Table of Contents

Titanium and titanium alloys are one of the critical materials in CNC machining. Its unique blend of properties makes it the ideal choice for high-end applications, even considering its higher cost and machining difficulty. The value it delivers justifies the effort.

To maximize the longevity and performance of titanium components—from prototypes to batch production—anodizing is the preferred surface treatment. This process hardens the surface, improving its resistance to wear and fatigue.

Key Takeaways:

- Titanium anodizing is classified into Type I (pretreatment/cleaning), Type II (functional/hard), and Type III (color/decorative), each serving distinct purposes.

- Type II anodizing improves wear resistance, anti-galling, and corrosion protection, while Type III color anodizing provides visual distinction for part identification.

- The anodizing process grows a dense TiO₂ layer on titanium surfaces, with thickness controlled by voltage, determining both color and surface stability.

1. What Is Titanium and Titanium Alloy Anodizing?

Titanium and titanium alloy anodizing is an electrochemical surface treatment process that creates a controlled, ultra-thin, and dense titanium oxide (TiO₂) layer on the surface of titanium parts.

During the titanium anodizing process, the titanium workpiece acts as the anode, while a DC voltage is applied in a carefully selected electrolyte—typically a mild acidic or neutral solution. By precisely adjusting the voltage, the thickness of the oxide layer can be accurately controlled.

This tightly controlled oxide film is what gives anodized titanium its stable surface properties and distinctive appearance, making the process widely used for functional and aesthetic applications in precision CNC-machined titanium components.

2. Different Types of Titanium Anodizing

According to AMS 2488D, titanium anodizing processes are classified based on the intended end use of the coating. In practical titanium manufacturing and CNC machining, anodizing is generally grouped into the following 3 types:

2.1 AMS 2488 Type I — Pre-Treatment / Cleaning Anodizing

In earlier specifications, Type I anodizing was mainly used for cleaning or surface preparation under specific chemical environments, and in some cases as a coating for high-temperature forming processes.

In modern production, however, Type I is rarely used as a final, customer-delivered surface finish.

Instead, it is typically treated as a preliminary step for Type II anodizing or as a specialized chemical passivation process.

Unless explicitly specified on the drawing or purchase order, Type I is uncommon in today’s titanium parts manufacturing.

2.2 AMS 2488 Type II — Functional (Hard) Anodizing

Type II coatings are defined as non-galling, non-stick coatings that can be used without additional lubrication, or as a pre-treatment layer to improve the adhesion of dry film lubricants. They are particularly suitable for applications requiring enhanced resistance to galvanic corrosion.

Type II anodized coatings are also compatible with high-energy propellants, such as hydrazine–unsymmetrical dimethylhydrazine (UDMH) and dinitrogen tetroxide (N₂O₄), and exhibit semiconductive properties.

Within the titanium industry, Type II is commonly referred to as “functional” or “hard” anodizing. It represents the core of the AMS 2488 specification and is the most widely used anodizing type for precision mechanical and CNC-machined titanium parts.

Titanium parts anodized to Type II typically exhibit a dark gray to silver-gray appearance.

Important note:

Today, unless a specific type is clearly called out, the industry generally assumes Type II by default. Type I is rarely used unless explicitly required.

2.3 Type III — Titanium Color Anodizing

Although AMS 2488 does not officially define a “Type III”, the term titanium color anodizing is widely used across the industry.

This process is primarily applied for color coding and part identification, and it has been adopted in a variety of industries.

While Type III color anodizing is not commonly specified for aerospace applications, it can still play a valuable role in complex assemblies.

By creating distinct interference colors on the titanium surface through controlled anodizing, engineers and technicians can visually distinguish specific components, improving efficiency in maintenance, inspection, and repair operations.

