Table of Contents

Titanium CNC-machined parts have become a cornerstone in high-performance industries thanks to their unique combination of strength, lightweight, corrosion resistance, and durability.

From aerospace structures and engine components to medical implants and high-end industrial machinery, titanium offers engineers and designers unmatched versatility.

This blog dives into the key applications of titanium CNC-machined parts across seven major sectors, highlighting why titanium continues to dominate in precision engineering.

Key Takeaways:

- Titanium CNC-machined parts provide high strength while remaining lightweight, making them ideal for aerospace, automotive, and other performance-critical industries.

- Titanium performs reliably in extreme environments—from seawater and chemical exposure to high-temperature engine zones—ensuring long-term durability and reduced maintenance.

- Advanced CNC technology allows titanium to be machined into complex, high-precision, and even patient-specific or custom components, expanding its usability across medical, industrial, and aerospace applications.

- From aircraft structures and medical implants to marine equipment and chemical processing machinery, titanium CNC parts are a go-to solution wherever performance, reliability, and longevity are critical.

1. Aerospace Applications of Titanium CNC-Machined Parts

In aerospace manufacturing, material performance is critical for flight safety, structural reliability, and fuel efficiency.

Titanium CNC machined parts are one of the most important structural and functional components due to their excellent combination of strength, lightweight, high-temperature resistance, and fatigue performance.

CNC machining enables the production of titanium components with high precision, complex geometries, and long-term stability, making them essential for aircraft, engines, and spacecraft systems.

1.1 Why Titanium CNC-Machined Parts Are Widely Used in Aerospace

High Strength-to-Weight Ratio: Titanium approaches the strength of high-strength steel while being about 40% lighter, significantly reducing overall weight and improving fuel efficiency and range.

Excellent High-Temperature Performance: Maintains mechanical properties at 300–600°C, ideal for engines and high-temperature structural areas.

Outstanding Fatigue and Fracture Resistance: Exhibits long fatigue life under cyclic loads and vibration, meeting strict aerospace safety requirements.

Superior Corrosion and Oxidation Resistance: Remains stable in humid, salty, and high-altitude environments, reducing maintenance and inspection costs.

Good CNC Machinability and Design Adaptability: Advanced CNC equipment enables integrated manufacturing of complex structures, reducing assembly components and enhancing reliability.

1.2 Typical Titanium CNC Machined Parts in Aerospace

- Airframe Structural Parts: Brackets, mounts, stiffeners, and support frames

- Engine Components: Compressor casings, blade mounts, support rings, and heat shield structures

- Aerospace Fasteners: High-strength bolts, nuts, and pins

- Landing Gear and Load-Bearing Components: Structures subjected to high impact and cyclic loads

- Spacecraft Structures and Supports: Lightweight components for satellites, rockets, and space platforms

