Types of Sheet Metal Finishing: The Complete Guide in 2023

Updated: May 05, 2024

Can I be totally honest with you? Hardly ever any sheet metal fabrication had been done without applying finishing techniques. That is why you just should know more about sheet metal finishing and some reasons it is used.

We will also discuss widespread methods you are typically offered to choose from. In case you have difficulty selecting the right finishing processes, you will find our recommendations detailed below useful.

1. What Is Sheet Metal Finishing?

It is the final stage of the sheet metal fabrication process. In other words, after all the cutting, turning, drilling, and other manufacturing techniques needed to make a functional part from a workpiece, finishing is due.

Rough shaping and assembling always leave small deformations. They deteriorate the appearance and durability of a component. You definitely want to get rid of them before moving machined parts to the next step of a production cycle.

Alternatively, you may want a part to have an additional layer of protection or some attractive polishing. Thus, sheet metal finishing is the manufacturing process of changing the surface of an object. In this particular case, an object is a flat component made of sheet metal.

The purpose of sheet metal finishing is to smoothen the surface of a metal sheet part. Or to place the metal coating on the surface of a metal sheet part.

2. Why Do You Need Sheet Metal Finishing?

For starters, metal finishing became a vital post-processing stage of manufacturing long ago. Let’s review the reasons for such popularity of the technique.

- Durability and corrosion resistance

Some coatings significantly enhance the endurance of a component, making them long-lasting. A flat object may be added a protective hard layer or a corrosion-resistant one.

- Change in properties of metal

Sometimes, metal finishing can be neglected. But it is definitely not the case when adding coatings is a substantial manufacturing stage. Depending on your needs, a component can be enhanced with abrasion, friction, or radiation resistance. It is also possible to increase the conductivity of parts made of sheet metal for its further use in electronics.

- Decor

This one is simple. You may require a colorful coating on your part to make it more attractive. Alternatively, you can just polish the surface of a component to perfection. Or in contrast, add the matte coating.

- Increase in functionality

You may frequently need some sort of functional coating on a part’s surface. Typically, besides decorative purposes, some finishing options can enhance components with additional features. An example is an abrasive surface. As you can see, sheet metal finishing is difficult to operate without. Think about it this way.

3. Sheet Metal Finishing Techniques

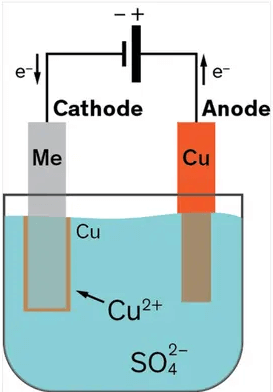

Electroplating

Let’s start with one of the most complex sheet metal finishing methods. Anode and cathode are put in an electrolyte chemical bath. The sheet metal part is placed in an anode position. At the same time, the sacrificial metal that is to be attached to the sheet component is in a cathode position.

Then, a continuous electrical charge makes negatively charged ions of the sacrificial metal move to the positively charged sheet metal plate. As a result, a metal coating is obtained. Depending on the type of sacrificial metal used, a different combination of properties can be obtained. That is the description of finishing we know as electroplating.

See the infographics attached below.

Benefits

- Versatile process compatible with many sheet metals and capable of enhancing surface with a number of properties.

- A processed part obtains excellent corrosion and abrasion resistance.

- It improves the conductivity, strength, and durability of components.

- Can be used with natural elements, such as leaves, to prevent decay; thus, it is a method of art.

- The method offers to add cosmetic metal finishes.

Limitations

- Expensive and time-consuming process.

- The process is rather inconsistent, and quality may fluctuate.

- In general, there are significant labor-based risks unless safety measurements are taken.

Anodizing

Here is the, perhaps, least versatile finishing method. Anodizing is compatible with sheet metal components made from aluminum and titanium only.

The technique exploits electrochemical reactions to create a corrosion-resistant coating on the surface of a part. It’s easier than you think. Sheet metal is put into an acid electrolyte bath and exposed to an electric current. It makes a thin surface layer transform into an anodic oxide layer.

