Top 5 best CNC machining manufactures and companies in China

Updated: December 19, 2023

Table of Contents

- 1. 1.CNC machining brief introduction

- 2. Brief overview of the global CNC machining market

- 3. Brief overview of the china CNC machining market

- 4. Why choose CNC machining services company in china

- 5. How to select the right CNC machining shops in china

- 6. Top 5 best CNC machining companies in china

- 7. Outsource CNC machining services with ECOREPRAP

China is the best country for CNC machining for reasonable prices, fast turnaround, and precision. The crucial is to select the right CNC machining manufacturers and companies. Based on data statistical analysis, there are tens of thousands of CNC machining shops in China, how to get the right one? What factors needed to be taken into consideration? Let’s dive into this topic and get you 5 top best CNC machining manufactures and companies in China.

1. CNC machining brief introduction

CNC technology originated in the United States, with top-of-the-line CNC equipment primarily sourced from Japan, Germany, and the United States. However, China has became the premier choice for CNC machining services. China CNC machining services offer unparalleled advantages, combining cost-effectiveness with advanced capabilities. Chinese CNC facilities boast cutting-edge equipment, a wide range of material expertise, and a skilled workforce, positioning themselves as crucial contributors to precision manufacturing on a global scale.

2. Brief overview of the global CNC machining market

According to Precedence Research, in 2022, the global Computer Numerical Control (CNC) machine market is estimated to reach 95 billion USD, and it is expected to reach 154 billion USD by 2032, with a compound annual growth rate (CAGR) of 5%.

There are many driving factors for the growth.

2.1 The CNC machine market is expected to be driven by rising demand for medical devices, electric vehicles (EVs), telecommunication equipment, and semiconductor manufacturing equipment.

During the COVID-19 pandemic, the application of CNC machines in medical device production witnessed an increase during the pandemic, particularly for vital medical equipment such as ventilators, thus helping the CNC market to recover gradually.

2.2 The application of CNC systems in large-scale production plants, capable of producing extremely precise components and parts, is expected to propel the market for CNC machines.

2.3 The adoption of industrial automation in global manufacturing is a key driving factor, as automation leads to higher productivity and lower operational costs for enterprises.

2.4 The strong adoption of the Internet of Things (IoT) can potentially increase the demand for CNC machines, as the integration of modern digital technologies opens up broader applications for CNC machines across industries.

Related research reports:

Computer Numerical Control (CNC) Machine Market By Precedence Research

CNC Machine Market Research Report by Market Research Future

The Global CNC (Computer Numerical Control) Machine Market by Fortune Business Insights

Computer Numerical Control Machines Market By Grand View Research

3. Brief overview of the china CNC machining market

The China CNC machining market is experiencing robust growth due to several driving factors, such as rapid industrialization, expanding manufacturing sectors, and increased investments in smart manufacturing and automation.

3.1 The Chinese government’s “Made in China 2025” initiative boosts the adoption of advanced manufacturing technologies, including CNC machining, and encourages self-sufficiency in high-tech industries.

3.2 The automotive, aerospace, and electronics industries are significant consumers of CNC machines in China, requiring precision components. A growing middle class, increased domestic consumption, and rising spending on infrastructure projects contribute to the growth of these industries.

3.3 Small and medium-sized enterprises are also embracing CNC technology to improve operational efficiency, reduce labor costs, and remain competitive in the global market.

4. Why choose CNC machining services company in China

4.1 Cost-effective manufacturing and economies of scale

Despite the continuous advancement in automation, the cost of manpower continues to play a crucial role in the overall expenses. China, with its large population, enjoys a relative advantage in terms of lower labor costs.

In China, there are numerous factories with considerable scale, employing thousands or even tens of thousands of workers. This capacity enables these CNC machining facilities to meet the demands of large-scale production effectively.

Additionally, Chinese workers are known for their diligence, often working overtime during evenings and weekends. Some factories in China even operate 24 hours a day.

4.2 Quality and precision

China has tens of thousands of CNC machining factories. There are many capable manufacturers with super good quality and precision.

