- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Stainless Steel CNC Machining Services-8 Tips to Get The Right One

Updated: December 27, 2023

Table of Contents

- 1. Stainless steel CNC machining testimonials

- 2. Stainless steel CNC machining capabilities

- 3. Versatility in stainless steel grades

- 4. CNC machined stainless steel parts quality check

- 5. Stainless steel parts industry application

- 6. 6.Lead times and turnaround

- 7. Package and transportation

- 8. Customer support and communication

Choosing the right stainless steel CNC machining services is crucial to the success of your projects. After producing tens of thousands of CNC-machined stainless steel parts, we have summarized some key points to consider when choosing CNC machining services, and hope they can be helpful to you.

1. Stainless steel CNC machining testimonials

Ask the CNC machining supplier whether they have had any successful stainless projects before, what type of stainless steel is used, what is the post-processing treatment, if is it a turned part or a milled part, and if can they provide some photos.

These questions can help you quickly understand the supplier’s processing capabilities for stainless steel. It will be more helpful if the supplier can provide a reference customer and you can call them and listen to what the customer say about them.

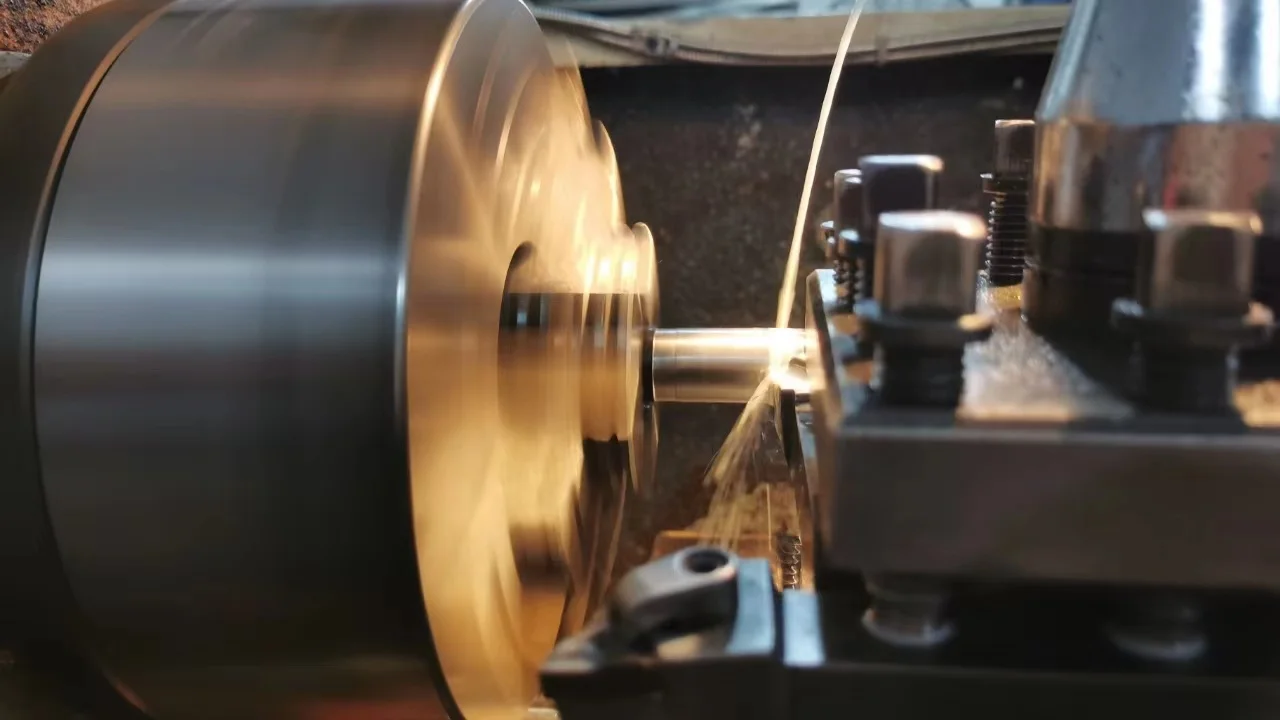

2. Stainless steel CNC machining capabilities

Stainless steel CNC machining is more complicated than aluminum CNC machining and plastic CNC machining because of its hardness and strength. A team of skilled engineers and machinists understand its unique properties, optimize stainless steel programming and tool paths, and set the right cutting and feeding speed.

Stainless steel is better machined at hard rail CNC machines. To achieve high-precision stainless steel machining, it is important to high quality tools and a slow cut and feed speed.

Read our blog Stainless Steel CNC Machining-A Complete Guide 2024 to learn more information about stainless steel machining knowledge.

