Table of Contents

We have previously shared insights on Phosphate Conversion Coating and Black Oxide, both of which are widely used surface treatments for CNC machined steel parts and cast iron parts.

In this article, we will take a closer look at these two surface treatment processes side by side—exploring their similarities and differences, including core principles, color, coating thickness, and more.

By the end, you’ll have a clearer understanding of which finish best suits your application, enabling you to make the right decisions for your CNC projects.

Key Takeaways – Phosphate vs Black Oxide:

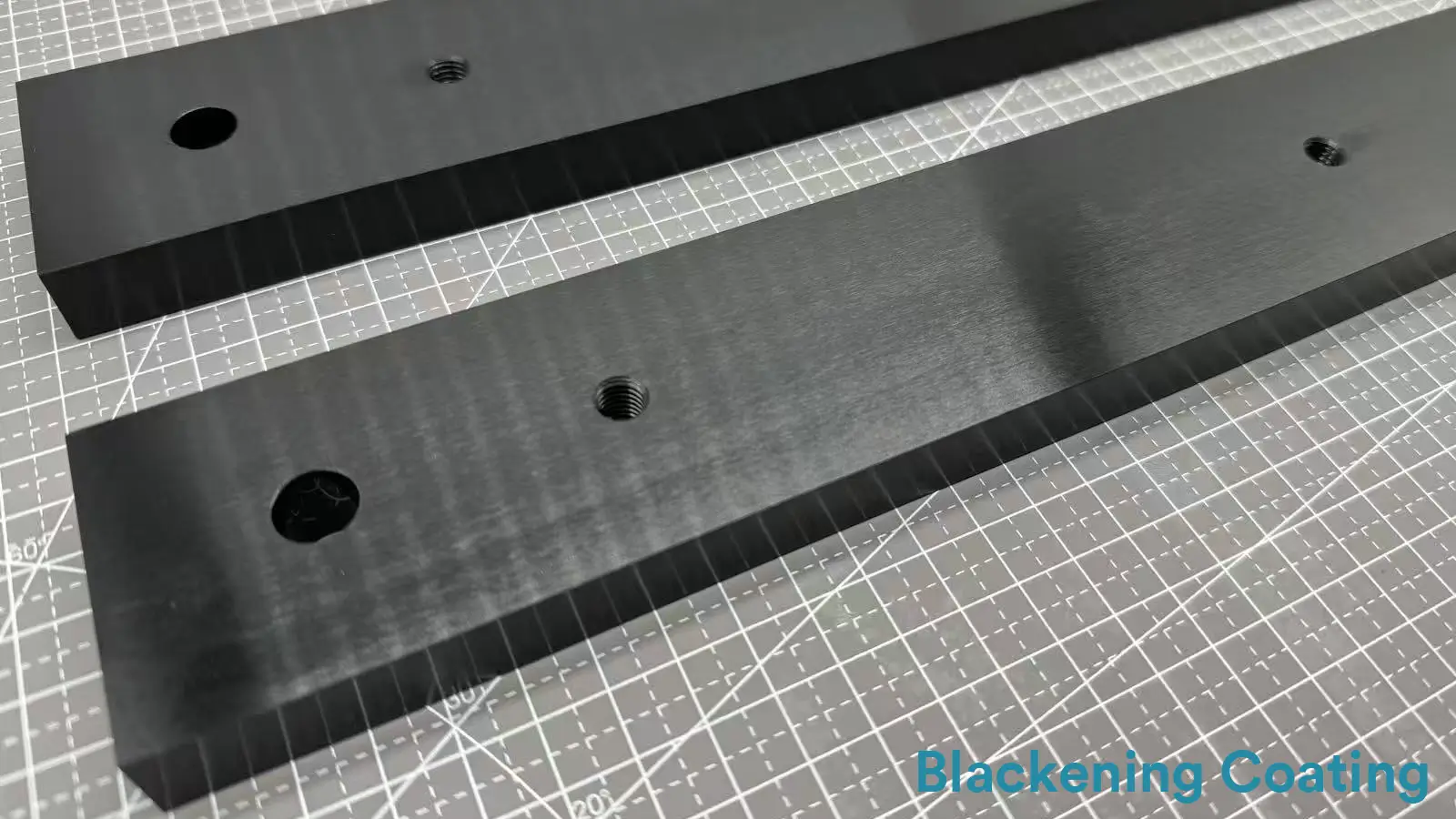

Black Oxide is als known as Blackening coating”. In this blog, we will use black oxide.

