Table of Contents

CNC rapid prototyping commonly uses plastics, metals, and composite materials, each offering unique properties and suitability for different applications.

This guide helps engineers, designers, and manufacturing enthusiasts select the most suitable material for their rapid prototyping projects.

You can make informed decisions to improve prototype quality and machining efficiency.

Top 7 Materials for CNC Rapid Prototyping

The following materials are the most widely used in CNC rapid prototyping due to their performance, availability, and ease of machining.

Each section provides quantitative data, applications, and supplier references to guide material selection.

1.ABS (Acrylonitrile Butadiene Styrene)

ABS is one of the most commonly used plastics in CNC rapid prototyping due to its strength and ease of machining.

- Properties: Density 1.04 g/cm³, Heat deflection temperature ≈ 105°C, Medium machining difficulty.

- Applications: Mechanical prototypes, consumer electronics housings.

- Suppliers & Data: SABIC, 2024 global supply data; ISO 9001 certified manufacturers.

2. PLA (Polylactic Acid)

PLA is a biodegradable plastic ideal for small-scale CNC prototyping.

Properties: Density 1.25 g/cm³, Low machining difficulty, suitable for CNC and 3D printing.

- Applications: Educational models, display prototypes.

- Suppliers & Data: NatureWorks, 2023 production 150 million tons; FDA food-grade certified.

