CNC Machining Materials

Choosing the Right One for CNC Machining Project

Updated: Jan. 16, 2024

CNC machining materials are available in both metal and plastic. There are hundreds of materials available for CNC machining, both milling and turning. Selecting the right one for your project is quite important. There are so many factors to be taken into consideration before starting your projects.

In this article, we will introduce steps to select the right materials, and factors to be considered when choosing the right materials, then we will give a brief introduction of common CNC machining materials’ advantages and uses.

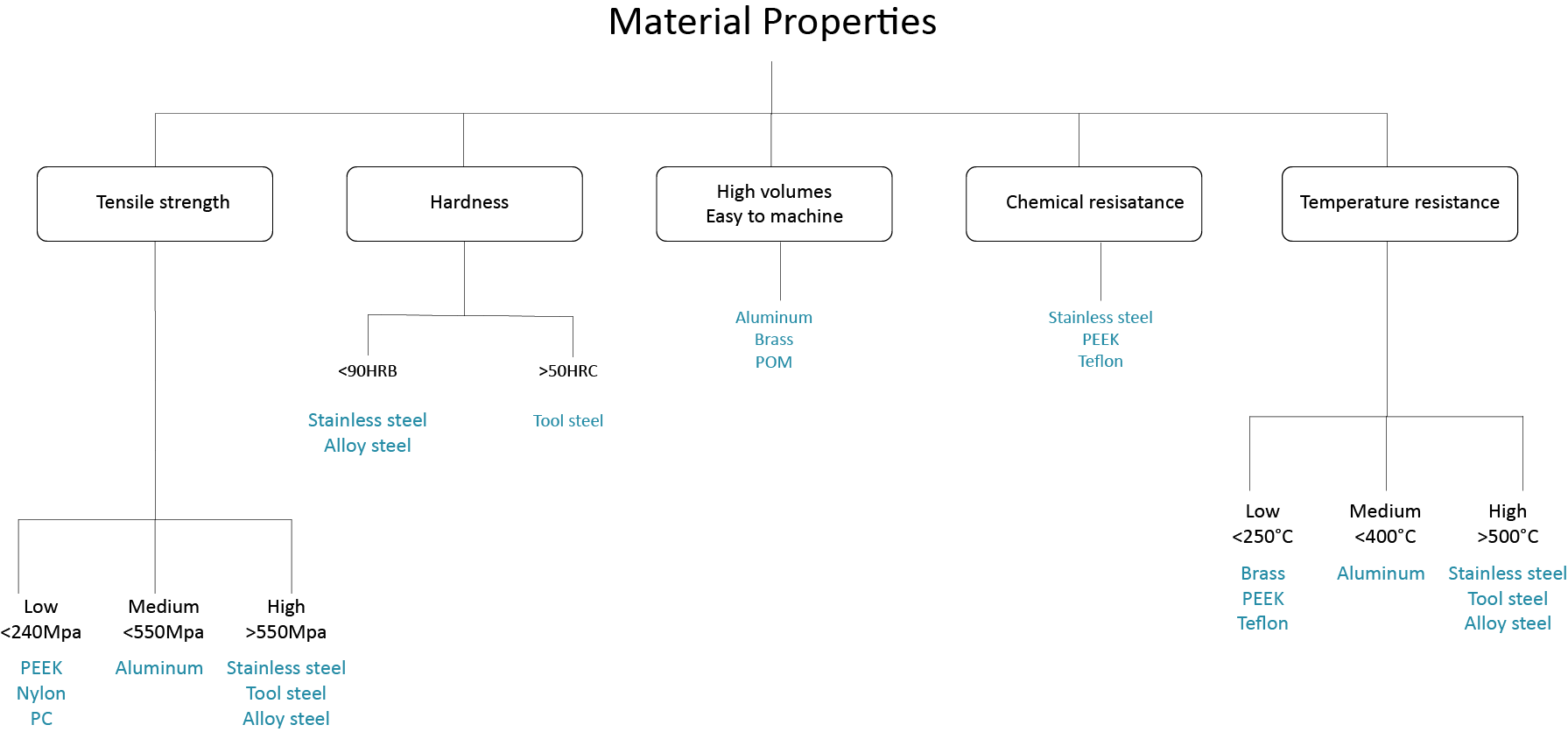

1. How to select the right CNC materials?

To select the right CNC materials for your custom parts, we follow 3 basic steps.