Coating Principle – Phosphate builds a crystalline layer (zinc/manganese/iron phosphate), while Black Oxide chemically converts the surface into magnetite.

Thickness & Tolerances – Phosphate is thicker (5–20 µm), may affect dimensions; Black Oxide is ultra-thin (≤3 µm), ideal for precision parts.

Appearance – Phosphate is gray/gray-black with a textured finish; Black Oxide is deep, uniform black with a premium look.Wear Resistance – Phosphate is harder, oil-retaining, suitable for sliding parts; Black Oxide is thinner and less durable.

Corrosion Resistance – Both require oil/wax sealing, but sealed phosphate generally performs better in harsh conditions.

Applications – Phosphate suits functional parts (gears, fasteners, shafts), while Black Oxide suits precision or decorative parts.

Cost & Process – Phosphate is more complex and costly; Black Oxide is simpler and more economical.

1. Phosphate vs Black Oxide: Core Differences

Phosphate Conversion Coating is a chemical conversion process that forms a crystalline phosphate layer, typically composed of zinc, manganese, or iron phosphates.

The resulting coating is porous, can retain oil, and has a relatively substantial thickness, making it an excellent base for subsequent coatings and an effective anti-seize surface.

Common types include zinc phosphate (Zn), manganese phosphate (Mn), and iron phosphate (Fe), depending on the application.

Black Oxide, on the other hand, is produced by a high-temperature alkaline salt bath that converts the steel surface into magnetite (Fe₃O₄).

The resulting layer is extremely thin, has minimal impact on dimensions, and provides a uniform black finish with slight matte properties.

Common post-treatments include oil, wax, or polymer coatings to enhance corrosion resistance and surface feel.

The commonality between Phosphate Conversion Coating and Black Oxide is that both form a protective conversion layer on the metal surface through chemical reactions.

Unlike electroplating or painting, they do not exhibit significant peeling and generally provide consistent coverage on edges and complex geometries.

The key difference lies in their nature: phosphate is an “additive” coating applied on top of the substrate, while black oxide is a “conversion” of the base surface itself.

2. Phosphate vs Black Oxide: Coating Thickness

Phosphate coatings range from 5–20 µm (Mn up to 30 µm), slightly affecting dimensions and enhancing wear/anti-seize performance.

Black oxide is 0.2–1 µm, ideal for precision parts but requires post-treatment for corrosion protection.

3. Phosphate vs Black Oxide: Color

Typical phosphate conversion coatings are gray to gray-black, with a slightly uneven tone due to their crystalline structure. The color has a subtle industrial appearance, which may vary slightly depending on the type (zinc, manganese, or iron phosphate) and processing conditions.

Black oxide presents a deep, uniform black, either satin or matte. The finish is highly consistent and visually appealing, giving parts a premium and professional look. The uniform black color also helps reduce glare and enhance the aesthetic quality of exposed components.

4. Phosphate vs Black Oxide: Appearance & Surface Feel

Phosphate conversion coating is a matte gray-black finish with fine crystalline texture and moderate color uniformity. The crystalline structure can slightly reveal surface grain patterns, giving it a subtle industrial aesthetic.

Phosphate coating is porous and slightly rough, with a small increase in Ra. This allows the surface to retain oil or lubricant, improving anti-seize performance and reducing friction in sliding components, threads, and high-contact areas.

