Table of Contents

3D printing transforms design validation by reducing time and cost,allowing designers and engineers to turn ideas into physical prototypes in just hours.

Whether you’re a startup testing product fit or an industrial manufacturer optimizing production, rapid prototyping with 3D printing helps you reduce time, cost, and risk before mass production.

In this guide, we’ll explore the best 3D printing methods, commonly used materials, and expert tips for achieving professional, high-quality prototypes.

What Is Rapid Prototyping in 3D Printing?

Rapid prototyping in 3D printing refers to the use of additive manufacturing techniques to quickly create a physical model from a digital design.

This approach significantly reduces the time and cost associated with traditional manufacturing methods, enabling designers and engineers to test and refine concepts more efficiently.

The produced model, known as a prototype, allows for visual inspection, functional testing, and design validation before moving into full-scale production.

By layering materials precisely, 3D printing supports complex shapes and customized features that accelerate innovation and shorten product development cycles.

1.Why Businesses Use 3D Printing for Prototyping?

Explore why 3D printing is a popular choice for business prototyping.

Key advantages include rapid production speed, which shortens development cycles, and cost savings by minimizing material waste and eliminating the need for expensive tooling.

Its design flexibility allows for the creation of complex shapes and quick adjustments, supporting innovation and customization.

Additionally, 3D printing facilitates early-stage testing and validation, helping businesses reduce risks and improve product quality before full-scale manufacturing.

Top 3D Printing Methods for Rapid Prototyping

Different 3D printing technologies serve different needs — from concept validation to functional testing. Understanding their pros and cons helps you choose the best method for your project.

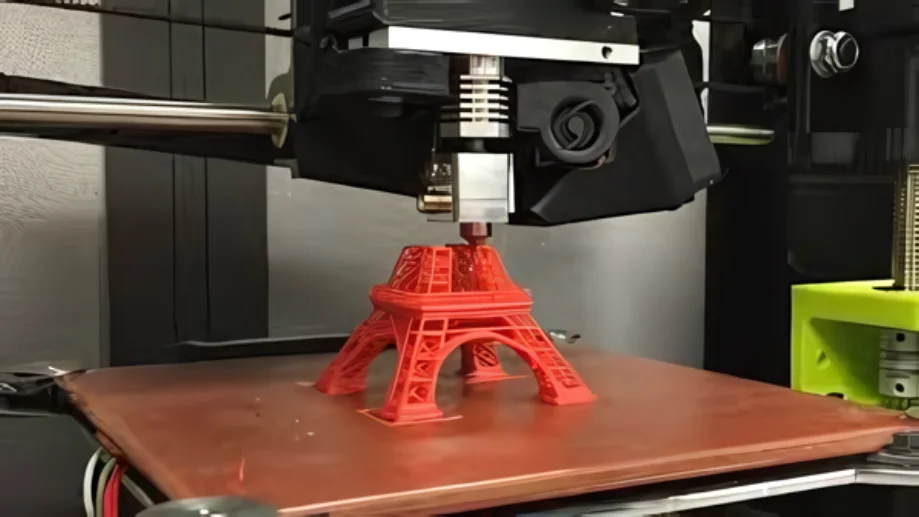

1. Fused Deposition Modeling (FDM)

- Best For: Low-cost concept models and functional prototypes

- Materials: PLA, ABS, PETG, Nylon

- Advantages: Affordable, strong mechanical properties

- Limitations: Lower surface resolution

- Tip: Choose verified FDM suppliers with experience in industrial-grade printers for consistent accuracy.

