Table of Contents

CNC machining, full name as Computer Numerical Control machining, is a type of subtractive manufacturing technique where specifically designed parts are produced by removing excess material from the solid raw material under the control of preprogrammed instructions on the machine tools.

It can achieve parts with high accuracy. However, tool marks and minor burrs might still leave on the surface. Therefore, polishing is usually required after CNC machining to smooth the parts.

Mechanical polishing is exactly one of the most popular surface treatment for CNC machining parts. This blog will provide a comprehensive guide of mechanical polishing.

Take aways:

- Mechanical polishing smooths surfaces through friction and micro-cutting, not chemical reactions.

- Use manual polishing for complex parts, wheel polishing for fast shine on simple shapes, and vibratory polishing for consistent finishing of many small parts.

- Manual polishing is suitable for most CNC-machined metals, including stainless steel, carbon steel, aluminum, copper, and titanium, but requires specific techniques and abrasives tailored to each material’s properties.

1. What is Mechanical Polishing?

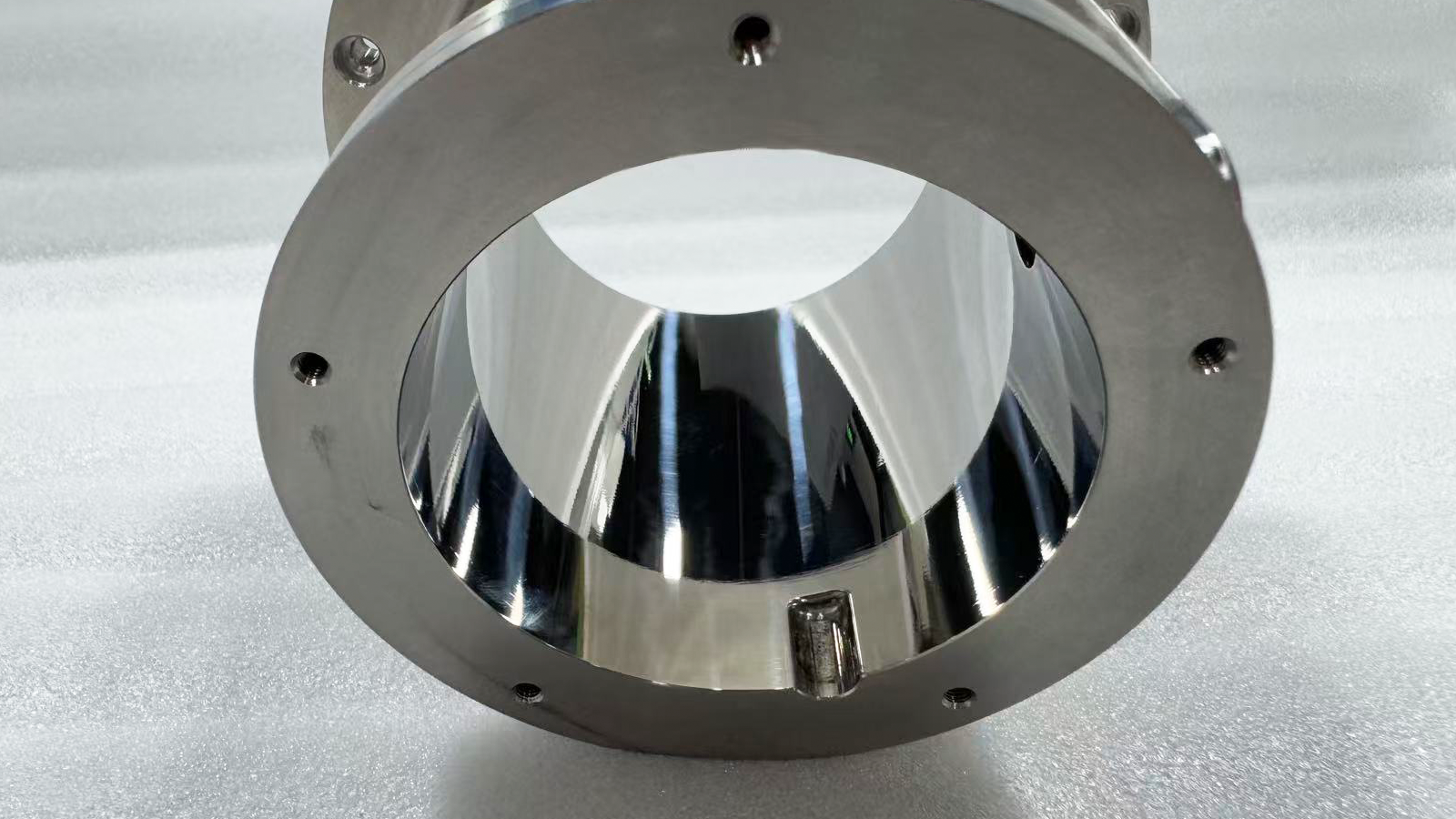

Mechanical polishing is a surface finishing technique that uses mechanical force through friction, micro-cutting, and deformation between abrasives and the part’s surface to reduce surface roughness, eliminate surface defects, and achieve a smooth or bright finish.

It is actually a physical finishing process that does not involve any chemical reactions or phase transformations.

And its core working mechanism involves three aspects.

The primary one is the micro-cutting action.

During the mechanical polishing process, abrasive particles such as aluminum oxide, chromium oxide, or diamond micron powders would scrape or cut the microscopic surface asperities of the part under applied pressure and relative motion.

These protrusions are preferentially removed to reduce the surface’s roughness and then make the surface smoother and brighter.

The second one is the plastic deformation and material flow.

Under the influence of polishing pressure and frictional heat, many soft metals such as aluminum, copper, and gold would undergo localized plastic flow, making the surface asperities flattened rather than fully removed.