Step 1: Determine the material requirements.

Considering how the parts will be used and the use environment, then we need to define the materials’ properties, which include mechanical properties, thermal conductivity, electrical conductivity, coefficient of thermal expansion, corrosion resistance, machinability, density, thermal stability, wear resistance, and environmental friendliness.

Step 2: Identify candidate materials.

Narrow the materials choices by selecting a few candidate materials that can meet your design requirements.

Step 3: Select the most suitable material.

Including the materials’ properties, parts’ application, and environments, many other factors influence the material selection, for example, material cost. A compromise may be needed between two or more design requirements.

In this article, we will focus on step one. In other words, the article will dive more into the factors which are needed to be taken into consideration for selecting the right materials. You can check the two blogs below for CNC machining metals and CNC machining plastics properties and usages introduction.

2. Considerations for selecting the right CNC materials

2.1 Part requirement

Each design is unique and you know the part application better than anyone else. Put your requirements for the custom parts first. Start by listing the must-haves, and then move on to the nice-to-haves. This way, you can narrow down your material options and make a smarter choice.

2.2 Use environment

For many applications, the environment will be an absolute top-of-the-list factor. Heat resistance, cold resistance, flame retardance, UV resistance, and chemical tolerance are all environmental factors.

Components for outdoor applications shall be resistant to UV and rain, which need materials with durable properties and a robust design. By contrast, indoor application parts do not need to be exposed to extreme environmental conditions, more materials are available for choice.

Parts for medical equipment may have very tight tolerance and have to withstand high temperatures and harsh chemical sterilization. For other applications, the materials have to be food-grade or medical-grade.

2.3 Material mechanical properties

The mechanical properties of materials include strength, hardness, and toughness.

Strength

Strength is the materials’ ability to withstand an applied force without breaking or deforming. According to ISO (International Organization for Standardization), it is often measured in tensile strength, compressive strength or shear strength.

Low tensile yield strength: below 240MPa Plastics are always with low tensile yield strength, for example, PEEK, Nylon, and PC.

Medium tensile yield strength: 240MPa-550Mpa Aluminum is with medium tensile yield strength.

High tensile yield strength: above 550Mpa Stainless steel, alloy steel, and tool steel are with high tensile yield strength.

Hardness

Hardness is the material’s resistance to indentation or scratching. Hardness is measured in Rockwell, Brinell, and Vickers hardness tests.

Low hardness is below 50HRB.

Medium hardness is between 50 to 90HRB.

High hardness is between 90HRB to 50HRC.

Very high hardness is above 50HRC.

To convert different hardness, please visit steel hardness conversion.

Toughness

Toughness is the materials’ ability to absorb energy and fracture plastically before breaking. It is tested by impact tests or Charpy V-notch tests.

Strength VS Toughness

Strength and toughness are two related but distinct concepts.

Strength is the stability of the material under stress. The higher the strength, the less likely the material will deform when exposed to external loads. Toughness is the ability to absorb energy and deform without fracturing when exposed to external loads. The higher the toughness, the more likely the material will undergo a certain degree of deformation without losing the overall structure.

Strength and toughness are independent, and there is no inherent correlation between them. In other words, materials with high strength do not necessarily possess high toughness.

In component design, there is often a need to require a balance between strength and toughness.

2.4 Materials’ corrosion resistance

When CNC machined parts are used in environments with corrosive elements such as moisture, chemicals, or harsh atmospheric conditions, selecting corrosion-resistant materials can save the surface treatment for materials without corrosion resistance.

Stainless steels, aluminum alloys, and certain alloys like Inconel and titanium are known for their ability to resist corrosion in different environments.

2.5 Materials’ electrical conductivity

If the parts need good conductivity, select metals with good electrical conductivity, for example, copper and aluminum.

2.6 Materials’ thermal conductivity

Copper and aluminum parts have good thermal conductivity.

2.7 Materials’ thermal stability

If the parts are to be used in high-temperature environments, choose materials with good thermal stability, such as stainless steel, nickel alloy, and titanium alloys.

2.8 Materials’ magnetic properties

Understand whether the application has specific magnetic requirements. Some applications may need materials without non-magnetic materials to avoid interference with magnetic fields. If magnetic shielding is required, consider materials with high magnetic permeability.

Most stainless steel, aluminum, and copper alloys are typically non-magnetic, carbon steel and nickel are magnetic.

