5 Ways to Deal with Scrap in CNC Machining

Updated: December 04, 2023

Introduction

The profitability of CNC machining service fully depends on the yield and the cost of consumables wasted. So, elevated rejection or scrap rate severely limits your business outcomes.

But actually, as an owner of a CNC machine shop, you can do something about high volumes or inadequate quality products. In this guide, you can reduce machining scrap significantly with the five methods.

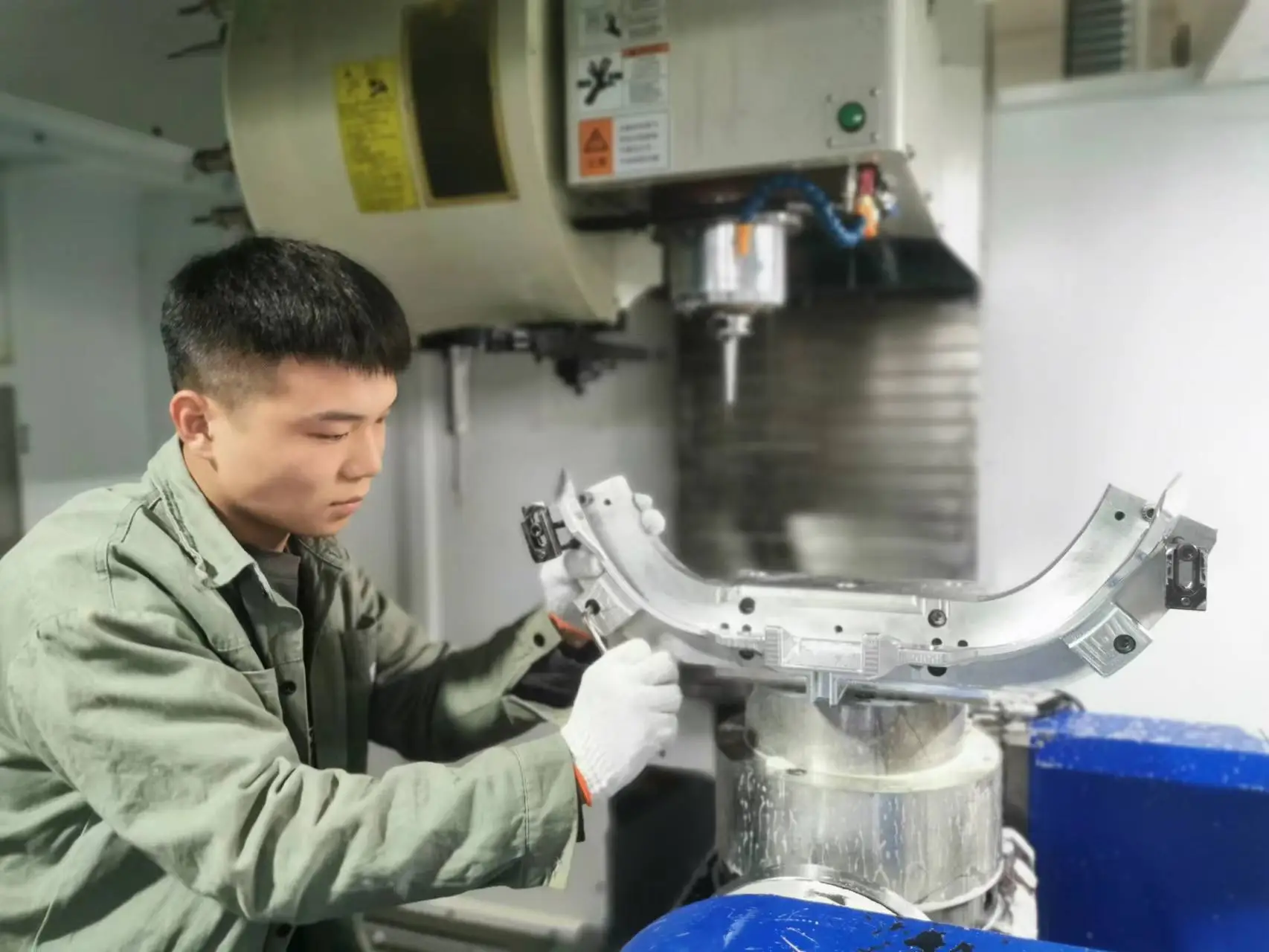

1. Minimize Manual Handling of Delicate Parts

Labor is involved in every machining process, from the reception of raw materials to packing finished products. Unfortunately, labor is not ever near as accurate and consistent in performing routine tasks.