Such a mechanism can help improve surface density and brightness, but heat generation must be carefully controlled to prevent burning or discoloration.

The third one is the friction and thermal effect.

As we all know, high-speed friction would generate local temperature rise. This can soften the surface layer of certain materials and promote micro-cutting or plastic flow.

However, excessive heat may cause metal oxidation, material distortion, or abrasive embedding. Therefore, it is often necessary to control rotational speed or apply cooling measures.

Based on the working mechanism, it is concluded that the polishing methods, tools and the whole control of polishing process determine the final surface finishing result.

2. What are the Types of Mechanical Polishing?

There are various mechanical polishing methods, including manual polishing, wheel polishing, vibration polishing, tumbling, barrel polishing, magnetic polishing, ultrasonic polishing, and abrasive flow polishing. They are all important and have their specific functions in different industries.

2.1 Manual Polishing

What is Manual Polishing?

Manual polishing is a hands-on finishing process where a technician uses tools like sandpaper, oil stones, polishing cloths, and pastes to refine a part’s surface step by step. It’s often used for touch-ups or parts that require a high-quality appearance.

How does it work?

The technician controls the pressure and movement by hand, allowing the abrasive material to gently remove tiny amounts of material and smooth the surface through friction. This gradually reduces surface roughness.

What’s the basic process?

Start with coarse sandpaper to remove imperfections, then move to finer grits for smoothing. Finally, apply polishing paste for a glossy finish, followed by cleaning and inspection.

Where is it commonly used?

Great for high-appearance parts, prototypes, small-batch CNC items, and complex or curved surfaces that need detailed attention.

Pros:

Highly flexible for intricate shapes

Can achieve a very smooth finish

Low equipment investment

Cons:

Relies heavily on the operator’s skill

Results can vary between parts

Time-consuming, not ideal for large batches

2.2 Grinding Wheel Polishing

What is Grinding Wheel Polishing?

This method uses a high-speed rotating grinding wheel to trim and smooth a part’s surface. It’s often chosen to remove noticeable tool marks or burrs quickly.

How does it work?

