Table of Contents

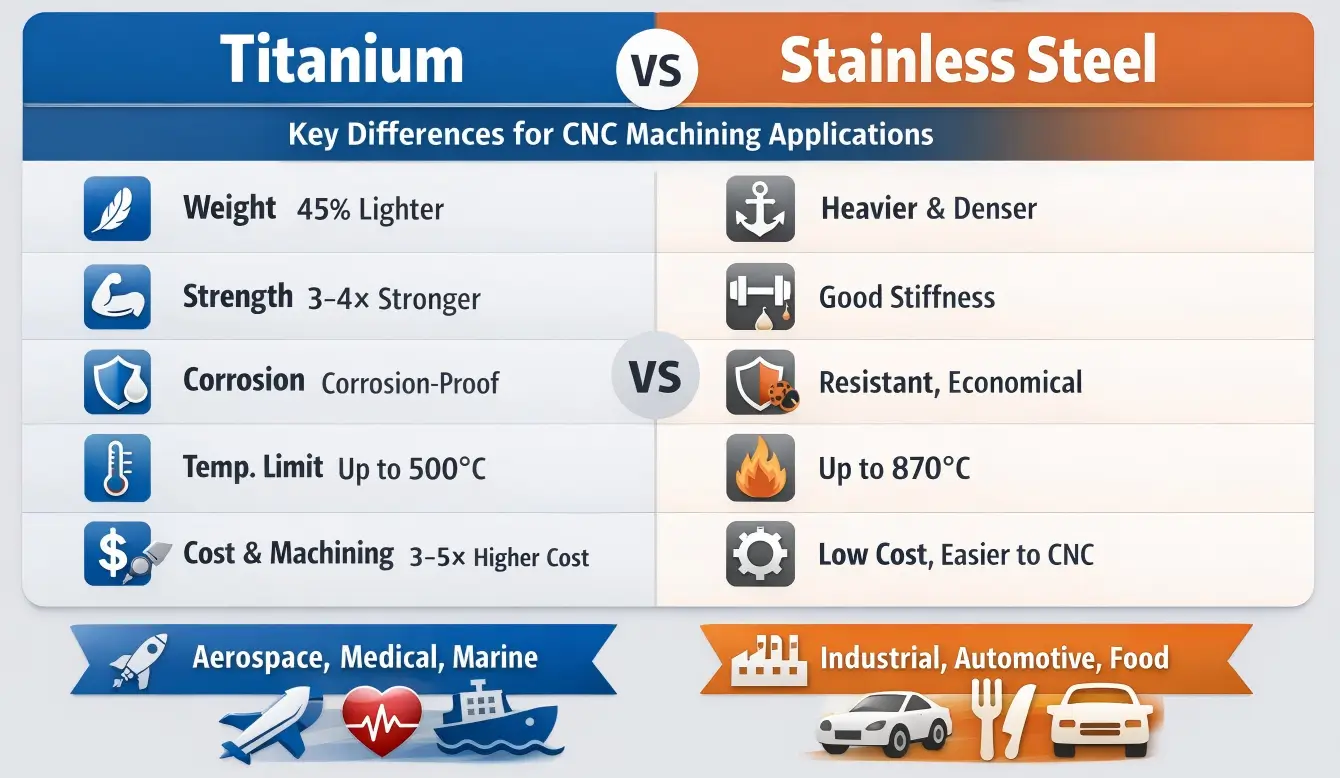

In precision CNC machining, material selection plays a critical role—it directly affects strength, weight, corrosion resistance, service life, and machining cost.

Both titanium alloys and stainless steels are considered high-performance materials, but each excels in very different application scenarios.

Titanium is ideal for weight-critical, corrosive, and long-life applications despite higher cost, while stainless steel remains the most economical and robust choice for high-temperature and general industrial CNC parts.

This article provides a clear, engineering-focused comparison of titanium alloys and stainless steels to help you make an informed decision across performance, manufacturability, and cost.

For clarity and relevance to real CNC production, we use the most commonly machined grades as examples:

Titanium alloy: Ti-6Al-4V (Grade 5)

Stainless steels: 304 and 316

Key Takeaways:

Ti-6Al-4V is ~45% lighter than stainless steel and offers 3–4× higher specific strength with near-perfect corrosion resistance.

