Polycarbonate vs Acrylic: Key Differences in Material and CNC Machining

Updated: Sep. 28, 2025

Table of Contents

Both polycarbonate and acrylic are commonly used in CNC machining because both have good transparency. Acrylic has better transparency than polycarbonate after vapor polishing. Polycarbonate has better toughness and strength than acrylic.

For CNC machining, polycarbonate is easier, because acrylic is easy to crack, especially when drilling or tapping depth is large.

This article will introduce the mechanical properties of PC and acrylic, optical properties, chemical properties, etc., and then will spend more time introducing the specific differences between PC and acrylic in processing.

Readers can directly click on the left navigation bar to jump directly to their interest in the paragraph.

Key Takeaways:

- Acrylic and polycarbonate are both commonly used plastic mateirals in CNC machining, especially for transparent parts.

- Acrylic (PMMA) is superior in optical clarity, UV resistance, and scratch resistance, making it ideal for applications requiring high transparency and outdoor durability.

- Polycarbonate (PC) is superior in strength, durability, and flame resistance, making it suitable for high-impact, high-stress, or fire-resistant applications.

1. What is Acrylic?

Acrylic is an amorphous thermoplastic material, also known as polymethyl methacrylate (PMMA), that comes in various forms such as sheet, rod, glue, paint, or fiber.

In this article, we mainly talk about acrylic glass, a commonly used industrial and engineering sheet and rod material. Some well-known brand names for acrylic include Plexiglas®, Perspex®, Lucite® and Altuglas.

Compared to polycarbonate and glass, acrylic is even more transparent.

It is known for its high toughness, although not as high as polycarbonate, and has 17 times the impact resistance of silicate glass.

Acrylic also has a higher tensile strength and UV resistance compared to polycarbonate.

It is often chosen as an alternative to polycarbonate when impact resistance is not the primary concern. Additionally, acrylic is less expensive and is commonly used when clarity and optical characteristics are critical.

Acrylic products can be found in various applications such as shop displays, ceiling skylights, media discs, and optic fiber applications, due to their flexibility and transparency.

It is a versatile material that combines transparency, durability, and lightweight properties, making it suitable for a wide range of purposes.

For more information about acrylic cnc machining, see our blog

The Ultimate Guide to CNC Machining Acrylic Parts

2. What is Polycarbonate?

Polycarbonate (PC) is a thermoplastic polymer material known for its unique blend of physical and optical characteristics.

Being amorphous, it has low crystallization and consists of randomly oriented polymer chains.

Due to its chemical structure, polycarbonate exhibits a low level of photon absorption, allowing a majority of light to pass through and giving it transparency similar to silicate glass.

Polycarbonate is more transparent than common plastics like HDPE, PET, and PS. It is also highly valued for its exceptional impact resistance, surpassing glass by 250 times. This makes it suitable for applications requiring protective barriers, windows, and flat panels.

Examples of such applications include bullet-proof glass, window and ceiling panels, displays, and enclosures. However, polycarbonate has the drawback of low scratch resistance.

One of the remarkable properties of polycarbonate is its ability to undergo extreme plastic deformation without cracking or breaking.

This characteristic allows it to be processed using methods similar to sheet metal, such as rolling, press brakes, heating, and hot-line forming. These fabrication processes allow polycarbonate to be shaped quickly and cost-effectively into forms that are impossible with silicate glass.

It can also be easily machined, fabricated through injection molding, and pressed into sheets of varying thickness.

For more information about acrylic cnc machining, see our blog on CNC machining polycarbonate

3. Polycarbonate vs Acrylic: Physical Property

| Physical Property | Test | Unit | Polycarbonate | Acrylic |

|---|---|---|---|---|

| Density | ASTM D792 | g/cm³ | 1.2 | 1.18 |

| Water Absorption, 24 hrs, Immersion | ASTM D570 | % by wt. | 0.15 | 0.3 |

Compared with glass, polycarbonate and acrylic are considered to be light weight plastic. Their density is about 1.2 while that of glass is about 2.5, about twice of them. That is one reason why polycarbonate and acrylic are used as glass substitute.