Abrasive grains on the wheel continuously cut into the workpiece, leveling uneven areas through rapid rotation and contact.

What’s the basic process?

Select the right wheel for the material, secure the part, grind with a coarse wheel first, then switch to a finer one. Finish with a surface check.

Where is it commonly used?

Common for initial polishing or deburring of metals like stainless steel and carbon steel before finer finishing.

Pros:

Fast material removal

Works well on hard materials

Reliable and well-established process

Cons:

Can generate heat, affecting the part

Less effective on complex geometries

Risk of over-polishing if not careful

2.3 Vibratory Polishing

What is Vibratory Polishing?

A batch process where parts and abrasives are placed in a vibrating tub. The motion creates constant friction to deburr and polish surfaces evenly.

How does it work?

High-frequency vibration causes parts, media, and compound to move together, creating uniform surface contact and a consistent finish.

What’s the basic process?

Load parts and media into the tub, add polishing compound, run the machine, then separate and clean the parts.

Where is it commonly used?

Ideal for large volumes of small CNC parts, hardware items, fasteners, aluminum, and plastic components.

Pros:

Great for batch processing

Delivers uniform results

Highly automated

Cons:

Limited effectiveness in deep or blind holes

Less control over precision for individual parts

2.4 Barrel Polishing

What is Barrel Polishing?

Parts and abrasives are tumbled together in a rotating barrel. The rolling action polishes surfaces through friction and light impact.

How does it work?

As the barrel turns, parts and media rub against each other, removing burrs and smoothing rough edges.

What’s the basic process?

Load the barrel with parts and media, let it rotate for a set time, then unload and clean the parts.

Where is it commonly used?

Best for large batches of simple, small metal or plastic parts.

Pros:

Simple equipment setup

Cost-effective

Handles high volumes well

Cons:

Longer cycle times

Parts may bump into each other

Limited surface precision

2.5 Tumbling Polishing

What is Tumbling Polishing?

An upgraded version of barrel polishing with more controlled, multi-axis motion for better uniformity.

How does it work?

Parts and media move in complex patterns, ensuring all surfaces contact the abrasive evenly for consistent deburring and finishing.

What’s the basic process?

Mix parts with media, run the tumbler, then clean and dry the parts.

Where is it commonly used?

Suitable for CNC parts and functional components needing moderate precision.

Pros:

More even surface treatment

Reliable deburring

Fits medium-accuracy needs

Cons:

Not for mirror-like finishes

Requires care with thin-walled parts

2.6 Magnetic Polishing

What is Magnetic Polishing?

A fine-finishing method that uses magnetic fields to drive abrasive media across a part’s surface.

How does it work?

A magnetic field moves magnetic abrasives rapidly over the workpiece, polishing intricate features and internal holes uniformly.

What’s the basic process?

Place parts in magnetic abrasive media, activate the magnetic field, polish, then clean and inspect.

Where is it commonly used?

Perfect for precision parts, internal structures, and medical device components.

Pros:

Excellent for holes and complex shapes

High surface quality

Gentle on parts

Cons:

Higher equipment cost

Limited to smaller part sizes

2.7 Ultrasonic Polishing

What is Ultrasonic Polishing?

Uses high-frequency sound waves to create microscopic vibrations for ultra-fine surface finishing.

How does it work?

Ultrasonic cavitation causes abrasive slurry to gently bombard the surface, removing tiny imperfections without heavy pressure.

What’s the basic process?

Immerse parts in polishing slurry, activate ultrasound, process, then clean and dry.

Where is it commonly used?

Preferred for precision molds, hard/brittle materials, and high-accuracy CNC parts.

Pros:

Ideal for delicate parts

Minimizes surface stress

Works well on hard, brittle materials

Cons:

Slower processing

Higher cost

2.8 Abrasive Flow Polishing

What is Abrasive Flow Polishing?

A specialized method that forces abrasive-laden fluid through internal passages to polish hard-to-reach areas.

How does it work?