2.9 Materials’ machinability

It is very important to understand the material’s machinability because the machining cost is cheaper for easy-machining materials.

Plastics, mild steel, aluminum, and copper alloy are easy for CNC machining. The machining for stainless steel, tool steel, and titanium can be a challenge because of their hardness. Magnesium CNC machining is also not easy because it tends to fire during production.

Whether the material is easy to cut, milled, and turned, it is closely related to CNC machining precision and efficiency.

2.10 Materials’ weight and density

For the aerospace and automotive industries, the weight is critical. Choosing a material with a lower density is preferred. Lighter materials reduce the finished parts themselves.

2.11 Environmental factors

Consider the sustainability and environmental impact of the materials chosen.

2.12 Machining tolerance

Some materials are easier to machine with high precision and get tighter tolerance, for example, aluminum. While some are difficult to get tight tolerance, such as plastics.

2.13 Surface finishing

In most applications, cosmetic is not an important consideration. But for some for components where aesthetics are crucial, the surface finish becomes a significant consideration in CNC machining material selection.

Plastics can be supplied in different colors while metals can be colored using post-processing treatment. But keep in mind that post-processing costs money.

2.14 Material cost

Cost can be an important factor in choosing CNC machining materials, especially for projects with limited budgets. Plastics or cheap metals are good choices in this situation.

3. Common CNC machining metals

Below is a brief introduction of some common CNC machining metals. For a complete and detailed introduction, please visit our blog Types of Metals for CNC Machining Materials.

3.1 What is aluminum? An economical and robust alloy.

Aluminum alloys have an excellent strength-to-weight ratio, and they also have good thermal conductivity, good electrical conductivity, and good corrosion resistance.

Aluminum has good machinability. Most aluminum is not expensive and cost-efficient in bulk, which makes aluminum the most economical for producing prototypes and low-volume CNC parts.

Compared with steel, aluminum alloys typically have lower strength and hardness, but they can be anodized to create a hard and protective layer on the surfaces.

Aluminum alloys characteristics

Typical density of aluminum alloys: 2.65-2.80 g/cm3

Can be anodized

Non-magnetic

Different types of aluminum alloys

Aluminum 6061 is a general-use aluminum alloy, the most commonly used and cheapest type. It has a good strength-to-weight ratio and super excellent machinability.

Aluminum 6082 has a similar composition and properties to 6061 but is mostly used in Europe.

Aluminum 7075 is most commonly used in the aerospace industry with excellent fatigue properties. It can be heat treated to improve its strength and hardness.

Aluminum 5083 has better strength than most other aluminum alloys. With exceptional resistance to seawater, 5083 is a better choice for construction and marine applications. It also has a good welding property.

| Material | Grade | Strength* | Hardness+ | Machinability | Cost | Typical applications |

| Aluminum | 6061 | Medium | Medium | ★★★★★ | $ | General purpose Aircraft components Automotive parts Bicycle frames Food containers |

| Aluminum | 6082 | Medium | Medium | ★★★★★ | $ | General purpose Automotive parts Food containers |

| Aluminum | 7075 | High | Medium | ★★★★ | $$$ | Aircraft & aerospace components Automotive parts Marine applications Sports equipment |

| Aluminum | 5083 | Medium | Low | ★★★★★ | $$ | Marine applications Construction Pressure vessels |