4. Polycarbonate vs Acrylic: Mechanical Property

| Mechanical Property | Test | Unit | Polycarbonate | Acrylic |

|---|---|---|---|---|

| Tensile Strength | ASTM D638 | psi | 9,500 | 10,000 |

| Tensile Modulus | ASTM D638 | psi | 345,000 | 400,000 |

| Tensile Elongation at Break | – | % | 50 – 120 | 2 |

| Flexural Strength | ASTM D790 | psi | 13,500 | 14,000 |

| Flexural Modulus | ASTM D790 | psi | 345,000 | 400,000 |

| Compressive Strength | ASTM D695 | psi | 12,500 | 14,000 |

| Compressive Modulus | ASTM D695 | psi | 345,000 | – |

| Hardness | ASTM D785 | – | 70-75 | 94-105 |

| IZOD Impact-Notched | ASTM D256A | ft-lb/in | 16 | 0.3 |

From the table, the IZOD of polycarbonate is 16 while that of acrylic is 0.3.

Compared to silicate glass, polycarbonate has a very high toughness, 250 times the impact resistance of silicate glass.

Acrylic has a 17 times the impact resistance of silicate glass. When impact resistance is a key factor, polycarbonate is preferred.

Look at the tensile strength and compressive strength of polycarbonate and acrylic, acrylic has a bit higher tensile strength.

Polycarbonate has a much larger tensile elongation at break than acrylic, which means when subjected to tensile force, polycarbonate can undergo greater elongation, exhibiting higher toughness and plasticity.

This also explains why acrylic is more prone to fracturing during CNC machining.

The hardness of polycarbonate is also a slightly lower than acrylic.

Generally speaking, Acrylic is relatively good at resisting scratches. This is because acrylic typically has a harder surface than polycarbonate (PC).

Acrylic is harder and more resistant to scratches and abrasions. In contrast, polycarbonate, while better in other areas (such as impact resistance), has a relatively softer surface and, therefore, may be more susceptible to scratching in some cases.

5. Polycarbonate vs Acrylic: Thermal Property

| Thermal Property | Test | Unit | Polycarbonate | Acrylic |

|---|---|---|---|---|

| Coefficient of Linear Thermal Expansion | ASTM D696 | ×10⁻⁵ in./in./°F | 3.75 | 5–9 |

| Heat Deflection Temp | ASTM D648 | °C at 264 psi | 132 | 100 |

| Heat Deflection Temp | ASTM D648 | °F at 264 psi | 270 | 210 |

| Max Continuous Operating Temp | – | °C | 121 | 65–96 |

| Max Continuous Operating Temp | – | °F | 250 | 150–200 |

| Minimum Operating Temp | – | °C | -30 | -20 |

| Minimum Operating Temp | – | °F | -22 | -4 |

| Thermal Conductivity | ASTM C117 | BTU-in/ft²-hr-°F | 1.35 | 3.9 |

| Flammability Rating | UL94 | – | HB (V-2 for flame-retardant PC) | HB |

From the thermal property table above, we can see, polycarbonate a higher heat deflection temperature, and the CNC machined polycarbonate parts can work from -30℃ to 121℃. While, acrylic service temperature is below 100℃。

Polycarbonate has lower coefficient of linear thermal expansion than acrylic which means it can better maintain dimensional stability during temperature changes.

The thermal conductivity of polycarbonate is also lower than that of acrylic. Polycarbonate has a better flammability than acrylic. Polycarbonate is flame-resistant and has good self-extinguishing properties.

6. Polycarbonate vs Acrylic: Optical Property

| Optical Property | Polycarbonate | Acrylic |

|---|---|---|

| Transparency | 88% | 92% |

| UV Resistance | Lower resistance to UV rays – easily degrades over time unless additionally coated | Good UV resistance – won’t degrade or discolor easily |

Transparent acrylic has exceptional optical clarity, with a precise light transmission of about 92%. It is the reason why acrylic has better weather resistance than polycarbonate.

