Table of Contents

Polishing is crucial for various CNC-machined parts in terms of surficial accuracy, appearance, and performance. Electropolishing and mechanical polishing are two common types of polishing techniques.

But they differ in various ways.

This guide will provide comprehensive knowledge of them and recommend best choice between them.

Key Takeaways:

- Electropolishing is an electrochemical process where direct current and chemical reaction are primarily needed. While mechanical polishing is a pure physical process where polished surfaces benefit from cutting and abrasion

- The polishing effect of electropolishing depends on electrolyte, current density, temperature, and polishing time while that of mechanical polishing depends on abrasive media, polishing tools, and operating experience.

- While mechanical polishing physically abrades the surface, electropolishing chemically removes material at the molecular level.

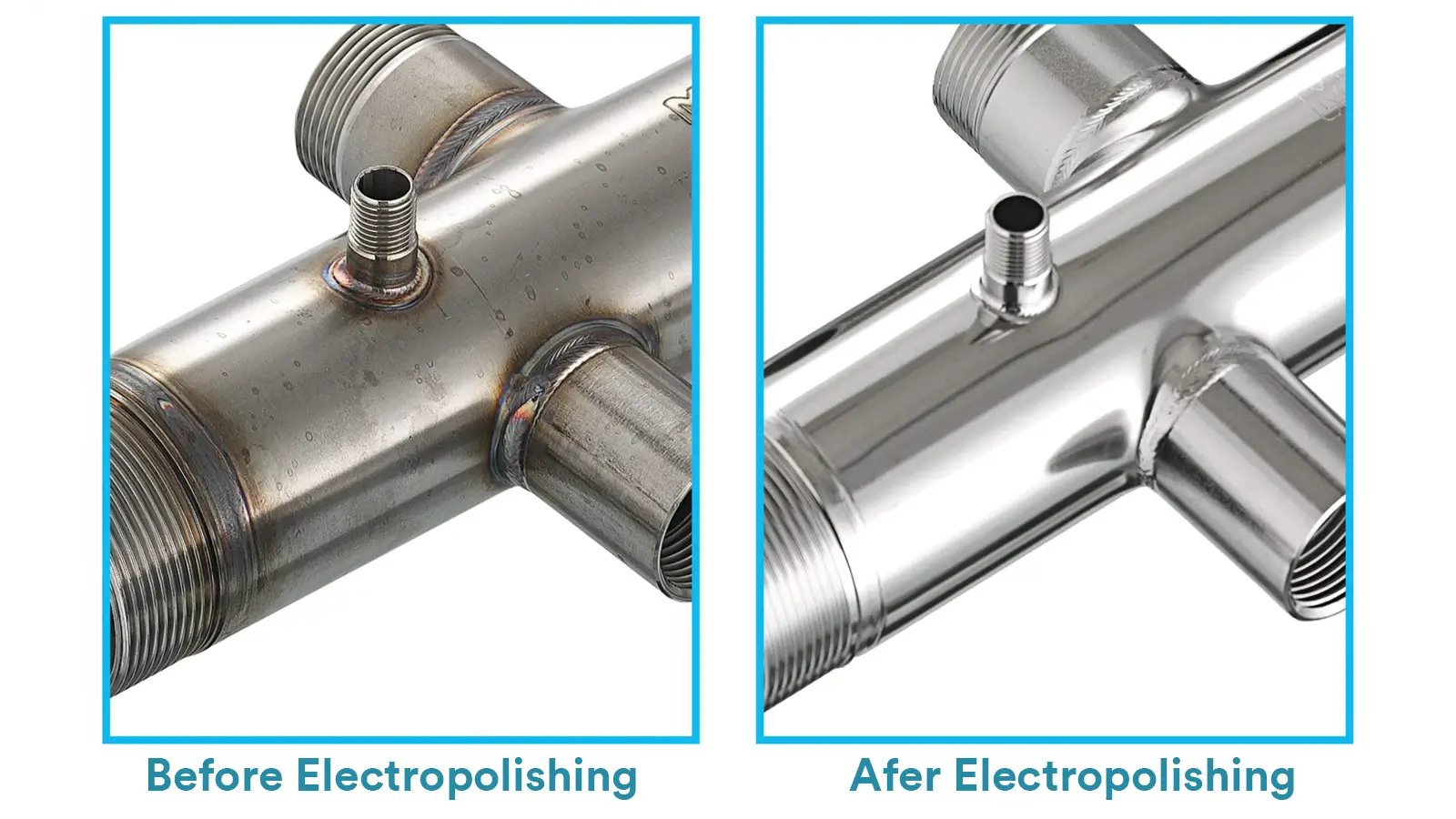

1. What is Electropolishing?

Electropolishing, also known as electrochemical polishing, is a surface finishing process that utilizes electrochemical reactions to refine metal surfaces.

By removing microscopic surface irregularities, burrs, oxide layers, and any other contaminants from the surfaces, they would be bright, smooth, clean, and more resistant to corrosion.

Electropolishing is widely applied to metals and alloys, including stainless steel, aluminum, copper, and titanium.

It plays a critical role in industries with extremely stringent requirements for surface quality and cleanliness, including medical devices, food processing, semiconductors, and aerospace.

The core principle of electropolishing is anodic dissolution. In a specific electrolyte, the metal part to be treated is connected as the anode, while an inert material such as stainless steel or lead serves as the cathode.

When direct current is applied, an electrolytic cell is formed. Under the influence of the electric field, selective dissolution occurs on the metal anode surface.

Since the surface asperities would experience higher current density, them will dissolve more rapidly. Reversely, the current density of the depressed areas would be lower, and then these areas would dissolve more slowly.

As a result, the surface would gradually be smoother and brighter due to such preferential removal. At the same time, a viscous liquid film or passive layer will form on the surface during electrolysis. This layer further suppresses excessive dissolution, making the polishing process stable and controllable.