Titanium Anodizing Types Comparison Table

| Feature & Benefit | Type I (Chromic Acid Anodizing) | Type II (Standard / “Hard” Anodizing) | Type III (Color Anodizing) |

|---|---|---|---|

| Primary Purpose | Pretreatment / Passivation: Primarily used for cleaning in specific chemical environments, as a pre-coating for high-temperature forming, or as a preparatory step for Type II. | Functional Protection: Provides excellent wear resistance and anti-galling properties to prevent cold welding of metal surfaces. | Visual Identification & Aesthetics: Enables quick part recognition and color coding through a durable colored oxide layer. |

| Key Specification | AMS 2488 (as pretreatment or standalone process) | AMS 2488 (industry standard for functional coatings) | No formal AMS specification; follows industry-accepted best practices |

| Typical Appearance | Light to dark gray (matte) | Dark gray or silver-gray (matte) | Wide color range: Silver, Bronze, Purple, Blue, Light Blue, Gold, Rose, Magenta, Teal, Green, etc. |

| Wear Resistance | Slight improvement | ✅ Significantly improved | ❌ Minimal to none |

| Anti-Galling / Lubricity | Limited (mainly serves as a base) | ✅ Excellent, often used without additional lubrication | ⚠️ Limited, not a primary feature |

| Biocompatibility | ✅ Yes (for medical implants, with validated processes) | ✅ Yes (widely used in medical devices) | ✅ Yes (suitable for instruments and implants with approved processes) |

| Current Industry Status | Rarely used as a final finish; typically considered a pretreatment for Type II or a special passivation | The default industry standard, most common for precision mechanical components | Widely adopted for part identification, coding, and decorative applications |

| Ideal Applications | Pretreatment for specific chemical or high-temperature environments; preparatory step before Type II | Aerospace fasteners, medical instruments, high-precision transmission parts—where wear and galling resistance are critical | Surgical tools (color-coded), consumer electronics, identification parts in complex assemblies, architectural trim |

Quick Selection Guide:

Choose Type I when specified for pretreatment, passivation, or as a required preparatory step.

Choose Type II for maximum wear resistance, anti-galling properties, and functional protection—this is the go-to choice for most engineering applications.

Choose Type III when visual distinction, color coding, or aesthetics are the primary needs, and high surface wear resistance is not required.

3. What Are the Benefits of Titanium Anodizing?

There are five primary benefits to anodizing titanium and its alloys:

3.1 Preventing Galling (The “Anti-Sticking” Solution):

This is the most critical engineering benefit, specifically for Type 2 Hard Anodizing.

Titanium surfaces are naturally “sticky,” making two titanium parts prone to “cold welding” or galling when they rub together.

Anodizing (especially AMS 2488 Type II) creates an ultra-thin solid lubricant film that significantly lowers friction, prevents threads from seizing, and ensures smoother assembly.

3.2 Color Coding & Aesthetics (Science-Based Colors):

Vibrant colors are created by adjusting voltage alone—no paints or dyes required.

In operating rooms, surgeons use these colors to quickly distinguish bone screw sizes (e.g., blue for 3.5mm, gold for 4.0mm).

For consumer electronics, it provides a high-tech metallic texture and fingerprint resistance for items like phone frames and earphone components.

3.3 Biocompatibility (Safety for the Human Body):

While titanium is already highly biocompatible, anodizing further enhances this trait.

The oxide film is non-toxic, reduces the release of metal ions, and encourages bone tissue growth on the surface of implants, making it a standard for medical devices.

3.4 Dimensional Stability (Precision at its Best):

For CNC precision parts, tolerance is everything.

The oxide layer thickness is typically in the nanometer to micron range, adding virtually zero dimension to the part.

The dimensions you machine are the dimensions you keep.

3.5 Corrosion & Wear Resistance (Double Protection):

The oxide film provides a “double insurance” policy for titanium’s natural corrosion resistance.

It withstands harsh chemical environments, such as high-temperature steam sterilization or strong acid cleaning, while increasing surface hardness to reduce scratches.

4. What Are the Limitations of Titanium Anodizing?

4.1 Physical Color Limitations:

Unlike aluminum, titanium colors come from light interference, not dyes.

Lack of Solid Colors: It is impossible to produce a true “jet black” or “vibrant red/white.”

Consistency Challenges: Even a tiny1V fluctuation can cause Color Variance, making it difficult to achieve perfect uniformity across large production batches.

4.2 Film Thickness & Mechanical Strength:

While beneficial, the film remains very thin.

Wear Constraints: Decorative (Type III) films are microscopic and can wear away in high-abrasion environments.

Fatigue Impact: Although AMS 2488 Type II increases wear resistance, the process can sometimes slightly reduce the part’s fatigue life.

4.3 Process & Material Sensitivity:

Chemical Sensitivity: The oxide film can be sensitive to certain strong acids or alkaline cleaners used in hospitals, which may cause fading.