Abrasive media flows back and forth under pressure, gently cutting and smoothing internal surfaces.

What’s the basic process?

Clamp the part, inject abrasive fluid, cycle multiple times, then clean and inspect.

Where is it commonly used?

Essential for complex internal channels, hydraulic components, and aerospace parts.

Pros:

Unmatched consistency inside channels

Highly controllable

Perfect for intricate passages

Cons:

High equipment and consumable costs

Requires precise parameter tuning

2.9 Cloth Wheel Polishing

What is Cloth Wheel Polishing?

A common mechanical polishing method using a rotating cloth wheel (cotton, linen, or layered) with wax or paste to add shine and smoothness to metal or plastic parts. In CNC, it’s often the final touch to reduce roughness, remove fine lines, and boost visual appeal.

How does it work?

The spinning wheel, paired with polishing wax, creates gentle friction that lightly cuts and polishes the surface. The wheel’s flexibility allows even, soft polishing without altering dimensions significantly.

What’s the basic process?

Start with a rough polish, choose the right wheel and wax, apply wax to the wheel, polish the part, clean off residue, and inspect the finish.

Pros:

Delivers high-gloss, near-mirror finishes

Minimal impact on part dimensions

Works well on curved and cosmetic surfaces

Mature technology with manageable costs

Cons:

Requires an experienced operator

Can lead to uneven spots or over-polishing

Not ideal for large batches needing perfect uniformity

Less effective in deep holes or internal cavities

Common Applications:

CNC parts made of aluminum, stainless steel, brass

Cosmetic parts, decorative items, handheld devices

Medical device housings, consumer electronics

Pre-treatment for anodizing or plating

3. What are the Benefits of Mechanical Polishing?

- Improving Surface Finish:

Mechanical polishing effectively removes scratches, burrs, oxide layers, and minor surface irregularities, resulting in a smoother and brighter surface.

