Table of Contents

This blog details the differences between traditional, manual knurling and modern CNC knurling, focusing on their control methods and production capabilities.

Key Takeaways:

- Traditional knurling primarily refers to knurling operations performed on manual lathes or non-CNC machinery.

- CNC knurling is a knurling operation performed using the high-precision control system of a CNC lathe, representing the modernization of knurling technology.

- For high-precision, repeatable results in medium to large batches, CNC knurling is unmatched. For quick, low-cost prototypes or simple parts where absolute precision isn’t critical, traditional knurling is the practical choice.

- Form Knurling is not the same as Traditional Knurling.

1. What is Traditional Knurling?

1.1. Definition of Traditional Knurling

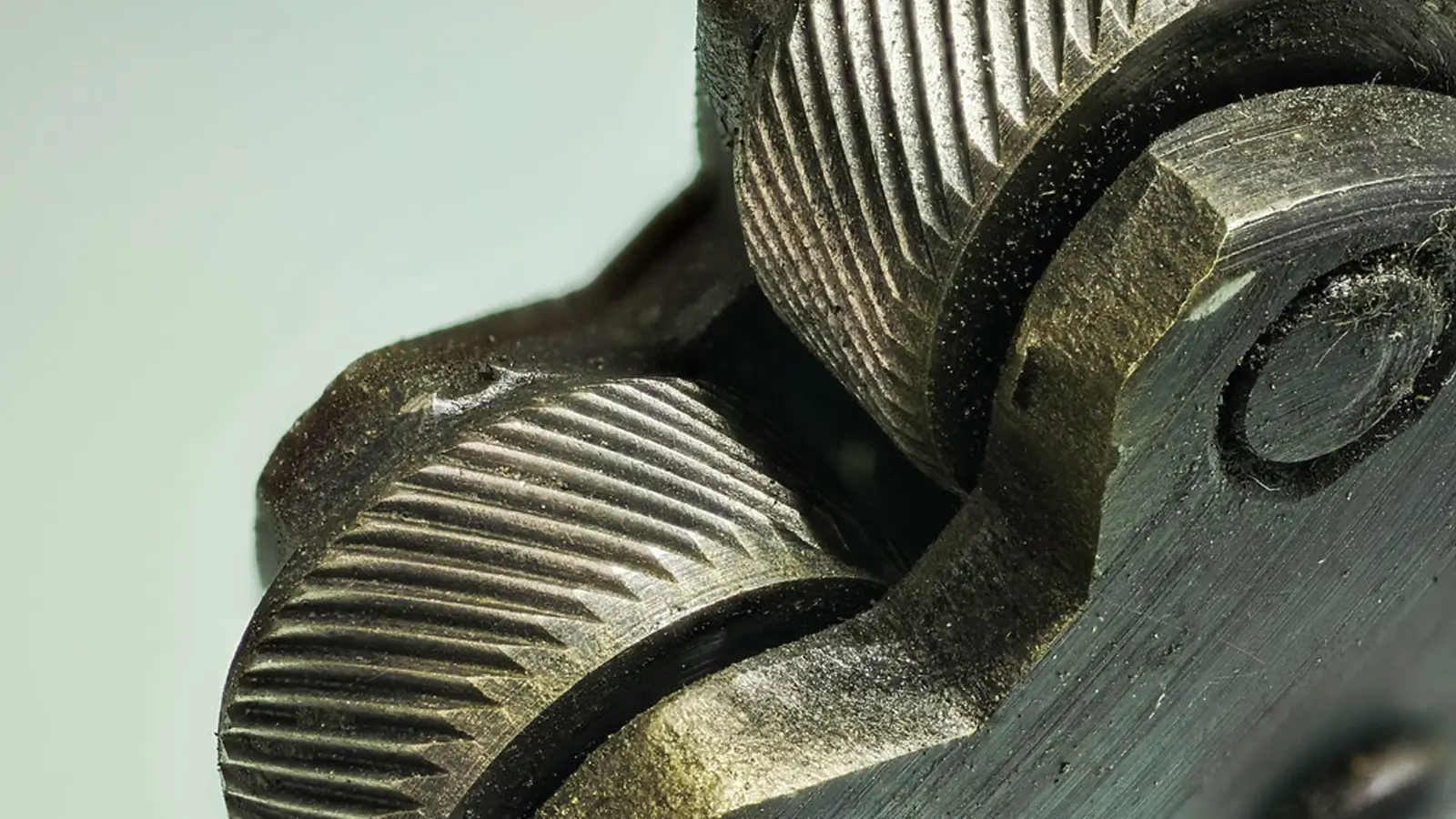

Traditional knurling primarily refers to knurling operations performed on manual lathes or non-CNC machinery. Its core characteristic is its reliance on the operator’s skill and experience.