Fingerprint Sensitivity: On decorative finishes, skin oils can change the light path, making colors look darker or seem to “disappear” (though they return after cleaning).

Alloy Variance: Different grades (e.g., Gr2 vs. Gr5) react differently to the same voltage, complicating mixed-material production.

4.4 Surface Defect Transparency:

Translucency: Because the layer is transparent or translucent, it will not hide tool marks or scratches like thick paint would.

Preparation Costs: Achieving a perfect color often requires expensive pre-treatments like polishing or Bead Blasting.

5. How Does Titanium Anodizing Work?

Titanium anodizing is a precisely controlled electrochemical process. At its core, an external electric field drives the in-situ growth of a highly adherent, functional titanium dioxide film directly on the titanium surface.

5.1 The Step-by-Step Anodizing Process

Pre-treatment (Thorough Cleaning): Parts must undergo ultrasonic degreasing and acid pickling to remove any residual cutting fluids or fingerprints. Even the smallest speck of dirt can lead to uneven coloring.

Racking: The parts are secured onto titanium racks. A firm, solid contact is crucial because this is where the electrical current flows.

Electrolytic Reaction (The Core): The parts are submerged in an electrolyte bath, typically containing phosphates or organic acids.

Anode: The titanium part to be anodized.

Cathode: An inert electrode (such as platinum, graphite, or stainless steel).

Electrolyte: Chosen based on the goal (phosphoric, sulfuric, or organic acids).

Power Supply: A precision DC stabilized power source (voltage control should be accurate to pm 0.1V).

Applying Voltage: The part is connected to the positive terminal (anode), and the tank or plates are connected to the negative terminal (cathode). As the voltage increases, the oxide film begins to grow.

Rinsing and Drying: Once the target color or thickness is reached, the parts are immediately removed, rinsed with pure water, and dried.