2. What is Mechanical Polishing?

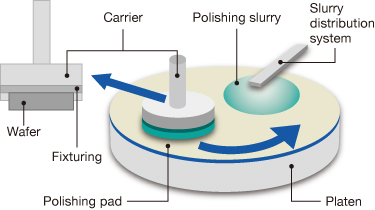

Mechanical polishing is a polishing process that uses the relative motion between abrasive particles and the part surface to gradually remove surface asperities.

It is actually a physical cutting process that reduces surface roughness and improves surface finish.

Mechanical polishing removes surface asperities mainly by two physical actions.

The primary one is the cutting action where the surface micro asperities would be cut down due to the pressing and rubbing actions of specific abrasive media during the polishing process.

The second one is the plastic formation effect. Because of the polishing pressure and frictional heat, the surface would be softer and then be plastically flattened. This means some super micro asperities might not be fully removed.

However, extreme heat might lead to oxidation, deformation, or abrasive embedding. Therefore, it is important to carefully control the polishing speed or setting suitable cooling measures for the mechanical polishing process.

3. What are the Common Tools for Electropolishing?

Electropolishing is a system process that requires chemical electrolytes and set of precision electro-mechanical equipment. Below is the list of common tools for electropolishing.

3.1 Power and Control Systems:

These systems are the core of the electropolishingprocess that would provide it with a controlled electrochemical reaction condition. They are direct current rectifier, temperature control system, as well as agitation and circulation system.

The direct current rectifier can convert alternation current into stable direct current. Constant voltage and current control are both crucial to the electropolishing process. And because electropolishing is highly sensitive to current density, high-frequency switching rectifiers are commonly recommended. Their low ripple factor helps ensure uniform polishing results.

The temperature control system includes heaters and cooling system. Since the electrolytes typically need to be heated to 60–80 °C, PTFE (Teflon) or quartz heating elements are commonly used for heating function. And metal heaters are usually not recommended because they are highly susceptible to corrosion by strong acids.

Meanwhile, electropolishing generates significant heat. In huge batch of production, cooling coils such as lead or titanium tubing with circulating cooling water are required to prevent electrolyte from overheating and thermal burning.