In this mode, the knurling depth, pressure applied by the knurl wheels, and feed rate all require manual control and feel from the operator.

The advantage of this method is lower equipment investment cost, making it suitable for prototyping, small batches, or repair work.

However, its biggest limitations are poor precision and consistency.

Due to the lack of precise computerized synchronous control, traditional knurling is prone to pattern misalignment (“ghosting”), part deformation from uneven pressure, and significant quality variations between batches.

Consequently, it struggles to meet the demands of modern high-precision manufacturing.

1.2. Characteristics of Traditional Knurling

- Operator-Dependent:

Requires the craftsman to manually adjust pressure and feed rate to control pattern depth and spacing.

- Low Cost & Simple Equipment:

Suitable for small workshops or individual machinists with limited budgets.

- Flexible Adjustments:

Faster setup and adjustments for one-off jobs, small batches, or custom products.

- Inconsistent Quality:

Prone to defects like skewed patterns, double-tracking, and torn patterns, making standardization difficult.

2. What is CNC Knurling?

2.1. Definition of CNC Knurling

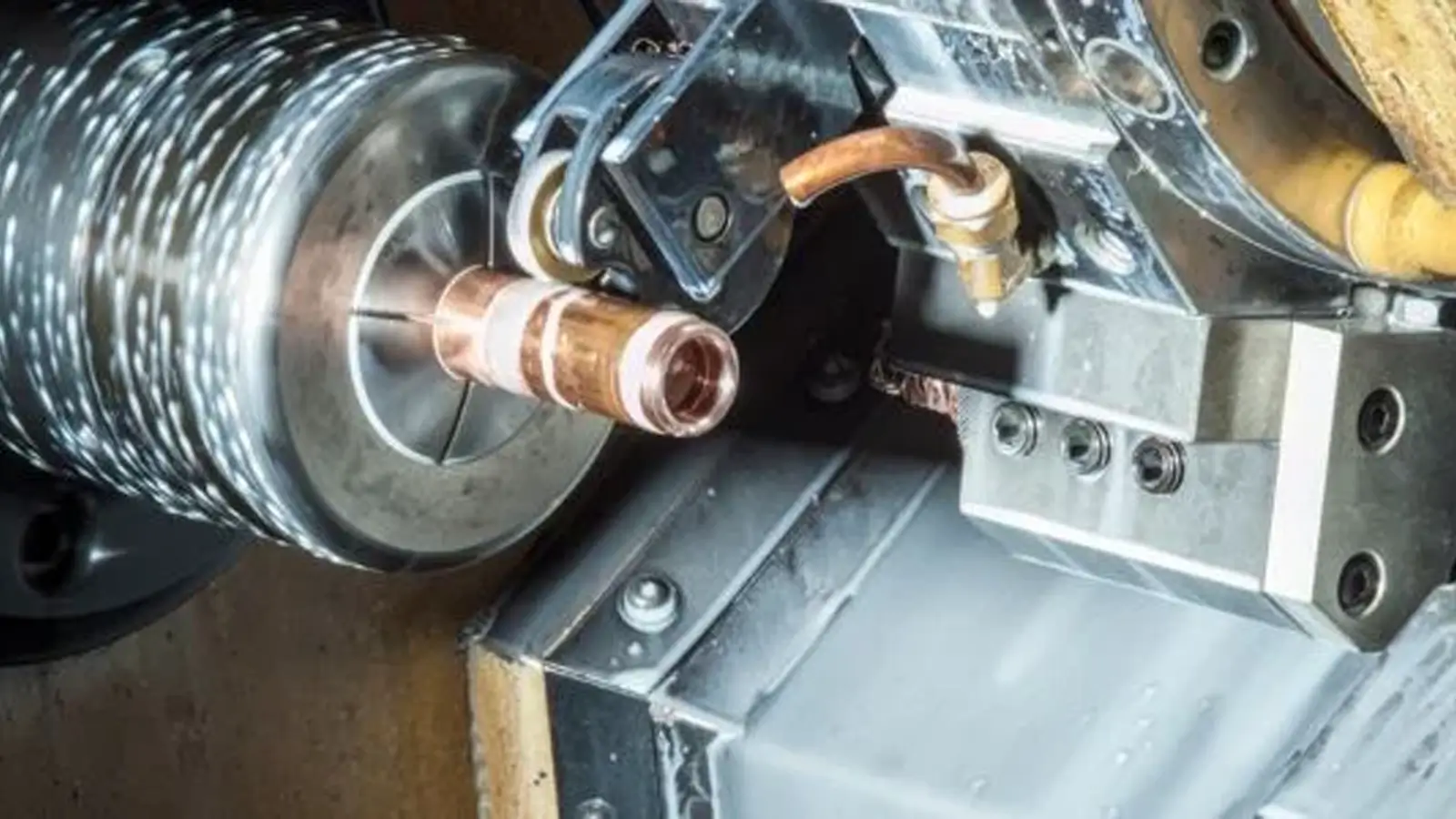

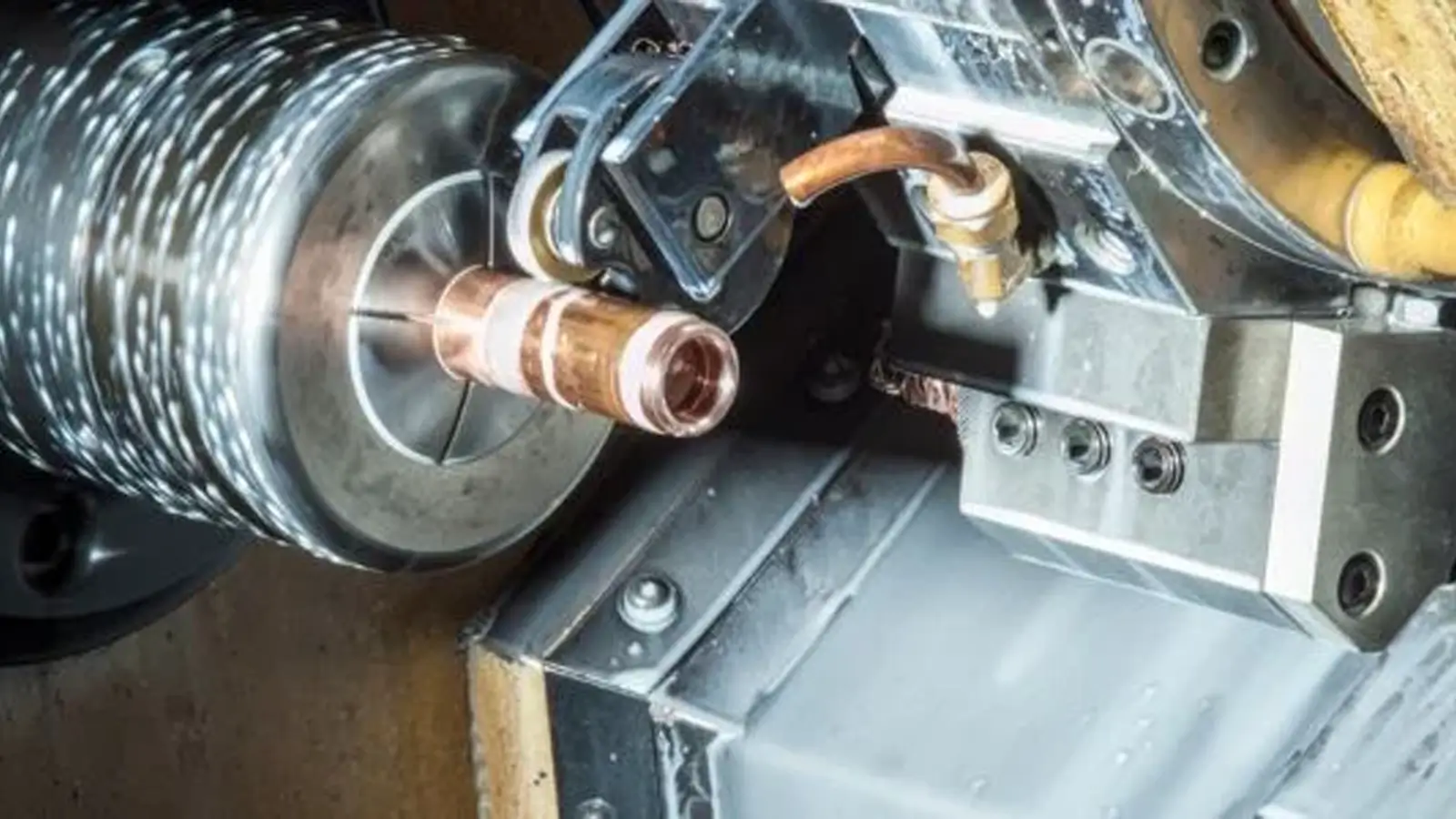

In contrast, CNC knurling is a knurling operation performed using the high-precision control system of a CNC lathe, representing the modernization of knurling technology.

Its core characteristics are high automation, precise control, and excellent repeatability.

