Table of Contents

Free state symbol is one of the significant modifiers in Geometric Dimensioning and Tolerancing(GD&T), making huge effects on flexible components to ensure effective assembly. It is important to learn the meaning of free state symbol well.

Key Takeaways:

- The free state symbol indicates tolerances must be verified on parts in their unrestrained “free state” – affected only by gravity and material flexibility.

- Used primarily for non-rigid parts, it’s placed after tolerance values in feature control frames to distinguish from restrained condition measurements.

- Free state ensures functional compliance of flexible parts while allowing reasonable free-state deformation, preventing manufacturing issues and reducing costs.

1. What is Free State Symbol in GD&T?

In Geometric Dimensioning and Tolerancing(GD&T), Free State Symbol refers to a symbol shown as a capital “F” within a circle(F). The symbol should be placed after the geometric tolerance value or any other indicated modifiers.

Free state symbol indicates that a specific dimensional tolerance or geometric tolerance is applied to a part at its free state, meaning that the tolerance is to be assessed in condition where the part should be unrestrained by any other physically forces except the weight and flexibility of the part.

In other word, if a feature is under control of free state symbol, it should be measured in its free state, unrestrained with any clamping or fixing tools.

Free state symbol is particularly relevant to non-rigid parts like plastic parts, sheet metal, and other flexible parts.

By default, all dimensions or geometric tolerances are assumed to be measured in a free state unless a restrained condition note is indicated on the engineering drawing.

For rigid parts, the difference between measurements under restraint and at free is commonly small since rigid parts cannot be deformed easily.

However, for non-rigid parts, since they would easily deform even at free state due to their own weight, flexibility, or the release of internal stress generated during manufacturing process, it is important to indicate the measuring condition clearly.

If any restrained condition to the part in needed, restrained condition notes should be indicated on the drawing clearly. The restrained condition should simulate the final actual assembly of the part for effective functions.

While if the tolerance in free state should be controlled, the free state symbol is to be applied to the part on the drawing.

2. An Example of a Part under Restraint

If specific features are designed to be controlled on orientation, location, or any geometric tolerances in restrained condition, a restrained condition note should be clearly indicated on the engineering drawing.

And the note should point out which features are to be restrained, how they are to be restrained, and to what extent they are to be restrained.