Stainless steel can be machined at 3-axis, 4-axis, and 5-axis CNC machining centers, turning centers, and also sheet metal fabrication shops. If you want to machine all the parts and do the assembling test before shipment, it is also important to check the supplier’s sheet metal fabrication and EDM capabilities.

3. Versatility in stainless steel grades

There are many different types of stainless steel, with distinct properties and different machining performance. Different industries have different stainless steel requirements. Take the marine industry for example, it has a high corrosion resistance because of deep-sea operations, 316 stainless steel is more suitable than 304.

However, 316 stainless steel is more difficult than 304 because it contains molybdenum element, which enhances its corrosion resistance but makes it rougher for CNC machining. The increased hardness and toughness of 316 stainless steel can cause higher tool wear, and require adjustments in machining parameters, to achieve optimal results.

Common stainless steel types include 304, 304L, 316, 316L, 416, 420, 430, 440C and 17-4PH. Check whether they can provide specific types of CNC machining services.

4. CNC machined stainless steel parts quality check

Rigorous quality control measures throughout the machining process are crucial to guarantee the precision and consistency of the parts. For low-volume and large-volume orders, besides regular checks during the machining process, a full inspection of the first article is a must.

During the whole production process, interval inspections shall be also performed, such as every 10 or 20 pieces, to ensure consistent quality across the entire batch of the order.

Before the shipment, use calipers, micrometers, plug gauges, ring gauges, thread gauges, projector, and CMM measurement tools to check the stainless steel machined parts. Record the measurement data, any components out of specified tolerances shall be reworked. After rework, the parts must go through inspection once again to ensure quality compliance.

5. Stainless steel parts industry application

Talk with the supplier about where the stainless steel parts will be used. Professional suppliers will bring forward some considerations. For marine cylinders, they have a high requirement on the surface finish. Ra 1.6 is basic, Ra 0.8 or Ra 0.4 is preferred.

For other industry applications of aerospace, automotive, and medical, offering more application descriptions will help the success of the project.

6. Lead times and turnaround

Lead time for CNC machining stainless steel parts is crucial to planning the manufacturing schedules. Confirm the quotation and reconfirm once the order is placed.

You can also ask the supplier to provide a schedule for specific projects, which can include the material purchase date, estimated milling dates, EMD dates, QC dates and logistic dates. It is good for big and important projects to make sure quality parts are produced on schedule.

At ECOREPRAP, the regular lead time for CNC stainless steel parts is 5 to 7 working days. For quick turnaround projects, lead time can be shortened to 1 to 3 days.

7. Package and transportation

Parts are produced on time, and QC inspections pass. Don’t let packaging and shipping ruin your project. The density of stainless steel ranges from 7.75 to 8.05 g/cm³, so the stainless steel CNC parts can be heavy.

Experienced CNC machining factories understand that packaging methods for small and large stainless steel components are entirely different. Professional and secure packaging is crucial.

Due to the substantial weight of stainless steel, bulk quantities of CNC-machined stainless steel components can be considered for sea freight to save costs.

At ECOREPRAP, for smaller CNC prototypes, we wrap the parts with white paper or kraft brown paper to prevent contact with each other. Then, wrap the components with multiple layers of pearl cotton and secure them with stretch film. Vacuum formed packaging box is a viable option for small CNC stainless steel parts.

For larger parts, after they are well packed, wood box will be used to avoid damage. We take all measures to make sure the parts are not damaged by transportation.

8. Customer support and communication

Clear communication, timely responsiveness, and mutual collaboration are important to the projects. A project manager or account manager shall under customers’ parts requirements clearly and transfer the information to the factory engineer. Any misunderstanding can cause project failure.

We can not only communicate one email per day due to the time difference. It will slow the project process. Best CNC machining manufacturers shall work according to customers’ work time and respond to any requirements from customers timely.

CNC machining manufacturers with good services shall also provide custom solutions to each project based on the customer’s specific needs.

At ECOREPRAP, our project managers work from 9:00 am to 10:00 pm. Email, WhatsApp, and Skype are all used for instant communication. They will respond within 30 minutes after receiving your information.

For each project, we have an engineer with the project manager to provide technical support. A detailed project schedule is provided for an important project and will be updated day by day.

Through the 8 considerations mentioned above, we believe you now have a clear understanding when selecting a CNC machining service provider. At ECOREPRAP, we are committed to delivering excellent stainless steel CNC machining parts with cutting-edge technology, a skilled team, and a high-quality standard.

Let's get your projects started, together!

Get custom parts machined in high quality, delivery on time.