Polycarbonate has a light transmission of 88% and is yellowing after exposure to sunlight over time unless otherwise coated.

7. Polycarbonate vs Acrylic: Chemical Property

| Chemical Property | Polycarbonate | Acrylic |

|---|---|---|

| Chemical Resistance | Stronger than acrylic – can be cleaned with common detergents like ammonia. | Poor – should only be cleaned with plastic cleaners or soapy water |

PMMA is resistant to many common chemicals, including alcohols and weak acids. However, it may be susceptible to damage from strong acids and bases.

Polycarbonate, on the other hand, has good resistance to acids but may be more susceptible to degradation in the presence of certain solvents and alkaline substances.

8. Polycarbonate vs Acrylic: Workability

| Workability | Polycarbonate | Acrylic |

|---|---|---|

| Cutting | Cutting can be done with conventional tools, but there may be some resistance to the initial push of a saw or milling machine. There is a low risk of shattering during the cutting process. | It can be cut with conventional tools, making the cutting process easier, but there is a higher risk of cracking when working with thinner sheets. |

| Drilling / Machining | When drilling near the edges of polycarbonate, cracks usually do not appear and conventional drill bits can be used. | It tends to crack if holes are drilled near the edges. A drill bit specialized for plastics is required. |

| Bending | Cold bending / Cold forming / Heat bending | — |

| Polishing | Buffed, polished, vapor polishing (best performance), flame vaporing | Buffed, polished, vapor polishing (may get cracking), flame vaporing |

| Gluing | The glue joint will not be as clean as acrylic. | Cleaner glue joint than polycarbonate. |

Generally speaking, polycarbonate has better machinability than acrylic. For acrylic thin sheet cutting or acrylic CNC machining, acrylic is prone to cracking.

Below is more information about polycarbonate CNC machining VS acrylic CNC machining.

Coolant

During CNC machining of polycarbonate and PMMA, coolants are often required to reduce tool and workpiece temperatures, prevent overheating, and improve cutting efficiency, surface quality, and smoothness.

When threading acrylic, the coolant is a must otherwise, it will crack easily.

The coolant used in both PC and PMMA processes can be the same.

However, it is important to note that some conventional metal coolants may contain components that are harmful to plastics, so it is necessary to choose cutting fluids designed for plastic materials to avoid adverse effects on material properties.

Cutting tools

The cutting tools of PC and PMMA during production are no big difference. Keep the cutting tools sharp always.

Cutting speed

Since acrylic has the potential to crack during production, it is advisable to set a lower cutting speed and cutting depth for acrylic than polycarbonate during CNC machining.