In a CNC environment, whether for form knurling or cut knurling, all parameters (including spindle speed, tool feed rate, and precise contact points) are accurately synchronized and controlled via programmed code.

This programmed operation eliminates human error, ensuring every single part has the same high-quality texture.

Although the initial equipment investment for CNC knurling is higher, the resulting extremely high production efficiency, very low defect rates, and the ability to handle complex designs and tight tolerances make it the standard choice for large-volume, high-precision production scenarios such as medical, aerospace, and high-end consumer electronics.

2.2. Characteristics of CNC Knurling

- Programmable Control:

CNC programs can precisely set the synchronized speed, feed rate, pressure, and depth of the knurl wheels relative to the workpiece, guaranteeing consistent texture.

- Supports Multi-Axis Synchronization:

5-axis or mill-turn centers can perform knurling on complex surfaces, such as non-circular shafts or inclined faces.

- Reduced Human Error:

Automatically controlled knurling depth and repeated paths significantly reduce errors stemming from variations in operator skill.

- Ideal for Batch Production:

Once the program is set up and verified, thousands of identical parts can be processed consecutively with completely consistent patterns.

- Integration with Other Operations:

CNC can complete multiple processes like turning, knurling, chamfering, and drilling in a single setup, reducing handling.

3. CNC Knurling vs. Traditional Knurling Comparison Table