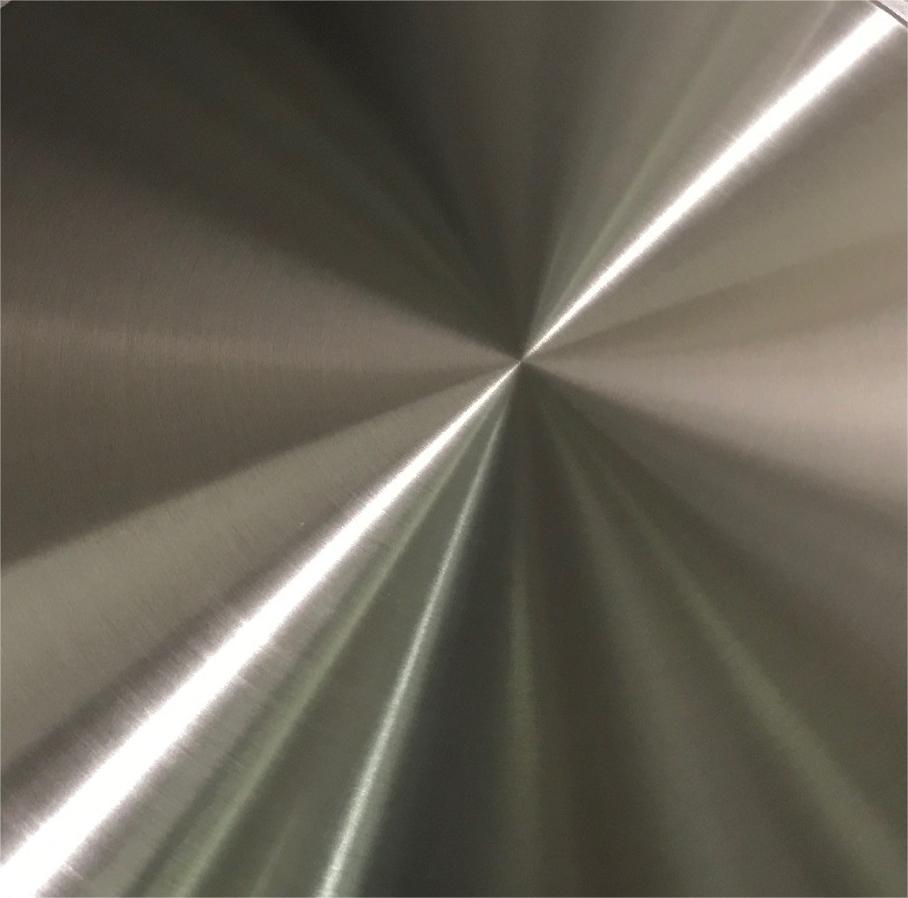

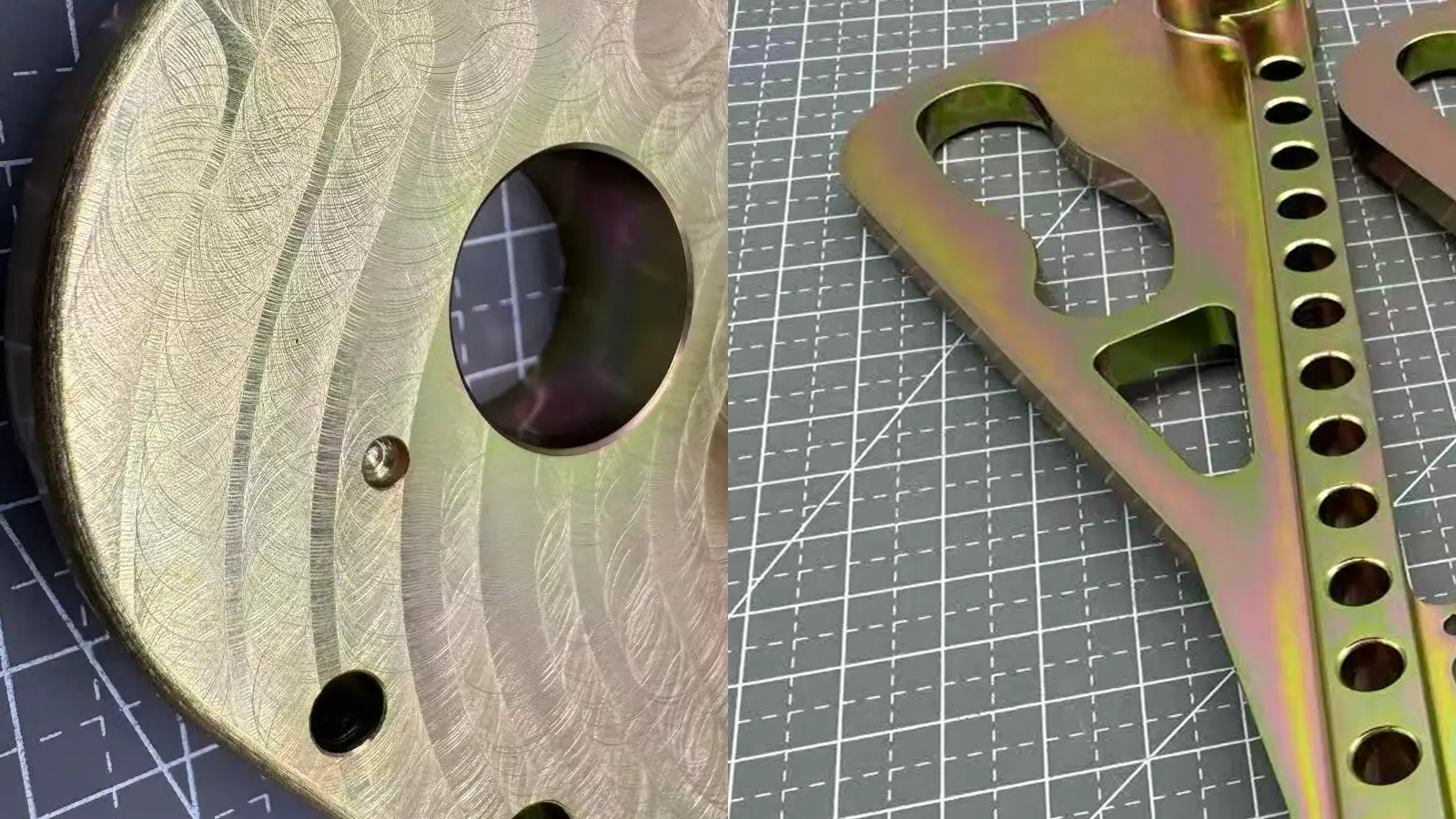

Below is the photo showing before and after mechanical polishing.

Left: Tooling marks are visible after zinc plating.

Right: Tooling marks are removed after mechanical polishing.

This enables achievement of both decorative and functional finishes, including mirror-like or matte appearances.

- Enhancing Corrosion Resistance:

Although mechanical polishing does not create a protective film, it can reducesurface roughness and then help to minimize the adhesion and penetration of corrosive agents on the surface. This indirectly improves the corrosion resistance of materials.

- Wide Applicability:

Mechanical polishing equipment comes in various types, making it suitable for workpieces of different shapes, sizes, and materials. It can handle complex surfaces, internal holes, edges, and other hard-to-reach areas when used with specialized tools.

- Low Cost:

Compared with electropolishing or chemical polishing, mechanical polishing requires lower equipment investment and operational costs.

It does not involve hazardous chemicals such as strong acids or alkalis, has minimal requirements for the working environment, and is suitable for batch production.

- Good Controllability:

By selecting different abrasive grit sizes, polishing wheel materials,applied pressure, rotation speed, and polishing time, surface roughness can be precisely controlled, meeting requirements ranging from coarse grinding to mirror finishes.

- Environmental Friendliness:

Mechanical polishing does not involve hazardous chemical waste. The main by-products are metal swarf and dust, which are easy to collect and dispose of.

4. What CNC Materials can be Mechanically Polished?

4.1 Mechanical Polishing Stainless Steel

Stainless steel is one of the most common metal types for mechanical polishing. It is recommended to use white alumina abrasives or other hard polishing compounds to mechanically polish stainless-steel parts.

