Table of Contents

The choice of knurling tool structure directly impacts speed, precision, and tool life. Knurling tools are fundamentally divided into two types based on their working principle: Form Knurling (Squeezing) and Cut Knurling (Slicing).

Key Takeaways:

- Form knurling is fast, chip-free, and ideal for soft to medium-hard metals, while cut knurling ensures precision for hard, high-strength, or work-hardening materials with minimal diameter change.

- Single wheel, twin wheel, adjustable twin wheel, three-wheel, and multi-tooth knurling tools have distinct benefits and limitations affecting spindle load, pattern accuracy, and suitability for slender or thin-walled parts.

- Material hardness, size, rigidity, and tolerance requirements are critical in tool selection to prevent part deformation and achieve precise knurling results.

- Form knurling tools excel in high-volume production for efficiency, while cut knurling tools provide accuracy for tight tolerances; adjustable and multi-tooth tools offer versatility for multiple patterns or specialized applications.

1. Form Knurling Tools: Principles & Characteristics

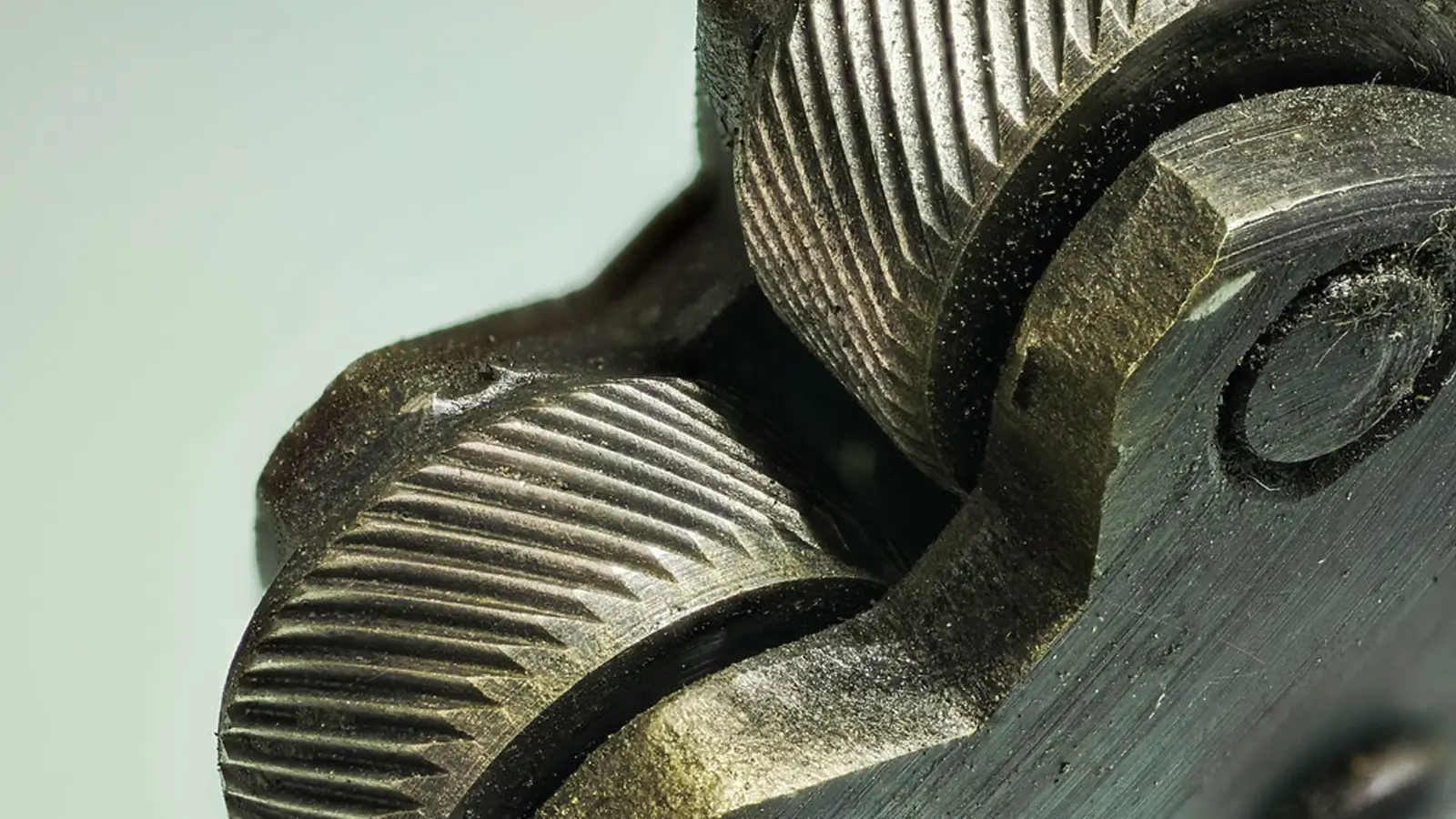

Form knurling tools operate on the principle of material deformation.

They utilize hardened steel or carbide wheels that apply significant radial pressure to the workpiece surface, forcing material to flow and form the pattern.

The greatest advantage of this method is its extremely fast processing speed, chip-free operation, and the added benefit of increased surface hardness through work hardening.

However, its main drawbacks include a high load on the machine spindle and bearings, unsuitability for slender shafts or thin-walled parts (risk of bending), and an increase in the part’s outer diameter after knurling, which requires tolerance consideration.

In terms of wheel design, form knurling wheels typically feature flat crests and rounded roots, which help them withstand high pressure.

These tools are best suited for soft metals like aluminum, brass, mild steel, and free-cutting steel.

2. Types of Form Knurling Tools & Applications

When you need to perform knurling on a lathe, the structure of your lathe knurling tool matters:

2.1. Single Wheel Knurling Tool

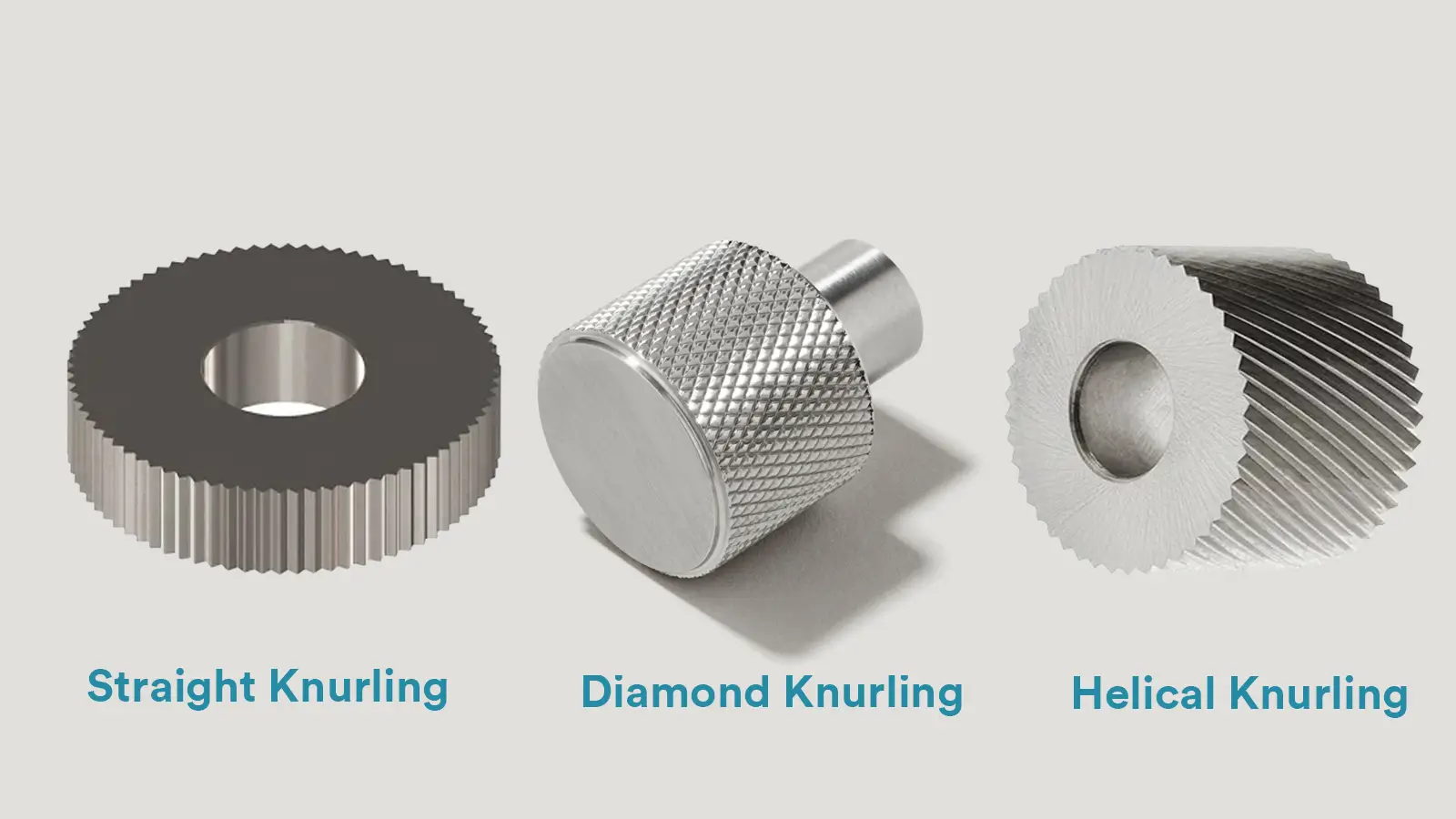

The single wheel knurling tool features a single knurling wheel mounted on a tool holder. It is typically used in pairs from both sides of the workpiece, with one wheel driving and the other following.

On CNC lathes, it can also be used as a single wheel. This type of knurling tool for lathe offers a simple structure, low cost, and high flexibility, allowing easy wheel changes for different pitches.

However, it demands high machine and workpiece rigidity and requires precise alignment to avoid defects such as “double-tracking.”

2.2. Twin Wheel Knurling Tool

The twin wheel knurling tool consists of two identical wheels mounted in a single holder, supporting each other and rotating freely.

Both wheels contact the workpiece simultaneously, usually gear-synchronized to ensure perfect timing.

This design is very common among manual lathe knurling tools, as it greatly simplifies operation and virtually eliminates tracking errors.

Its main drawbacks are a higher cost compared to single wheel tools and the limitation that each holder accommodates only one pitch.

2.3. Adjustable Twin Wheel Knurling Tool

An enhanced version of the twin wheel tool, the adjustable twin wheel knurling tool allows the angle between the wheels to be changed.

By adjusting this angle, operators can create both straight knurling and diamond patterns of various specifications.

This versatility makes it ideal for shops that require multiple patterns with a single tool.

The main trade-offs are higher cost and the need for time and experience to properly adjust the tool.

2.4. Three Wheel Knurling Tool

The three-wheel knurling tool provides optimal self-centering, with evenly distributed force that reduces radial load on the spindle.

It is often chosen for high-precision knurling on lathe applications, where accuracy and minimal deformation are critical.

Leading brands such as Dorian knurling tool and Eagle Rock knurling tool offer specialized three-wheel options to meet demanding production needs.

3. Cut Knurling Tools: Principles & Characteristics

Cut knurling tools work on the material removal principle. Their wheels feature sharp cutting edges with positive rake angles, forming patterns by removing material similar to turning operations, thereby producing chips.

The advantages of this method include minimal machine load, no increase in part diameter (slight decrease possible), high dimensional accuracy, and suitability for parts requiring tight outer diameter tolerances.

Cut knurling tool wheels feature sharp crests with defined cutting angles.

These knurling tools are the only reliable choice for hard, high-strength, or work-hardening materials (like stainless steel, titanium alloys), despite their higher wheel cost and chip management requirements.