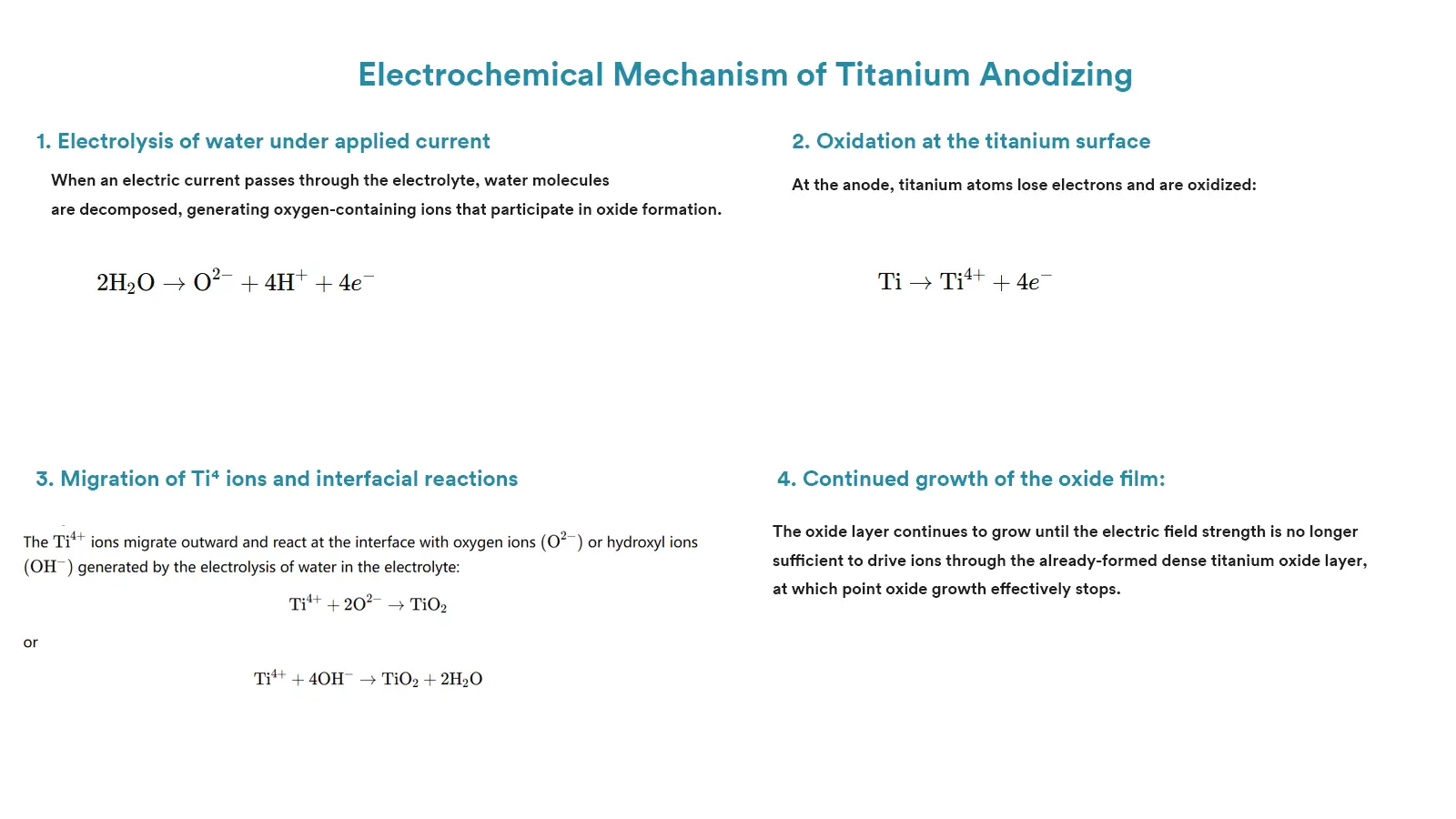

5.2 The Science Behind It

Electrochemical Transformation: When current passes through, water molecules are broken down.

Oxygen ions bond with titanium atoms on the surface to form titanium dioxide (TiO2).

Because this film is transformed from the metal itself, it is fully integrated with the substrate and will never peel off like paint.

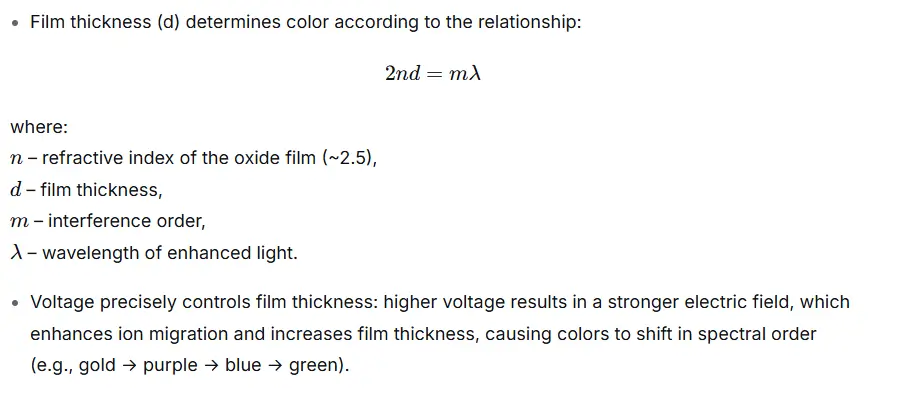

Thin-Film Interference (The Secret to Color): This is the most fascinating part.

The oxide layer is translucent. When light hits the surface, some light reflects off the top of the oxide film, while the rest passes through the film and reflects off the metal surface underneath. These two waves of light create “interference.”

Voltage Determines Thickness: Higher voltage results in a thicker oxide layer.

Thickness Determines Color: Minute changes in thickness (at the nanometer level) filter out different wavelengths of light, revealing colors like gold, purple, or blue.

The Logic Chain:

Different Voltage →Different Film Thickness →Different Light Interference →Human Eye Sees Different Colors

Titanium Anodizing Voltage vs Color

| Voltage (V) | Color Appearance | Visual Characteristics & Applications |

|---|---|---|

| 10V−15V | Bronze / Brown | Initial color at lower voltages, subdued and understated. |

| 20V−25V | Purple / Dark Blue | Thicker oxide layer develops, deep and rich color, often used in high-end decorative applications. |

| 30V−35V | Sky Blue / Bright Blue | Highly popular color, commonly used for size identification in medical instruments. |

| 45V−55V | Gold / Bright Yellow | Closely resembles real gold, offering high visual appeal. |

| 60V−70V | Pink Purple / Rose Red | Vibrant color, often seen in jewelry or personalized electronic products. |

| 75V−85V | Turquoise / Green | High-voltage color, difficult to achieve uniformity, with a distinctive appearance. |

In summary, titanium anodizing uses voltage control to grow a nanometer-scale, dense TiO2 layer on the surface. The film’s thickness dictates how light interferes, presenting different colors while simultaneously improving surface stability and adhesion.