| Feature | Traditional Knurling | CNC Knurling |

|---|---|---|

| Control Method | Manual, relies on operator skill | Automated, programmed (G-code) |

| Precision & Consistency | Low, variable | High, excellent repeatability |

| Equipment Cost | Low | High |

| Setup Time | Fast for simple jobs | Longer for programming |

| Ideal Production Volume | Prototypes, small batches, repairs | Medium to high volumes |

| Suitable Materials | Softer, more forgiving materials | All materials, including hard/difficult ones |

| Complexity/Integration | Standalone operation, limited complexity | Can be integrated into complex multi-step operations |

| Operator Dependency | High | Low |

| Typical Applications | Tool handles, simple pins, repair work | Medical devices, aerospace, precision instruments |

4. How to Choose Between CNC Knurling and Traditional Knurling

Choose CNC Knurling when:

- High precision and consistency are primary requirements: e.g., for medical devices, aerospace, and precision instrument components.

- Materials are expensive or difficult to machine: e.g., stainless steel, titanium alloys, hardened steel, which traditional knurling cannot form or may cause cracking.

- Workpiece rigidity is low: e.g., slender shafts, thin-walled sleeves, which would deform under the high pressure of traditional knurling.

- Medium to high production volumes: The initial setup cost can be amortized, and automated production significantly improves efficiency and stability.

- Complex, multi-operation parts are needed: The part requires turning, grooving, knurling, and threading in a single chucking.

