Table of Contents

During the last 50 years, nickel plating has been popularly applied to a range of products for surface finishing. It can critically improve the functional performance and appearance of various parts. Therefore, this article will provide a detailed guide for nickel plating.

1. What is Nickel Plating?

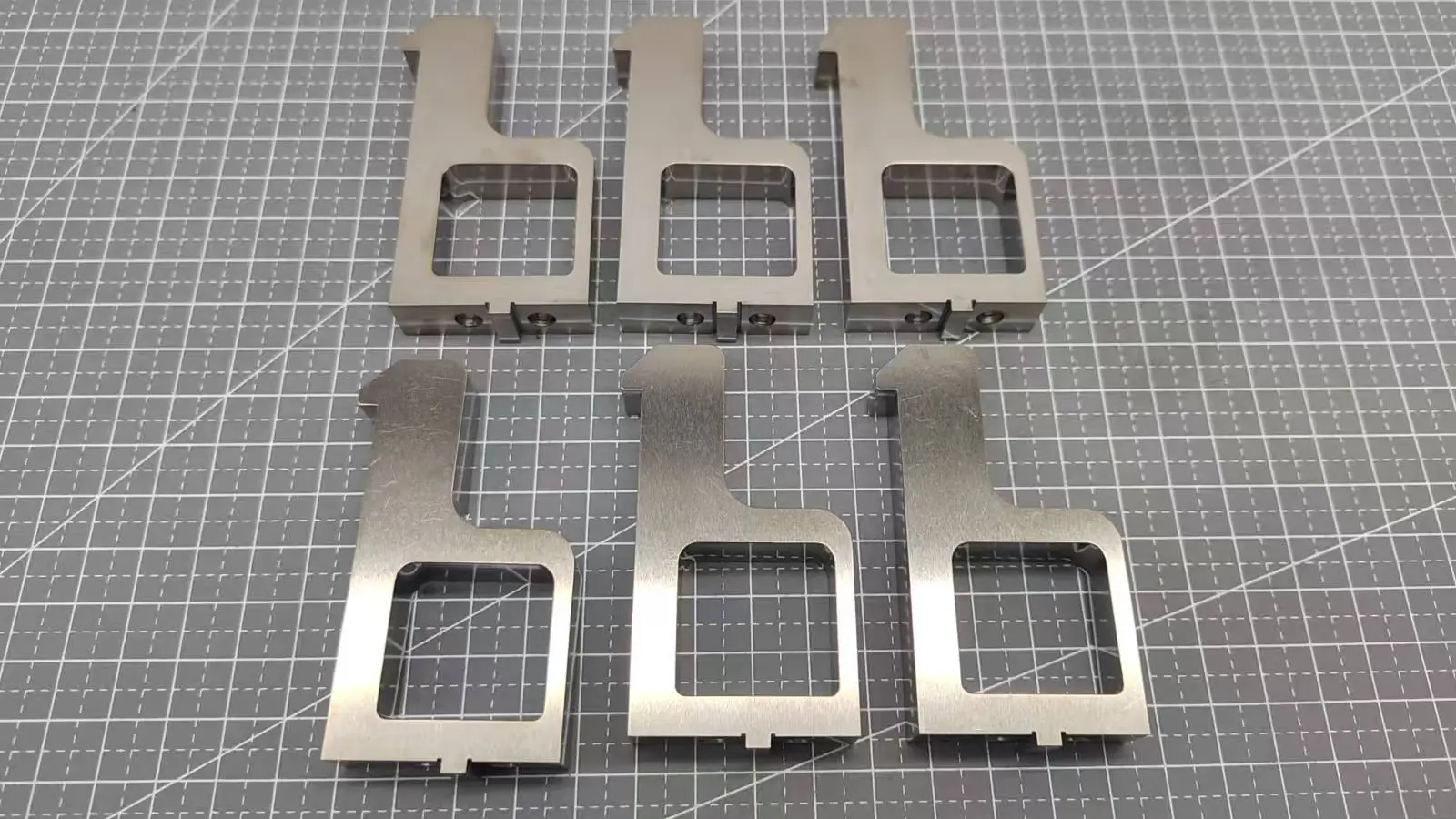

Nickel plating is a kind of finishing technology that coats a thin nickel film onto allowable parts through electroplating or chemical methods. It can effectively enhance the substrate’s corrosion resistance, wear resistance, and electrical conductivity, and also can impart an aesthetically pleasing metallic luster for the surface.

Nickel plating has developed for a long history and gotten more and more various applications in these few decades. It can be traced back to the early 19th century by Luigi Brugnatelli’s nickel plating experiments in 1805.

And then through 30 years’ development, electroplating nickel plating has come into the world, by Golding Bird in 1837.

While, nickel plating got its most notable advancement in 1916 due to the invention of the Watts bath by Oliver P. Watts, within which nickel sulfate, nickel chloride, and boric acid are combined together to be a reliable technique for nickel electroplating.

Nickel plating has developed decades and still remains improved.

10. Conclusion

With excellent corrosion resistance, strong hardness, proper conductivity, and good wear resistance, nickel plating plays huge role in various industries such as automotive parts, daily hardware, and electronic parts etc.

Shall you have any CNC parts with nickel plating requirements, please contact ECOREPRAP. Fast quotation will be offered, stable quality with fast turn around service will be provided.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.