Table of Contents

Titanium alloy is known for its high strength, low thermal conductivity, and high chemical reactivity, which makes it particularly challenging to machine.

Selecting the right cutting tool is crucial for controlling costs, ensuring quality, and enhancing efficiency.

1. Key Features of Tools Designed for Titanium Machining

To handle the “difficult-to-machine” nature of titanium, specialized cutting tools generally include the following design characteristics:

- Excellent Heat Resistance & Red Hardness

Heat concentrates at the tooltip during titanium machining, so the tool must retain its hardness and toughness even at high temperatures to avoid softening and rapid wear.

- Strong Resistance to Chemical Reactivity

Titanium tends to react and bond with tool materials, leading to built-up edge and tool chipping. Therefore, tools are often coated with high-temperature-resistant layers or made from special substrates to minimize adhesion and diffusion wear between the chip and the tool.

- Sharp Cutting Edges & Optimized Geometry

Large rake angle: Reduces cutting force and lowers cutting temperature.

Reinforced edge and efficient chip flute design: Maintains sharpness while strengthening the edge, ensures smooth chip evacuation, and prevents chip buildup.

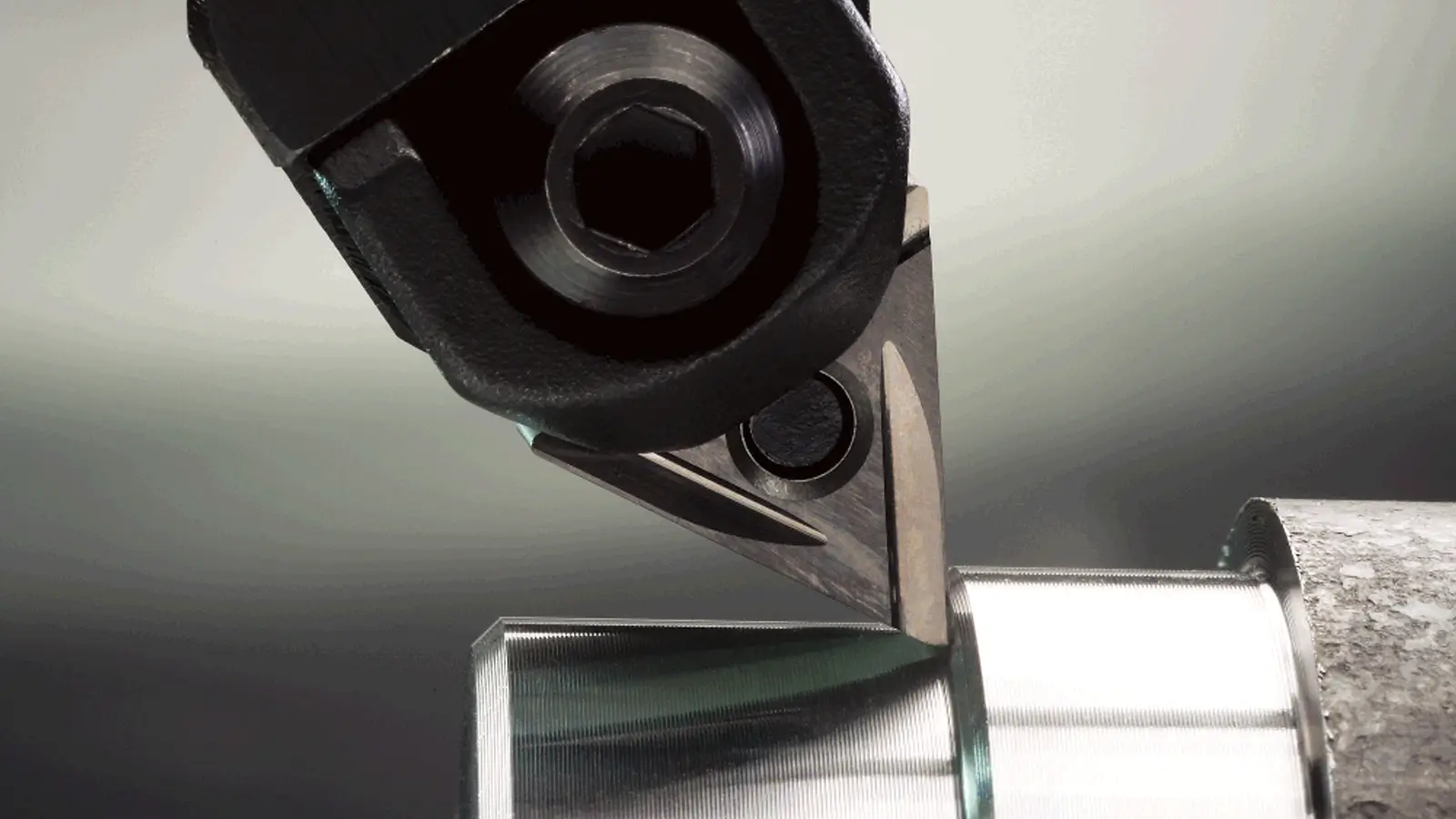

- High Rigidity with Short Overhang Design

Using a rigid toolholder and keeping overhang as short as possible greatly reduces vibration and tool deflection during machining—a crucial factor when working with titanium’s relatively low elastic modulus.

2. Types of Titanium Machining Tools

Selecting the right tool material is like picking the right specialist for a job. Each has its own strengths, limitations, and “perfect day” at the shop.