4. Types of Cut Knurling Tools & Applications

4.1. Single Point Cut Knurling Tool

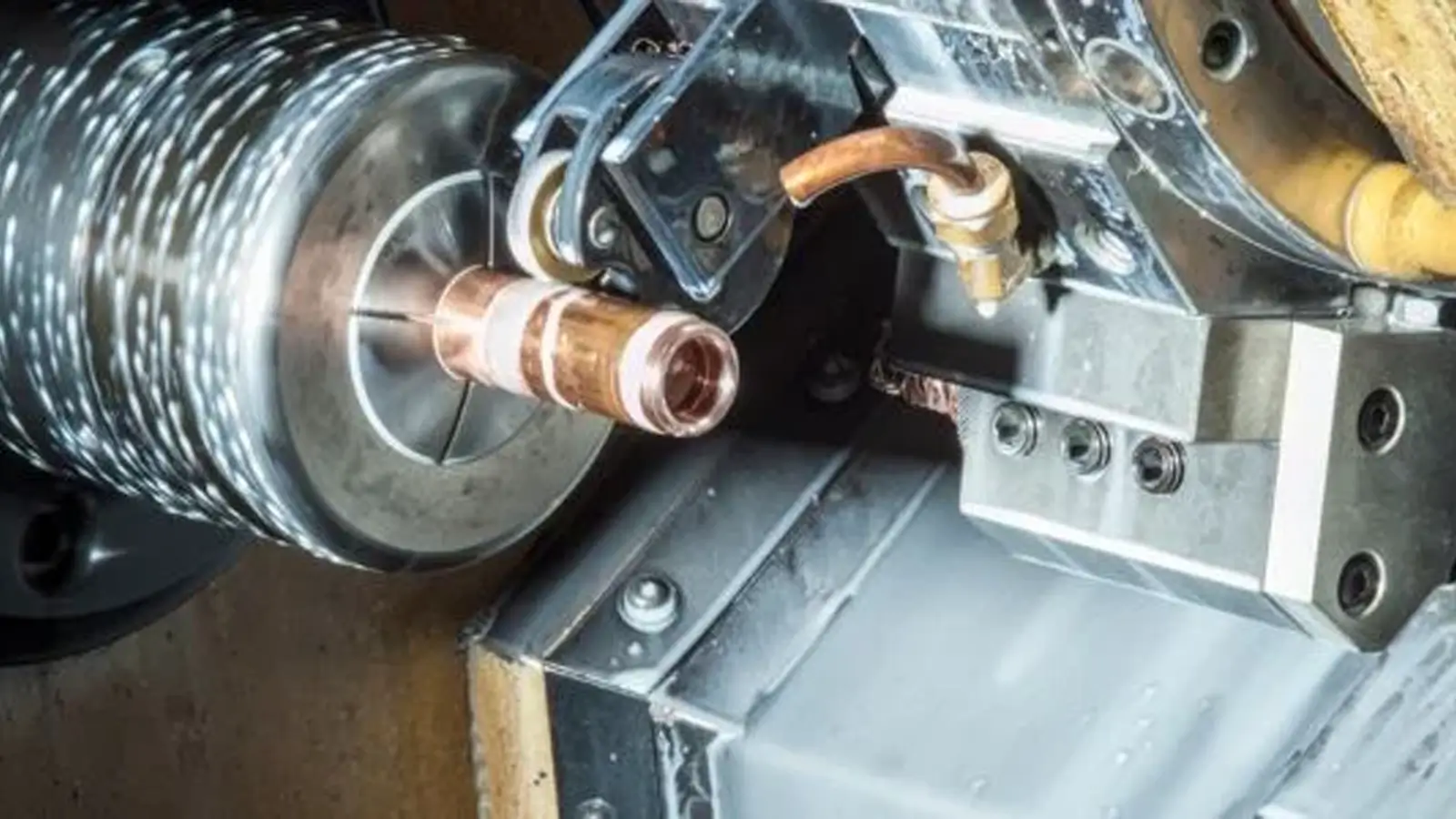

The single point cut knurling tool is structurally similar to single wheel form knurling tools but uses carbide wheels with sharp cutting edges.