Polishing

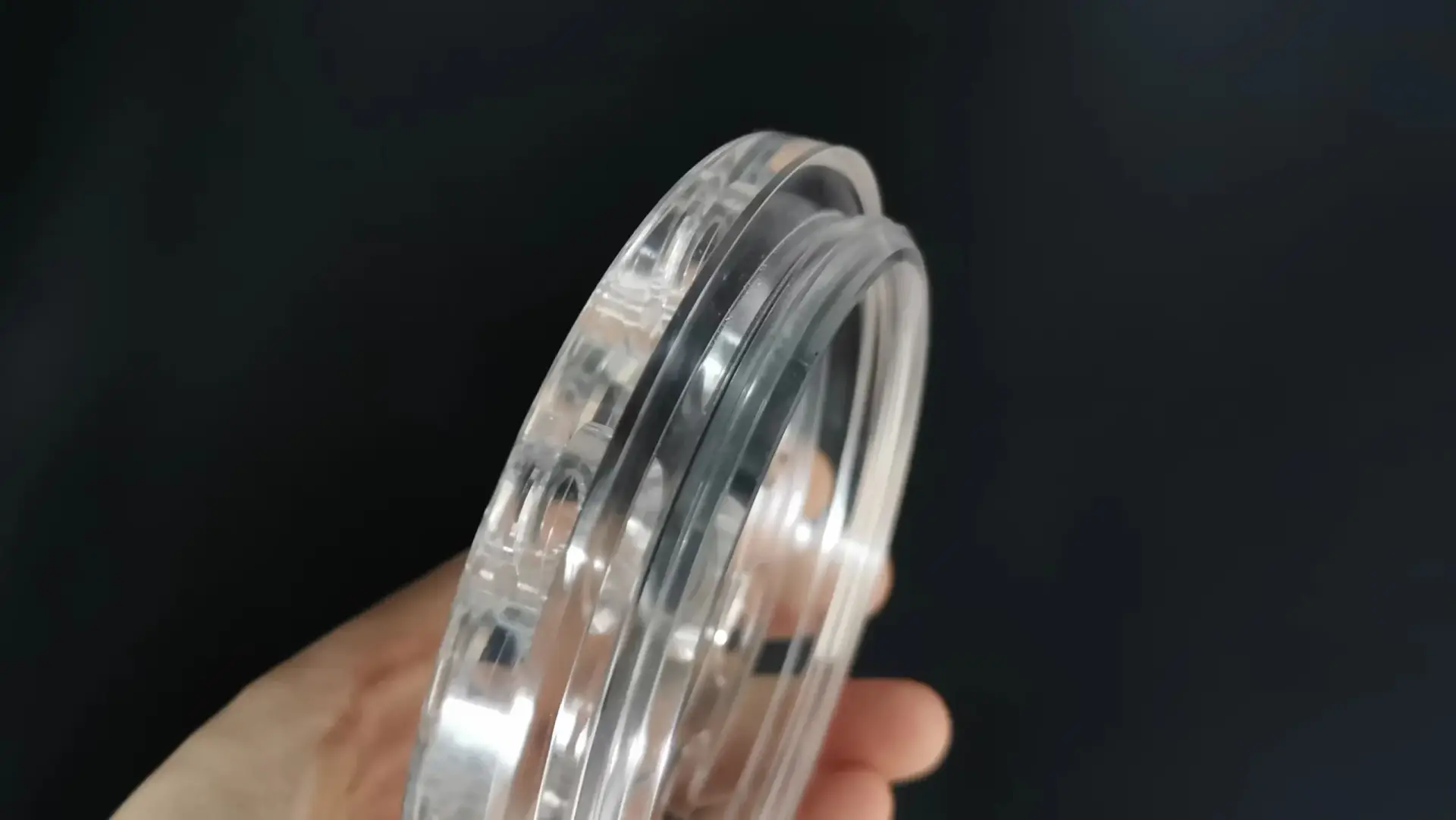

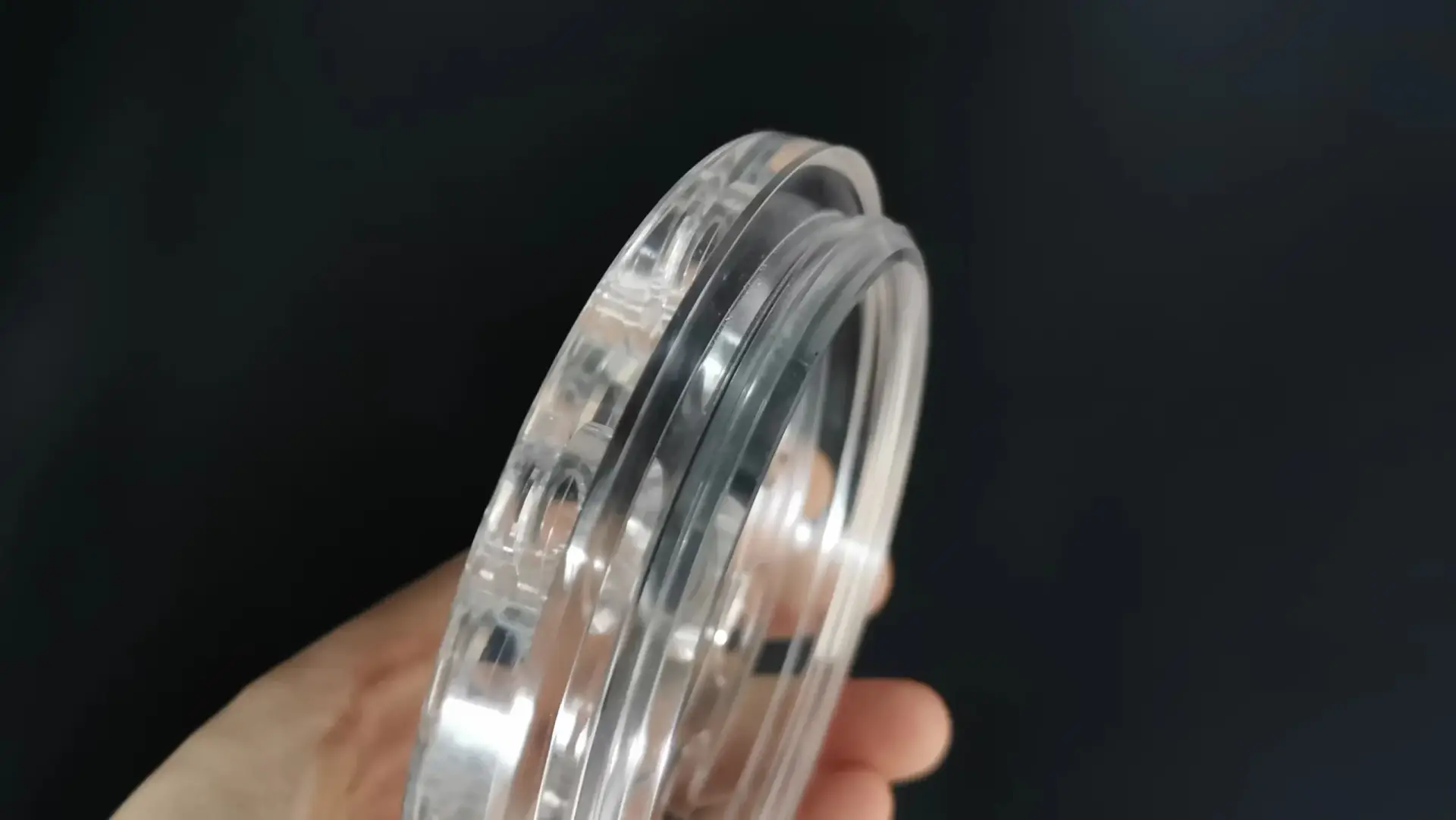

Both PC and PMMA have a matte finish after CNC machining. To achieve high transparency, buffing, and hand polishing are needed. The difference is that after coarse and fine manual polishing, PMMA can achieve a high degree of transparency.

For most acrylic parts, vapor polishing is not a must. But for polycarbonate CNC parts, manual polishing can not make it high transparency, it must be vapor polished.

Some acrylic parts with particularly high transparency requirements, can be further vapor polished but special attention shall be paid as they may crack during vapor polishing.

PMMA/Acrylic PC/Polycarbonate

Disassembly processing/Dismantling processing

PMMA and PC are versatile materials and can be dismantled and re-glued into different shapes for different purposes.

The glue used for PMMA and PC disassembly processing are different.

For PC parts, commonly used glues include cyanoacrylic-based glues, which are known for their fast curing and strong bonding properties. These glues are suitable for materials that are compatible with polycarbonate.

On the other hand, for PMMA parts, a specific type of glue known as ultraviolet curing glue or UV glue is often used. UV curing glues are transparent and cure quickly when exposed to UV light.

These glues are sometimes referred to as “shadowless” glues and are known for their ability to produce a transparent bond after UV exposure. The use of UV-curable adhesives in PMMA applications helps to maintain the optical transparency of the material.

Transparency may be slightly reduced in areas where glue is applied compared to other areas.

Annealing

Acrylic generally does not require stress relief before CNC machining.

But the dimensional accuracy and thermal stability or size of the larger PC parts need to be annealed, the purpose is to reduce or eliminate the internal stress caused by processing, to prevent the parts from deforming or cracking.