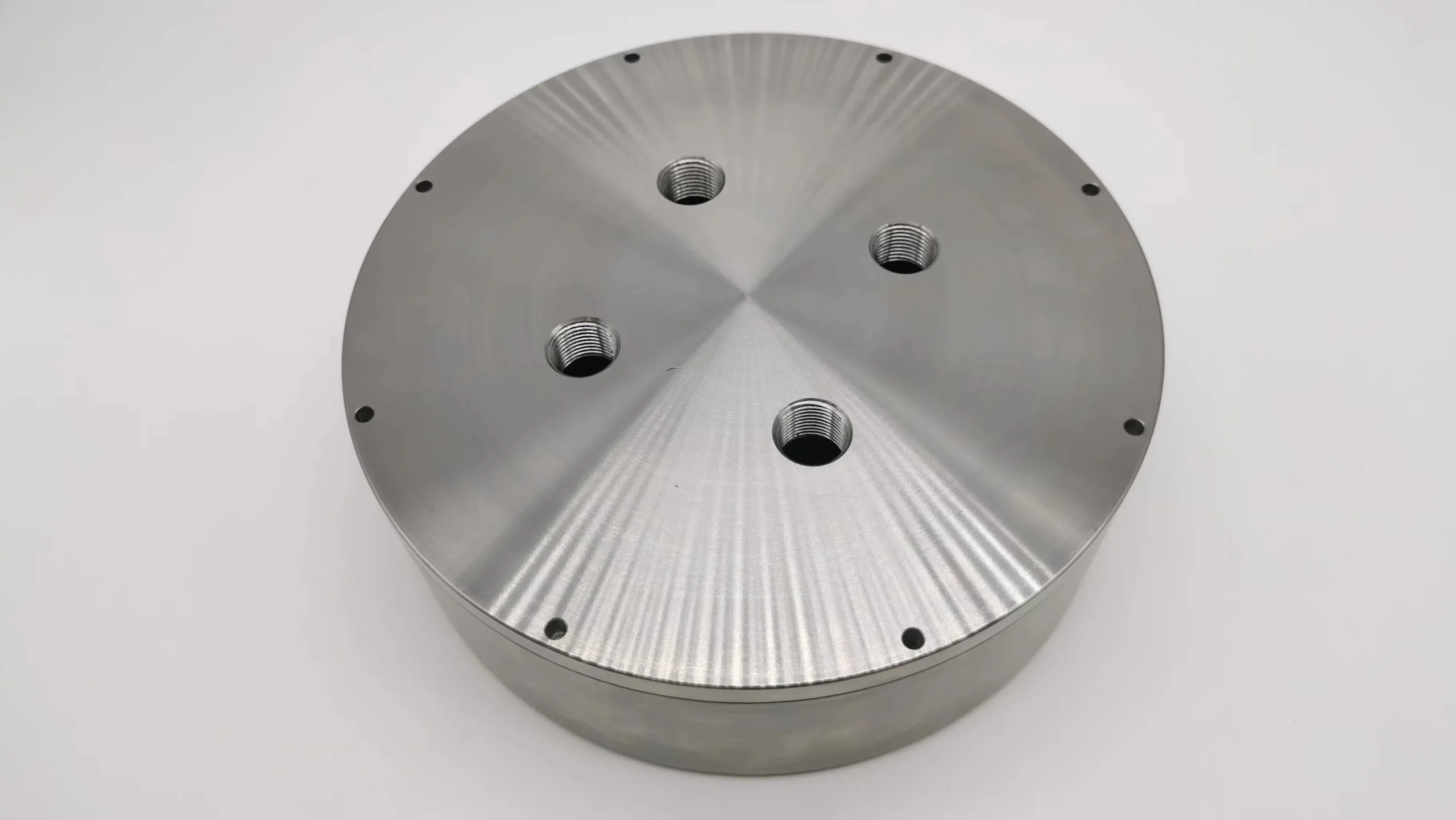

3.2 What is stainless steel? A strong and durable alloy.

Stainless steel has many outstanding properties, including high strength and ductility, excellent wear resistance, and corrosion resistance. It can be welded, machined, and polished easily. Stainless steel can be nonmagnetic or magnetic due to its different composition.

Stainless steel characteristics

Typical density: 7.7-8.0 g/cm3

Non-magnetic stainless steel alloys: 304, 316, 303

Magnetic stainless steel alloys: 2205 Duplex, 17-4

Different types of stainless steel

Stainless steel 304/304L has excellent mechanical properties and is easy to CNC machined. It is corrosion-resistant and is recognized as the most common stainless steel alloy.

Stainless steel 316/316L has better corrosion and chemical resistance than 304/304L, especially saline solutions (for example seawater). For harsher environment applications, 316/316L is more suitable than 304/304L.

Stainless steel 2205 Duplex has the highest strength among stainless steel alloys. With excellent corrosion resistance, it is often used in extreme environments, for example, oil and gas transportation parts.

Stainless steel 303 is also called easy machinable stainless steel because it has excellent machinability. Compared with 304 stainless steel, it has lower corrosion resistance but good toughness. 303 stainless is only machined in high volume to produce nuts and bolts.