Black oxide coating displays a deep, uniform satin black or matte black finish, offering a more premium, professional look with consistent visual quality.

The black oxide layer is dense and smooth, with minimal change in Ra. The black finish is even and matte, producing soft light reflection, making it ideal for exposed parts or decorative components.

5. Phosphate vs Black Oxide: Corrosion Resistance

Phosphate Conversion Coating has a porous crystalline structure, which provides only limited inherent corrosion protection.

To achieve effective rust resistance, it is typically sealed with oil, wax, or a polymer coating, which significantly enhances its performance. This makes phosphate coatings an excellent base layer for subsequent paint or protective finishes, as the sealed layer bonds well and provides durable corrosion protection.

In CNC parts, especially sliding components, gears, threaded fasteners, and mechanical assemblies, a properly sealed phosphate layer not only prevents rust but also improves wear resistance and anti-seize performance.

Black Oxide, on the other hand, forms an extremely thin layer, typically less than 1 µm, which alone offers very limited corrosion resistance.

To achieve practical protection, black oxide parts must be sealed with oil, wax, or other rust inhibitors. This process makes black oxide particularly suitable for precision CNC parts, decorative components, optical elements, and tight-tolerance threads, as the thin coating has minimal impact on dimensions or fits.

However, the corrosion resistance relies entirely on the sealed oil layer—once the oil wears off or the part is exposed to high humidity or salt spray, rust can develop quickly.

6. Phosphate vs Black Oxide: Wear Resistance

Phosphate Conversion Coating forms a relatively thick and hard layer, particularly in the case of manganese phosphate, providing significant wear resistance.

Its porous crystalline structure allows the surface to retain oil or other lubricants, effectively reducing friction and wear in sliding contact applications.

In CNC components such as gears, shafts, threaded fasteners, and sliding guides, a phosphate coating can extend service life and reduce the risk of seizing.

It can also be combined with lubricants like engine oil, dry-film lubricants, or solid lubricants such as MoS₂ to further enhance wear and friction reduction performance.

Black Oxide, by contrast, forms an extremely thin layer, typically less than 1 µm, with limited hardness. It is easily worn or removed under mechanical friction.

As a result, black oxide is not suitable for high-friction or heavy-load sliding components, where the coating may lose protection over time and additional lubrication is required.

It is better suited for low-friction, decorative, or precision-fitting parts, such as aesthetic components, threaded fasteners, or optical assemblies, where minimal wear occurs.

7. Phosphate vs Black Oxide: Dimensions and Tolerances

Phosphate Conversion Coating adds a measurable thickness, typically ranging from a few microns up to 20 µm or more, depending on the type and application.

High-precision mating parts—such as shafts, gears, and hydraulic components—should account for the coating thickness in their design tolerances to ensure proper fit and function.

Black Oxide, in contrast, forms a very thin layer, usually around 1–2 µm, which is generally negligible in terms of dimensional impact.

This makes black oxide an ideal choice for precision components, where maintaining tight tolerances and exact fits is critical.

8. Phosphate vs Black Oxide: Material Compatibility

Phosphate Conversion Coating is primarily suitable for ferrous metals, including carbon steel, low- to medium-alloy steels, and cast iron. Its chemistry and coating formation are optimized for these substrates, ensuring effective conversion and adhesion.

Black Oxide can be applied to carbon steel, low- to medium-alloy steels, and certain stainless steels (the latter typically requiring high-temperature or acidic processes). Its versatility makes it suitable for a range of CNC machined steel components, though process parameters must be adjusted for different materials.

We can see that CNC parts made from low- and medium-carbon steels are highly suitable for both phosphate conversion coating and black oxide treatments.

For more detailed information on material suitability and process specifics, you can refer to our previous blog posts on Phosphate Conversion Coating and Black Oxide。

9. Phosphate vs Black Oxide: Process Complexity & Cost

Phosphate Conversion Coating typically involves multiple steps, including degreasing → acid pickling → phosphate reaction → rinsing → drying → post-treatment with oil or wax.