Choose Traditional Knurling when:

- Prototyping or single-piece/low-volume repair: No programming is needed; setup is fast and cheap.

- CNC equipment is unavailable: Only a manual lathe is on hand.

- Machining soft materials where precision is not critical: e.g., simple tool handles, basic pins.

- A highly skilled operator is available: An experienced machinist can produce decent-quality knurls on a manual lathe.

CNC knurling represents precision, automation, and reliability, making it the standard for modern manufacturing.

Traditional knurling offers flexibility, low entry cost, and accessibility, retaining its value in repair shops and low-volume scenarios.

The choice depends on your quality requirements, batch size, material, budget, and available equipment.

5. Traditional Knurling vs Form Knurling

When discussing traditional knurling, also named conventional knurling (traditional manual operation), it is common for another concept to be confused with it: form knurling (pressure/squeeze knurling).

The two share similarities but are not completely identical.

5.1. Core Differences

The distinction between these concepts lies in their fundamental focus.

“Traditional Knurling” emphasizes the equipment and control method.

It is defined by the use of a manual lathe, where the operator relies on personal skill and “feel” to control the feed and pressure.

Due to this manual nature, it is exceptionally difficult to achieve the precise synchronization required for cut knurling.

Consequently, on a manual lathe, form knurling emerges as the only practical and mainstream choice.

This leads to the common approximation: Traditional Knurling is essentially manually performed Form Knurling.

In contrast, “Form Knurling” emphasizes the physical principle behind the operation, which is plastic deformation via pressure.

This principle is not tied to a specific machine type. Form knurling can be performed on both traditional manual lathes and modern CNC lathes.

On a CNC machine, the process is elevated through programmatic control over depth and feed, resulting in significantly higher consistency and quality than manual operation, even though the underlying principle of plastic deformation remains the same.

5.2. The Correct Relationship between Traditional Knurling vs Form Knurling

To clarify the relationship, it’s important to recognize that these terms belong to different classification systems.

Form Knurling and Cut Knurling are categories based on the forming mechanism (deformation vs. material removal).

On the other hand, Traditional Knurling and CNC Knurling are categories based on the equipment and control method (manual vs. automated).

Therefore, it is incorrect to treat them as equivalents: Form Knurling ≠ Traditional Knurling.

However, in practice, a high degree of overlap exists:

Traditional Knurling ≈ Manually operated Form Knurling, as manual machines primarily rely on the forming method.

CNC Knurling ≈ Program-controlled Form Knurling OR Program-controlled Cut Knurling, as CNC machines possess the capability to accurately implement both processes.

Form Knurling is a type of process and should not be used as the sole synonym for Traditional Knurling.

Traditional Knurling specifically emphasizes a non-CNC, manual operation method.

It is crucial to understand that modern, high-volume CNC knurling operations also extensively utilize the form knurling principle, demonstrating that it is not exclusive to traditional methods.

6. Summary

This comprehensive guide explores the fundamental differences between traditional (manual) knurling and modern CNC knurling.

While traditional knurling relies on operator skill using manual lathes, making it cost-effective for prototypes and small batches, CNC knurling delivers precision and consistency through automated programming, ideal for high-volume production and complex parts.

The choice between them ultimately depends on your specific needs regarding precision, budget, production volume, and material requirements.

Related blog:

- The Complete Guide to Knurling: Types, Uses, and Design Tips

- Types of Knurling Tools and How to Choose the Right One

- CNC Knurling vs Conventional Knurling: Key Differences, Features, and How to Choose

- How Material Properties Affect Knurling: Choosing Between Form and Cut Knurling

- Types of Knurling Patterns and How to Choose the Right Knurling Type

- Knurling Process: Form Knurling vs. Cut Knurling

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

Form Knurling vs. Cut Knurling

Cut Knurling is for Precision; Form Knurling is for Speed: Choose cut knurling when dimensional accuracy is critical, as it doesn’t change the workpiece diameter.