It is a common choice for knurling tool lathe applications. Operating like a turning tool, it is controlled via a CNC knurling tool program, specifying depth and feed rate. Usually, a single wheel is sufficient for the operation.

This design generates minimal radial force, making it ideal for slender shafts, thin-walled components, and hard materials. It produces clean, burr-free knurl patterns, ensuring high-quality finishes.

The main drawbacks are the higher cost of carbide wheels and the requirement for CNC programming and equipment.

4.2. Multi-Tooth Form Knurling Tool

The multi-tooth form knurling tool features multiple carbide inserts mounted on a single head, collectively forming a segment of the knurl pattern.

The pattern is “form turned” in one or several passes, typically used for diamond patterns of specific sizes. This tool is extremely efficient, creating a complete pattern in a single pass while maintaining excellent dimensional consistency.

However, it is highly customized and expensive, usually justified only for high-volume production of parts requiring precise knurling.

5. Knurling Tool Selection Guidelines

To understand how to knurl on a lathe successfully, you must follow these guidelines:

5.1. Core Principle: Workpiece Material & Hardness

The primary consideration is material hardness and machining tendency.

For soft or medium-hard, ductile metals like aluminum, brass, or mild steel, prioritize form knurling tools for their efficiency and surface hardening benefits.

For high-strength steels, stainless steels (e.g., 304/316), or strongly work-hardening materials, cut knurling tools are essential as they remove material rather than displacing it, preventing tool and machine damage while ensuring clear patterns.

5.2. Key Consideration: Workpiece Size & Rigidity

The second crucial factor is avoiding deformation during processing. Knurling, particularly form knurling, generates substantial radial pressure.

For slender shafts, thin-walled tubes, or parts with poor rigidity, prioritize knurling tooling that balances or minimizes radial force.

In these cases, twin-wheel form knurling tools or cut knurling tools are preferred as they effectively reduce spindle load and prevent bending.

Many hand knurling tools are designed with this scissor mechanism.

5.3. Accuracy Requirements & Diameter Changes

Final part accuracy dictates process selection. When the knurled area must fit precisely with other components with tight outer diameter tolerances, cut knurling is optimal as it barely changes the original diameter.

For less critical applications where pre-machining diameter can be calculated to compensate for expansion (perhaps with a knurling calculator), efficient form knurling may be considered.

Always ensure the knurl for lathe wheel’s modulus (M) or pitch exactly matches drawing specifications – this is mandatory for correct pattern formation.

5.4. Production Environment & Efficiency

Finally, production volume, machine rigidity, and cost-effectiveness matter. For large-scale production, form knurling tools offer the best cost efficiency where material allows.

If the machine lacks rigidity or struggles with form knurling forces, switch to cut knurling or twin-wheel form tools even for suitable materials.

Additionally, consider that knurling tooling requires chip management while form knurling doesn’t – factor this into overall cost calculations.

6. Summary

This comprehensive guide explores all types of knurling tools and their applications. Learn the key differences between form knurling (squeezing) and cut knurling (slicing) methods, discover various tool types from single wheel to multi-tooth designs, and understand how to select the perfect knurling tool based on material, precision requirements, and production needs.

Related blog:

- The Complete Guide to Knurling: Types, Uses, and Design Tips

- Types of Knurling Tools and How to Choose the Right One

- CNC Knurling vs Conventional Knurling: Key Differences, Features, and How to Choose

- How Material Properties Affect Knurling: Choosing Between Form and Cut Knurling

- Types of Knurling Patterns and How to Choose the Right Knurling Type

- Knurling Process: Form Knurling vs. Cut Knurling

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

Form Knurling vs. Cut Knurling

Cut Knurling is for Precision; Form Knurling is for Speed: Choose cut knurling when dimensional accuracy is critical, as it doesn’t change the workpiece diameter.