Stainless steel 17-4 (SAE grade 630) has similar mechanical properties as 304. but can be precipitation hardened to a very high degree (comparable to tool steels). It has excellent chemical resistance and is suitable for very high-performance applications, such as manufacturing wind turbine blades.

| Material | Grade | Strength* | Hardness+ | Machinability | Cost | Typical applications |

| Stainless steel | 304 | High | Medium | ★★ | $$$ | General purpose Medical devices Food industry Marine applications Chemical processing |

| Stainless steel | 316 | High | Medium | ★★ | $$$$ | Food preparation equipment Marine applications Architecture Surgical implants Chemical containers |

| Stainless steel | 2205 Duplex | High | High | ★ | $$$$$ | Oil & gas Marine applications Chemical processing Heat exchangers |

| Stainless steel | 303 | High | High | ★★★ | $$$$ | Aircraft components Machine parts Nuts, bolts, gears, bushings |

| Stainless steel | 17–4 | High | Very High | ★★ | $$$$$ | Turbine blades Marine applications Chemical vessels Oil & Gas Nuclear applications |

3.3 What is mild steel? A general-purpose alloy.

Mild steel is low-carbon steel. Though the cost of mild steel is low, it has good mechanical properties, good machinability, and weldability. Mild steel is prone to corrosion and chemical damages and, thus is often used for general-purpose applications like fixtures and jigs.

Carbon steel material characteristics:

Typical density: 7.8-7.9 g/cm3

Magnetic

Different types of carbon steel

Mild steel 1018 is the most commonly used mild steel alloy with a general-use application. It has good machinability and weldability, and excellent toughness, strength, and hardness.

1045 is a medium carbon steel with good weldability, good machinability, and high strength and impact resistance.

Mild steel A36 has good weldability and is used as a common structural steel.

| Material | Grade | Strength* | Hardness+ | Machinability | Cost | Typical applications |

| Carbon Steel | 1018 | Medium | Medium | ★★★ | $$ | General purpose Machinery parts Jigs & fixtures |

| Carbon Steel | 1045 | Medium | High | ★★ | $$$ | General purpose Machinery parts |

| Carbon Steel | A36 | High | Medium | ★★★ | $$ | Construction Machinery parts Jigs & fixtures |

3.4 What is alloy steel? A tougher, wear-resistant alloy.

Compared with mild steel, alloy steel has improved hardness, toughness, better fatigue, and wear resistance, due to the existence of other elements. It is also susceptible to corrosion and chemical damage.

Alloy steel material characteristics:

Typical density: 7.8-7.9 g/cm3

Magnetic

Different types of alloy steel

Alloy steel 4140 has good strength and toughness. With good overall mechanical properties, 4140 is suitable for industrial applications but is not suitable for welding.

Alloy steel 4340 can be heat treated to get higher strength and hardness while keeping its good toughness, wear resistance, and fatigue strength. 4340 is weldable.

| Material | Grade | Strength* | Hardness+ | Machinability | Cost | Typical applications |

| Alloy steel | 4140 | Medium | High | ★★ | $$$ | General purpose Machinery parts Tooling |

| Alloy steel | 4340 | High | High | ★★ | $$$ | Aircraft landing gear Power transmission Tooling |

3.5 What is tool steel? An exceptionally tough and resistant alloy.

Tool steels are metal alloys with exceptionally high hardness, stiffness, abrasion, and thermal resistance, so long as they undergo heat treatment. They are used to create manufacturing tools (hence the name) such as dies, stamps, and molds.

Tool steels have exceptionally high hardness, stiffness, abrasion, and thermal resistance after being heat treated. Tool steels are often used to manufacture tools such as blades, dies, stamps, and molds.

Tool steel material characteristics:

Typical density: 7.8 g/cm3

Typical hardness: 45-65 HRC

Different types of tool steels

Tool steel D2 is a wear-resistant alloy and is commonly used to manufacture cutting tools and dies. D2 tool steel can keep its hardness even at a high temperature up to 425°C.

Tool steel A2 has good toughness and excellent dimensional stability at high temperatures. It is an air-hardened alloy and is used for general purposes to make injection molding dies.

Tool steel O1 is an oil-hardened alloy with a high hardness of up to 65 HRC. It’s commonly used for knives, blades, and cutting tools.

| Material | Grade | Strength* | Hardness+ | Machinability | Cost | Typical applications |

| Tool steel | D2 | High | Very High | ★ | $$$$ | Cold-working tooling Dies & stamps Cutting tools & knives |

| Tool steel | A2 | High | Very High | ★ | $$$$ | Cold-working tooling Dies & stamps Cutting tools & knives |

| Tool steel | O1 | High | Very High | ★ | $$$$ | Cold-working tooling Dies & stamps |

4. Common CNC machining plastics

Below is a brief introduction to some types of common CNC machining plastics. For a complete detailed introduction, please visit our blog Types of Plastics for CNC Machining Materials.