2. Stereolithography (SLA)

- Best For: High-detail visual prototypes and smooth surface finishes

- Materials: Photopolymer resin

- Advantages: High precision and excellent surface quality

- Limitations: Brittle material, less durable under stress

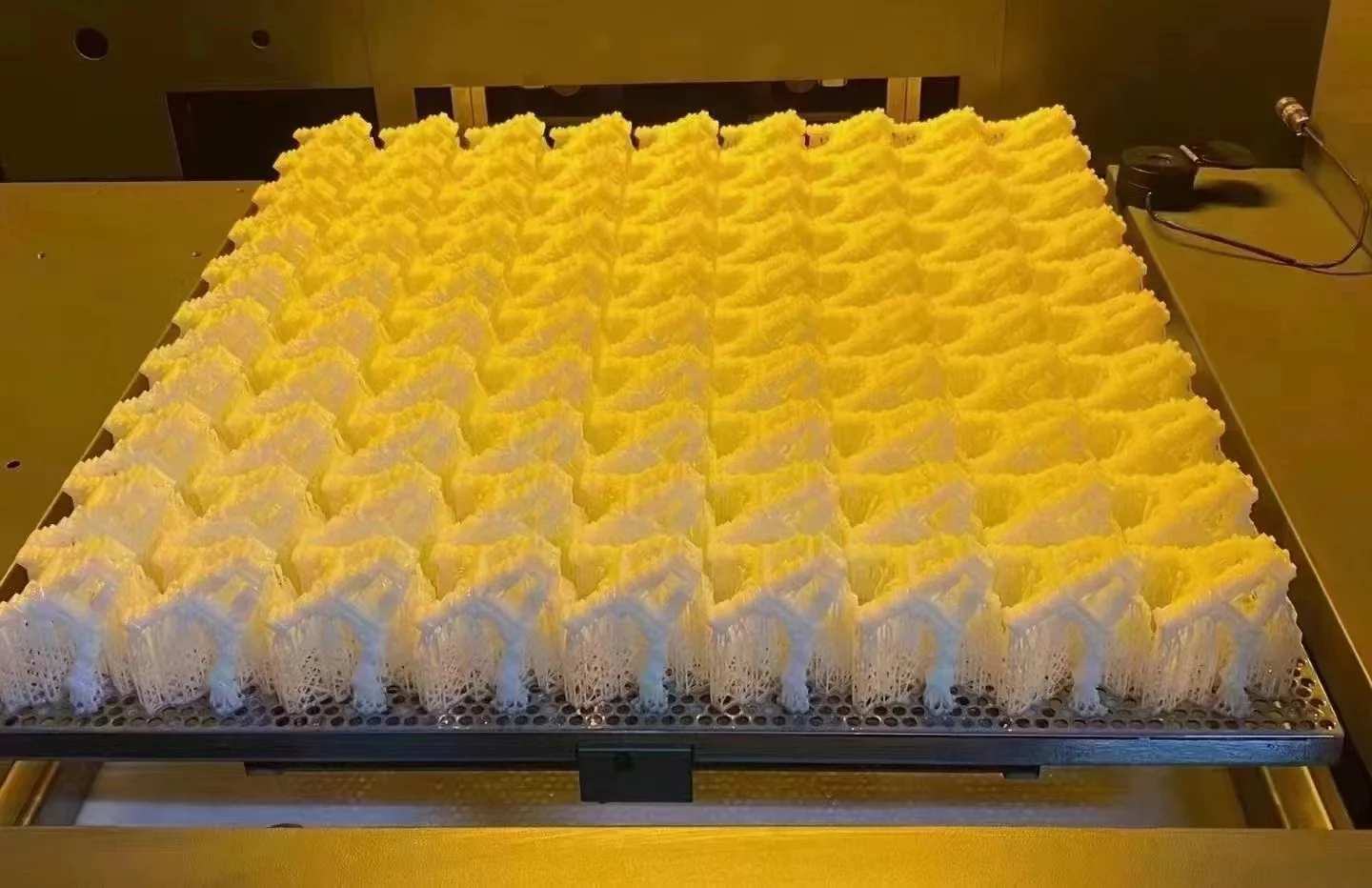

3. Selective Laser Sintering (SLS)

Best For: Functional parts requiring strength and durability

Materials: Nylon 12, Nylon 11, TPU

Advantages: No support structures needed; excellent for complex shapes

Limitations: Slightly higher cost than FDM or SLA

Pro Tip: If you need small-batch prototypes or functional testing parts, SLS 3D printing is often the most reliable choice.

Common 3D Printing Materials for Prototyping

Selecting the right 3D printing material depends on the prototype’s purpose.

PLA is popular for easy-to-print, visual models, while resin offers high detail and smooth finishes for precise prototypes.

ABS and PETG are preferred when durability and heat resistance are needed, making them suitable for functional testing.

Nylon provides strength and flexibility for more demanding applications. For parts requiring elasticity, TPU is ideal.