The agitation and circulation system includes filtration pump and motion system. The filtration pump is used to continuously circulate the electrolytes and remove generated metal sludge. And the motion system is applied to make the parts move slowly back and forth within the tank. This can prevent gas entrapment that would cause gas streaks or channeling defects on the surface.

3.2 Tank and Auxiliary Facilities:

These facilities include electropolishing tank, ventilation system, andmulti-stage rinsing system. The electropolishing tank is where the whole electrochemical process occurs. Therefore, it must be resistant to strong acids and provide good sealing performance as well as thermal resistance. The tank is usually made of PP or PVC plastic material. Steel tank lined with PTFE is also suitable for the electropolishing process.

What’s more, since acid mist and hydrogen gas would typically be generated during the electropolishing process, high-efficiency side-draft or overhead exhaust hoods are required, together with an acid mist scrubber system.

Multi-stage rinsing system for electropolishing processes includes overflow water rinse tanks, ultrasonic cleaning tanks, and hot-water rinse tanks. They are used to completely remove viscous electrolyte or any other chemical residues from the parts.

3.3 Racks and Electrodes:

The racks must be electrically conductive and corrosion-resistant. Titanium alloys are the preferred choice, as they form a passive film in the electrolyte and are not consumed during operation. If copper racks are used, non-contact areas must be insulated with protective coating.

In addition, these fixtures must ensure firm electrical contact with the parts to carry high current loads. Poor contact would lead to arcing and localized burn marks at the contact areas.

The cathodes are commonly made of lead plates or stainless steel. The shape is recommended to ideally complement the geometry of the part to ensure uniform current distribution, especially when the parts have complex internal features or deep holes.

3.4 Chemical Solutions:

As an electrochemical polishing technique, electropolishing requires various chemical solutions such as electrolytes, additives, degreasing agents, pickling solutions, neutralizing agents, and passivation

The electrolytes are the most critical chemical material for electropolishing processes. They are typically composed of concentrated phosphoric acid (H₃PO₄) and sulfuric acid (H₂SO₄). Phosphoric acid forms a viscous film on the surface, while sulfuric acid provides conductivity and facilitates metal dissolution.

And the electrolytes are usually mixed with brightening agents, corrosion inhibitors, and mist suppressants to reduce acid mist emissions.

Degreasing agents and pickling solutions are used for the pre-process to clean the surface. Degreasing agents are often strongly alkaline or neutral cleaning solutions to remove surface oils and grease. And pickling solutions are typically dilute hydrochloric acid or dilute sulfuric acid to remove weld spots or oxide scales.

While neutralizing agents and passivation solutions are used for post-process. The former one is commonly mild alkaline solution like sodium carbonate used to neutralize residual acid. The latter one is used to further enhance corrosion resistance of the parts.

4. What are the Common Tools for Mechanical Polishing?

Unlike electropolishing, mechanical polishing relies on physical friction. Its core components include power equipment, polishing tools, and abrasives.

4.1 Core Power Equipment:

The core power equipment for mechanical polishing is polishing machines. There are variouspolishing machines according to the size and batch of parts, such as bench-top polishing machines, vertical or horizontal polishing machines, CNC polishing machines, and vibratory or barrel polishing machines.

Bench-top polishing machines are suitable for small parts and manual operation. While vertical or horizontal polishing machines are mainly used for medium parts, and they are usually equipped with variable-speed spindles.

And CNC polishing machines are primarily designed for high-precision and high-volume production, with fully controllable polishing paths and applied pressure. Vibratory or barrel polishing machines are suitable for batch finishing of large quantities of small parts.

Besides polishing machines, dust extraction and chip removal system as well as cooling or lubrication system are also important. Polishing processes would generate large amounts of dust, especially during dry polishing processes.

Industrial dust collectors or exhaust systems are required to ensure a safe working environment. And for heat-sensitive materials, wet polishing with sprayed coolant or lubricants is necessary to prevent overheating and surface burn damage.

4.2 Polishing Tools:

There are various polishing tools thatare respectively suitable for different stages of mechanical polishing. Grinding wheels, flap wheels, and cloth buffing wheels are all common tools for mechanical polishing.