In summary, titanium anodizing uses voltage control to grow a nanometer-scale, dense TiO2 layer on the surface. The film’s thickness dictates how light interferes, presenting different colors while simultaneously improving surface stability and adhesion.

6. Types and pH Ranges of Electrolytes for Titanium Alloy Anodizing

The selection of electrolyte for titanium alloy anodizing directly determines the color, performance, and process stability of the oxide film.

| Electrolyte Type | Typical Formulation | pH Range | Key Features & Applications | Color Control & Film Thickness |

|---|---|---|---|---|

| Phosphoric Acid-Based | Phosphoric acid (H₃PO₄): 10-15% vol. | 1.5 – 3.5 (Acidic) | Aerospace standard process (e.g., AMS 2488). Dense film with excellent adhesion and strong corrosion resistance. Widely used for structural component anti-corrosion and adhesive pretreatment. | Narrow color range (golden yellow to blue-violet). Film thickness typically 0.5 – 2.5 µm. |

| Organic Acid-Based | Malic acid/Citric acid: 50-100 g/L | 3.0 – 5.5 (Weakly Acidic) | Mainstream choice for decorative coloring. Vibrant and saturated colors with obvious interference effects. Wide process window, environmentally friendly, and low toxicity. Commonly used in consumer electronics and jewelry. | Rich voltage-color relationship (full spectrum colors achievable at 10-80V). Film thickness 0.5 – 5 µm. |

| Sulfuric Acid-Based | Sulfuric acid (H₂SO₄): 5-10% vol. | < 1.0 (Strongly Acidic) | Low-cost industrial solution. Fast film formation but relatively porous film with slightly lower corrosion resistance. Requires strict parameter control to prevent over-etching. | Dark color palette (blue-black tones dominant), prone to gray haze. Film thickness 1 – 4 µm. |

| Chromic Acid-Based | Chromic acid (CrO₃): 30-50 g/L | 1.0 – 2.5 (Acidic) | Traditional high-corrosion-resistance process (e.g., AMS 2488 Type I). Dense film with excellent wear resistance. Limited use due to hexavalent chromium toxicity; requires wastewater treatment systems. | Colors range from light gray to dark gray (no vibrant colors). Film thickness 0.5 – 2 µm. |

| Alkaline Electrolyte (Micro-arc Oxidation) | Sodium silicate + Sodium phosphate: 10-20 g/L each | 10 – 13 (Alkaline) | Functional hard anodizing. Generates ceramic-like thick films (10-100 µm) through high-voltage discharge. Extremely high hardness (HV > 1000). Used for wear resistance, insulation, and thermal barrier coatings. | Colors include gray, white, black, etc., depending on alloy composition and process—not interference-based colors. |

- Commercial vs. Aerospace Standards:In non-aerospace sectors like medical devices, jewelry, and electronics, Phosphoric Acid or Organic Acid baths are preferred. These acidic solutions provide a more stable voltage-color relationship and a wider process window for achieving beautiful “interference colors”.

- Performance Limitations of Acidic Baths:While acidic anodizing produces aesthetic results, these films generally cannot match the rigorous wear resistance and anti-galling requirements of AMS 2488 Type 2.

- The Power of Alkaline Environments:Under high pH (strongly alkaline) conditions, titanium more easily forms a dense, hard ceramic layer. This microscopic structure has excellent oil-retention capabilities, which is the “secret sauce” for achieving superior anti-galling functionality.