The process can be quite complex. Take Manganese phosphate coatings for example. They are thicker and heavier, requiring careful control during rinsing, drying, and post-sealing.

For components with complex geometries, such as slots, holes, or threads, special attention must be paid to coating uniformity and local build-up.

Black Oxide, by contrast, usually consists of degreasing → acid pickling → black oxide reaction → water rinse → oil sealing, with fewer steps and shorter processing time.

The thin and uniform layer is easy to control and adapts well to complex geometries. It has minimal impact on dimensions and fits, and requires less process adjustment.

In summary, phosphate conversion coating is more complex and costly while black oxide is simpler and more economical.

10. When to Choose Phosphate or Black Oxide

Let’s summarize what we talked above and make the comparison table below.

| Dimension | Phosphate | Black Oxide |

| Coating Thickness | 5–20 µm, relatively thick and hard | 0.2–1 µm, extremely thin |

| Dimensions & Tolerances | Significant thickness, may require compensation or secondary machining | Very thin, negligible impact on dimensions |

| Wear Resistance | Excellent, can retain oil for friction reduction | Thin layer prone to wear, requires external lubrication |

| Corrosion Resistance | Good after oil/wax sealing | Corrosion protection relies mainly on post-treatment oil |

| Appearance | Matte gray with noticeable crystalline texture | Uniform satin or matte black, aesthetically appealing |

| CNC Applications | Functional parts, sliding components, gears, threaded parts | Precision-fitting parts, aesthetic or optical components |

When selecting a surface finish for CNC machined parts, decisions should balance function vs aesthetics, wear resistance vs precision, and cost vs process complexity.

Phosphate Conversion Coating is ideal when functionality takes priority, providing wear resistance, anti-seize performance, corrosion protection, and an excellent base for subsequent coatings.

Black Oxide is suitable when dimensional precision and appearance are the focus, offering light corrosion protection and low-friction or decorative finishes.

11. Key Recommendations for Designers and Engineers

Clearly specifying phosphate or black oxide treatments on engineering drawings is critical for ensuring part functionality, dimensional control, and subsequent assembly.

Recommended elements to include on drawings are listed below:

Standards: Indicate the relevant international or military standards (MIL, ISO, etc.).

Type/Grade: Specify the phosphate coating type (M/Z) and class (Class 1–4), or black oxide class.

Post-Treatment Medium: Note whether the coating will be sealed with oil, wax, or polymer, along with specific process requirements.

Critical Surface Masking: Mask mating holes, threads, and precision surfaces.

Surface Cleanliness: Specify degreasing, cleaning, and residue-free requirements.

Inspection Methods: Include criteria for thickness/weight, visual appearance, and corrosion testing (salt spray or environmental tests).

Phosphate Conversion Coating is typically specified according to MIL‑DTL‑16232 (Type M/Z, Class 1–4) or ISO 9717 for steel parts.

Example Drawing Note of phosphate conversion coating is as below.

Phosphate conv. coat per MIL-DTL-16232, Type M, Class 2; post-treat with oil per MIL-PRF-3150; thickness 8–20 µm; mask Ø10 g6 bore.

Black Oxide / Blackening is generally specified according to MIL-DTL-13924 (Class 1–4; Class 4 for stainless steel), with post-treatment such as wax or oil sealing to ensure corrosion resistance.

Example Drawing Note of black oxide is as below.

Black oxide per MIL-DTL-13924, Class 1; post-dip wax/oil (dry-to-touch); no build.

12. Conclusion

Both phosphate conversion coating and black oxide are widely used for CNC machined steel and cast iron parts, with phosphate offering thicker, wear-resistant, and corrosion-protective layers and black oxide providing a thin, precise, and aesthetically appealing finish.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He also spent three years in CNC engineering, quoting, design, and project management. Lucas holds an associate degree in mold design and has self-taught knowledge in materials science. He’s a lifelong learner who loves sharing his expertise.