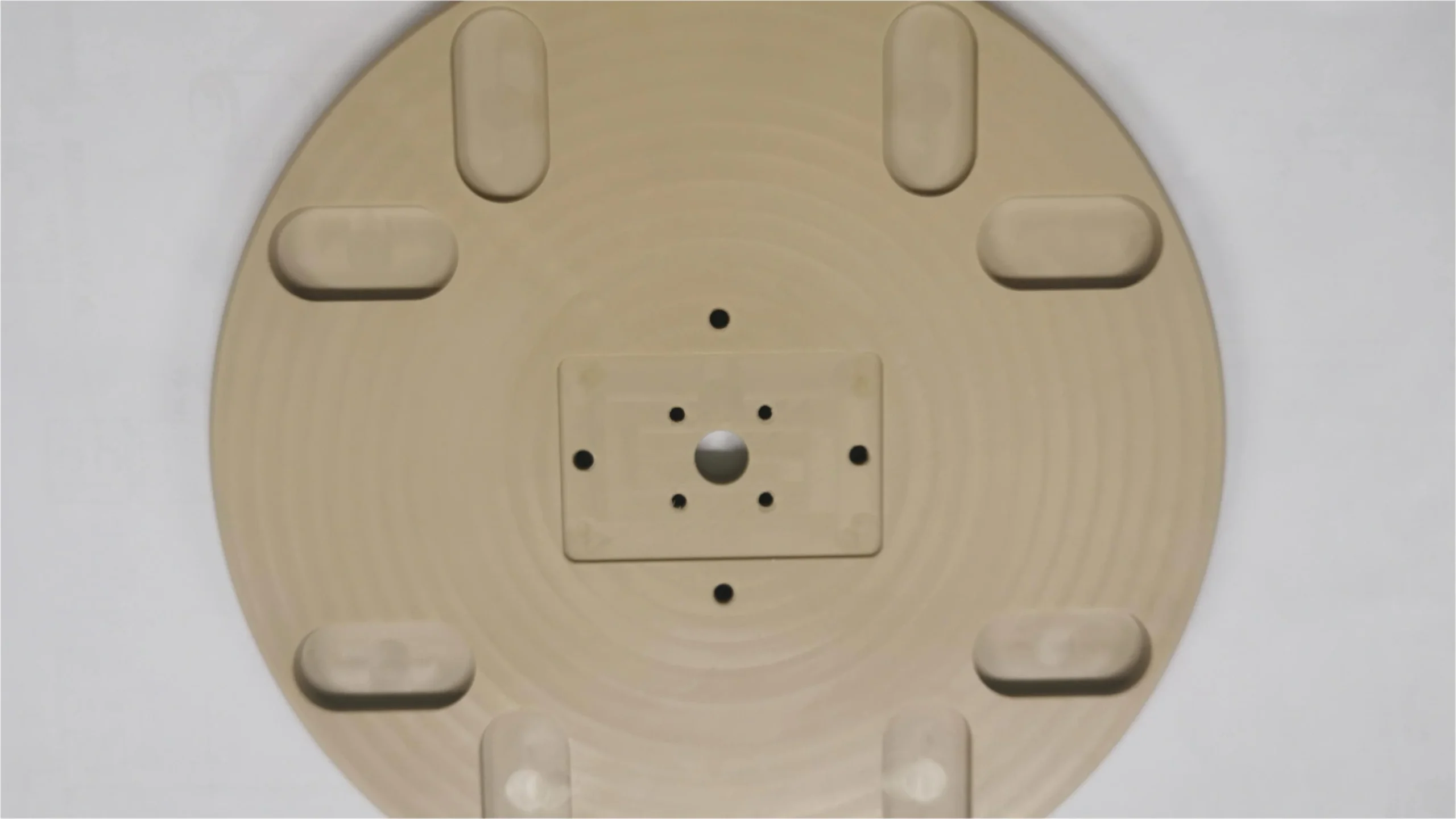

3. Nylon (Polyamide)

Nylon is valued for its high strength and wear resistance, commonly used in CNC prototyping due to its high strength and wear resistance.

- Properties: Density 1.15 g/cm³, Tensile strength 75 MPa, Medium-high machining difficulty, moisture sensitive.

- Applications: Functional prototypes, gears, mechanical components.

- Suppliers & Data: DuPont, top 3 global supplier; ISO 14001 environmental management certified.

4. Aluminum (6061, 7075)

Aluminum is lightweight and easy to machine, widely used in functional and industrial prototypes.

- Properties: Density 2.7 g/cm³, Hardness HB 95–150, Medium machining difficulty.

- Applications: Aerospace components, automotive prototypes.

- Suppliers & Data: Alcoa, 2023 production 1.5 million tons; ASTM B209 certified.

5. Stainless Steel (304, 316)

Stainless steel provides high strength and corrosion resistance for functional prototyping.

- Properties: Density 7.9 g/cm³, Hardness HB 180–220, High machining difficulty.

- Applications: Mechanical parts, medical device prototypes.

- Suppliers & Data: ArcelorMittal, annual production 10 million tons; ISO 9001 & ASTM A240 certified.

6. Polycarbonate (PC)

Polycarbonate offers high impact strength and transparency, suitable for industrial and consumer prototypes.

- Properties: Density 1.2 g/cm³, Impact strength 60 kJ/m², Medium machining difficulty.

- Applications: Electronic housings, optical prototypes.

- Suppliers & Data: Covestro, 2024 production 90,000 tons; UL certified.

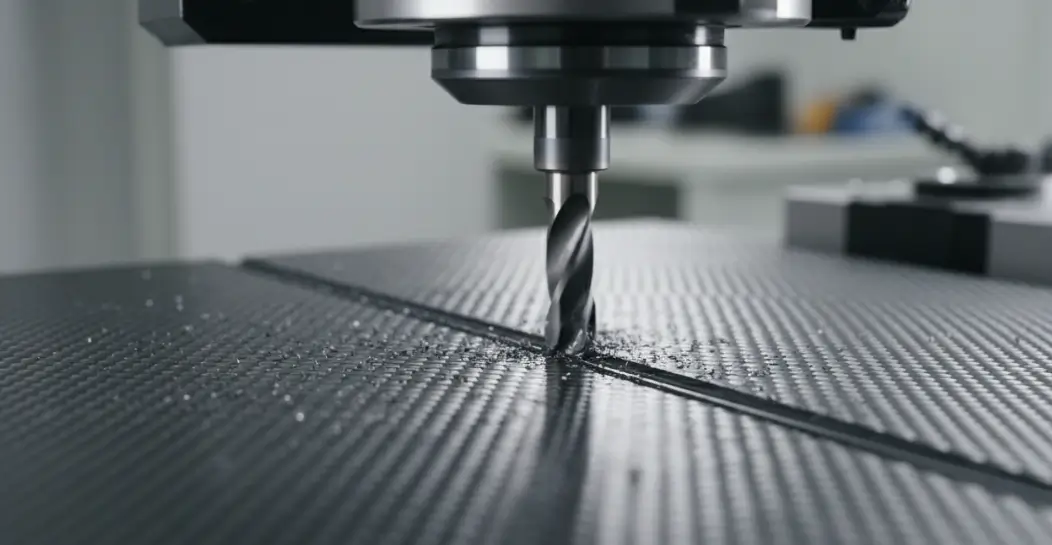

7. Composite Materials (Carbon Fiber / Glass Fiber Reinforced)

Composite materials combine lightweight and high strength, making them ideal for advanced CNC prototyping.

- Properties: Density 1.4–1.6 g/cm³, High machining difficulty, requires specialized tooling and fixtures.

- Applications: Aerospace, motorsports prototypes.

- Suppliers & Data: Hexcel, 2023 global carbon fiber production 90,000 tons; ISO 9001 & ASTM D3039 certified.

How to Choose CNC Rapid Prototyping Materials?