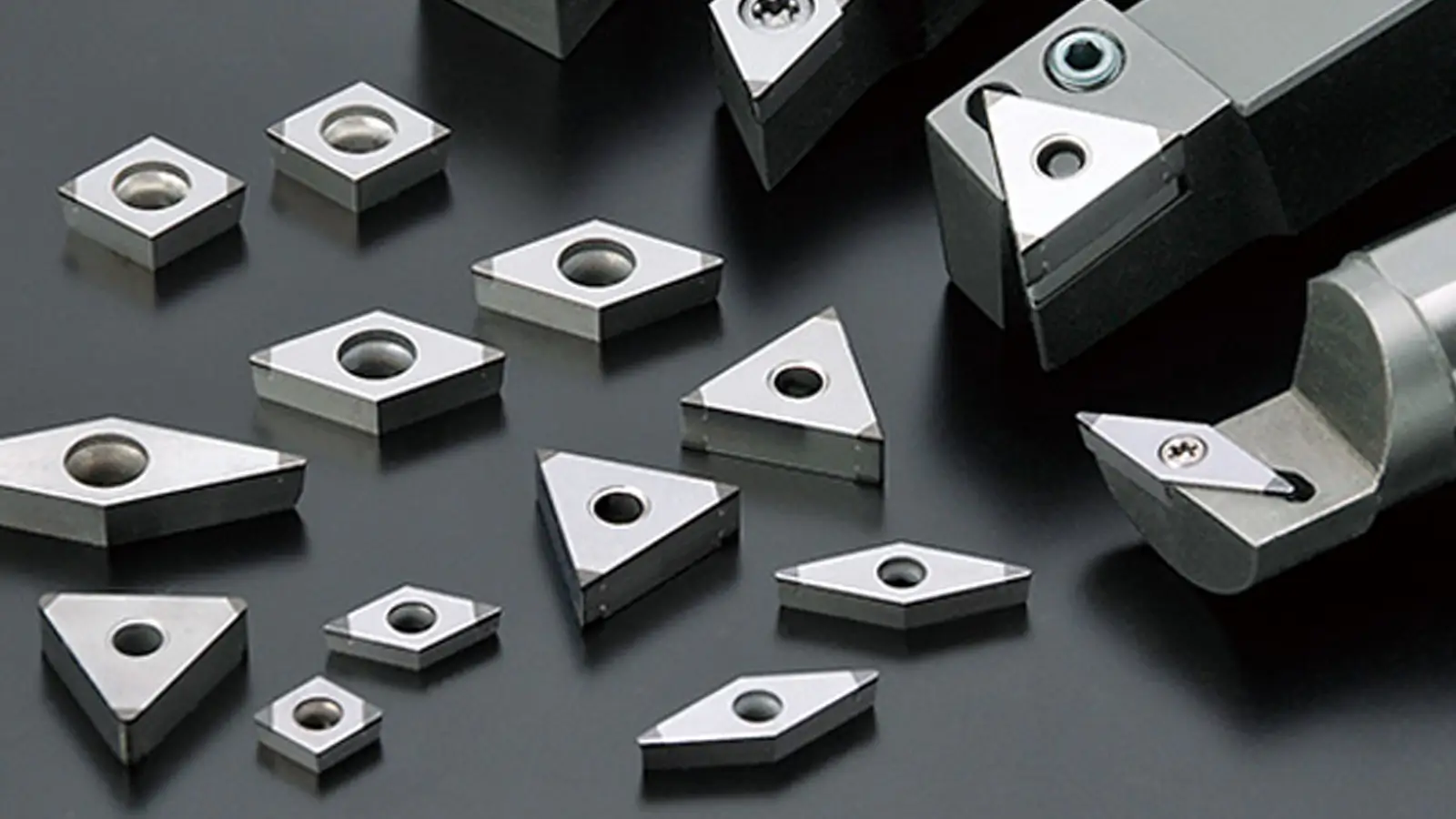

2.1 Carbide Tools

Carbide tools are the most widely used and mainstream option for machining titanium alloys, suitable for most roughing and semi-finishing operations.

They offer high toughness and wear resistance, and are often paired with PVD or CVD coatings (such as TiAlN or AlCrN).

The key lies in the optimized microstructure of the substrate material.

Core Material:

Ultra-fine or sub-micron grain carbide. This structure significantly increases the density and uniformity of the hard phase (tungsten carbide) at a microscopic level.

Key Features:

Achieves the best balance between toughness, wear resistance, and impact resistance.

The ultra-fine grain structure ensures sufficient cutting edge sharpness and wear resistance while providing better fracture toughness than conventional carbide, making it more capable of handling fluctuating cutting forces and thermal shock during titanium machining.

Typical Applications:

As the general-purpose workhorse, it covers the majority of operations from roughing to semi-finishing. It’s the go-to choice for efficient material removal and stable transition to finishing stages.