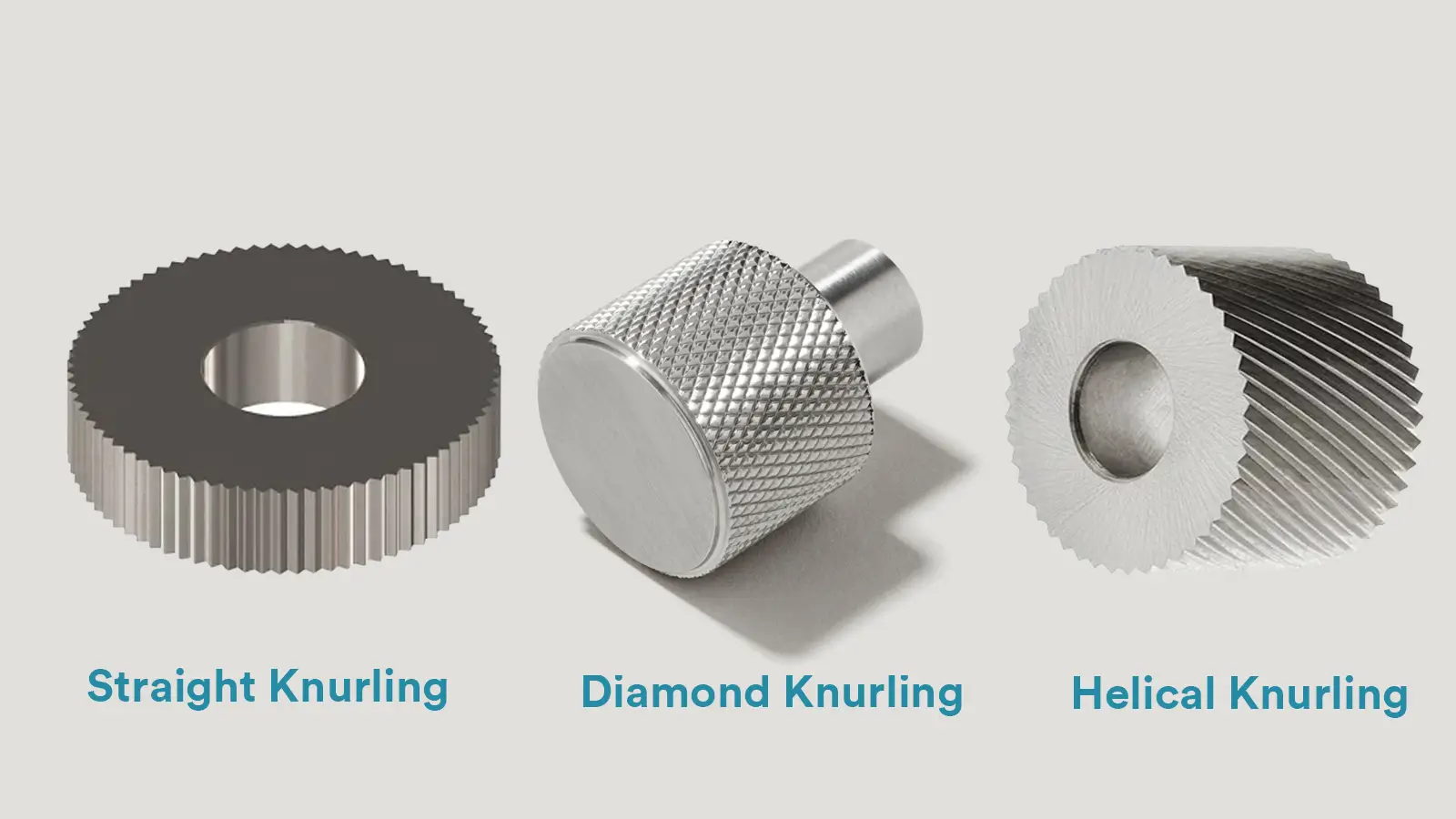

Types of Knurling Patterns

The most common types of knurling textures are Straight Knurling, Diagonal (Helical) Knurling, and Diamond Knurling.

CNC Knurling vs Conventional Knurling

For high-precision, repeatable results in medium to large batches, CNC knurling is unmatched.

Types of Knurling Tools

Form knurling tools excel in high-volume production for efficiency, while cut knurling tools provide accuracy for tight tolerances.