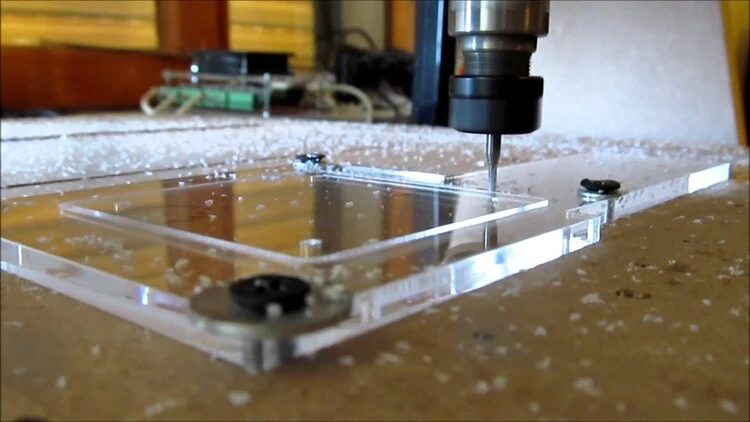

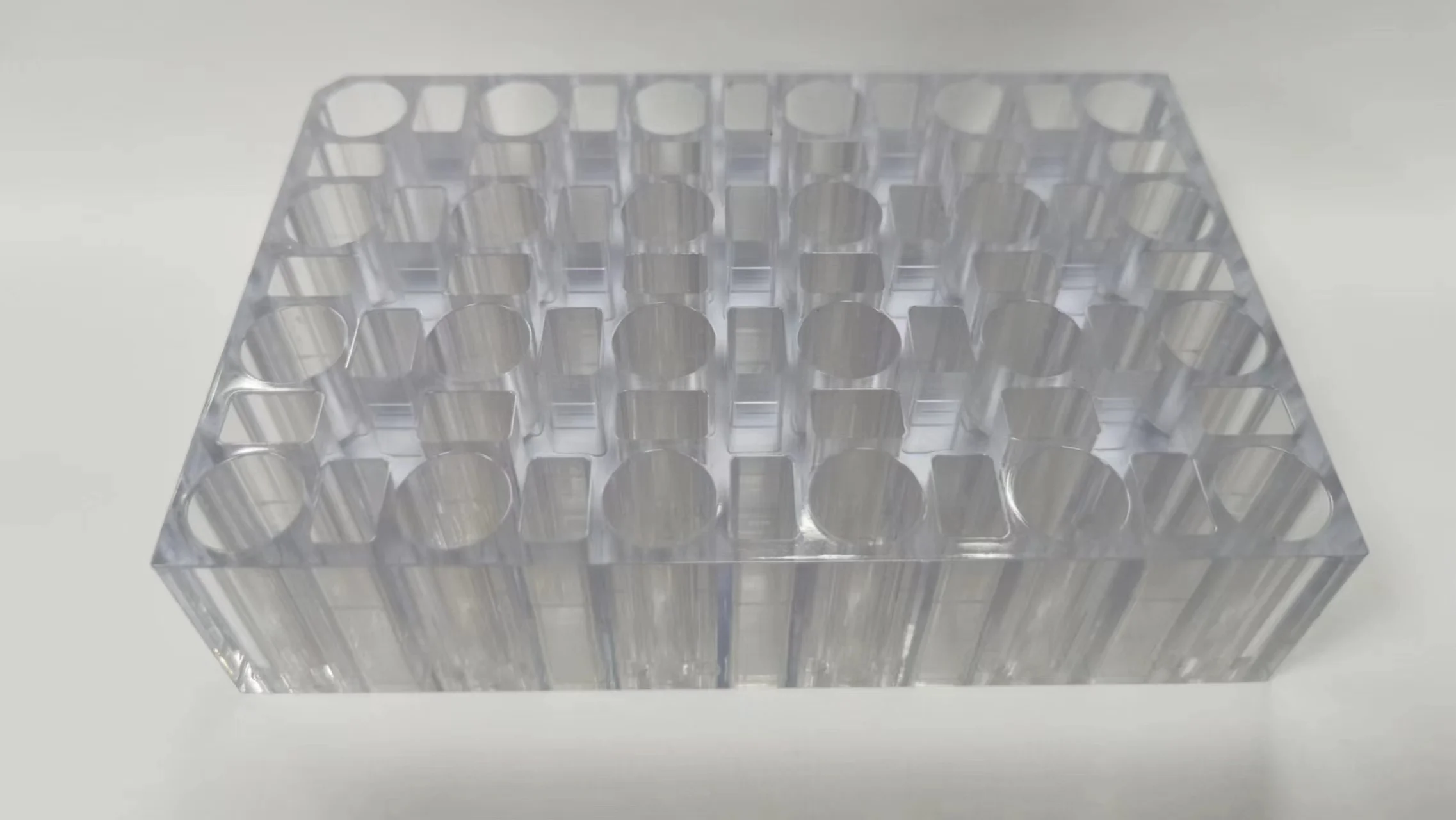

These companies invest significantly in high-tech machinery, including advanced CNC equipment with multi-axis capabilities and automated systems. The integration of automation and robotics not only enhances efficiency but also ensures consistent and precise execution of machining tasks.