2.2 Coated Carbide Tools

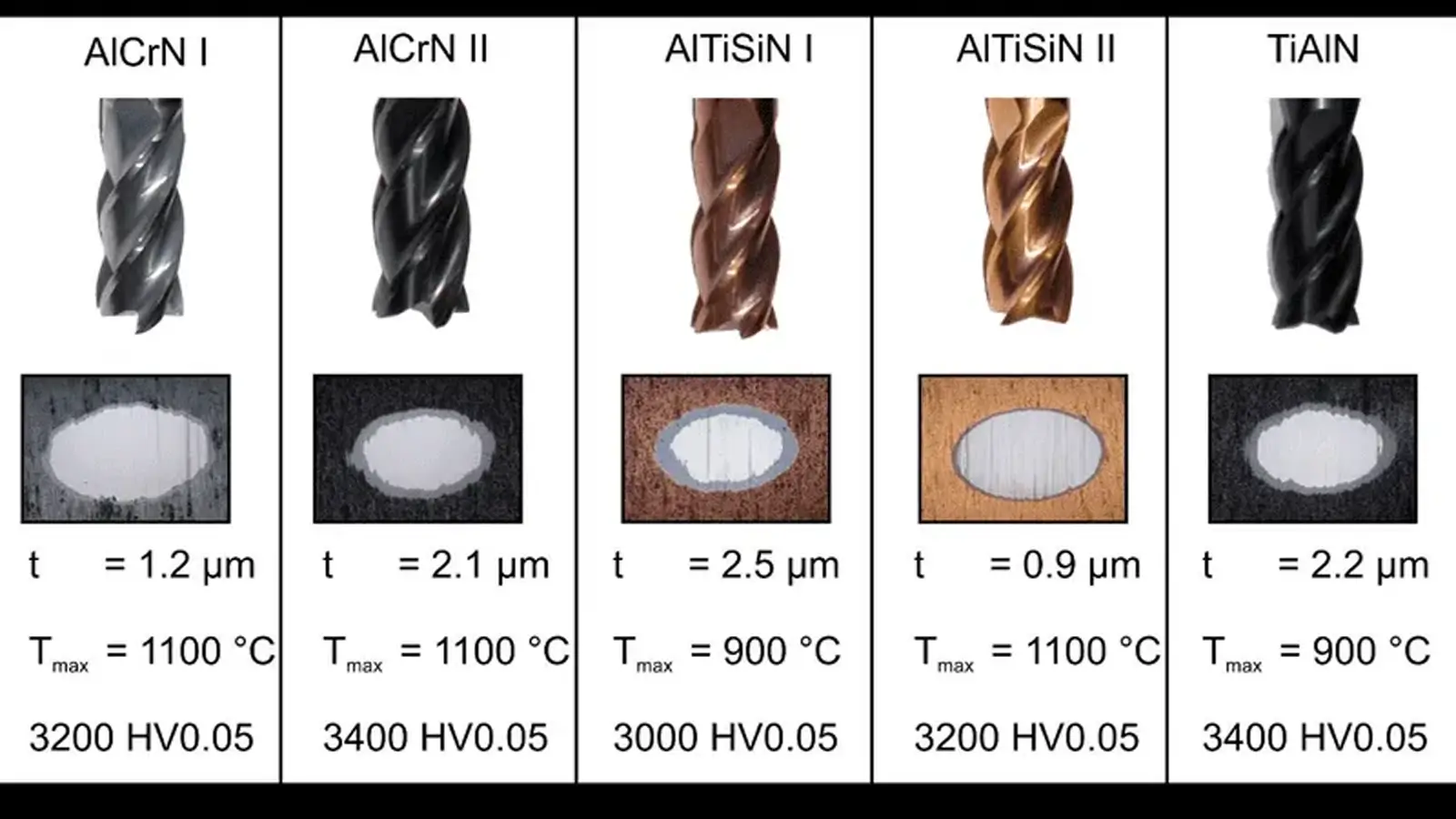

These tools are built on a high-quality carbide substrate and enhanced with a high-performance “armor” coating—usually applied via Physical Vapor Deposition (PVD)—to improve specific properties.

Core Coating:

Advanced PVD coatings like TiAlN (titanium aluminum nitride), AlTiN (aluminum titanium nitride), or TiSiN (titanium silicon nitride). These are often multi-layered with a nano-structured composition.

Key Features:

The coating offers extremely high hardness, very low friction, and excellent oxidation resistance (thermal stability).

During machining, this “armor” effectively blocks heat from transferring into the tool substrate, significantly reducing chemical affinity and material adhesion between the titanium chips and the tool surface.

This protects the substrate under high temperatures and extends tool life.

Typical Applications:

Primarily used in finishing and high-speed cutting operations where surface quality, dimensional accuracy, and process stability are critical.

It’s the key choice when higher cutting parameters are needed to achieve a good surface finish.

2.3 Cermet Tools

Cermet is a composite material consisting of a ceramic hard phase (such as TiCN) and a metallic binder (like Ni or Co). Its performance falls between that of ceramic and carbide tools.

Core Material:

TiCN (titanium carbonitride)-based cermet is the most common.

Key Features:

Offers higher hardness and wear resistance than carbide, along with very low chemical affinity to titanium alloy. This helps effectively resist built-up edge and adhesive wear.

However, its main weakness is lower toughness, making it sensitive to impact and vibration. It is not suitable for interrupted cuts or unstable machining conditions.

Typical Applications:

Ideal for continuous-cut finishing of titanium alloys, especially where excellent surface finish is required. It can deliver stable cutting performance and high-quality surfaces.

