3D printers became a widespread instrument for making three-dimensional physical objects. A process of extruding successive thin layers of molten plastic by a digital file is called “additive manufacturing.” Despite this technique not being complicated, errors are probable, the most common of which is under-extrusion,” to occur.

Under-extrusion happens when too little filament, which is a thermoplastic material, is extruded during a print. This results in producing sub-quality objects with gaps, dots and holes, and even missing layers. A printed part may look incomplete, rough, and be less durable physically than expected.

It is unarguable that under-extrusion is incompatible with hi-end manufacturing.

Read below to learn about the causes of under-extrusion 3d printing and the complete procedure for this problem-solving.

What Is Under Extrusion in 3d printing?

The definition of under-extrusion is when a 3D printer’s extruder is not pushing enough filament to build an object coded in a digital file. Shortage of thermoplastic materials extruding from the nozzle leads to irregular recesses within a layer.

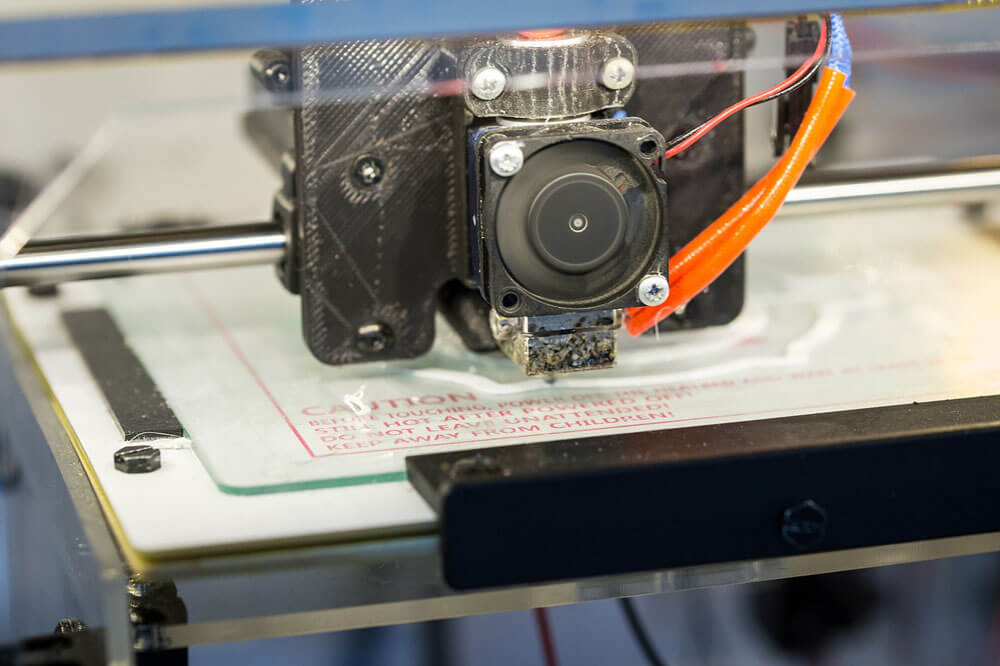

The consequence of under extrusion is not printing some layers or not sticking it to others strongly enough to form a solid shape. An object printed with such error in technology shown on the image below cannot be used for its intended purpose and is considered defective.

Let’s delve into the main causes of under extrusion in more detail in the context of detecting this issue, fixing, and preventing from repetitive occurrence.

The Main Causes of Under Extrusion

Tangled Filament

Filament tangling is when the material cannot be appropriately unrolled from the spool. Thus, the feeder cannot maintain the set speed rate, resulting in not enough filament moving.

Filament Diameter

It is a common mistake when a filament with a diameter that exceeds the printer slicer’s settings is used. This discrepancy leads to the deterioration of the speed at which the extruder operates; thus, it often causes under-extrusion.

Grinded Filament

Filament grinding is the issue when the material is moved at a higher speed than it can be melted, and knurled gear slips against it. This issue leads to not letting the feeder push it and, therefore, to under-extrusion.

Speed is too High

The setting of an optimal speed is crucial, as an increase in the rate a printer operates at proportionally decreases printing quality and leads to under-extrusion.

Temperature is too Low

Printing temperature is a vital factor that should be adjusted to types of filaments, colors, and flow rate. Lower temperate than needed does not enable a printer to melt filament resulting in unsatisfactory printing fully.

End of the Spool

Reaching the end of the spool results in extra friction in the Bowden tube that is a direct cause of under-extrusion. It is explained by an inability of a 3D printer to move clogging material further at the same speed as under normal circumstances.

Clogged Nozzle

The nozzle of a 3D printer can be clogged because of the change in filament types without adjusting the printing settings. The inability of material to reach the nozzle’s exit leads to under-extrusion.