Choosing the right material for CNC rapid prototyping requires balancing cost, machinability, strength, and intended use.

Creating a comparison table of density, hardness, heat deflection temperature, and cost index can simplify selection.

Engineers should also consider supplier reliability, production capacity, and material certifications such as ISO or ASTM standards to ensure consistent prototype quality.

Selecting the wrong material can increase costs, prolong production time, or compromise the functional integrity of prototypes.

Frequently Asked Questions (FAQs)

1.What are the best CNC rapid prototyping materials for functional prototypes?

The best CNC rapid prototyping materials for functional prototypes include ABS, Nylon, aluminum, and stainless steel.

ABS and Nylon are suitable for mechanical and consumer parts due to their strength and wear resistance, while metals like aluminum and stainless steel provide high durability for industrial and aerospace prototypes.

Choosing the right material depends on prototype load, durability, and machining requirements.

2. How to choose the right plastic for CNC rapid prototyping, like ABS or PLA?

When selecting plastics for CNC rapid prototyping, consider mechanical strength, heat resistance, and machinability.

ABS offers strong, durable prototypes for functional parts, while PLA is ideal for low-load models or educational projects due to its biodegradability and ease of machining.

Compare density, tensile strength, and supplier certifications to ensure consistent prototype quality.

3. Which metals are suitable for CNC rapid prototyping, aluminum or stainless steel?

Aluminum and stainless steel are the most common metals for CNC rapid prototyping. Aluminum is lightweight and easy to machine, ideal for automotive or aerospace prototypes.

Stainless steel provides higher strength and corrosion resistance for mechanical parts or medical device prototypes.

Selecting the right metal depends on weight, hardness, and intended use.

4. What are the advantages of using composite materials for CNC rapid prototyping?

Composite materials, such as carbon fiber or glass fiber reinforced plastics, offer high strength-to-weight ratios, suitable for aerospace and motorsports applications, according to Hexcel 2023 data.

They are ideal for aerospace, motorsports, and high-performance applications, combining lightweight design with structural integrity.

However, composites require specialized tooling and high machining expertise.

5. Which CNC prototyping material is easiest to machine for beginners?

For beginners, PLA and ABS plastics are the easiest materials to machine in CNC rapid prototyping.

PLA is low-cost and biodegradable, perfect for educational or display models, while ABS balances machinability and strength for functional parts.

Metals and composites have higher machining difficulty, requiring advanced tools and experience.

Conclusion

Choosing the right material is a critical step in CNC rapid prototyping, as it directly impacts prototype performance, production efficiency, and overall project cost.

Plastics like ABS and PLA are ideal for low-load or educational prototypes, while metals such as aluminum and stainless steel provide strength and durability for functional parts.

Advanced composite materials offer unmatched strength-to-weight ratios for aerospace, motorsports, and high-performance applications.

By understanding each material’s properties, machining difficulty, applications, and certified suppliers, engineers and designers can make informed decisions that help select materials that meet project requirements efficiently.

For successful CNC rapid prototyping, always consider material-specific requirements, verify supplier certifications, and match the material choice to your project goals.

Selecting the right material not only ensures prototype functionality but also reduces rework, saves cost, and accelerates time-to-market.

Rapid Prototyping Knowledge Hub

1.Understanding CNC Rapid Prototyping

- What is CNC Rapid Prototyping? Complete Guide for 2025

- What are the Benefits of CNC for Rapid Prototyping?

- CNC Machining for Rapid Prototyping: How to Choose the Right Solution

- 3 Types of Prototyping Services for Fast and Cost-Effective Prototypes

2.CNC vs Other Prototyping Methods

- CNC Rapid Prototyping vs 3D Printing: Which to Choose in 2025?

- 3D Printing vs CNC Machining: Which Is Right for You?

- CNC Milling vs CNC Turning: Which Is Better for Prototyping?

3.Engineering & DFM Considerations

- CNC Prototype Tolerances Explained

- How to Optimize CAD Files for CNC Prototyping

- How Material Selection Affects CNC Prototype Performance

- ABS vs Aluminum: Which is Better for CNC Prototypes?

- Why Production Time Matters in Prototype CNC Parts Manufacturing?

4.From Prototype to Production

- CNC Machining for Small Batch Prototyping

- From Prototype to Production: How CNC Companies Support Scalability

5.CNC Prototyping Services in China

- CNC Prototyping Services China (Complete Buying Guide)

- Key Factors to Consider When Sourcing CNC Prototypes from China

- Top 5 Prototype Manufacturers in China

- 5 Key Benefits of Using Chinese Prototyping Services

Get Rapid Prototyping Services

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.