China CNC machining shops implement comprehensive training programs to keep machinists with the latest technologies and techniques. Experienced and multidisciplinary teams, comprising engineers, technicians, and quality control professionals, collaborate to handle complex projects with precision.

These China precision CNC machining services providers purchase advanced quality check equipment, for example, CMM. Adhering to strict standards, precision measurement tools, and robust quality management systems, they pursue contentious improvement.

4.3 Powerful machining capabilities

China offers comprehensive cnc machining services including milling, turning, grinding, EDM, welding, sheet metal bending, and sheet metal cutting. It is your one-stop solution for various machining requirements. In some China CNC machining shops, you can get all the services. ECOREPRAP is one, for example.

4.4 Wide materials choices

China cnc machining centers provide a broad spectrum of materials, which include metals, such as aluminum, steel, stainless steel, brass, and copper. Various plastics are also available, for example, ABS, POM, PMMA, and nylon.

For specific materials, like aerospace-grade aluminum,high-temperature alloys for automotive application, some precision machining companies can also machine them, though it requires a depth of knowledge and skill in handling specific materials.

5. How to select the right CNC machining shops in China

Selecting the right CNC machining shops is crucial for your project success. Take the following factors into consideration.

5.1 Experience and reputation

Ask the supplier to provide client testimonials and customer reviews. Good CNC machining manufactures always get positive feedback.

5.2 Manufacturing capabilities

Capable CNC machining factory can provide various process including milling, turning, grinding and EDM. Even if they do out sourcing, you do not have to coordinate with different suppliers for your project, which saves time and effort.

Consider both prototype and low volume production from the beginning. Make sure the factory can produce batch order maintaining quality and precision.

5.3 Quality assurance

Good precision CNC manufacture know the importance of quality assurance. They have edge-cut precision measurement tools, set high strict quality standards, and implement inspection protocols at different stages of production. They make 100% quality check before shipment.

5.4 Communication

Effective communication is crucial for CNC projects. It is essential to ensure that the CNC machining facility fully comprehends the client’s requirements for drawings. This necessitates that the communication personnel in the factory, whether project managers or customer managers, are not only fluent in English but also possess a solid understanding of various aspects of CNC machining processes.

6. Top 5 best CNC machining companies in China

From the table below, you can find the top 5 best CNC machining companies in China, with different advantages.

| Company Name | City | Year Founded | Main Business | Employee Size |

| Star Rapid | Zhongshan | 2005 | Vacuum Casting | 51 – 100 |

| ECOREPRAP | Shenzhen | 2012 | CNC machining Sheet Metal Fabrication | 51 – 100 |

| Wenext | Shenzhen | 2015 | 3d printing CNC machining | 51 – 100 |

| Sogaworks | Shenzhen | 2015 | 3d printing CNC machining | 51 – 100 |

| NICE Rapid | Zhongshan | 2012 | Vacuum Casting Aluminum Extrusion | 51 – 200 |

7. Outsource CNC machining services with ECOREPRAP

Are you looking for a reliable CNC machining manufacturer in China? We fully understand the challenge. That is also why we connect you with top CNC machining shops in China. When choosing a CNC machining services provider, key considerations shall include the quality and reliability of machining, production capacity along with lead times, cost-effectiveness, flexibility for customization, and the availability of technical support.

Considering these factors, ECOREPRAP is a good choice for advanced CNC machining services. As an ISO-certified prototype company, ECOREPRAP is well-equipped with cutting-edge CNC machines and state-of-the-art parts inspection facilities. They offer a comprehensive range of machining services, encompassing CNC milling, CNC turning, Electrical Discharge Machining, and various surface finishes.

With over 10 years of experience, advanced technology, and a skilled engineering team, ECOREPRAP is a highly productive and results-driven CNC machining service provider committed to ensuring your satisfaction.

Feel free to submit your design file for an instant CNC machining quote. We eagerly anticipate the opportunity to collaborate with you!