9. Polycarbonate vs Acrylic: Price

The cost of polycarbonate and acrylic are less than glass and other engineering plastics.

With better chemical resistance and durability, polycarbonate is more expensive than acrylic.

The unit price of PC sheet is 2.5usd/kg to 3.5usd/kg, for acrylic, it is about 1.5usd/kg to 2usd/kg. Though the cost is related to the form, thickness, and grade, generally speaking, acrylic is cheaper than PC.

10. Polycarbonate vs Acrylic: Sustainability and Recyclability

Both polycarbonate and acrylic are thermoplastic polymer materials, which allows them to be recycled and reprocessed in a variety of ways.

Although they lose quality with each melting and molding, they can still go through the recycling process many times. Ultimately, these materials can be used as fillers and packaging materials for other plastics.

As for sustainability, polycarbonate and acrylic use less heat and energy to manufacture than producing the same amount of glass. In addition, polymer materials are easier to recycle than glass, and their energy costs can be spread over multiple uses over their lifetime.

However, these materials must be properly disposed of and recycled to minimize their negative impact on the environment. Both materials do not decompose over time and, if not disposed of properly, can lead to landfill buildup or debris entering waterways.

11. Polycarbonate vs Acrylic: Pros and Cons

Below is a simple summary of polycarbonate and acrylic pros and cons.

| Polycarbonate | Acrylic | |

|---|---|---|

| Pros |

|

|

| Cons |

|

|

12. Polycarbonate vs Acrylic: CNC-machined Parts Application

Comparisons of polycarbonate and acrylic provide a clear understanding of selecting the right material for a CNC project.

Polycarbonate vs Acrylic: Key Material Properties Comparison

| Property | Polycarbonate (PC) | Acrylic (PMMA) |

|---|---|---|

| Strength | Generally stronger; high-impact engineering plastic; withstands more impact and pressure | Weaker than PC; less impact resistant |

| Durability | More durable; excellent impact and abrasion resistance; performs well in stressful environments | Less durable; more prone to scratching and abrasion; better optical clarity may suit specific applications |

| Transparency / Optical Clarity | Light transmission ~88%; may appear slightly cloudy at greater thickness; requires sanding and vapor polishing for high clarity | Light transmission ~92%; higher optical clarity; also requires sanding and polishing for high transparency |

| UV Resistance | Good UV resistance; may require additional stabilizers or coatings for extended outdoor use | Better inherent UV resistance; maintains clarity longer; ideal for outdoor signage, windows, protective barriers |

| Scratch Resistance | More prone to scratches; small particles may leave marks | More scratch resistant; maintains transparency longer |

| Flame Retardancy | Generally superior; can reach UL 94 V-2 or V-0 | Inferior; typically reaches UL 94 HB |

Understanding the differences between processing acrylic and polycarbonate can help determine the right material for a specific application.

Here are some considerations to help choose between these two materials.

Require higher transparency and better light clarity

If your product requires a high-gloss surface and excellent visibility, acrylic is a perfect choice because it offers superior light transmission and transparency. However, it is prone to cracking when subjected to high stress or impact.

Related post: Vapor Polishing: A Detailed Process Guide for Plastics like PMMA and PC

Notably, acrylic machined parts are prone to degradation due to prolonged exposure to UV radiation. Therefore, the use of UV stabilizers is recommended for acrylic parts used in outdoor applications.

Need for high-impact resistance

While acrylic offers higher light transmission, polycarbonate offers higher impact resistance and wide operating temperatures. Therefore, polycarbonate is ideal when your product requires high strength and low-temperature resistance.

Need for high heat resistance

Polycarbonate is tougher and easier to CNC machining than acrylic. Polycarbonate has better heat resistance than acrylic.

However, many factors such as material, polishing technique, severity of surface roughness and available equipment will determine the final surface quality of the product.

Therefore, it is recommended that all of these differences be considered to understand the selection of the right material for a product between acrylic and polycarbonate.