Grades 304/316 provide excellent stiffness, good corrosion resistance for most environments, superior performance above 600–870°C, and far lower machining and material costs—making them the go-to choice for industrial, automotive, food, and construction applications.

Titanium parts typically cost 3–5× more to CNC machine, but in aggressive environments their zero-maintenance, long service life can outperform stainless steel on total cost over decades.

1. Core Performance Comparison: Titanium vs. Stainless Steel

| Property | Titanium (Ti-6Al-4V) | Stainless Steel (316) | Stainless Steel (304) | Engineering Impact |

|---|---|---|---|---|

| Density | 4.43 g/cm³ | 7.99 g/cm³ | 7.93 g/cm³ | Titanium is ~45% lighter; the ultimate choice for weight-saving. |

| Tensile Strength | 900–1100 MPa | 485–620 MPa | 505–700 MPa | Titanium is 1.5–2x stronger than standard stainless steel. |

| Elastic Modulus | 110 GPa | 193 GPa | 193 GPa | Stainless steel is ~75% stiffer. Titanium’s flexibility mimics human bone. |

| Specific Strength | 203–248 MPa·cm³/g | 61–78 MPa·cm³/g | 64–88 MPa·cm³/g | Titanium offers 3–4x the strength-to-weight ratio. |

| Corrosion Resistance | Exceptional: Immune to salt, sea, and body fluids. | Excellent: Molybdenum adds resistance to chlorides/pitting. | Good: Stable in most environments but prone to salt pitting. | Titanium is the “gold standard” for harsh or medical environments. |

| Thermal Stability | Up to 500°C | Up to 870°C | Up to 870°C | Stainless steel wins for high-heat, “hot-end” applications. |

| Biocompatibility | Best: Non-toxic, non-allergenic, promotes bone growth. | Good: Used in surgical tools, but nickel content may cause allergies. | Fair: Not recommended for long-term implants. | Titanium is the primary choice for permanent medical implants. |

| Machinability | Difficult | Moderate / Challenging | Moderate | Titanium requires slower speeds and specialized cooling. |

| Material Cost | 8–15x (High) | 2.5–4x (Medium) | 1x (Base) | Titanium is a premium investment for performance-critical parts. |

2. Weight and Specific Strength

Titanium’s density is approximately 55% that of stainless steel.

In aerospace, reducing just 1 kg can deliver fuel savings and performance gains that far outweigh material cost.

In medical applications, lighter implants and instruments reduce patient burden and improve comfort.

When weight is not a critical constraint, or when mass is actually beneficial (counterweights, inertia components), stainless steel becomes the more practical choice.

3. Corrosion Resistance

Titanium alloys rely on a dense, self-healing TiO₂ passive layer, providing near-perfect resistance in seawater, wet chlorine, ferric chloride, and similar environments.

Stainless steels rely on chromium oxide films. They perform well in oxidizing environments but may suffer pitting or stress corrosion cracking in chloride-rich or reducing acids.

For mild environments (air, freshwater, weak acids/alkalis), stainless steel is sufficient and far more economical.

For chloride-rich or aggressive media, titanium is often irreplaceable.

4. High- and Low-Temperature Performance

Mid-high temperatures (300–600°C): Titanium maintains high strength and superior specific strength.

Very high temperatures (>600°C): Stainless steels outperform titanium in oxidation resistance and creep.

Both austenitic stainless steels (304/316) and certain titanium grades retain good toughness, with titanium maintaining its specific-strength advantage.

5. Biocompatibility and Medical Applications

Titanium alloys: Chemically inert, non-allergenic, promote osseointegration—ideal for long-term implants.

Stainless steel (316L VM): Acceptable biocompatibility, but nickel may cause sensitivity; mainly used for surgical tools and temporary implants.

Titanium is the gold standard for permanent implants; stainless steel is the cost-effective choice for short-term medical devices.

6. Material Cost

Stainless steel (304/316): ~USD $5–15/kg

Titanium alloy (Ti-6Al-4V): ~USD $20–50/kg

n practice, titanium raw material cost is 4–8× higher than stainless steel.

7. Machining and Manufacturing Cost Analysis

Titanium: Low cutting speeds, rapid tool wear, specialized tooling and cooling—high machining cost per part.

Stainless steel: Work hardening and tool adhesion exist, but cutting speeds are higher and tooling is more mature.