2.4 Polycrystalline Diamond (PCD) Tools

PCD represents the peak of hardness and thermal conductivity in cutting tools. It is sintered from diamond powder under high temperature and pressure.

Core Material:

Polycrystalline diamond (PCD) tip.

Key Features:

Possesses the highest hardness and thermal conductivity of all tool materials. It offers exceptional wear resistance and extremely long tool life. Most importantly, diamond is chemically inert with titanium, meaning it hardly reacts, fundamentally avoiding adhesive wear.

Typical Applications:

High-speed finishing of titanium alloys with silicon content (such as common Ti-6Al-4V), enabling high material removal rates and excellent surface quality.

Machining composite components, such as titanium-aluminum stacked structures common in aerospace. PCD tools can efficiently machine both materials without tool changes, offering clear advantages.

2.5 Polycrystalline Cubic Boron Nitride (PCBN) Tools

PCBN is an ultra-hard material second only to diamond in hardness. It is mainly used for hard turning of ferrous metals and has limited applications in titanium machining.

Core Material:

Polycrystalline cubic boron nitride (PCBN).

Key Features:

Extremely high hardness and excellent heat resistance (maintains hardness above 1200°C).

However, it tends to react chemically with titanium alloy at high temperatures, which limits its use.

Typical Applications:

Very limited in titanium alloy machining. It is mainly used for specific hard turning applications (e.g., finishing hardened titanium) or as an alternative to grinding—not a mainstream option for general titanium cutting.

Quick-Reference Guide for Titanium Alloy Cutting Tool Selection

| Tool Type | Core Material / Coating | Key Characteristics | Typical Applications |

|---|---|---|---|

| Carbide Tools | Ultra-fine / Sub-micron Grain Carbide | Excellent balance of toughness and wear resistance; the most versatile choice for titanium machining. | Most roughing to semi-finishing operations; efficient material removal. |

| Coated Tools | PVD Coatings (e.g., TiAlN, AlTiN, TiSiN) | High hardness, low friction, and excellent heat/oxidation resistance; reduces adhesion and thermal impact. | Finishing, high-speed cutting, and operations requiring high surface quality and precision. |

| Cermet Tools | TiCN-based Cermet | High hardness and wear resistance, low affinity to titanium, but relatively low toughness and impact sensitivity. | Finish machining in continuous cuts; ideal for achieving high surface finishes. |

| PCD Tools | Polycrystalline Diamond (PCD) | Extremely hard, high thermal conductivity, exceptional wear resistance, and chemically inert with titanium. | High-speed finishing of high-silicon titanium alloys (e.g., Ti-6Al-4V); machining composites like titanium-aluminum stacks. |

| PCBN Tools | Polycrystalline Cubic Boron Nitride (PCBN) | Second only to diamond in hardness; excellent heat resistance, but tends to react chemically with titanium. | Limited use; mainly for hard turning of titanium or as an alternative to grinding. |

3. How to Choose Cutting Tools for Titanium Alloy Machining

Selecting the right tools for machining titanium isn’t just about brand or price—it requires a systematic approach that moves from defining your goals to fine-tuning parameters, from theory to practice.

Follow these four steps to build your tool selection strategy:

Step 1: Define the Machining Stage and Primary Objective

Your goals and tool priorities should shift significantly depending on the machining stage.

Roughing

Goal: Remove large amounts of material efficiently and stably.

Tool Focus: Prioritize toughness and impact resistance. Choose robust insert geometries and carbide grades that are wear-resistant and tough. Using a larger nose radius can enhance stability.

Semi-Finishing

Goal: Prepare a uniform stock allowance for finishing while beginning to control dimensions and thermal distortion.

Tool Focus: Balance toughness with wear resistance. High-performance coated carbide tools (e.g., PVD TiAlN coatings) are recommended—their coatings help control cutting heat and tool wear effectively.

Finishing

Goal: Achieve final dimensional accuracy and excellent surface quality.

Tool Focus:

Prioritize wear resistance, thermal stability, and edge sharpness. Select precision coated tools (mainly PVD) with sharp edges, or polycrystalline diamond (PCD) tools for specific materials. For extreme surface-finish requirements, cermet tools can be considered.