Stainless steel has relatively high hardness and poor thermal conductivity, making it particularly susceptible to overheating during polishing. Once discoloration is observed, it indicates overheating, and the rotation speed should be reduced.

Additionally, abrasive wheels or brushes that have been used on carbon steel must never be used on stainless steel, as iron contamination can become embedded in the surface and later cause rust spots and pitting corrosion.

4.2 Mechanical Polishing Carbon Steel

Mechanical polishing is also suitable for carbon steel. But carbon steel is very easy to be chemically corroded.

If wet mechanical polishing is used for caron steel parts, it is supposed to dry the parts with compressed air immediately and coat them with a rust-preventive oil after polishing, or the residual water droplets can cause yellow rust spots within minutes.

And during high-humidity conditions, freshly polished surfaces may darken even without direct water contact due to moisture in the air.

It is recommended to add a dedicated water-soluble rust inhibitor to the polishing solution.

The black swarf generated during carbon steel polishing is magnetic and tends to adhere to the workpiece surface.

If not completely cleaned from the surface, these hard particles would scratch the already smoothed surface.

However, if the part is magnetized, it must be demagnetized prior to polishing. Otherwise, abrasive debris cannot be effectively removed by simple wiping or cleaning.

In addition, steels with high content of carbon are hard and brittle. They are prone to microcracking if polishing pressure is not be carefully controlled.

4.3 Mechanical Polishing Aluminum

Aluminum is extremely soft and has a low melting point, making it highly susceptible to abrasive loading and orange peel effects during polishing. Fine abrasive compounds are recommended to prevent scratching.

Aluminum chips readily adhere to sandpaper or polishing wheels, which would cause secondary scratching. It is supposed to control the pressure and speed well and use lubricants to prevent loading.