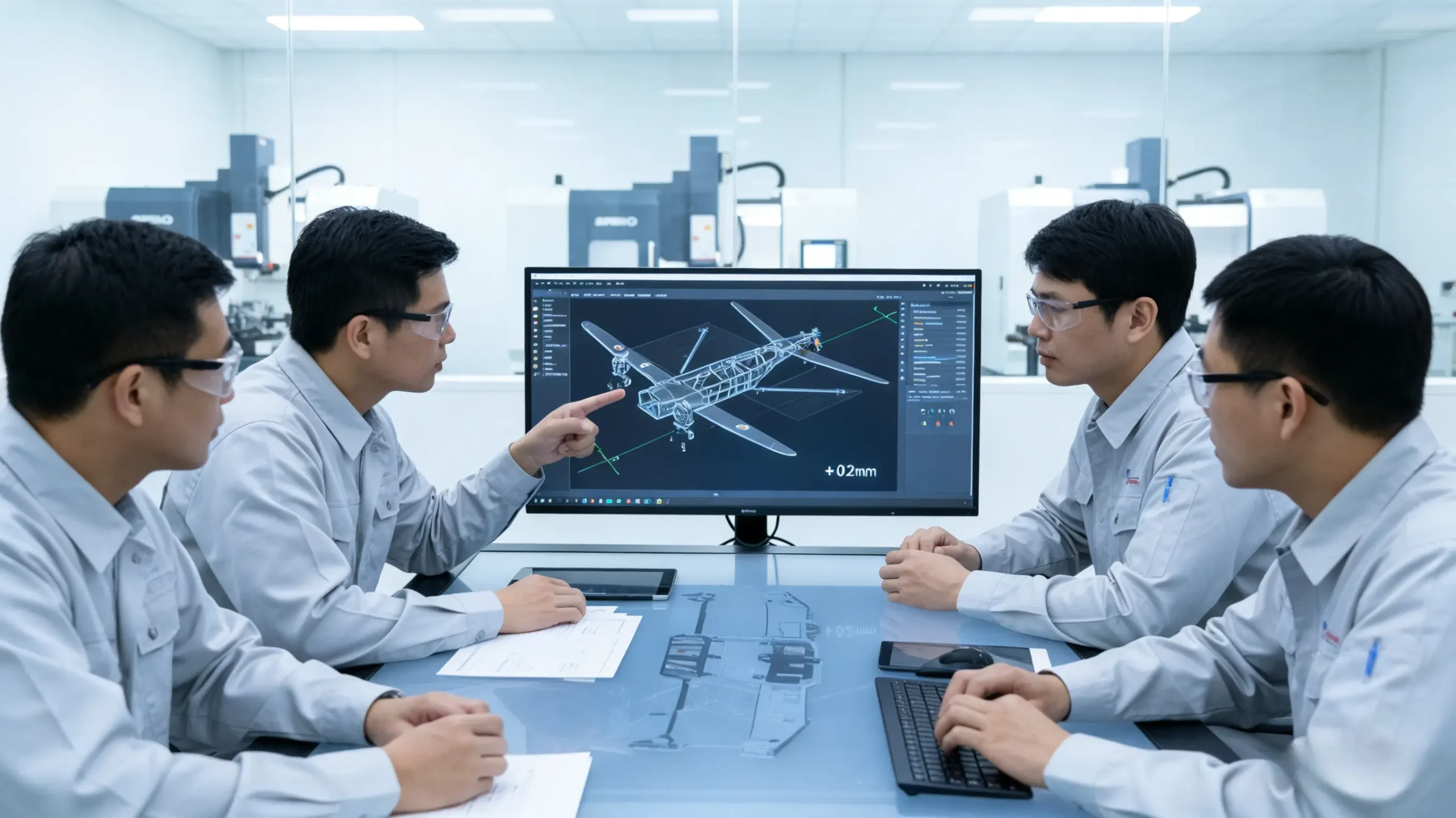

2. Drone & UAV Applications of Titanium CNC Machined Parts

Drones and UAVs require lightweight, high-strength, and precise components to maximize flight efficiency, payload capacity, and durability. Titanium CNC machined parts are increasingly used in commercial, industrial, and military drones due to their exceptional strength-to-weight ratio, corrosion resistance, and fatigue performance.

2.1 Why Titanium CNC-Machined Parts Are Used in Drones & UAVs

High Strength-to-Weight Ratio: Reduces overall UAV weight while maintaining structural integrity, extending flight time and payload capability

Durable and Fatigue-Resistant: Handles continuous vibrations, rotor stresses, and dynamic flight loads without failure

Corrosion Resistance: Performs reliably in outdoor environments, including rain, humidity, and salt spray

Precision CNC Machining: Allows complex geometries for lightweight frames, rotor mounts, and custom UAV components

2.2 Typical Titanium CNC Machined Parts in Drones & UAVs

- Airframe structural components: frames, brackets, mounts

- Rotor hub and arm assemblies

- Landing gear components

- Payload mounting structures

- Custom UAV parts for industrial, surveying, or military applications

2.3 Engineering Advantages & Applications

- Long-term durability in high-vibration, outdoor environments

- Lightweight design improves flight efficiency and stability

- CNC machining enables precise, integrated, and complex geometries

- Suitable for commercial, industrial, and defense UAVs requiring high performance

3. Medical & Healthcare Applications of Titanium CNC Machined Parts

Materials in the medical industry must meet mechanical strength, biocompatibility, corrosion resistance, and long-term stability requirements.

Titanium CNC machined parts are preferred for implants and medical devices due to their high strength, low weight, corrosion resistance, and excellent biocompatibility.

CNC machining enables complex shapes and patient-specific custom components.

3.1 Why Titanium CNC Machined Parts Are Used in Medical Applications

- Excellent Biocompatibility: Closely matches human bone tissue, minimizing rejection reactions

- Corrosion Resistance in Bodily Fluids: Maintains mechanical properties and surface integrity over long-term implantation

- Strength and Elastic Modulus Matching Bone: Improves comfort and functional performance

- Machinable into Complex, High-Precision Structures: Supports minimally invasive procedures and personalized implants

3.2 Typical Titanium CNC Machined Parts in Medical & Healthcare

- Orthopedic implants: Plates, screws, joint components

- Dental implants and abutments

- Minimally invasive surgical instruments

- Precision structural parts for medical devices

3.3 Engineering Advantages & Applications

- Long-term stability in implantation environments with fatigue and creep resistance

- Supports micron-level precision machining

- Handles dynamic loads generated by human activity

- Suitable for patient-specific and custom medical solutions

4. Automotive & Motorsport Applications of Titanium CNC Machined Parts

In automotive and motorsport applications, weight reduction, strength, and fatigue resistance directly influence vehicle performance.