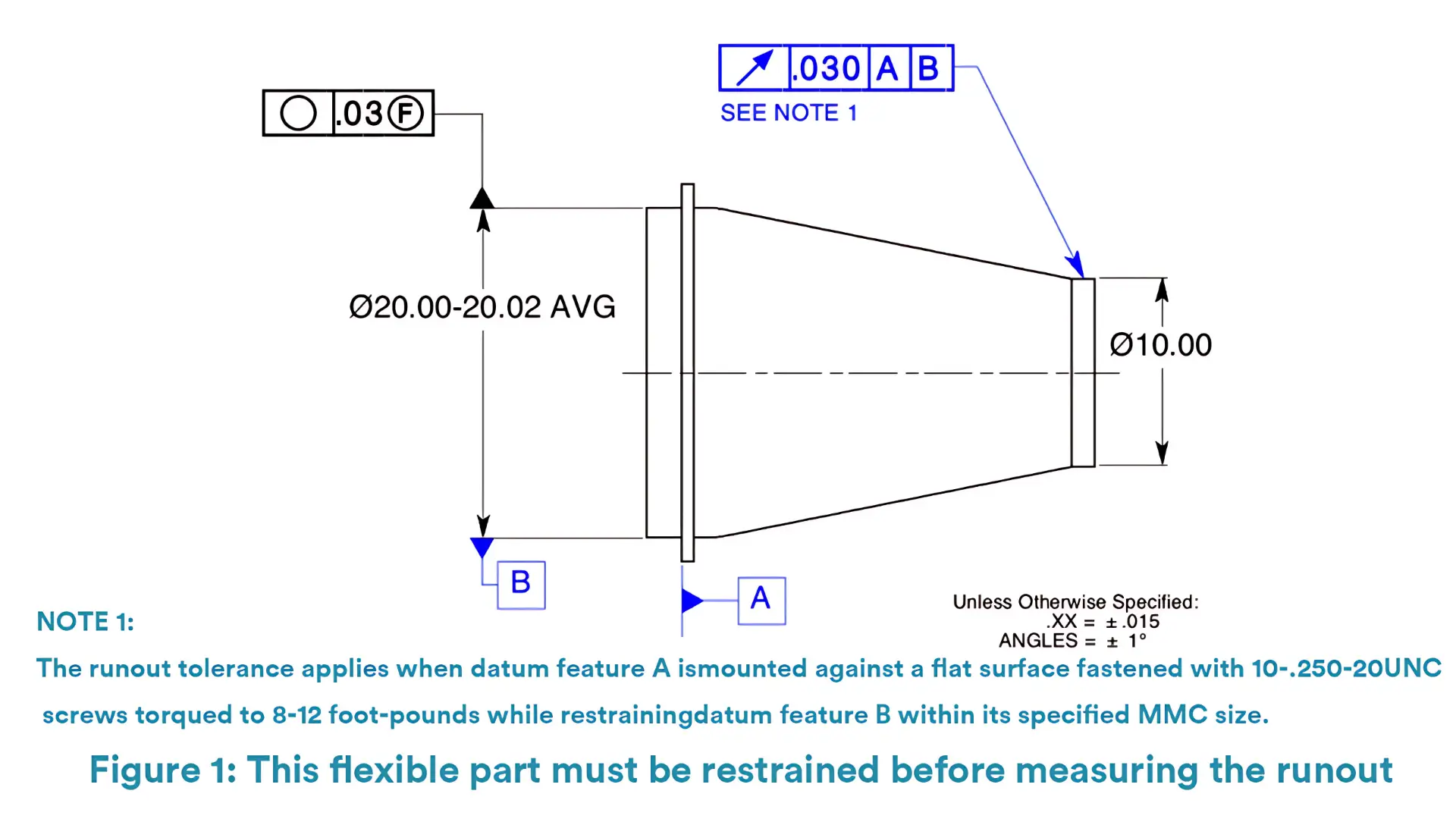

Figure 1 below shows an example of a part under restraint specified on the runout control. The restrained condition mimics the state where the part will reside in at final assembly.

In this example, the Note 1 clearly states the restrained condition of the specific feature on its runout tolerance.

The note confines that during inspection the datum feature A should be mounted against a flat surface fastened with 10-.250-20 UNC screws torqued to 8-12 foot-pounds and the datum B should be restrained within its specified MMC size.

Only under such a restraint can the runout tolerance be measured. And the restrained condition simulate the final state of the part in the assembly. Therefore, if the runout passes measurement, the part can be assembled well with its mating part finally.

3. An Example of a Part with Free State Symbol

If specific features are designed to be controlled on dimension or geometric tolerances in the free state, the free state symbol should be placed within the feature control frame after the tolerance value and any modifiers.

One of the most typical situations where the free state symbol will be applied on a specific feature is when checking the circularity of average diameter. Average diameter tolerance is usually applied on the diameters of non-rigid cylindrical parts.