Step 2: Optimize Key Tool Geometry and Design Parameters

This is where theory translates into performance. Correct geometric design directly addresses the force, heat, and vibration challenges in titanium machining.

Tool Angles: Aim for “Sharp Yet Strong”

Rake Angle: Use a relatively large positive rake angle (typically 10°–15°). This acts like a sharp blade, significantly reducing cutting forces and heat.

Clearance Angle: Apply a moderate clearance angle (e.g., 10°–12°) to minimize friction between the tool and the machined surface.

Edge Preparation: Keep edges very sharp, but apply a slight chamfer or hone. This prevents micro-chipping from a “sharp-but-brittle” edge while avoiding excessive strengthening that could spike cutting forces.

Milling Cutter Design: Say No to Vibration

Helix Angle: Choose a larger helix angle (usually 35°–45°). This makes the cut smoother, like a zipper engaging, reducing axial force and suppressing chatter.

Unequal Pitch / Variable Helix: A premium option, especially for thin-wall parts. By breaking up the regular cutting frequency, it effectively eliminates resonance—a true “vibration killer.”

Tool Nose and Overhang: The Foundation of Stability

Nose Radius: Keep it moderate. Too small weakens the edge; too large concentrates cutting force and can induce vibration.

Tool Overhang: Shorter is always better! This is the law of rigidity. A 20% increase in overhang can reduce tool rigidity by nearly 50%, directly leading to chatter, dimensional errors, and poor surface finish.

Step 3: Match with Proper Cutting Conditions and Auxiliary Systems

A good tool needs a good “saddle”—the right operating environment multiplies tool performance.

Cutting Parameters: Follow the basic principle of “lower cutting speed, moderate feed rate, and shallow depth of cut.” This helps control heat buildup. Tip: When machine and fixture rigidity allow, increasing the feed rate to raise metal-removal rates is often safer and more effective than increasing spindle speed.

Cooling System: High-pressure coolant (preferably ≥70 bar) is essential. Make sure coolant reaches the cutting edge precisely and under high pressure to force cooling, chip evacuation, and lubrication. Without effective cooling, even the best tool will underperform.

Process Synergy: When using strategies like trochoidal or dynamic milling, pair them with dedicated tool geometries and parameters to enable stable, efficient machining with wide radial and shallow axial engagement.

Step 4: Implement Detailed Tool Life and Cost Management

Move beyond “changing tools by feel” to data-driven, scientific management.

Stop “Running Tools to Failure”: Based on machining data or tool-supplier recommendations, set scientific tool-life limits for different operations and change tools preventively.

It’s better to use a fresh tool than a dull one. Once a tool dulls, heat generation rises sharply and can instantly damage the workpiece.

Find the Cost-Effectiveness Sweet Spot: The ultimate goal isn’t the longest tool life per edge, but “the lowest cost per finished part.” Sometimes moderately increasing parameters to shorten cycle times—even if tool wear accelerates slightly—can actually lower total cost.

Efficiency Tip: When machining titanium, using a multi-flute cutter (when machine power and chip evacuation allow) spreads the load per tooth, enabling higher feed rates and boosting productivity.

4. Practical Suggestions & Final Summary

Always prefer a fresh tool over a dull one. Once a tool begins to dull, heat builds exponentially and can quickly ruin the workpiece.

Multi-flute cutters are more efficient. Increasing the number of teeth spreads the load per tooth, allowing higher feed rates in titanium.

Keep tool overhang as short as possible—for rigidity! The longer the tool extends, the more it behaves like a spring and vibrates.

In summary, a successful tool strategy for taming titanium is the precise integration of materials science (substrate & coating), geometric engineering (edge design), and manufacturing process (parameters, cooling, strategy).

Establishing and following this systematic tool-selection and application process is your path from reactive troubleshooting to proactive control—and ultimately to high-quality, efficient, and cost-effective machining of this “star material” in manufacturing.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.