4.1 What is ABS? A common prototyping thermoplastic.

ABS is a common thermoplastic material that has good mechanical properties, good impact strength, good heat resistance, and good machinability.

The density of ABS plastic is 1.00-1.05 g/cm3, which is low. CNC-machined ABS parts are ideal for lightweight applications. Typical ABS parts are for prototypes before mass production with injection molding.

4.2 What is nylon? An engineering thermoplastic.

Nylon is an engineering thermoplastic with excellent mechanical properties, and good impact strength. It has high chemical and abrasion resistance. Nylon is susceptible to water and moisture absorption.

Nylon 6 and nylon 66 are the most commonly used types in CNC machining. The typical density of Nylon is 1.14 g/cm3.

4.3 What is polycarbonate? A thermoplastic with impact strength.

Polycarbonate or PC is a thermoplastic with high toughness and good machinability. It has better impact strength than ABS. PC material is usually transparent but can be dyed to different colors.

CNC-machined PC parts are used for fluidic devices or automotive glazing. The typical density of PC is 1.20-1.22 g/cm3.

4.5 What is POM (Delrin)? The most machinable CNC plastic.

POM, the commercial name Delrin, is also an engineering thermoplastic. Among all CNC machining plastics, POM has the highest machinability.

POM/Delrin is the best choice for CNC machined parts that need high precision, high stiffness, and low friction. Delrin also offers excellent dimensional stability at high temperatures and does not absorb water easily.

The typical density of Delrin is 1.40-1.42 g/cm3.

4.6 What is PTFE (Teflon)? An extreme temperature thermoplastic.

PTFE is known as Teflon. As an engineering thermoplastic, Teflon has excellent chemical and thermal resistance, which can withstand high temperatures up to 200℃. It also has the lowest friction coefficient.

The typical density of PTFE is 2.2 g/cm3.

4.7 What is HDPE? An outdoor & piping thermoplastic.

High-density polyethylene (HDPE) has a high strength-to-weight ratio. With high impact strength and good weather resistance, HDPE is suitable for outdoor use and piping. Like ABS, it is often used to create prototypes before Injection Molding.

The typical density of HDPE is 0.93-0.97 g/cm3, and HDPE is lightweight thermoplastic.

4.8 What is PEEK? A plastic to replace metal.

PEEK has a high strength-to-weight ratio and is often used as a substitute to replace metal. It is a high-performance engineering thermoplastic.

PEEK has excellent mechanical properties, excellent chemical resistance, and thermal stability over a wide range of temperatures. Medical grade EEK is also available.

The typical density of PEEK is 1.32 g/cm3.

| Material | Strength* | Operating temperature+ | Machinability | Cost | Typical applications |

| ABS | Medium | Up to 60℃ | ★★★ | $$ | Automotive Electronic enclosures Pipes & fittings Consumer products |

| Nylon | High | Up to 100℃ | ★ | $$ | Automotive parts Mechanical parts Fasteners |

| Polycarbonate (PC) | High | Up to 120℃ | ★★ | $$ | Architecture Automotive Electronic enclosures Food containers |

| POM (Delrin) | Medium | Up to 82℃ | ★★★★ | $$ | Mechanical parts Electronic enclosures Bushings & fittings |

| PTFE (Teflon) | Low | Up to 260℃ | ★★★★ | $$ | High-temperature applications Chemical processing Electronic enclosures Food processing |

| HDPE | Low | Up to 80℃ | ★ | $$ | Chemical containers Pipes & fittings Consumer products |

| PEEK | High | Up to 260℃ | ★★ | $$$$ | Medical applications Chemical processing Food processing High-pressure valves |

5. Conclusion

Selecting the right material for your CNC machining project can be a time-consuming process. There are so many types of metals and plastics suitable for CNC machining. Consult with professional CNC machining workshops about your parts application, they can offer professional suggestions.

At ECOREPRAP, we offer more than 100 CNC machining materials with 20-plus surface treatments. Whether it is for prototypes or low-volume production, there is always a solution.