Choosing materials that align with the prototype’s functional requirements ensures accurate, cost-efficient results.

| Material Category | Types & Descriptions |

|---|---|

| Thermoplastics | PLA (Polylactic Acid): Popular for quick visual models, easy to print, biodegradable, with good surface detail but brittle and less heat-resistant—ideal for concept models and form/fit prototypes. ABS (Acrylonitrile Butadiene Styrene): Durable, impact-resistant, and heat-resistant, suitable for functional prototypes and mechanical parts but requires a heated bed and ventilation during printing. PETG (Polyethylene Terephthalate Glycol): Combines strength, flexibility, chemical resistance, and ease of printing, good for prototypes needing durability. Nylon (Polyamide): Strong, flexible, and wear-resistant, excellent for functional prototypes exposed to stress or friction, though it requires careful printing conditions due to moisture sensitivity. TPU (Thermoplastic Polyurethane): Flexible and impact-resistant, suitable for prototypes requiring elasticity like gaskets or seals. |

| Resins | Standard resins: Offer high-detail, smooth surface finishes for visual or intricate prototypes. Engineering resins: Provide strength, durability, and heat resistance, suitable for functional parts. Flexible resins: Simulate rubber-like properties for flexible prototype needs. |

| Metals | Stainless steel, titanium, and aluminum are used for high-strength, durable functional prototypes, especially in aerospace, medical, and industrial applications where material performance is critical. |

| Composite Materials | Carbon fiber and fiberglass composites offer high strength-to-weight ratios and stiffness, used for structural and high-performance prototypes. |

| Considerations | Material choice depends on prototype function—whether it’s for visual modeling, functional testing, or specialized performance—balancing factors like strength, flexibility, printability, and cost. |

Best 3d printing practice for prototyping

3D printing is a transformative method for prototyping that enables fast iterations, cost savings, and the creation of complex designs, making it invaluable in product development workflows.

1.Key 3D Printing Techniques for Prototyping

- Fused Deposition Modeling (FDM):A widely used technique that builds parts by extruding heated thermoplastic filament layer by layer. It is best suited for quick and affordable prototypes focused on form and fit, offering moderate mechanical functionality.

- Stereolithography (SLA):This technology cures liquid photopolymer resin with ultraviolet light to produce highly detailed models with smooth surfaces. It excels in prototypes demanding fine detail and surface finish, favored in industries like dental and jewelry design.

- Selective Laser Sintering (SLS):Using a laser to fuse powdered materials into solid structures, SLS allows for producing complex shapes without needing support material. It is ideal for functional testing and durable prototype parts in engineering and aerospace.

- Digital Light Processing (DLP):Similar to SLA but faster, DLP cures resin through a digital projector, offering quick turnaround for intricate designs. It is useful for rapid prototyping in small production runs where detail and speed are critical.

2.Best Practices for 3D Printing Prototypes

- Clarify Prototype Intent: Define whether the goal is visual proof, functional assessment, or end-use validation, as this directs the choice of printing technology and materials.

- Select Appropriate Materials: Match material properties to the prototype’s needs—thermoplastics for strength and durability, resins for detailed aesthetics and smooth finishes.

- Iterative Development: Leverage 3D printing’s quick turnaround to repeatedly test and refine designs, reducing risk before moving to mass production.

- Design for Manufacturability: Tailor the design to the capabilities of the chosen technology, minimizing complex overhangs, and optimizing for support needs to improve print success rates and reduce post-processing.

- Post-Processing Preparation: Allocate time for finishing steps such as sanding, polishing, or assembly to achieve functional and visual requirements.

By embracing these principles, 3D printing empowers teams to rapidly bring concepts into physical form, accelerate design cycles, and produce high-quality prototypes tailored to real-world applications. This strategic use of technology advances innovation while controlling development costs.

FAQs About 3D Printing for Rapid Prototyping

Q1: How long does it take to 3D print a prototype?

3D printing a prototype typically takes from 20 minutes to over 10 hours, depending on factors like size, detail, and printing method.

Simple small parts print quickly, while larger or highly detailed models require more time.

Each printing technology has different speed characteristics, so understanding these helps in planning rapid prototyping efficiently.

Print time is crucial for balancing quality, cost, and development speed.

Q2: What’s the average cost for rapid prototyping?

The average cost for rapid prototyping typically falls between $500 and $20,000, influenced by factors such as the prototype’s size, the complexity of the design, choice of materials, selected 3D printing or molding technology, and the number of iterations required.

Small, simple prototypes using standard materials like PLA or resin tend to be at the lower end, while large, functional, or highly detailed models using advanced materials like metal or engineering-grade plastics can push costs higher.

Q3: Can I use 3D printed parts for final production?

3D printed parts can be used for final production in certain cases, especially when printed with durable materials and proper finishing techniques such as powder removal and surface treatment.

However, suitability depends on the part’s function, required strength, and quality standards.

For critical or high-volume applications, traditional manufacturing may still be preferred, but 3D printing offers a flexible option for customized, low-volume, or complex parts.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.