Grinding wheels are usually made of aluminum oxide, silicon carbide or zirconia alumina, with 80 to 320 grits.

Flap wheels are constructed from multiple layers of abrasive-coated cloth flaps. With good flexibility, they are suitable for curved surfaces and complex contours. And they are usually 80 to 400 grits.

Cloth buffing wheels are made from laminated layers of cotton, linen, or wool, used for intermediate and fine polishing. For these wheels, sisal wheels are used for moderate cutting action, typically with coarse polishing compounds.

Cotton or wool wheels are used for fine or mirror polishing, typically with fine polishing compounds.

The wheels are often mounted on the polishing machine spindle, with typical operating speeds of 1000 to 3000 rpm, depending on the material.

4.3 Polishing Materials:

Polishing compounds and abrasive media are also crucialto mechanical polishing

Polishing compounds are typically composed of fine abrasive powders bonded in a grease-based matrix and formed into solid bars. Their applications are commonly identified by color.

Black compounds contain emery or silicon carbide. With the strongest cutting action, they are used for removing surface pits and for coarse grinding of hard metals.

Brown compounds are suitable for soft metals. They are used for initial brightening, scratch removal, and achieving a medium luster.

White compounds are finer compounds for fine polishing of hard metals.

Green compounds contain chromium oxide, specifically designed for final mirror finishing of stainless steel and other hard metals.

Abrasive media include aluminum oxide, silicon carbide, and diamond. Aluminum oxide is the most common type. Silicon carbide is used for initial grinding of hard materials. And diamond polishing media is used for materials with extreme hardness.

5. Key Differences Between Mechanical Polishing VS Electropolishing

On Process:

Electropolishing is an electrochemical process where the part to be polished is placed as the anode. The part’s micro asperities would undergo preferential dissolution and then the surface would gradually be smoother and brighter.

While mechanical polishing removes surficial asperities through physical friction between the part and abrasive media.

On Smoothness:

Compared with mechanical polishing, electropolishing is always a more precise and high-end finishing technique. Electropolishing can completely remove surface contaminants and oxide layers.

The treated surface reveals the true metallic crystalline structure, resulting in an exceptionally clean and passive surface, making electropolishing particularly suitable for high-purity applications such as biopharmaceutical, semiconductor, and other ultra-clean industries.

It can make the surface much smoother and brighter, without directional surface texture.

However, the polishing performance of mechanical polishing relies on operating experience and abrasive media. There might be microscopic abrasive particles or debris embedded in the surface.

In addition, mechanical polishing can also achieve a mirror-like finish but there might be polishing lines and directional gloss. And unsuitable operation would develop microcracks, residual stresses or surface alteration.

On Compatibility:

Both electropolishing and mechanical polishing have limitations on material compatibility.

Electropolishing can only polish metals with electrical conductivity. It is most commonly applied to stainless steels, aluminum alloys, copper, and copper alloys. It also delivers excellent results on special alloys such as titanium, nickel, and molybdenum.

What’s more, it also has requirements on material’s microstructure. For materials with complex compositions, such as cast iron or steels with high impurity levels, surface pitting or uneven coloration might occur due to selective corrosion.

But electropolishing is suitable for parts with complex geometries, such as internal bores, threads, and narrow gaps.

Compared with electropolishing, mechanical polishing can be applied to various materials including different metals, and nonmetal materials such as plastics, wood, ceramics, and glass.

And mechanical polishing provides consistent surface leveling for multi-phase alloys or composite components, avoiding uneven dissolution that will occur in electropolishing since constituent materials have different electrochemical potentials.

However, mechanical polishing is unsuitable for internal walls of slender tubes, very narrow crevices, or components featuring complex deep holes owing to the constraints of physical contact.

And for extremely soft metals, mechanical polishing might cause abrasive embedment or surface fuzzing.

On Corrosion Resistance:

Electropolishing can improve the surface’s corrosion resistance by removing inclusions and promoting the formationof a chromium passive layer, particularly for stainless steel.