Deformed Teflon Insulator

Deformation of the Teflon insulator as a result of improper 3D printer usage leads to preventing the filament from passing through it.

Feeder Wheel is not Tight

The screw of the wheel that moves the filament in the Bowden tube may not be securely attached. As a result, the material is not transported at an expected speed rate.

The mentioned above causes of under extrusion may not be simple to detect. It is why there is a need for a complex examination of a 3D printer and, potentially, for an adjustment of some settings. Below you can read all the tips helpful in fixing above-mentioned causes of under-extrusion. You can also find further some additional issues, which more specifically related to the material or some equipment parts of the 3D printer.

How to Fix Under-Extrusion?

Material

The first potential factor leading to under-extrusion to check is the correctness of the material setting. Often material profile does not match the material, leading to incorrect 3D printer operation.

On the other side, the material used can be the route cause of the problem. Thus, it can be recommended to ensure that the filament is not stuck before entering the printer’s feeder. Also, the filament should not overlap on the spool.

The other material-related reasons for under-extrusion it the absorption of too much moisture by the sensitive filament, such as PVA. It may be advised not to store any thermoplastic material for printing in a humid environment to prevent lose of quality.

Equipment

A set of programs that control printing and some parts of equipment comprising a 3D printer should be examined to fix under-extrusion.

1. Software and Firmware. Under-extrusion, as well as any other printing-related issue, can be caused by inappropriately operating programs. Thus, it can be recommended to check a slicing software such as Cura (or another installed) for new updates. At the same time, outdated firmware, can conceive bugs affecting the operation of a 3D printer.

2. Bowden Tubes. Bowden tube is a part of filament feeding mechanism and is a hollow tube through which the material is moved. This gear is in constant friction with the filament. The bad shape of the Bowden leading to an excess of friction is a frequent reason for under-extrusion. Therefore, it is necessary to clean or replace the tube from time to time.

3. Cooler Fans. Excess in temperature leading to a clog in the hotend causes gradually increasing under-extrusion. Often, the solution is cleaning cooler fans with a vacuum cleaner or a brush from clumps of dust and other rotation preventing objects.

4. Hotend. Under-extrusion caused by a clogged hotend frequently occurs when the different materials are used multiple times. It can be recommended to clean the hotend with nylon before changing the material every time.

5. Extruder Board. This part controls both cooling fans and the temperature in the hotend. In the event of under-extrusion, the extruder board that potentially causes overheating issues should be replaced with a new one.

6. Extruder motor. If a 3D printer produces repetitive clicking noise, it may indicate that the extruder motor does not move the filament correctly. In this case, the part should be fixed or replaced.

As well as any other highly-technological tool, a 3D printer requires completing procedures for maintenance of its equipment parts, software, and firmware periodically.

Printer Settings

If, after completion of the procedures mentioned above, the under-extrusion issue is still present, some settings of a 3D printer are likely to be set incorrectly.

1. Feeder’s Pressure. Sufficient pressure on the feeder ensures that the filament is fed forward. In the event thermoplastic material is not moved to the extruder, you should consider gradually increasing pressure until the issue is fixed.

2. Printing Temperature. The other essential parameter is the print temperature, which may not be adjusted to a particular filament. Most printing filaments have a range of temperatures indicated on their packaging by the manufacturer. You may start from the top of the range and gradually lower it until you find the optimal temperature.

3. Printing Speed. Printers have three sets of printing speeds, from 40 to 150 mm/s. For instance, 50 mm/s is a good speed for such filaments like ABS, PLA, and PET-G within a lower speed range. Simultaneously, other types of thermoplastic material may need another printing speed, usually a lower one.

4. Extrusion Multiplier. It is also possible that the extruder’s rate at which its motors operate is not high enough to move enough filaments. It can be recommended to increase the extrusion multiplier by 2.5% gradually. Another method to find an optimal rate is to multiply the size of the nozzle by the layer height and the speed of printing.

The printer settings require frequent adjustments, especially if the type of filament is changed regularly.

Extruder Kit

Extruder kit used as part of a 3D printer is the vital part contributing to the quality of extrusion. Despite most printers having a basic extruder, users often purchase extruder upgrade kits. It is done to adjust the functionality of a printer to changing needs.

For consistent extrusion, it can be recommended to check the compatibility of an extruder kit with a printer and a filament diameter it works with. The other technical characteristics such as even flow of material and the correctness of pressure applied to filament should also be checked.

Summary

Under-extrusion is a prevalent issue that occurs during 3D printers’ operation and significantly reduces the quality of printed objects.

Numerous potential reasons for under-extrusion should be carefully examined to detect and eliminate the root cause. It can be recommended to conduct procedures for the maintenance of parts of a 3D printer and not forget to adjust its settings.

Finally, it is worth paying attention to the characteristics of extruder kits before purchasing one.

If you need any 3d printing service, just feel free to contact us.