Typical cutting speeds based on CNC experience:

Stainless steel: 50–120 m/min

Titanium: 30–60 m/min

This alone cuts titanium’s material removal rate to less than half.

Machining the same part, pure cutting time for titanium can be more than 2×, directly doubling machine and labor costs.

Under identical geometry, total CNC cost for Ti-6Al-4V is typically 3–5× that of 304/316 stainless steel.

| Cost component | Stainless steel (316) | Titanium (Ti-6Al-4V) | Multiplier |

|---|---|---|---|

| Material cost | $10–20 | $80–150 | 8–10× |

| Machining time | X (baseline) | 2X–2.5X | 2–2.5× |

| Tooling cost | Y (baseline) | 3Y–5Y | 3–5× |

| Total cost (est.) | (10–20)+X+Y | (80–150)+2X+4Y | 3–5× |

Lifecycle cost matters. In harsh environments, titanium’s zero-maintenance nature can result in lower total cost over 20 years compared to stainless steel components that require repair or replacement.

8. Application Selection Guide

When Titanium Is the Best Choice

- Aerospace & motorsports: Weight-critical load-bearing parts, fasteners, engine mounts

- High-end medical devices: Permanent implants, surgical tool handles

- Chemical & marine engineering: Pumps, valves, heat exchangers, desalination systems

- Premium consumer products: High-end outdoor gear, watch cases, eyewear frames

When Stainless Steel Is the Better Choice

- Construction & infrastructure: Facades, bridges, architectural hardware

- Food & pharmaceutical equipment: Tanks, piping, work surfaces

- General industry & automotive: Bolts, springs, exhaust systems

- Everyday durable goods: Cookware, appliances, household products

9. Summary

This blog compares titanium alloy Ti-6Al-4V with stainless steels 304 and 316 from an engineering and CNC manufacturing perspective.

Titanium excels where weight savings, biocompatibility, fatigue strength, and extreme corrosion resistance are critical, but it is expensive and difficult to machine due to low thermal conductivity and high tool wear.

Stainless steel, while heavier and offering lower specific strength, is stiffer, easier to machine, performs better at very high temperatures, and is far more cost-effective for most industrial uses.

The article emphasizes that the right choice depends on application priorities—weight, environment, temperature, and lifecycle expectations—rather than raw material performance alone.

10. FAQ

Q1: Is titanium more durable than stainless steel?

In harsh environments, yes. It has better fatigue resistance and doesn’t rust. However, Stainless Steel is harder to “scratch” because it has a higher surface hardness than some titanium grades.

Q2: What should be considered when CNC machining titanium?

The core challenge is heat and tool wear control:

- Specialized Tools & Conservative Parameters: Use sharp, wear-resistant carbide tools with heat-resistant coatings (like AlTiN). Employ a strategy of “low speed, moderate feed rate, and high depth of cut”to control heat generation.

- Effective Cooling:High-pressure coolant systems or through-tool cooling are essential. They forcefully remove built-up heat from the cutting zone, preventing tool overheating and workpiece surface hardening.

- Ensure System Rigidity: The machine tool, fixture, and toolholder must have high rigidity to withstand the significant cutting forces during titanium machining. This avoids vibration-induced dimensional errors and tool damage.

- Optimize Programming & Chip Evacuation: Utilize climb milling and well-planned tool paths to ensure chips are evacuated quickly and smoothly. This prevents chip recutting and heat accumulation.

Q3: Is stainless steel suitable for high-temperature applications?

Yes—this is one of its key strengths.

Austenitic stainless steels (304/316) can operate above 870°C in oxidizing environments, far beyond titanium’s limit.

For extreme temperatures (>1000°C), special heat-resistant steels or nickel-based alloys are required.

Q4: Why is Titanium so expensive to machine?

It’s a “Heat Trap.” Because titanium doesn’t conduct heat well, the heat stays on the cutting tool. This requires us to slow down the machine and use high-pressure cooling systems to prevent the tool from melting.

Q5: Can I use Stainless Steel for medical purposes?

Yes, 316L (Surgical Steel) is common for tools and temporary fixes. However, for permanent implants, Titanium is preferred because it is nickel-free and “bio-compatible,” meaning the body won’t reject it.

Note: Performance data references include AMS 4911 (titanium alloys), ASTM A276 (stainless steel), and ASM handbooks.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.