Below is a simpler table to show you the PH when selecting.

| Characteristic | AMS 2488D Specification (Type 2) | Commercial/Decorative Anodizing (Common Acidic Process) |

|---|---|---|

| Electrolyte pH | > 13.0 (Strongly Alkaline) | 1.0 – 5.5 (Acidic to Weakly Acidic) |

| Main Objective | Mechanical Performance (Anti-Galling, Wear Resistance, Lubrication) | Aesthetic Appearance (Coloration, Decoration, Dimensional Identification) |

| Typical Formulation | Sodium Silicate + Sodium Phosphate + Hydroxide | Phosphoric, Sulfuric, or Citric Acid Solution |

| Color | Typically Dark Gray (Functional Color) | Full-Spectrum Colors (Decorative Colors) |

7. Quality Standards for Titanium Alloy Anodized Coatings

The anodized coating shall meet the following requirements: It shall be continuous and uniform, with a smooth surface, firmly adherent to the base metal, and consistent in texture and appearance.

The coating shall be free from defects such as burnt or powdery areas, loose film, cracks, or scratches (except at contact points), and shall not exhibit any other damage or flaws that could affect its performance in service.

8. Summary

This blog covers titanium and titanium alloy anodizing, a key surface treatment for CNC-machined parts.

It explains the three anodizing types (Type I pretreatment, Type II functional/hard, and Type III color anodizing), their applications, and benefits including anti-galling, corrosion resistance, dimensional stability, and color coding.

9. Common FAQs About Titanium Anodizing

9.1 Is AMS 2488D Specification (Type 2) Hard Anodizing?

Yes. In the titanium industry, Type 2 is known as “functional” or “hard” anodizing. Its core purpose is not aesthetics, but enhancing part functionality by increasing surface hardness and providing superior anti-galling properties.

It typically produces a dense, dark grey or silver-grey layer, which is distinct from vibrant decorative anodizing.

9.2 Is AMS 2488D Type 2 the same as Alkaline Electrolyte (Micro-arc Oxidation)?

They share similarities but are not identical.

AMS 2488D requires a strongly alkaline electrolyte (pH 13 or higher), which is consistent with the alkaline systems used in Micro-arc Oxidation (MAO).

However, Type 2 usually operates at lower voltages to create a thin, dense TiO_2 film (approx. 1u m – 5u m), whereas MAO uses extremely high voltages to trigger arc discharges, creating a much thicker (10u m – 100um) and harder ceramicized layer.

9.3 How To Anodize Titanium?

It is an electrochemical process. The titanium workpiece is immersed in an electrolyte as the anode. By applying direct current, oxygen ions react with the titanium surface to grow a titanium dioxide film in situ.

9.4 What Are the Materials Needed To Anodize Titanium?

The essentials include: titanium alloy parts, electrolyte (such as phosphoric, sulfuric, or organic acids), cathode materials (like stainless steel, graphite, or titanium), pure water for rinsing, and titanium racks/hooks.

9.5 How Long Will Anodized Titanium Last?

Since the oxide film is converted directly from the base metal, it is fully integrated with the part and will not peel off. Under normal conditions, it is chemically stable and can last for many years.

9.6 How Long Does It Take To Anodize Titanium?

The actual oxidation reaction is very fast, usually completed within minutes once the target voltage is reached. Most of the time is typically spent on pre-treatment (cleaning and degreasing).

9.7 Is Anodized Titanium Prone to Rust?

No. Titanium itself is highly corrosion-resistant. Anodizing further enhances this trait by providing an extra layer of protection, making it even more resilient in harsh environments.

9.8 Is the Anodizing of Titanium Permanent?

Yes, it is a permanent surface transformation. It will not fade or disappear on its own unless the layer is destroyed by mechanical grinding or specific chemical etching. However, extremely thin layers may wear off in high-abrasion environments.

9.9 Why does anodized titanium change color?

This is due to the phenomenon of light interference. The oxide film is semi-transparent; light reflects off both the top of the film and the bottom metal interface, causing interference. The voltage determines the film thickness, which in turn determines the wavelength of light filtered out, resulting in different colors.

9.10 What are Equipments for Anodizing Titanium?

Core equipment includes: a precision DC stabilized power supply (accurate to ± 0.1V), an electrolytic tank, an ultrasonic cleaner, a temperature control system (for cooling the electrolyte), and drying equipment.

9.11 How To Do Type 3 Color Titanium Anodizing?

Preparation: Clean the part thoroughly and secure it on a titanium rack.

Electrolysis: Submerge the part in an acidic or neutral electrolyte.

Voltage Adjustment: Apply a specific voltage based on the desired color (e.g., around 35V for blue).

Completion: Remove the part once the color is achieved, rinse with deionized water, and dry.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.