Depending on the type of acid and modification of the method, layers with different properties are obtained. Let me give you some examples: Type I anodization exploits chromic acid to create a nice-looking irremovable layer. Type II uses sulfuric acid to create a corrosion-resistant layer.

And type III or hardcoat anodizing, conducted with sulfuric acid under tough conditions, creates corrosion and wear-resistant layers. As a bonus, anodization can create a variety of finish colors, making painting or powder coating unnecessary.

Benefits

- It is possible to obtain great corrosion and abrasion resistance qualities.

- A modified layer is fully integrated into the surface; thus, no risk of adhesion failure or fading.

- This finishing cannot be removed and is extremely wear-resistant.

- No other finishing adds similar properties to the surface of sheet metal.

- The finished product is ultraviolet stable.

Limitations

- Expensive and time-consuming process.

- The range of compatible materials is extremely low.

- Typically used metals have lower thermal conductivity (vital for some industries, such as electronics).

Bead Blasting

Simple enough, but impressive finishing processes. It involves shooting many tiny abrasive particles at the surface using the flow of compressed air.

It creates a high-quality, smooth matte texture on a part’s metal surface. Bead and sand blasting, about which you may also have heard, are grounded on the same fundamental blasting process.

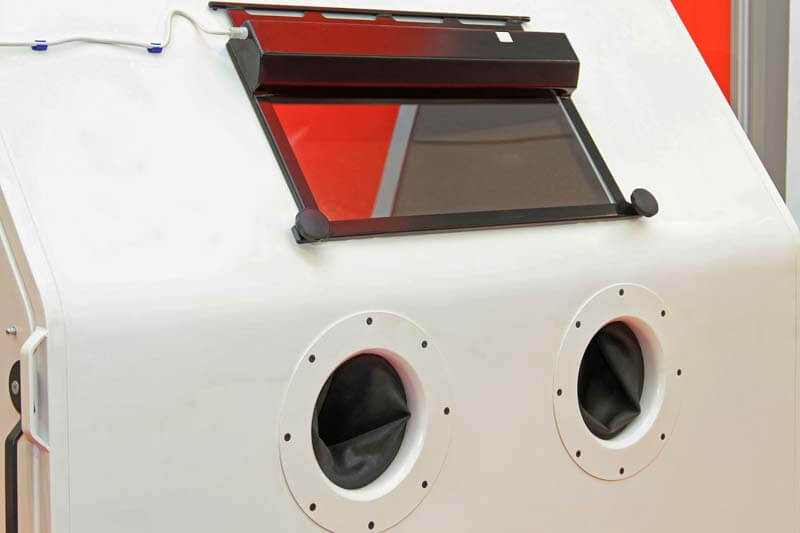

But, they have some principal differences you can learn from this post. As a bonus, bead blasting removes unnecessary paint from finished parts and cleans them somewhat. Such a finishing method exploits bead blaster cabinets to keep details in a hermetically sealed environment.

In the cabinet, components are bombed with abrasive particles. Examples of such abrasive materials are typically sand or glass beads. The last is lead-free, soda-lime glass shaped into spherical objects. They are environment-friendly (it may be important if your company should adhere to good green manufacturing practices).

Let’s review some pros and cons of bed blasting sheet metal finishing.

Benefits

- The method is completely safe from the perspective of labor-associated risks if safety measurements are taken.

- It does not deteriorate the surface of sensitive metal due to proceeding gently.

- The process is environment-friendly, and abrasive particles can be reused and recycled up to 30 times.

- Abrasives exploited are typically non-reactive.

- The polished surfaces look highly attractive and expensive.

Limitations

- Typically, it is one of the most time-consuming finishes (depending on the toughness of the metal).

- It absolutely cannot be used for preparing a component for further painting.

- It is not cost-effective for small-scale projects.

- It requires multiple precaution measures by the operator.

- Silica, which can be used as an abrasive material, leads to lung disease and cancer if inhaled.

Situation-Dependent Points

- The price of such finishing may vary.

- It removes previously-added paintings.

Powder Coating

In contrast to other finishing methods, powder coating is all about aesthetics. In sheet metal fabrication, such finishing is simply spraying powdered paint onto a component’s surface. Then, the metal is baked until paint bonds to its surface. The coating is obviously superior to other painting methods due to its wear-resistant properties.