Titanium CNC machined parts reduce unsprung mass and total vehicle weight, improving acceleration, handling, and durability, especially in high-performance and racing vehicles.

4.1 Why Titanium CNC Machined Parts Are Used in Automotive & Motorsport

- Significant Weight Reduction: Lowers unsprung mass and total vehicle weight

- Exceptional Fatigue Life: Withstands high-speed, high-load, and high-vibration environments

- Outstanding High-Temperature Performance: Suitable for engine and exhaust system components

- High-End Performance: Meets extreme performance requirements of racing and high-performance vehicles

4.2 Typical Titanium CNC Machined Parts in Automotive & Motorsport

- Engine parts: Connecting rods, valves, valve seats

- Suspension and steering components

- High-strength bolts and nuts

- Racing structural and power-transmission components

4.3 Engineering Advantages & Applications

- Reliable under continuous high-speed engine operation

- Long fatigue life for suspension under heavy loads

- Enables lightweight design for improved handling and acceleration

- Ideal material for high-performance and specialty vehicles

5. Industrial & High-End Machinery Applications of Titanium CNC Machined Parts

Industrial equipment often operates in high-load, corrosive, or reliability-critical environments.

Titanium CNC machined parts provide stable mechanical performance and corrosion resistance, making them essential for specialized industrial applications.

5.1 Why Titanium CNC Machined Parts Are Used in Industrial Equipment

- Exceptional Corrosion Resistance: Resists acids, alkalis, salts, and other harsh chemicals

- High Structural Stability: Resistant to fatigue over long-term operation

- Reduced Maintenance Costs: Extends equipment service life

- Supports Complex CNC Designs: Enables integrated and precise component fabrication

5.2 Typical Titanium CNC Machined Parts in Industrial & High-End Machinery

- Key chemical processing parts

- Valve bodies, piping, and sealing components

- Precision structural and load-bearing parts

- Custom components for specialized operating conditions

5.3 Engineering Advantages & Applications

- Reliable under continuous high-load operation

- Stable performance in corrosive environments

- Supports high-precision motion and load-bearing applications

- Provides high reliability and low-maintenance solutions

6. Marine & Offshore Applications of Titanium CNC Machined Parts

Marine and offshore equipment is exposed to saltwater, high humidity, and highly corrosive conditions.

Titanium CNC machined parts resist seawater corrosion, ensuring high-precision, durable components for ships and offshore platforms.

6.1 Why Titanium CNC Machined Parts Are Used in Marine Applications

- Outstanding Seawater Corrosion Resistance

- No Need for Protective Coatings, reducing maintenance costs

- High Strength with Lightweight Design

- Suitable for Long-Term Marine Service

6.2 Typical Titanium CNC Machined Parts in Marine & Offshore

- Seawater pumps and fluid system parts

- Marine fasteners and structural connectors

- Support structures for offshore equipment

- Key mechanical components for offshore platforms

6.3 Engineering Advantages & Applications

- Long-term reliability in marine environments

- Load-bearing structures withstand impacts and fatigue

- CNC machining ensures precision and assembly accuracy

- Suitable for long-term operation under extreme weather conditions

7. Energy, Chemical & Specialized Industry Applications of Titanium CNC Machined Parts

Energy, chemical, and specialized industries involve high temperature, high pressure, corrosive, and safety-critical conditions.

Titanium CNC machined parts maintain reliable performance in extreme conditions, making them widely used in nuclear, oil & gas, and chemical equipment.

7.1 Why Titanium CNC Machined Parts Are Used

- Excellent High-Temperature Stability: Withstands prolonged high-temperature service

- Strong Resistance to Chemicals: Suitable for acids, alkalis, and saline environments

- Long-Term Reliability: Reduces downtime and maintenance costs

- Suitable for Safety-Critical Systems

7.2 Typical Titanium CNC Machined Parts in Energy, Chemical & Specialized Industries

- Structural components for nuclear systems

- Key parts for oil & gas equipment

- Components for chemical reactors

- Custom CNC parts for high-temperature, high-pressure applications

7.3 Engineering Advantages & Applications

- Reliable under extreme high-temperature and high-pressure conditions

- Highly resistant to aggressive chemical environments

- Supports complex CNC custom machining

- Meets strict safety and performance requirements

8. Summary

Across aerospace, medical, automotive, industrial, marine, and energy industries, Titanium CNC Machined Parts demonstrate unparalleled performance in challenging environments.

Their high strength-to-weight ratio, excellent fatigue and corrosion resistance, and compatibility with CNC precision machining make them ideal for critical structural and functional components.

Whether reducing aircraft weight, enabling custom medical implants, or enhancing durability in marine and industrial applications, titanium remains the material of choice for engineers seeking reliability, longevity, and performance.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.