Polycarbonate (PC) vs. Acrylic (PMMA) Material Selection Guide Table

| Basis | Preferred Material | Key Reasons & Important Considerations |

|---|---|---|

| Requiring High Transparency & Optical Clarity | Acrylic (PMMA) | Advantages: Higher light transmission (92%) than polycarbonate, provides excellent surface gloss and visual clarity. Ideal for optical components and display items. Risks: Poor impact resistance, prone to cracking or shattering under stress; requires UV stabilizers for outdoor use to prevent yellowing and degradation. |

| Requiring High Impact Resistance & Durability | Polycarbonate (PC) | Advantages: Extremely high impact strength (approx. 50x that of acrylic), wide operating temperature range (-30°C to 121°C). Highly suitable for safety guards, outdoor enclosures, etc. Risks: Softer surface, more susceptible to scratching than acrylic. |

| Application Involves High Temperatures | Polycarbonate (PC) | Advantages: High heat deflection temperature (132°C), can withstand long-term use in higher temperature environments, better thermal stability during CNC machining. |

| Limited Budget, Seeking Cost-Effectiveness | Acrylic (PMMA) | Advantages: Material cost is significantly lower than polycarbonate (approx. 35% less). A cost-effective choice for applications where optical performance is critical but extreme mechanical properties are not required. |

13. FAQs

13.1 Which plastic is stronger, polycarbonate or acrylic?

Polycarbonate is generally stronger than acrylic. Polycarbonate is a high-impact engineering plastic that, in comparison, can withstand more impact and pressure than acrylic.

This makes polycarbonate more suitable for applications that require greater strength and durability, such as the manufacture of clear or glassy parts, as well as areas where higher impact resistance is required.

13.2 Which plastic is more durable, polycarbonate or acrylic?

In terms of durability, polycarbonate is generally more durable than acrylic.

Polycarbonate is a tough plastic with excellent impact and abrasion resistance, so it performs well in highly stressful and risky environments. On the other hand, acrylic is typically more prone to scratching and abrasion than polycarbonate.

It is important to note that while polycarbonate is more durable, there are specific applications where acrylic may be better suited because of its greater transparency and optical clarity. The choice of plastic depends on the specific application and the properties required.

13.3 Which plastic is clearer, polycarbonate or acrylic?

Transparent acrylic sheet has a light transmission of about 92% and transparent PC sheet has a light transmission of about 88%, so acrylic has a higher optical transparency and is more transparent than PC. At greater thicknesses, polycarbonate may be slightly cloudy.

CNC machined acrylic and polycarbonate parts have to be sanded and polished to achieve a high level of transparency. PC parts also need to be vapor polished.

13.4 Which is more UV resistant, polycarbonate or acrylic?

Both polycarbonate and acrylic have good UV resistance, but acrylic is typically more UV resistant than polycarbonate over extended periods of time.

Acrylic has better inherent UV resistance due to its chemical structure, allowing it to maintain clarity longer and resist yellowing and clouding. It is commonly used in applications such as outdoor signage, windows and protective barriers.

Polycarbonate is also UV resistant, but may require additional UV stabilizers or coatings to increase its resistance to UV radiation.

Considering acrylic is more UV resistant, it is better for outdoor use than polycarbonate.

13.5 Which is more scratch-resistant, polycarbonate or acrylic?

Acrylic is generally considered to be more scratch resistant than polycarbonate. Polycarbonate is more susceptible to scratches, as even small particulate matter may leave marks on its surface.

On the other hand, acrylic tends to have better scratch resistance and can maintain its transparency for a longer period of time.

13.6 Which is more flame-retardant?

Polycarbonate (PC) is generally superior to acrylic (PMMA) in terms of flame-retardant performance.

PC can achieve UL 94 V-2 or V-0 while acylic reaches UL 94 HB.

13.7 How to tell polycarbonate from acrylic?

In polycarbonate formulations, bluing agents are commonly used.

Although both acrylic and polycarbonate appear clear on the surface, you will notice that the edges of the polycarbonate have a bluish color while the acrylic is clear.