It also adds corrosion resistance somewhat. But here’s the kicker. Powder coating offers a wide range of colors, and types of finishing, such as glossy, textured, etc.

Benefits

- It enhances parts with moderate corrosion and abrasion resistance.

- The finished product is non-toxic and less flammable.

- The range of offered textures and colors is broad.

- There is no risk of adhesion failure.

- Great consistency.

- It is compatible with any sheet metal type.

Limitations

- Powder cannot be simply mixed.

- It is a bit costly.

- Such coating can be removed.

Metal Polishing

It is as simple as it sounds. With the help of abrasive materials, a metal surface can be polished to perfection. Surfaces become smooth, reflective, shiny, and deprived of defects. Typically, several abrasives are applied to a part. Depending on the condition of the material.

As an example, a rougher abrasive can be used to remove imperfections of the material. Then, a finer abrasive is used to leave metal unmarked. Finally, polishing wheels with buffing compound applied helps to achieve a mirror-like finish.

Examples of abrasives are gray silicon carbide ones for hard processing. Iron and nonferrous alloys come in handy for finer finishing. And cotton, leather, plastic, paper, wool, etc., are used for buffing wheels.

Benefits

- One of the most cost-effective finishes.

- It offers to obtain a nice-looking and reflective surface.

- Deprived of labor-associated risks.

Limitations

- It does not enhance metal with any additional property.

- Surfaces can be easily damaged.

- Visual attractiveness is typically not long-lasting.

Reference Post: Electropolishing vs Mechanical Polishing: What’s the Difference?

Brushed Finishing

The other simple finishing utilizes multiple brushes to achieve the desired surface. Abrasive brushes and perfect to finish uneven surfaces. It helps to comply with a product’s specifications after rough machining.

Employed brushes are typically made of steel, carbon steel, ferrous, and non-ferrous wires. Additionally, natural and synthetic fibers can be used. Brushes may eliminate surface contaminants, blend edges, and polish. Such finishing can be both manual and computer-controlled.

Benefits

- One of the most cost-effective finishes.

- Provides a great base for further painting.

- Enhance durability and corrosion resistance somewhat.

- Removes defects and maintains specifications of products.

- Serves aesthetic purposes.

Benefits

- Brushed finish is not long-lasting and can be easily damaged.

- Brushed surfaces are hard to clean.

- Brushed components cannot be further proceeded using bead blasting.

- May leave brush marks.

4. How to Select the Right Sheet Metal Finishing Process

Functional purposes

Well, you are a bit limited in your choice, when it comes to highly specific characteristics required for a certain flat part. Typically, you can’t just replace, for instance, bead blasting with, let’s say, powder coating.

They simply have different applications. In case you need a particular feature, just review all the finishing techniques detailed above. Find the one fulfilling your need, and you are good to go.

Decoration purposes

In contrast, you have a wider range of options of how to make a component more attractive. You may add colorful or matte coating, or simply polish a metal part making it more attractive. Even functional coatings mostly change the appearance of a flat component. So you may select a method that would combine the creation of a design with adding an extra feature.

Turnaround time

It is described above that some finishing options are more time-consuming than alternatives. It is not common that time is the determining factor.

But, if it is, we suggest you select the less sluggish metal finishing solutions if several appropriate ones are available. Frequently, you don’t have much of a choice.

Cost saving

The simple truth is that some finishing methods are significantly more expensive than others. You still have a limited range of options (typically 1 to 3) suitable for a particular flat part. However, you always may prefer, for instance, simple metal polishing over powder coating or bead blasting if production costs are crucial, while décor or some properties aren’t.

You may also choose cheaper variations of the same technique. As an example, I just prefer a more affordable granular abrasive for bead/sandblasting.

5. Final Word

At first glance, it may seem like you don’t have much of a choice while selecting finishing. Indeed, all the methods have their specific scope of applications.

It is a rare opportunity to switch from one to another finishing easily. However, now you know enough to select the most appropriate sheet metal finishing for your project. And your understanding of metal fabrication is complete.