And excessive polishing pressure or prolonged contact can produce an uneven and orange-peel-like surface texture. Once this occurs, the process must revert to the previous two finishing steps for rework.

What’s more, it is supposed to apply wax sealing or anodizing immediately after mirror polishing sinch aluminum would quickly form an oxide film.

4.4 Mechanical Polishing Copper

Copper is relatively soft and sensitive to chemical environments. It is easy to oxidize and darken due to frictional heat during polishing, so rotational speeds should be maintained low.

And some copper parts have high porosity, which might lead polishing compounds to become embedded in fine crevices. Therefore, mild alkaline cleaning solutions should be used for thorough removal.

Additionally, inclusions on the copper surface may produce comet-like trailing marks during polishing, which can be mitigated by reducing the nap length of the polishing cloth.

4.5 Mechanical Polishing Titanium

Titanium is one of the most challenging metals to polish due to its high chemical reactivity and very low thermal conductivity.

It would easily form chemical bonds with abrasive media, which can directly tear the surface. Therefore, the polishing process must use inert media.

And titanium powder is highly flammable. Wet mechanical polishing is recommended for titanium parts, with good ventilation. Dust collectors should be cleaned regularly to prevent accumulation of combustible metal dust.

More information about titanium surface treatment, visit our blog: CNC Titanium Parts Surface Treatment Guide

4.6 Mechanical Polishing of PMMA/Acrylic

PMMA is a classic transparent thermoplastic. Mechanical polishing is a crucial post-processing method for restoring its “crystal-clear” transparency, but the process demands high precision.

With its relatively low hardness (approximately M90 on the Rockwell scale) and extreme sensitivity to scratches, polishing PMMA requires ultra-fine abrasives (such as micron-grade diamond paste or cerium oxide polishing fluid) paired with high-density soft polishing pads (such as sheepskin pads or specialized fiber pads).

The polishing process must maintain low temperatures, low speeds (recommended 500–800 RPM), and even pressure distribution.

Any localized overheating may cause surface softening, haze, or an “orange peel” texture. For repairing deep scratches, a progressive process from coarse to fine is typically followed: start with wet sanding using 2000–3000 grit sandpaper, then proceed with progressively finer polishing compounds.

After polishing, it is essential to wipe the surface with dedicated plastic cleaner and a lint-free cloth to remove all micro-scratches and residues.

It is particularly important to note that mechanical polishing slightly alters the surface morphology of PMMA. For high-precision optical components, flame polishing or vapor polishing should be combined to achieve a more perfect optical surface.

4.7 Mechanical Polishing of Polycarbonate

Polycarbonate is an engineering plastic known for its excellent impact resistance and transparency. However, its surface often exhibits noticeable tool marks and a hazy texture after CNC machining.

Mechanical polishing can be used to improve its surface gloss and optical clarity, but the process requires extreme caution.

Due to its relatively low hardness (approximately M70 on the Rockwell scale) and limited heat resistance (glass transition temperature around 147°C), polycarbonate is highly susceptible to melting, scorching, or surface whitening caused by frictional overheating during polishing.

It is recommended to use a dedicated soft polishing wheel (such as a fleece or flannel wheel) with a low-temperature polishing compound (such as diamond paste or cerium oxide-based paste) and perform multi-stage progressive polishing at low speeds (typically below 1000 RPM) with light pressure.

The key is to strictly control temperature—this can be achieved by intermittent polishing combined with compressed air cooling to prevent heat buildup. After polishing, thorough cleaning is necessary to remove any residual compound, as it may otherwise affect transparency.

5. Conclusion

Mechanical polishing is one of the most common polishing types for CNC machining parts.

The process can smooth and brighten the metal surfaces well. But it is crucial to choose the suitable polishing tools and abrasive media.

At the same time, the rotating speed and applied pressure should be controlled carefully. All in all, mechanical polishing is a good choice to achieve reflective finish.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.