This is due to the bluing agent added during the polycarbonate manufacturing process, which gives it a blue appearance at the edges. This blue edge is due to the scattering effect of light in the polycarbonate. In contrast, acrylic does not have a similar blue edge and is usually more transparent.

13.8 What is more often used in aquariums, polycarbonate or acrylic?

In aquarium applications, polycarbonate is more often used. Polycarbonate has excellent impact resistance and is more durable than acrylic, able to withstand pressure and impact in the water.

Additionally, polycarbonate is less likely to break or crack compared to acrylic, making it ideal for installations large aquariums or applications that require more strength.

However, it is important to note that polycarbonate can yellow from UV rays with prolonged exposure, so additional protection may need to be considered for outdoor or direct sunlight environments.

Acrylic may also be used in some small aquariums or specific applications, but needs to be weighed against its relatively low impact resistance.

13.9 Which is better, acrylic backboard vs polycarbonate backboard?

Acrylic backboards offer excellent optical clarity, meaning better game visibility and improved rebounding characteristics. They are known for being unaffected by UV light and resistant to yellowing over time.

Acrylic backboards are also typically more resistant to scratches than polycarbonate. However, it’s worth noting that acrylic can be more brittle and prone to cracking under heavy impact.

Polycarbonate backboards, on the other hand, are highly durable and impact-resistant. They can withstand intense play and are less likely to crack or shatter compared to acrylic.

Polycarbonate backboards are often advertised as “bulletproof,” highlighting their strength and toughness. However, polycarbonate backboards may become cloudy when exposed to UV light over time.

Ultimately, the choice between acrylic and polycarbonate for a basketball backboard depends on the specific priorities and requirements of the user. Acrylic is advantageous for its optical clarity and scratch resistance, while polycarbonate excels in durability and impact resistance.

Considering factors such as budget, intended use, and desired visual clarity is recommended when deciding between the two materials.

13.10 Which is better, acrylic vs. polycarbonate, for the greenhouse?

Regarding greenhouse choices, polycarbonate is generally a more common choice than acrylic and is considered a more suitable covering material for greenhouses.

Polycarbonate has excellent impact resistance and durability and is able to withstand a wide range of weather conditions such as wind, rain and hail.

It also has good insulating properties that help maintain a stable temperature inside the greenhouse. In addition, polycarbonate is more resistant to UV rays, helping to extend the life of the covering material.

In contrast, acrylic, while offering better clarity, may not be as good as polycarbonate in terms of impact resistance and durability. In a situation such as a greenhouse, which is subjected to the stresses of the external environment for an extended period of time, polycarbonate is usually more appropriate.

However, the exact choice also depends on individual needs and budgets. If there is a higher demand for transparency and in milder climates, acrylic may still be a viable option.

13.11 Which is better, polycarbonate vs acrylic windshield?

Polycarbonate and acrylic are both viable materials for vehicle windshield options, but they each have different properties.

Polycarbonate is commonly used in vehicle windshields because of its excellent impact resistance and durability. Vehicles can be exposed to various situations while traveling, such as flying debris, bugs, etc.

Polycarbonate is better able to resist these impacts and reduce the risk of shattering. Additionally, polycarbonate has better UV resistance, which helps prevent sunlight damage to the windshield.

In contrast, acrylic is typically used less in windshields. While it offers greater optical clarity, it may not be as good as polycarbonate in terms of impact resistance and durability. The main advantages of acrylic are its lighter weight and lower cost.

Overall, the choice of vehicle windshield should be based on a combination of specific needs, safety and budget.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

A Complet Guide to CNC Machining Acylic

Explore acrylic material properties, cutting, drilling, polishing, and finishing techniques. Learn best practices for precision acrylic parts and achieve highest transparency.

Vapor Polishing: A Detailed Process Guide for Plastics like PMMA and PC

Acrylic and polycarbonate CNC-machined parts can achieve high transparency after manual polishing and vapor polishing.

CNC Machining Polycarbonate-A Complete Guide 2025

Polycarbonate is a commonly used thermoplastic for CNC machining because of its excellent transparency, high strength and hardness, easy machinability, and other properties.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.