bending is shaping a sheet metal section by section using stringers and formers. The technique is especially helpful when there is a need to bend an extended workpiece in a periodically repeated pattern.

The working principle of the method is pushing a sheet metal workpiece in an equipment unit or a brake. Bend the metal by 20° to 30° using the formers. Release the part, turn it over, and bend it again. Repeat till the correct height of the section or the joggle is achieved.

You may familiarize yourself with the process of joggle bending and tools for it from the image below.

Joggle bending has the following essential strengths:

- Versatile process producing intricate shapes in accordance with the intended pattern.

- Bent workpieces show a minor spring-back effect.

- Low to moderate production costs per part fabricated.

However, the process is not deprived of a few weaknesses to consider:

- It is an expensive method requiring moderate to high initial investments.

- Moderate to high production costs per part fabricated.

- Some shapes require custom tooling.

- High-pressure bending method with an applied force distributed unevenly.

- Inevitably causes deterioration of a workpiece’s surface.

- It is a complex method overall.

8. Summary

All the methods are frequently used in the manufacturing process. You may be advised to go for air bending services if you occasionally need to fabricate a small batch of components.

Consider bottoming for the production of intricate components on a regular basis. And employ coining for workpieces with engravings.