It’s often that operators that have to guide the work of machine tools manually. turn a single component or even an entire batch into scrap. It’s because they easily may get distracted, lose their focus, get a muscle spasm, or just sneeze and have their hand twitched. The human factor is what results in avoidable operational costs frequently.

Consider switching from manual machining to a CNC-based or robotic-based one where possible. This way, advanced software and machining centers will take care of most heavy-duty to delicate work, from cutting to loading/unloading pallets. It’ll shorten the time to market, enhance worker safety, reduce scrap, and even improve the quality of your products.

2. Use the Right Cutting Tool for the Part

Minimizing scrap rates in CNC manufacturing have everything to deal with the cutters you use. An important consideration here is the suitability of a chosen cutter to a particular manufacturing operation. Depending on what design you intend, what raw materials are processed, and other factors, you are deciding between these types of cutters:

- Single point cutting tools

- Double point cutting tools

- Multi-point cutting tools

But there is more to it. Cutters come in various types, forms, and materials they are made of. Inappropriately chosen material either will not let you achieve the desired degree of precision; you will cause quick tool deterioration. Here are the most common materials your cutters may be made of:

- High-Speed Steel (HSS)

- Tungsten Carbide

- Ceramics

- Cubic Boron Nitride (CBN)

Don’t aim at choosing “universal” solutions. As experience shows, such cutters perform poorly in many aspects. Aim at choosing the perfect-fit cutter to every distinct machining operation, design, and material of the workpiece.

3. Keep Employees Trained and Motivated

Truth be told, it’s still impossible to completely eliminate the need for labor involvement. In the machining process, there are always operators, technical specialists, quality assurance specialists, and representatives of other machining jobs. Since you cannot run production without them, the right call is to keep them well-trained and exceptionally motivated.

When it comes to the handling of delicate parts, adequate skills are key. Not only it minimizes the impact of the human factor, but it also improves the precision with which an operation is performed and increases the effective speed. In its turn, motivation impacts the goodwill of a worker to apply their skills diligently.

It’s often that governmental and private organizations offer training for workers on a paid basis. They educate on how to use manufacturing equipment, take good care about safety, and more. As for motivation, it mostly depends on the pay your workers receive and the extent to which they feel they belong to a common project. You may consider running motivation-oriented programs on a regular basis.

4. Care About the Package in the Process

Delivery of your components manufactured is when a large portion of scrap may be generated. The reason is that transportation companies don’t care much about the conditions in which they deliver goods. There is not much you can do about it but use your own vehicle.

But actually, as a manufacturer, you may pay extra attention to the packaging of your products. Primary packaging is what wraps your bare details. Secondary packaging boxes in which goods are packed in large quantities. By using more reliable packaging or adding material that may absorb external shocks and stresses, you may significantly lower risks to your products that exist during their delivery.

5. Regular Maintain the Equipment

It’s a frequent mistake not to conduct regular checks of the state of your CNC units, cutters, cables, and other equipment involved. Unfortunately, every piece of equipment in use has the tendency to wear off over time. The first, usually unnoticeable impacts are chatter, occasional fails, and reduction in the machining accuracy. If left unsupervised, equipment wear may result in the stop of the production line and lengthy, expensive repair.

The right call to minimize scrap would be to schedule regular maintenance of the equipment involved, such as CNC machines. For example, twice a year is considered normal for capital maintenance.

Tools such as cutters should be examined as frequently as needed to ensure that they would not fail. Depending on how extensively you use your cutters, you may want to test them once or twice biweekly. But make sure that your workers visually examine the tooling every time prior to installing it. It will ensure that no defect is left unnoticed.

6. Summary

As a manufacturer, you want to minimize the scrap rates since it reduces the profitability of your business. You should establish multiple processes from the use of equipment and training of your personnel to the way you package your finished goods.

In the best-case scenario, the amount of sub-quality goods in production is limited to a few cases per batch only. But that’s quite a result you should pay a good effort into achieving.