Compared with electropolishing, mechanical polishing has more limitations on enhancement of corrosion resistance. If the surface can be polished well and passivated in time, its corrosion resistance would be improved.

But mechanical polishing might leave contaminants or scratches on the surface, which may act as initiation sites for corrosion.

At the same time, mechanical damage can compromise the passive layer on the metal surface. If not promptly restored through passivation, the surface would become more susceptible to corrosion.

On Size:

Electropolishing results in a controlled material removal of typically a few to several tens of micrometers. Material removal is controllable; however, it is typically substantial and highly dependent on operational accuracy.

6. How to Choose between Electropolishing and Mechanical Polishing?

6.1 When Electropolishing is Preferred

- For extremely complex or small parts:

Mechanical wheels and cloth buffs cannot reach internal bores, deep holes, fine gaps, blind holes, or intricate surfaces. But electropolishing enables consistent and reproducible surface finishing.

- For high cleanliness andsanitary requirements:

Electropolishing removes free iron and surface contaminants meanwhile form a chromium passive layer, improving corrosion resistance of the surface. It is widely applied to semiconductor piping, pharmaceutical equipment, food processing tools, and medical implants.

- For precisionparts requiring stress relief:

Mechanical polishing may introduce a hardened layer or residual stresses, whereas electropolishing is a non-contact process that generates no thermal or mechanical stress, preserving the original physical properties of the parts.

- For high-volume processing of small parts:

With automated production systems, electropolishing is well-suited for high-volume processing of parts with high efficiency and excellent consistency.

6.2 When Mechanical Polishing is Preferred

- For removal of deep scratches, weld seams, or major defects:

If the original surface is very rough, electropolishing cannot level these large defects. Mechanical grinding is required first for coarse flattening.

For processing of large and flat surfaces:

For large plates or simple cylindrical exteriors, mechanical polishing is generally more cost-effective and can easily achieve uniform appearance over a wide area.

- For non-conductive materials or specific alloys:

Electropolishing is limited to conductive metals. Non-conductive materials such as plastics, ceramics, or alloys incompatible with electrolytes must be polished mechanically.

- For small batch production:

Mechanical polishing provides a cost-effective and adaptable solution for low-volume, diverse product runs or field repairs. It does not need electrolytes, rectifiers, and effluent handling systems.

- For specific textures or matte finishes:

When surfaces need to exhibit brushed, satin, or directional finishes, mechanical polishing is the preferred practical choice.

7. Summary

All in all, electropolishing is an electrochemical finishing process that can provide the surface with better corrosion resistance, smoothness, and brightness, with high automatization and efficiency.

Mechanical polishing is a physical finishing process that has wider compatibility on materials and better effect on hard rust or weld seams.

They are different in various aspects. It is important to choose the correct one for the parts.

8. FAQs

8.1 Can electropolishing replace mechanical polishing?

It depends on the initial surface condition. Electropolishing functions more as a fine finishing process. It cannot eliminate visibly deep physical marks. For surfaces with deep scratches, weld irregularities, or severe machining marks, mechanical polishing is preferred first.

8.2 How to visually distinguish between electropolishing and mechanical polishing?

Reflectivity and texture are the primary differences. Mechanical polishing exhibits directional texture with fine scratches left by abrasives. Electropolishing produces a non-directional and mirror-like bright finish.

8.3 Can mechanical polishing achieve the same level of cleanliness as electropolishing?

No. Electropolishing is superior for achieving surfaces with high purity and smoothness because it removes embedded particles, burrs, and cracks. While mechanical polishing can introduce or smear contaminants into the surface.

8.4 Is electropolishing more expensive than mechanical polishing?

It depends. Electropolishing has higher upfront chemical and equipment costs but can be more cost-effective for high-volume or complex parts due to automation and reduced labor. Mechanical polishing may be cheaper for simple shapes or low-volume manual finishing but requires skilled labor and consumables.

8.5 Can I combine both methods for better results?

Yes, and it is common practice. Mechanical polishing is often used first to remove large imperfections or achieve a specific aesthetic, followed by electropolishing to enhance smoothness, clean the surface, and improve corrosion resistance.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.