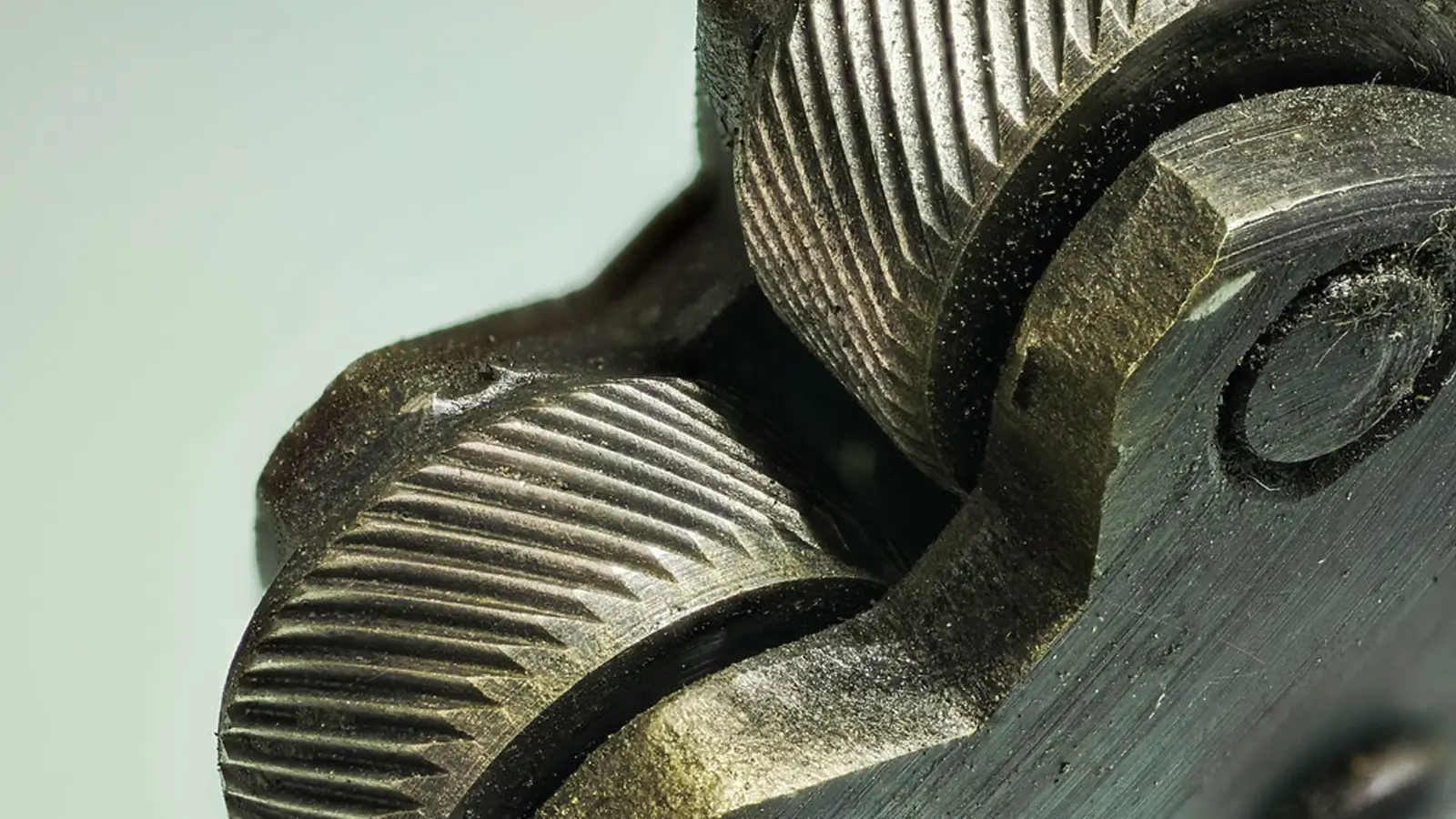

Types of Knurling Patterns

The most common types of knurling textures are Straight Knurling, Diagonal (Helical) Knurling, and Diamond Knurling.

CNC Knurling vs Conventional Knurling

For high-precision, repeatable results in medium to large batches, CNC knurling is unmatched.

Types of Knurling Tools

Form knurling tools excel in high-volume production for efficiency, while cut knurling tools provide accuracy for tight tolerances.