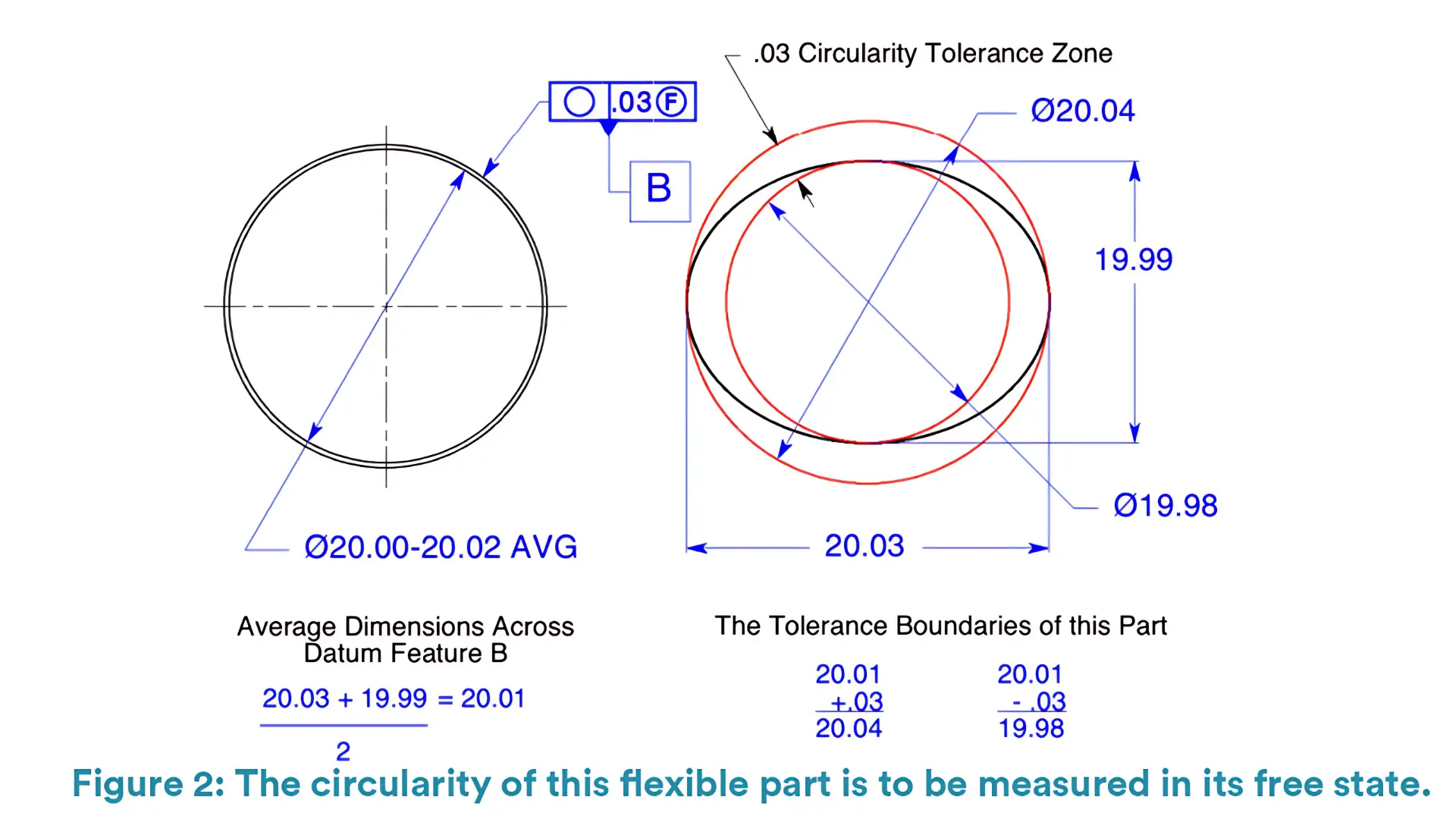

Figure 2 below is an example of a part with free state symbol for circularity of average diameter.

In this example, the dimension tolerance is followed by AVG, the abbreviation of “average”, indicating that the measurements are to be averaged as shown in the Figure 2 above.

In this example, the dimension tolerance is followed by AVG, the abbreviation of “average”, indicating that the measurements are to be averaged as shown in the Figure 2 above.

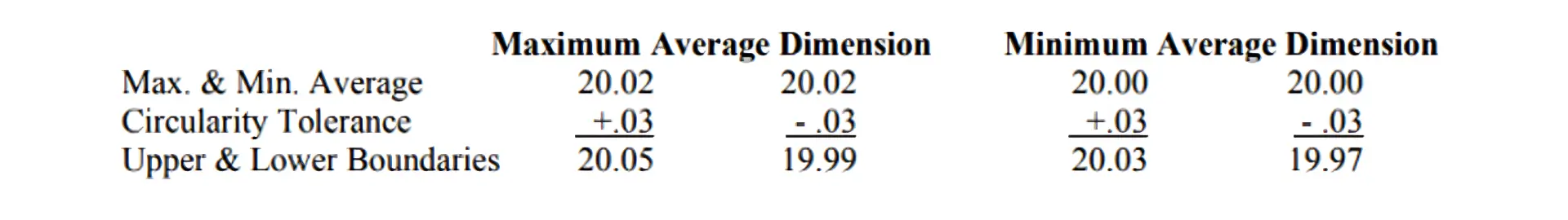

The upper boundary of the maximum average dimension is the maximum average 20.02 plus the circularity tolerance .03. And the lower boundary of the maximum average dimension is 20.02 minus .03.

In addition, the upper boundary of the minimum average dimension is the minimum average 20.00 plus the circularity tolerance .03. While the lower boundary of the minimum average dimension is 20.00 minus .03.

These extreme dimensions are not allowed to be occur in the same cross section at the same time.

If the average of measurements of this feature lies within the average size tolerance zone, the feature would pass on circularity.

For instant, if the 20.00 diameter in Figure 2 is measured 20.03 in one direction and 19.99 in the other direction finally, then the average diameter is 20.01, which lies within the average size tolerance zone. Therefore, the average diameter is in tolerance and up to the standard.

And pay attention to that at least four measurements should be taken on the specific feature for accuracy.

4. What are Functions of Free State Symbol?

The key function of free state symbol is to ensure that non-rigid parts can still satisfy the designed geometric tolerance even at its free state and can at the same time ensure its required functions in the final assembled state.

The concrete functions of free state symbol are as follows:

- Control Manufacture and Inspection of Non-rigid Parts

Free state symbol plays critical role in clearly indicating the specific non-rigid part’s tolerance requirement in free state. Then the part can prevent from being mismeasured as oversize part.

For example, a thin-walled plastic part may warp in its free state but can be flattened when bolted in assembly. The free state tolerance helps to leave properly allowable deformation during manufacturing.

- Specify Measuring Condition

Free state symbol clearly indicates the required measuring condition of the specific features. For instant, the diameter tolerance of a rubber seal may be much loose in its free state, but needs to be tight for good sealing in installation, at this moment, both conditions should be specified clearly.

- Reduce Manufacturing Cost

Free state symbol allows proper deformation on non-rigid parts, avoiding excessive constraint. For non-rigid parts, forcing they satisfy the same tolerance with rigid parts in their free state would increase extra manufacturing cost.

For instant, a large sheet metal part is allowed to have a relaxed flatness tolerance in its free state since it can be easily straightened when fastened.

5. Conclusion

In summary, the GD&T free state symbol (ⓕ) is essential for ensuring the functional viability of non-rigid parts. By specifying that tolerances must be verified in an unrestrained condition, it accounts for the inherent flexibility of materials like plastics and sheet metal, preventing good parts from being falsely rejected due to natural deformation.

This symbol provides a critical link between design intent and manufacturing reality. It enables realistic quality control by defining appropriate inspection conditions, which in turn helps avoid overly strict—and costly—manufacturing constraints. For any assembly involving flexible components, the proper application of the free state symbol is fundamental to achieving reliable performance and cost-effective production.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.